Technical Contents

Engineering Guide: 3-Axis Cnc Machining

Engineering Insight: The Critical Role of Precision in 3-Axis CNC Machining

In the realm of precision manufacturing, 3-axis CNC machining remains a foundational technology, delivering reliable, repeatable, and highly accurate results for a broad spectrum of industrial applications. At Wuxi Lead Precision Machinery, we recognize that precision is not merely a performance metric—it is the cornerstone of functional integrity, safety, and long-term value in engineered components. Whether producing aerospace housings, medical device enclosures, or high-tolerance mechanical assemblies, the consistency and accuracy of 3-axis machining directly influence the performance and reliability of the final product.

The principle of 3-axis CNC machining involves tool movement along the X, Y, and Z linear axes, enabling precise material removal from a stationary workpiece. While newer multi-axis systems offer expanded capabilities, the enduring relevance of 3-axis machining lies in its simplicity, cost-efficiency, and exceptional accuracy for prismatic and planar geometries. However, achieving micron-level tolerances consistently demands more than advanced machinery—it requires mastery in process control, tooling strategy, thermal management, and quality assurance.

At Wuxi Lead, our engineering team leverages over a decade of specialized experience in high-stakes manufacturing environments. Our work has supported mission-critical components for military defense systems and precision parts used in Olympic-grade sporting equipment, where even a 5-micron deviation can compromise performance. These applications demand not only technical precision but also rigorous documentation, material traceability, and compliance with international quality standards such as ISO 9001 and AS9100. Our facility employs calibrated CNC centers with closed-loop feedback systems, in-process probing, and post-machining inspection via coordinate measuring machines (CMM) to ensure every component meets exacting specifications.

The success of 3-axis machining also hinges on strategic material selection and fixturing design. We prioritize minimizing workpiece deflection and vibration through custom workholding solutions, ensuring dimensional stability during high-speed cutting operations. Additionally, our process engineers conduct detailed toolpath optimization to reduce cycle times without sacrificing surface finish or edge definition.

Our commitment to precision is reflected in the performance metrics of our 3-axis machining systems, as detailed below:

| Specification | Performance Capability |

|---|---|

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Maximum Work Envelope | 1000 x 600 x 500 mm |

| Spindle Speed | Up to 24,000 RPM |

| Tolerance Range | ±0.01 mm (standard), down to ±0.005 mm (tight-tolerance) |

| Surface Finish | Ra 0.8 μm (typical), down to Ra 0.4 μm (fine finish) |

| Materials Supported | Aluminum (6061, 7075), Stainless Steel (303, 316), Titanium, Brass, Engineering Plastics |

Precision in 3-axis CNC machining is not an automatic outcome—it is engineered through expertise, discipline, and a relentless focus on quality. At Wuxi Lead Precision Machinery, we combine advanced equipment with deep application knowledge to deliver components that meet the highest standards of performance and reliability.

Precision Specs & Tolerances

Technical Capabilities: Precision Machining Beyond Conventional Limits

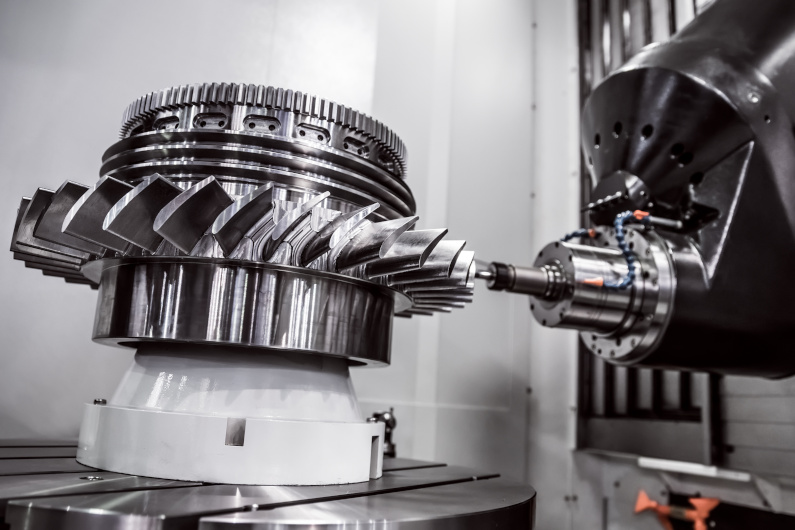

Wuxi Lead Precision Machinery operates at the forefront of advanced CNC manufacturing, strategically transcending foundational 3-axis capabilities to deliver complex, high-integrity components. While 3-axis machining remains a fundamental process within the industry, our facility is engineered for superior complexity and precision through dedicated 5-axis CNC machining centers. This strategic investment enables us to efficiently produce intricate geometries—such as deep cavities, undercuts, and organic aerospace contours—in a single setup. Eliminating multiple fixturing steps drastically reduces cumulative error, enhances part accuracy, and significantly shortens lead times for our clients. Our Haas UMC-750 and DMG MORI DMU 50 5-axis platforms provide the rigidity, thermal stability, and sub-micron positioning accuracy essential for mission-critical applications across aerospace, medical device, and energy sectors.

