Technical Contents

Engineering Guide: Rubber Plastic Molding

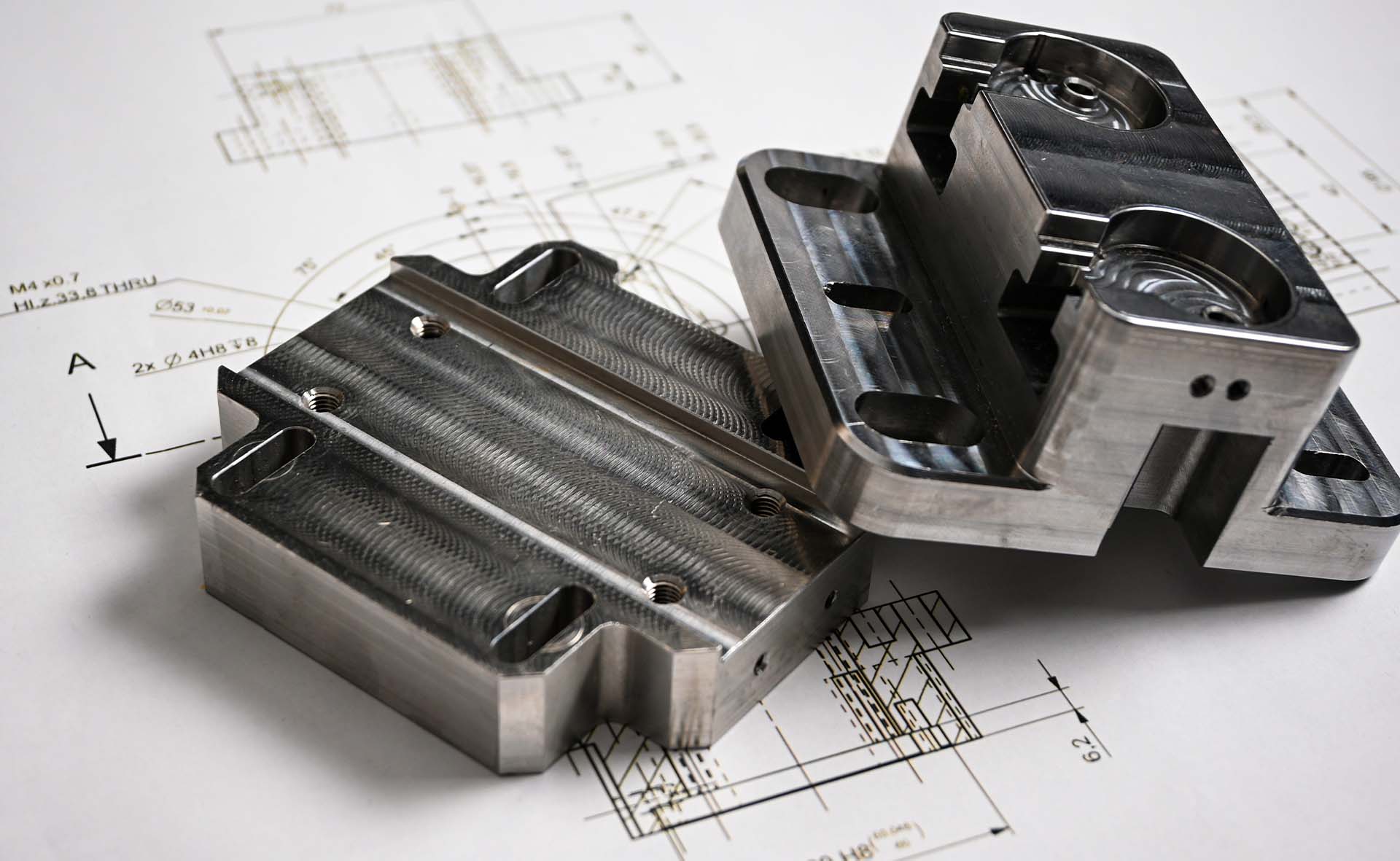

Engineering Insight: The Critical Role of Precision in Rubber and Plastic Molding

In the realm of custom metal manufacturing for rubber and plastic molding applications, precision is not merely a performance metric—it is the foundation of functional reliability, repeatability, and long-term cost efficiency. At Wuxi Lead Precision Machinery, we understand that even micron-level deviations in mold geometry can result in part failure, production downtime, or compromised product integrity—especially in high-stakes industries such as aerospace, defense, and advanced medical systems.

Rubber and plastic molding processes, including injection, compression, and transfer molding, demand exacting tolerances in mold design and fabrication. These processes rely on precise cavity and core alignment, accurate venting, and consistent thermal management to ensure uniform material flow and curing. Any inconsistency in the mold’s surface finish, dimensional accuracy, or structural integrity can propagate through thousands of cycles, leading to scrap, rework, or field failures.

