Technical Contents

Engineering Guide: Fast Parts

Engineering Insight: The Critical Role of Precision in Fast Parts Manufacturing

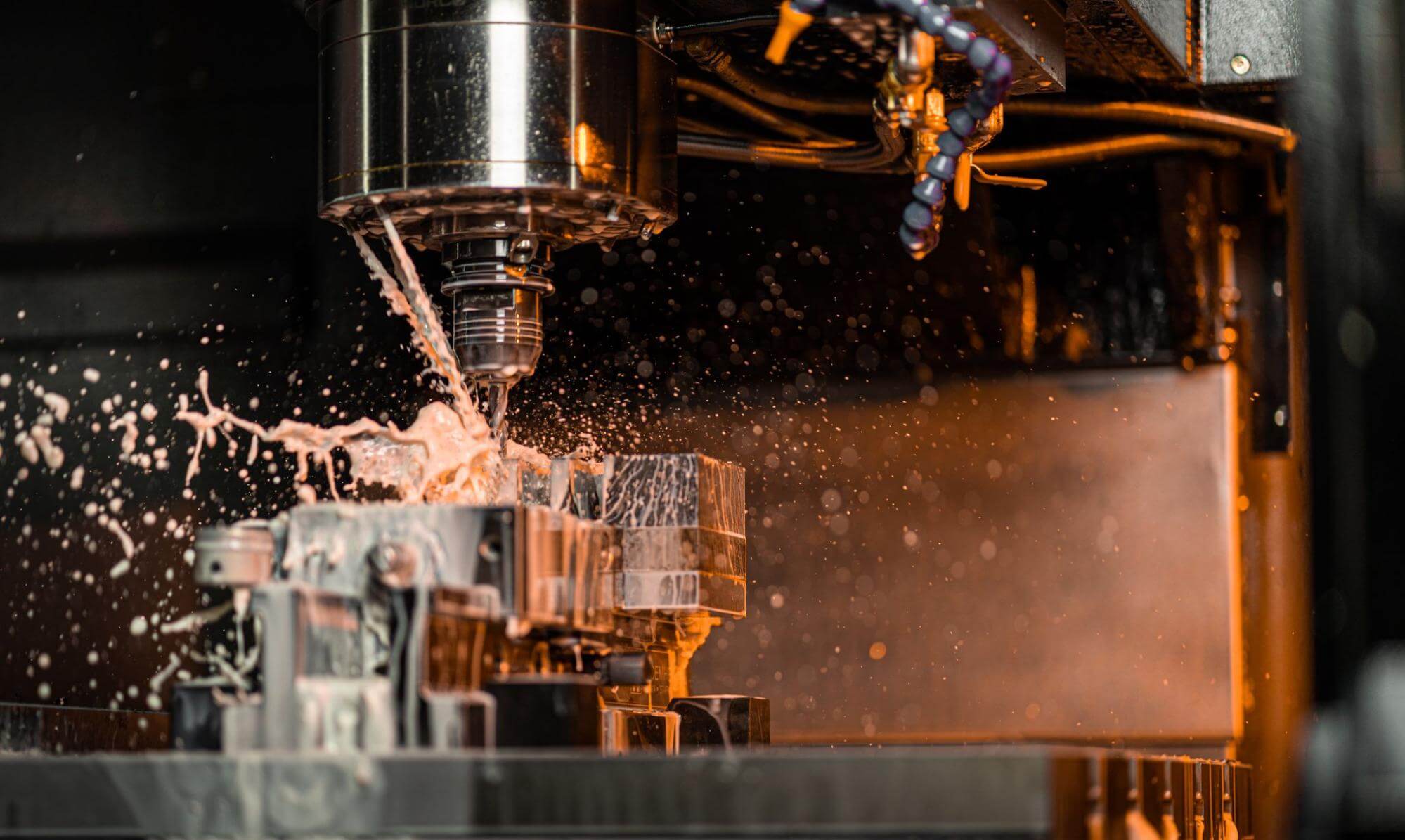

In high-performance industries such as aerospace, defense, and advanced robotics, the term “fast parts” does not merely refer to rapid production timelines—it signifies the seamless integration of speed, accuracy, and reliability in custom metal component manufacturing. At Wuxi Lead Precision Machinery, we understand that delivering fast parts goes beyond expediting workflows; it demands uncompromising precision at every stage of production. This precision ensures that components meet exact design specifications, maintain structural integrity under extreme conditions, and integrate flawlessly into complex assemblies.

Precision in fast parts manufacturing begins with advanced CNC machining technologies capable of tolerances within ±0.002 mm. Such tight tolerances are not optional in mission-critical applications—they are mandatory. A deviation of even a few microns can lead to system failure, costly rework, or safety risks. Our facility in Wuxi, China, leverages state-of-the-art 5-axis machining centers, automated inspection systems, and real-time process monitoring to maintain consistency across both prototyping and high-volume production runs.