Precision is non-negotiable in high-end manufacturing. Every component undergoes rigorous quality verification utilizing state-of-the-art Coordinate Measuring Machine (CMM) inspection. Our Zeiss CONTURA G2 CMM with VAST XT gold sensor and 750 mm x 1050 mm x 600 mm measurement volume ensures comprehensive dimensional validation against complex CAD models. This metrology-grade verification, coupled with in-process probing on machining centers, guarantees adherence to the most stringent geometric dimensioning and tolerancing (GD&T) requirements. Statistical process control (SPC) data is actively monitored and provided to clients, offering full traceability and confidence in production consistency.

Our technical execution consistently achieves demanding tolerances across diverse materials including titanium alloys, Inconel, aluminum 7075, and engineered plastics. The table below reflects our standard achievable capabilities under controlled environmental conditions. Tighter tolerances are attainable for critical features through optimized process planning and extended inspection protocols.

| Feature Type | Standard Capability | Critical Feature Capability | Surface Finish (Ra) |

|---|---|---|---|

| Linear Dimensions | ±0.010 mm | ±0.005 mm | 0.8 μm |

| Geometric Tolerances | ±0.015 mm | ±0.008 mm | 0.4 μm (Polished) |

| Hole Position | ±0.012 mm | ±0.006 mm | 1.6 μm |

| Angular Features | ±0.05° | ±0.02° | 3.2 μm |

Material integrity and surface quality are equally prioritized. Advanced high-speed machining strategies, coupled with optimized toolpath generation and premium cutting tools, minimize thermal distortion and burr formation. We implement strict material certification protocols and non-destructive testing (NDT) coordination for critical applications. Our engineering team collaborates directly with clients during DFMA (Design for Manufacturing and Assembly) stages to identify opportunities for cost reduction without compromising performance. This integrated approach—from digital twin simulation to final CMM certification—ensures components meet exact functional requirements while maximizing production efficiency. Wuxi Lead delivers not just parts, but guaranteed precision engineered for real-world performance.

Material & Finish Options

Material Selection for 3-Axis CNC Machining: Aluminum, Steel, and Titanium

Selecting the appropriate material is critical in 3-axis CNC machining, where precision, strength, and manufacturability directly impact component performance and production efficiency. At Wuxi Lead Precision Machinery, we specialize in high-tolerance machining of key engineering metals—aluminum, steel, and titanium—each offering unique properties suited to specific industrial applications. Understanding material behavior under machining conditions ensures optimal tool life, dimensional accuracy, and final part functionality.

Aluminum is a preferred choice for lightweight, high-strength components in aerospace, automotive, and consumer electronics. Its excellent machinability allows for high cutting speeds and tight tolerances, reducing cycle times and tool wear. The 6061 and 7075 aluminum alloys are particularly common, balancing strength, corrosion resistance, and weldability. Post-machining, aluminum benefits significantly from anodizing—a controlled electrochemical process that enhances surface hardness, wear resistance, and aesthetic finish. Type II (sulfuric acid) and Type III (hardcoat) anodizing are widely used, with the latter providing superior durability for demanding environments.

Steel remains indispensable in applications requiring high tensile strength, durability, and resistance to deformation. We frequently machine alloy steels such as 4140 and 1045, which offer excellent response to heat treatment and are ideal for structural components, tooling, and mechanical systems. While steel is more abrasive than aluminum, our precision toolpaths and optimized feeds and speeds ensure consistent surface finishes and dimensional stability. Stainless steels like 304 and 316 add corrosion resistance, making them suitable for medical, food processing, and marine applications. Surface treatments such as passivation or electropolishing further enhance performance in sterile or corrosive environments.

Titanium, particularly Grade 5 (Ti-6Al-4V), delivers an exceptional strength-to-density ratio and outstanding resistance to extreme temperatures and corrosion. It is widely used in aerospace, defense, and medical implant manufacturing. However, titanium’s low thermal conductivity and high chemical reactivity require specialized tooling and conservative machining parameters to prevent work hardening and tool degradation. At Wuxi Lead, we employ rigid setups, sharp carbide tools, and controlled coolant application to ensure precision and surface integrity when machining titanium components.