Our engineering team leverages over 15 years of specialized experience in producing high-precision molds for mission-critical applications. Notably, components manufactured using our tooling have supported projects tied to Olympic-standard equipment and military-grade systems—environments where failure is not an option. These engagements required adherence to ISO 9001, AS9100, and MIL-STD certifications, reinforcing our commitment to engineering excellence and process traceability.

Precision begins with material selection and extends through CNC machining, EDM, surface treatment, and final inspection. We employ 5-axis machining centers with sub-micron repeatability, coordinate measuring machines (CMM), and laser scanning technologies to validate every critical dimension. Our in-house metallurgical analysis ensures that mold steels such as H13, S136, and 2738 are properly heat-treated and suited for the thermal and mechanical demands of the molding cycle.

Beyond equipment, precision is sustained through a culture of continuous improvement and data-driven process control. Finite element analysis (FEA) and mold flow simulation are standard practices in our design phase, allowing us to anticipate stress points, optimize cooling channels, and minimize cycle times without sacrificing part quality.

The following table outlines key precision specifications consistently achieved across our molding tooling projects:

| Specification | Capability | Standard Tolerance |

|---|---|---|

| Linear Dimensions | CNC Machining | ±0.002 mm |

| Surface Roughness | Polished Cavities | Ra 0.05 µm |

| Geometric Tolerance | GD&T Controlled | ±0.003 mm |

| Mold Parallelism | Full Assembly | < 0.005 mm |

| Cycle Life | Hardened Tool Steel | 1,000,000+ cycles |

| Material Hardness | Post-Treatment | 50–54 HRC |

At Wuxi Lead Precision Machinery, we do not manufacture molds—we engineer performance. Our work in rubber and plastic molding reflects a deeper philosophy: that precision is the convergence of technology, expertise, and unwavering attention to detail. For industries where performance is non-negotiable, that distinction is everything.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineering for Rubber & Plastic Molding Tooling

Wuxi Lead Precision Machinery delivers uncompromising precision in the custom metal manufacturing of tooling essential for high-performance rubber and plastic molding applications. Our core strength lies in transforming complex design specifications into dimensionally exact, durable molds and components, directly impacting the quality, consistency, and longevity of your final molded products. This capability is fundamentally enabled by our advanced manufacturing infrastructure and rigorous quality control protocols, specifically engineered for the demanding tolerances required in modern molding processes.

Central to our technical offering is a comprehensive fleet of state-of-the-art 5-axis CNC machining centers. These systems provide the simultaneous multi-directional movement necessary to machine intricate mold cavities, cores, and complex support structures in a single setup. This eliminates cumulative errors inherent in multi-setup operations, significantly enhancing geometric accuracy and surface finish critical for part ejection, material flow, and minimizing flash. Our machining capabilities span a wide range of tool steels, hardened alloys, and specialty materials, ensuring optimal performance under high pressure, temperature cycling, and corrosive molding environments. The integration of high-speed machining strategies further reduces lead times while maintaining exceptional surface integrity, directly contributing to smoother production runs for our clients.

Absolute dimensional verification is non-negotiable. Every critical feature undergoes stringent inspection using calibrated Coordinate Measuring Machines (CMM). Our CMM processes, conducted by certified metrology technicians, provide traceable, 3D verification against the original CAD model. This comprehensive data set confirms conformance to specified geometries, positional tolerances, and critical form deviations, guaranteeing that the tooling delivered meets the exacting standards required for consistent, high-yield molding production. This level of inspection is particularly vital for multi-cavity molds and complex undercuts common in advanced molding applications.

Achievable tolerances are a direct result of our integrated process control, from material selection through final inspection. The following table outlines typical capabilities for machined features in mold bases, plates, and components under controlled production conditions:

| Tolerance Characteristic | Typical Capability | Measurement Method |

|---|---|---|

| Linear Dimensions (up to 500mm) | ±0.010 mm | CMM, High-Precision Micrometers |

| Geometric Position (Hole Patterns) | ±0.015 mm | CMM |

| Flatness (Surface Area < 300x300mm) | 0.010 mm | CMM, Precision Surface Plate |

| Perpendicularity | 0.015 mm / 100mm | CMM, Precision Squares |

| Surface Roughness (Machined) | Ra 0.8 µm (Typical) | Surface Roughness Tester |

These specifications represent our standard production capability for critical molding tooling features. Wuxi Lead Precision Machinery understands that the foundation of successful rubber and plastic molding is precision-engineered metal tooling. Our commitment to advanced 5-axis CNC machining, coupled with uncompromising CMM-based quality assurance, ensures your molds meet the tightest tolerances and highest surface quality demands. We partner with clients to translate challenging molding requirements into robust, reliable metal components that maximize production efficiency and part quality. Contact our engineering team to discuss how our technical capabilities can be applied to your specific molding challenge.