Our engineering expertise has been validated through demanding projects, including components for Olympic-grade athletic equipment and precision subsystems for military defense systems. These applications require materials that withstand high stress, corrosion, and thermal variation—such as titanium, Inconel, and high-strength aluminum alloys—while maintaining dimensional stability. Our experience in these elite sectors underscores our capability to deliver fast parts without sacrificing quality or performance.

Material selection, toolpath optimization, and post-machining treatments like stress relieving and surface finishing are all calibrated to meet the functional demands of the end-use environment. Furthermore, our quality assurance protocols adhere to ISO 9001 standards, with full traceability from raw material to final inspection. Every part is verified using coordinate measuring machines (CMM) and optical comparators to ensure compliance with client specifications.

Speed, when decoupled from precision, leads to waste. At Lead Precision, we integrate speed into a disciplined engineering framework where every process is optimized for accuracy first—ensuring that fast parts are not only delivered quickly but perform reliably in the field.

Typical Fast Parts Specifications at Wuxi Lead Precision Machinery

| Parameter | Capability |

|---|---|

| Machining Tolerance | ±0.002 mm |

| Max Work Envelope | 1200 x 800 x 650 mm |

| Materials Processed | Aluminum, Stainless Steel, Titanium, Inconel, Brass, PEEK |

| Surface Finish (Ra) | As low as 0.4 µm |

| Lead Time (Prototype) | 5–10 working days |

| Lead Time (Production) | 10–20 working days (volume-dependent) |

| Quality Standards | ISO 9001, Full First Article Inspection (FAI), PPAP Level 3 |

Our commitment to precision engineering enables Wuxi Lead Precision Machinery to serve as a trusted partner in fast parts manufacturing—where speed meets uncompromised quality.

Precision Specs & Tolerances

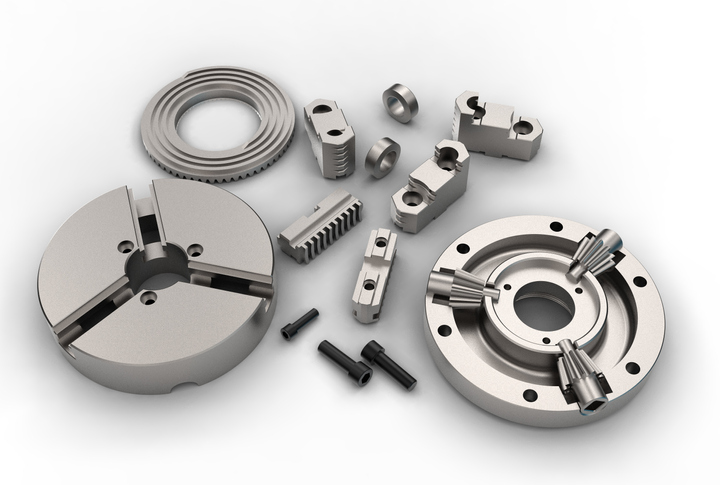

Technical Capabilities: Precision Engineered for Complex Metal Components

Wuxi Lead Precision Machinery delivers uncompromising accuracy and efficiency for mission-critical metal components across aerospace, medical, and energy sectors. Our integrated 5-axis CNC machining centers form the backbone of rapid, high-complexity production. These systems execute simultaneous multi-axis movements, eliminating manual repositioning and ensuring geometric integrity for organic shapes, deep cavities, and intricate contours that challenge conventional 3-axis platforms. Material versatility spans titanium alloys, Inconel, stainless steel, and aluminum, with machining envelopes accommodating parts up to 1,200 x 800 x 750 mm. Sub-micron repeatability is maintained through thermal compensation systems and rigid machine structures, enabling first-article success rates exceeding 98% for demanding geometries.

Quality assurance is embedded at every phase, beginning with digital process validation via Mastercam and Siemens NX simulations. All critical features undergo full-spectrum inspection using Zeiss and Hexagon CMMs, certified to ISO 17025 standards. Our metrology suite captures 3D point clouds for deviation analysis against nominal CAD data, with real-time SPC monitoring of dimensional drift during production runs. This closed-loop system ensures compliance with AS9100 and ISO 13485 requirements, providing full traceability from raw material to final certification. Statistical process control dashboards track capability indices (Cp/Cpk) for high-volume orders, guaranteeing sustained conformance without sacrificing throughput.