Below is a comparative overview of key properties for commonly machined materials:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Machinability Rating | Common Finishes | Typical Applications |

|---|---|---|---|---|---|

| Aluminum 6061 | 310 | 2.7 | Excellent | Anodizing, Bead Blast | Aerospace, Electronics, Automotive |

| Steel 4140 | 655 | 7.85 | Good | Passivation, Painting | Tooling, Shafts, Structural Parts |

| Stainless 304 | 505 | 8.0 | Moderate | Electropolishing, Passivation | Medical, Food Processing |

| Titanium Ti-6Al-4V | 950 | 4.43 | Fair | Anodizing, Passivation | Aerospace, Medical Implants |

Material selection in 3-axis CNC machining is not solely about mechanical properties—it also involves evaluating cost, lead time, and post-processing requirements. At Wuxi Lead Precision Machinery, we collaborate closely with engineers to recommend the optimal material and finish combination, ensuring every machined part meets functional, regulatory, and performance demands.

Manufacturing Process & QC

3-Axis CNC Machining: Precision Production Process from Design to Zero-Defect Delivery

At Wuxi Lead Precision Machinery, our 3-axis CNC machining process delivers uncompromising quality for prismatic components through rigorously controlled stages. This methodology ensures geometric simplicity translates to cost efficiency without sacrificing accuracy, critical for aerospace, automotive, and medical applications where tolerances directly impact performance.

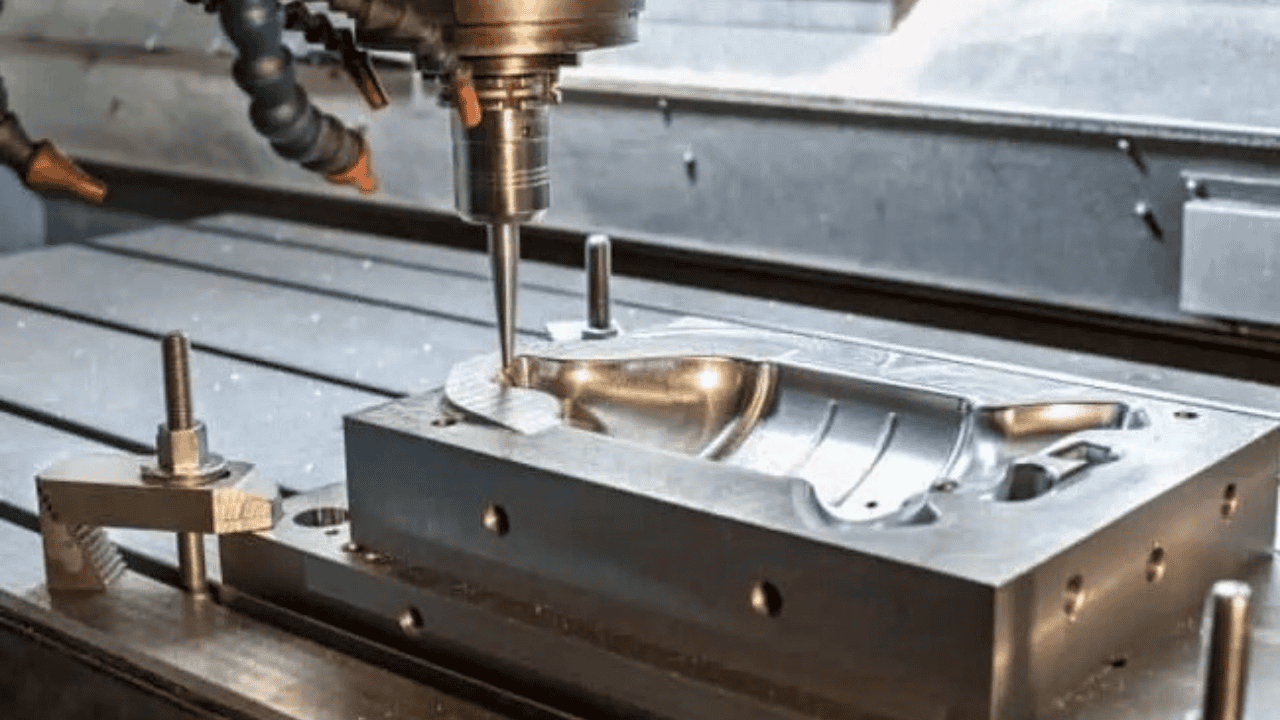

The process begins with Design Validation and DFM Optimization. Engineering teams conduct thorough Design for Manufacturability (DFM) reviews using CAD/CAM software to identify potential tool access issues, wall thickness inconsistencies, or non-optimal fillet radii. We collaborate with clients to refine geometries early, eliminating costly revisions later. Material selection is validated against mechanical stress simulations, ensuring compatibility with 3-axis machining constraints like fixed tool orientation. This phase reduces prototyping iterations by up to 40% while establishing baseline GD&T requirements.