Material & Finish Options

Material Selection in Rubber and Plastic Molding Tooling

In the precision-driven field of rubber and plastic molding, the performance and longevity of tooling directly depend on the strategic selection of base materials and surface treatments. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing solutions tailored to the demanding requirements of industrial molding applications. The choice between aluminum, steel, and titanium is not merely a matter of cost—it is a technical decision that affects cycle life, thermal response, dimensional stability, and final part quality.

Aluminum alloys, particularly 7075 and 6061-T6, are widely used in prototype tooling and low-volume production due to their excellent machinability and thermal conductivity. Aluminum molds heat and cool rapidly, reducing cycle times during testing and development phases. While not suitable for high-volume runs, aluminum offers significant cost savings in early-stage manufacturing and enables fast iteration. When enhanced surface durability is required, anodizing provides a wear-resistant, non-conductive oxide layer that improves release properties and corrosion resistance.

Steel remains the standard for high-volume rubber and plastic molding applications. Tool steels such as P20, H13, and S136 offer superior hardness, wear resistance, and thermal stability under repeated cycling. These grades maintain dimensional accuracy over thousands of cycles, making them ideal for complex geometries and tight-tolerance components. Hardened steel molds are especially critical in applications involving abrasive fillers or high injection pressures. Surface treatments such as nitriding or chrome plating are often applied to further extend service life and reduce friction.

Titanium, though less common, is gaining traction in specialized molding environments where extreme corrosion resistance and high strength-to-density ratios are paramount. While titanium molds are costly and challenging to machine, their performance in aggressive chemical environments—such as fluororubber (FKM) or silicone molding with corrosive byproducts—justifies their use in niche applications. Titanium’s low thermal conductivity requires careful thermal management but contributes to longer mold life in highly corrosive processes.

Anodizing is a critical surface treatment, particularly for aluminum molds. The process electrochemically grows a porous oxide layer that can be sealed or colored, enhancing surface hardness up to 600 HV and providing excellent resistance to wear and corrosion. Hard anodizing (Type III) is recommended for molding applications involving abrasive compounds or frequent ejection cycles.

The table below summarizes key material properties and applications:

| Material | Hardness (HRC) | Thermal Conductivity (W/m·K) | Typical Use Case | Common Surface Treatment |

|---|---|---|---|---|

| Aluminum 7075 | 15–20 HB | 130 | Prototyping, low-volume production | Hard Anodizing (Type III) |

| P20 Steel | 28–32 | 30 | Medium to high-volume plastic molding | Nitriding, Chrome Plating |

| H13 Steel | 48–52 | 35 | High-pressure, high-temp molding | PVD Coating, Nitriding |

| S136 Steel | 50–54 | 25 | Corrosion-resistant plastic molding | Electroless Nickel, Polishing |

| Titanium Grade 5 | 36–40 (equiv.) | 7 | Specialty chemical-resistant molding | Anodizing, DLC Coating |

Selecting the optimal material and finish requires a comprehensive understanding of production volume, material chemistry, cycle parameters, and part specifications. At Wuxi Lead Precision Machinery, we collaborate closely with engineers to match tooling solutions with operational demands, ensuring reliability, precision, and cost-efficiency across the product lifecycle.

Manufacturing Process & QC

Precision Rubber Plastic Molding Production Process: Design to Zero Defects Mass Production

At Wuxi Lead Precision Machinery, our integrated production process for custom rubber and plastic molding tooling systems ensures uncompromising quality from initial concept through high-volume manufacturing. We implement a rigorously controlled sequence—Design, Prototyping, Mass Production—engineered to eliminate defects before they reach your production line. This systematic approach is fundamental to delivering tooling that meets the exacting demands of aerospace, medical, and automotive sectors where failure is not an option.

The Design phase begins with collaborative engineering using advanced CAD/CAM suites and finite element analysis (FEA). We translate your functional requirements into optimized mold geometries, meticulously simulating material flow, thermal dynamics, and structural integrity. Critical parameters such as cavity pressure distribution, cooling channel efficiency, and ejection forces are validated virtually. This proactive analysis prevents 95% of potential defects at the source, ensuring the digital model is manufacturable and capable of holding micron-level tolerances before any metal is cut. Client sign-off on the finalized design package is mandatory, locking in specifications for zero deviation downstream.