Tolerance execution is rigorously defined by part complexity and material properties. The table below reflects achievable standards under controlled production conditions for features machined in stable environments. Tighter specifications require collaborative process validation.

| Feature Type | Standard Tolerance | Tight Tolerance | Typical Application Example |

|---|---|---|---|

| Linear Dimension | ±0.010 mm | ±0.005 mm | Hydraulic valve bodies |

| Angular Deviation | ±0.05° | ±0.02° | Turbine blade root forms |

| Positional (Ø) | ±0.012 mm | ±0.008 mm | Multi-hole fuel injector plates |

| Surface Finish (Ra) | 0.8 µm | 0.4 µm | Implant contact surfaces |

Our technical team collaborates early in the design phase to optimize manufacturability, leveraging DFM analysis to identify tolerance stack-up risks and suggest cost-effective material allowances. This proactive approach reduces lead times by up to 30% while ensuring zero concessions on functional performance. For mission-critical applications requiring micron-level precision, we deploy in-process laser probing and adaptive machining strategies to dynamically correct for tool wear and thermal expansion. Every component ships with a comprehensive inspection report, including GD&T verification and material certification, providing auditable proof of conformance for your quality systems. Wuxi Lead transforms complex engineering intent into physically perfect metal reality—rapidly, reliably, and with absolute dimensional authority.

Material & Finish Options

Material selection is a critical step in custom metal manufacturing, directly influencing part performance, durability, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in precision CNC machining of high-performance materials including aluminum, steel, and titanium—each offering unique mechanical properties suited to specific industrial applications. Understanding the trade-offs between strength, weight, corrosion resistance, and machinability enables engineers and procurement teams to make informed decisions for mission-critical components.

Aluminum is widely favored for its excellent strength-to-weight ratio and good thermal conductivity. It is particularly suitable for aerospace, automotive, and consumer electronics applications where weight reduction is essential. The most commonly used grade, 6061-T6, provides balanced mechanical properties and weldability, while 7075-T6 offers higher strength for more demanding structural roles. Aluminum’s natural oxide layer provides inherent corrosion resistance, but when enhanced surface protection and wear resistance are required, anodizing is the preferred finishing process.

Steel remains the backbone of industrial manufacturing due to its high tensile strength, durability, and cost-effectiveness. Grades such as 4140 and 1045 are frequently machined for tooling, shafts, and high-load components. While steel is heavier than aluminum, its superior hardness and fatigue resistance make it ideal for heavy machinery and structural applications. For environments prone to corrosion, stainless steel variants like 304 and 316 are selected for their chromium content, which forms a passive oxide layer that resists rust and chemical degradation.

Titanium, particularly Grade 5 (Ti-6Al-4V), is the material of choice in extreme environments such as aerospace, medical implants, and marine engineering. It combines exceptional strength-to-density ratio with outstanding corrosion resistance, even in saltwater and high-temperature conditions. Though more challenging to machine due to its low thermal conductivity and tendency to gall, titanium’s longevity and performance under stress justify its use in critical systems.

Anodizing is a key surface treatment for aluminum components, enhancing both functional and aesthetic qualities. The process electrochemically grows a thicker, porous oxide layer on the surface, which can be sealed to improve corrosion and wear resistance. Type II (sulfuric acid) anodizing is standard for general protection and dyeing, while Type III (hardcoat) anodizing delivers a denser, thicker layer suitable for high-wear applications. Anodized finishes are non-conductive and maintain dimensional stability, making them ideal for precision parts.

Below is a comparative overview of key material properties to guide selection:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Corrosion Resistance | Common Applications | Typical Finishes |

|---|---|---|---|---|---|

| Aluminum 6061 | 310 | 2.7 | Moderate (improved with anodizing) | Enclosures, brackets, heat sinks | Anodizing, bead blasting |

| Steel 1045 | 600 | 7.8 | Low (prone to rust) | Shafts, gears, fixtures | Zinc plating, powder coating |

| Stainless 304 | 515 | 8.0 | High | Food processing, medical | Passivation, polishing |

| Titanium Ti-6Al-4V | 900 | 4.4 | Very High | Aerospace, implants, marine | Anodizing, grit blasting |

Selecting the right material and finish ensures optimal performance, longevity, and value in custom metal parts. Wuxi Lead Precision Machinery supports clients with expert consultation and precision manufacturing to meet the highest industry standards.

Manufacturing Process & QC

Production Process: Precision Engineered from Concept to Completion

At Wuxi Lead Precision Machinery, our production process for custom metal components is engineered for speed, accuracy, and absolute reliability. We integrate advanced CNC technology with rigorous quality management to deliver true Zero Defects performance for demanding fast parts applications. This seamless workflow ensures your components meet exact specifications while accelerating time-to-market.

The journey begins with collaborative Design for Manufacturability (DFM) analysis. Our engineering team meticulously reviews your CAD models, identifying potential machining challenges and material constraints early. We optimize toolpaths using Mastercam and Siemens NX CAM, ensuring efficient material removal and structural integrity. This phase includes thermal distortion modeling and fixture design validation to prevent errors before metal is cut, significantly reducing rework risk and accelerating the path to production.