Prototyping and Process Qualification follows, where initial parts undergo iterative refinement. Using HAAS VF-2 and DMG MORI CTX beta 1250 machines, we produce 2–5 prototypes with full first-article inspection (FAI). Critical dimensions are verified via CMM and optical comparators against AS9102 standards. Process parameters—spindle speed, feed rate, stepover—are optimized to minimize vibration and thermal drift. Any deviation triggers immediate root-cause analysis; tool wear compensation algorithms are calibrated to maintain ±0.005mm tolerances. Only after 100% conformance is achieved does the process advance to mass production.

Zero-Defect Mass Production leverages closed-loop quality control. Each batch runs under monitored conditions with in-process gauging: probes check critical features after roughing and semi-finishing stages. Statistical Process Control (SPC) charts track key parameters in real time, halting production if CpK falls below 1.67. All finished parts undergo 100% visual inspection and random CMM validation per ISO 2768-mK. Our traceability system logs machine IDs, tool offsets, and operator certifications, enabling full lot追溯.

This integrated approach ensures defect rates remain below 50 PPM. Below are core capabilities enabling this standard:

| Parameter | Specification | Control Method |

|---|---|---|

| Positioning Accuracy | ±0.003 mm | Laser interferometer calibration |

| Repeatability | ±0.002 mm | Daily ballbar testing |

| Surface Finish | Ra 0.8 µm (typical) | In-process profilometer checks |

| Max Work Envelope | 1000 x 500 x 500 mm | Pre-run digital fixture simulation |

| Lead Time Reduction | 25% vs. industry avg | Automated tool presetting system |

Wuxi Lead’s process excellence transforms design intent into flawless physical components. By embedding quality at every phase—from virtual validation to final inspection—we eliminate waste and deliver mission-critical parts that perform exactly as engineered. Contact our engineering team to optimize your next 3-axis machining project for zero-defect outcomes.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched 3-Axis CNC Machining Excellence

At Wuxi Lead Precision Machinery, we understand that precision, consistency, and speed are non-negotiable in high-end manufacturing. As a trusted leader in the field of precision CNC machining, we specialize in delivering superior 3-axis CNC machining services tailored to meet the rigorous demands of industries such as aerospace, automotive, medical devices, and industrial automation. Our advanced manufacturing capabilities, combined with decades of engineering expertise, ensure your components are machined to exact specifications—every time.

When you partner with Lead Precision, you gain more than a service provider—you gain a strategic manufacturing ally. Our state-of-the-art facility in Wuxi, China, is equipped with a full suite of high-performance 3-axis CNC milling and machining centers, all maintained to the highest international standards. Our team of certified engineers and machinists applies a meticulous approach to every project, from initial design review to final inspection, ensuring optimal material utilization, tight tolerances, and repeatable accuracy.

We support a wide range of materials, including aluminum alloys, stainless steel, titanium, brass, and engineering plastics, enabling us to serve diverse application requirements. Whether you require rapid prototyping, low-volume production, or high-volume manufacturing runs, our agile production system ensures on-time delivery without compromising quality. All processes are backed by comprehensive quality control protocols, including CMM inspection, surface finish testing, and first-article reporting, ensuring full traceability and compliance.

Our commitment to excellence is reflected in our certifications and continuous investment in technology and workforce development. We adhere to ISO 9001 standards and implement lean manufacturing principles to drive efficiency and eliminate waste. At Lead Precision, we don’t just manufacture parts—we engineer solutions that enhance your product performance and reduce your total cost of production.

Below are the core specifications of our 3-axis CNC machining capabilities:

| Specification | Detail |

|---|---|

| Machine Types | Vertical and Horizontal CNC Machining Centers |

| Axis Configuration | 3-Axis (X, Y, Z) with optional 4th Axis indexing |

| Maximum Work Envelope | 1200 x 600 x 500 mm |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.003 mm |

| Spindle Speed | Up to 12,000 RPM |

| Tool Capacity | Up to 30 tools (automatic tool changer) |

| Supported Materials | Aluminum, Steel, Stainless Steel, Titanium, Brass, Plastics (e.g., PEEK, Delrin) |

| Tolerances | As tight as ±0.01 mm |

| Surface Finish | As low as Ra 0.8 µm (polished finishes available) |

| Quality Standards | ISO 9001, Full Inspection Reports, First Article Inspection (FAI) |

Partnering with Wuxi Lead Precision Machinery means choosing precision, reliability, and long-term value. Let us help you bring your most demanding designs to life with engineering precision and manufacturing excellence.

Contact us today at [email protected] to discuss your next project. Our engineering team is ready to support you with expert consultation, rapid quoting, and scalable production solutions.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.