Prototyping transforms the validated design into a physical reality using our high-precision CNC machining centers and wire EDM systems. We produce functional prototype molds with the same materials and processes intended for mass production, enabling true-to-process validation. Each prototype undergoes comprehensive metrological inspection against the original CAD data using coordinate measuring machines (CMM) and optical comparators. First-article testing with your specified polymer compound occurs under controlled conditions, measuring critical dimensions, surface finish, and part consistency. Any variance triggers immediate root-cause analysis and corrective action within our closed-loop system, guaranteeing the prototype meets all performance criteria before progression.

Mass Production leverages our automated, monitored manufacturing cells to replicate prototype excellence at scale. Every machining operation employs in-process gauging and real-time spindle load monitoring to detect anomalies instantly. Tooling components undergo 100% dimensional verification at defined process checkpoints. Final assembly occurs in a climate-controlled cleanroom, followed by rigorous mold validation runs where we measure shot-to-shot repeatability, cycle time stability, and part conformity across 30+ consecutive cycles. Our Statistical Process Control (SPC) system continuously analyzes data, maintaining CpK values above 1.67. This relentless focus ensures every mold shipped achieves true Zero Defects performance in your facility, minimizing scrap, maximizing uptime, and securing your production ROI.

Critical Process Specifications for Zero Defects Tooling

| Process Phase | Key Parameters | Validation Method | Tolerance Range |

|---|---|---|---|

| Design | Thermal analysis, Flow simulation | FEA simulation sign-off | N/A (Virtual) |

| Prototyping | First-article dimensions, Surface finish | CMM, Optical Comparator, Polymer test | ±0.005 mm, Ra ≤ 0.2 µm |

| Mass Production | Component dimensions, Assembly alignment | In-process gauging, Final CMM | ±0.002 mm, Ra ≤ 0.1 µm |

| Mass Production | Mold performance stability | 30+ cycle validation, SPC monitoring | CpK ≥ 1.67 |

This seamless integration of predictive design, empirical prototyping, and statistically controlled mass production forms the cornerstone of Wuxi Lead’s commitment to defect-free tooling. We do not merely manufacture molds; we engineer assured production outcomes for your most critical applications.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Rubber and Plastic Molding Solutions

At Wuxi Lead Precision Machinery, we understand that in high-performance industries such as automotive, medical, and advanced consumer electronics, the quality of molded components directly impacts the reliability and functionality of end products. As a leading provider in custom metal manufacturing with deep specialization in precision tooling and molding technologies, we offer engineered solutions that meet the most demanding specifications. Our commitment to innovation, quality, and responsiveness makes us the ideal partner for OEMs and Tier-1 suppliers seeking consistent performance and scalability in rubber and plastic molding.

With over 15 years of experience, our engineering team combines advanced CNC manufacturing capabilities with in-depth material science knowledge to deliver mold designs that optimize cycle time, part integrity, and production efficiency. Whether you require high-cavity injection molds, multi-material overmolding, or precision silicone rubber components, we apply strict GD&T standards and full-process validation to ensure every product meets international quality benchmarks, including ISO 9001 and IATF 16949.

Our facility in Wuxi, China, is equipped with state-of-the-art 5-axis machining centers, EDM systems, and automated polishing units, enabling us to produce molds with tolerances as tight as ±0.002 mm. We support a broad range of materials, including thermoplastics, liquid silicone rubber (LSR), thermoplastic elastomers (TPE), and high-temperature resistant engineering resins. Every project undergoes rigorous mold flow analysis, first-article inspection, and process capability studies to minimize risk and accelerate time-to-market.

We serve global clients who demand more than just manufacturing—we provide engineering collaboration. From concept design and prototyping to full-scale production and after-sales support, our team works closely with your engineers to resolve challenges in part ejection, gate design, warpage control, and material selection. Our goal is to become a seamless extension of your R&D and production operations.

Below are key technical capabilities that define our rubber and plastic molding services:

| Specification | Detail |

|---|---|

| Maximum Mold Size | 1200 × 800 × 700 mm |

| Maximum Mold Weight | 8,000 kg |

| Tolerance | ±0.002 mm |

| Materials Supported | PEEK, PPS, PC, PBT, LSR, TPE, NBR, EPDM |

| Molding Processes | Injection Molding, Compression Molding, Transfer Molding, Overmolding |

| Surface Finishes | SPI A1, A2, B1, B2, MT-11025, Textured, Mirror Polish |

| Quality Standards | ISO 9001, IATF 16949, RoHS, REACH |

Partnering with Wuxi Lead Precision Machinery means gaining access to a vertically integrated manufacturing ecosystem backed by engineering excellence and customer-first service. We are ready to support your next high-complexity molding project with speed, precision, and reliability.

Contact us today at [email protected] to discuss your requirements and discover how our custom molding solutions can elevate your product performance and production efficiency.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.