Prototyping is not merely a formality but a critical validation step within our Zero Defects framework. Utilizing our high-speed 5-axis machining centers, we produce functional prototypes from your specified aerospace-grade aluminum, stainless steel, or titanium alloys. Each prototype undergoes comprehensive metrology: CMM inspection verifies geometric dimensioning and tolerancing (GD&T) compliance, while surface roughness and hardness testing confirm material properties. This stage validates both design intent and our process capability, providing tangible proof of quality before committing to volume runs.

Mass production leverages the validated process parameters under stringent statistical process control (SPC). Our automated production cells, featuring FANUC and DMG MORI machines with robotic palletization, maintain consistent cycle times and dimensional stability. Real-time in-process gauging monitors critical features, automatically triggering corrective actions if deviations approach tolerance limits. Full material traceability, from heat number to final inspection report, is maintained via our integrated MES. Every component undergoes 100% final inspection against your print, with certified reports provided. This closed-loop system, combined with our ISO 9001 and AS9100-certified quality management, ensures batch-to-batch uniformity and eliminates defects at the source.

Our technical capabilities support rapid execution without compromise:

| Capability | Specification | Application Impact |

|---|---|---|

| Tolerance Range | ±0.005 mm standard, ±0.001 mm achievable | Precision fit for aerospace & medical assemblies |

| Material Range | Aluminum 6061/7075, Stainless 303/316/17-4PH, Titanium Gr5, Brass | Broad compatibility with high-stress environments |

| Max Work Envelope | 1200 x 800 x 600 mm | Accommodates complex structural components |

| Typical Lead Time | 7-15 days (prototype), 10-25 days (production) | Accelerates project timelines without quality trade-offs |

| Surface Finish | Ra 0.8 µm standard, Ra 0.4 µm achievable | Meets stringent functional and aesthetic requirements |

This integrated approach transforms design intent into flawless physical reality. By embedding quality at every phase—from virtual validation to automated production—we deliver fast parts that perform reliably in your most critical applications, ensuring your supply chain operates with zero disruption.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Custom Metal Manufacturing Excellence

In the fast-paced world of industrial production, time is not just a metric—it’s a competitive advantage. At Wuxi Lead Precision Machinery, we understand that delays in component delivery can cascade into costly downtime, missed deadlines, and lost opportunities. That’s why we’ve engineered our operations around speed, precision, and reliability—delivering high-quality custom metal parts faster than traditional manufacturers, without compromising on accuracy or material integrity.

Our advanced CNC machining capabilities, combined with a streamlined production workflow, enable us to support rapid prototyping and low-to-mid volume production runs with industry-leading turnaround times. Whether you’re in aerospace, automation, medical device manufacturing, or precision instrumentation, our team acts as an extension of your engineering department—ensuring your designs are translated into flawless metal components, on schedule, every time.

What sets Lead Precision apart is not just our technology, but our commitment to partnership. We don’t treat orders as transactions. Instead, we engage early in your design process, offering expert manufacturability feedback to optimize for cost, performance, and speed. From material selection to finishing requirements, our engineers collaborate with you to eliminate bottlenecks before production begins.

Our facility in Wuxi, China, is equipped with state-of-the-art 3-, 4-, and 5-axis CNC machining centers, Swiss-type lathes, and automated inspection systems. All parts undergo rigorous quality control, including CMM and optical measurement verification, ensuring compliance with ISO 9001 standards and your exact specifications.

We specialize in complex geometries, tight-tolerance components, and challenging materials such as titanium, Inconel, aluminum alloys, stainless steel, and engineering plastics. Our vertical integration allows us to control every step in-house—cutting lead times and ensuring consistent quality from raw material to final shipment.

Below are key capabilities that define our fast-part manufacturing service:

| Specification | Detail |

|---|---|

| Machining Types | 3-axis, 4-axis, 5-axis CNC milling, CNC turning, Swiss machining |

| Tolerances | As tight as ±0.005 mm |

| Materials | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Titanium, Inconel, Brass, PEEK, Delrin |

| Max Work Envelope | 1200 x 600 x 500 mm (milling), Ø20–Ø38 mm (Swiss) |

| Lead Times | As fast as 5–7 days for machined parts, 10–12 days for complex assemblies |

| Finishes | As-machined, anodizing (Type II & III), passivation, powder coating, polishing |

| Quality Standards | ISO 9001:2015, Full First Article Inspection (FAI) reports, PPAP support |

Speed without sacrifice is our promise. When you partner with Wuxi Lead Precision Machinery, you gain more than a supplier—you gain a precision-focused ally committed to accelerating your time to market.

Contact us today at [email protected] to discuss your next project. Let us prove how fast, accurate, and reliable custom metal manufacturing can be.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.