Technical Contents

Engineering Guide: Prototype & Plastic Mold

Engineering Insight: The Critical Role of Precision in Prototype & Plastic Mold Development

In the realm of custom metal manufacturing, the development of prototypes and plastic molds stands as a foundational phase that directly influences the success of end-product performance, scalability, and time-to-market. At Wuxi Lead Precision Machinery, we recognize that precision is not merely a technical requirement—it is a strategic advantage. Every micron of deviation in a prototype or mold can cascade into significant functional, aesthetic, or compliance issues in mass production. This is especially critical when serving high-stakes industries such as aerospace, defense, and advanced medical equipment, where tolerances are non-negotiable.

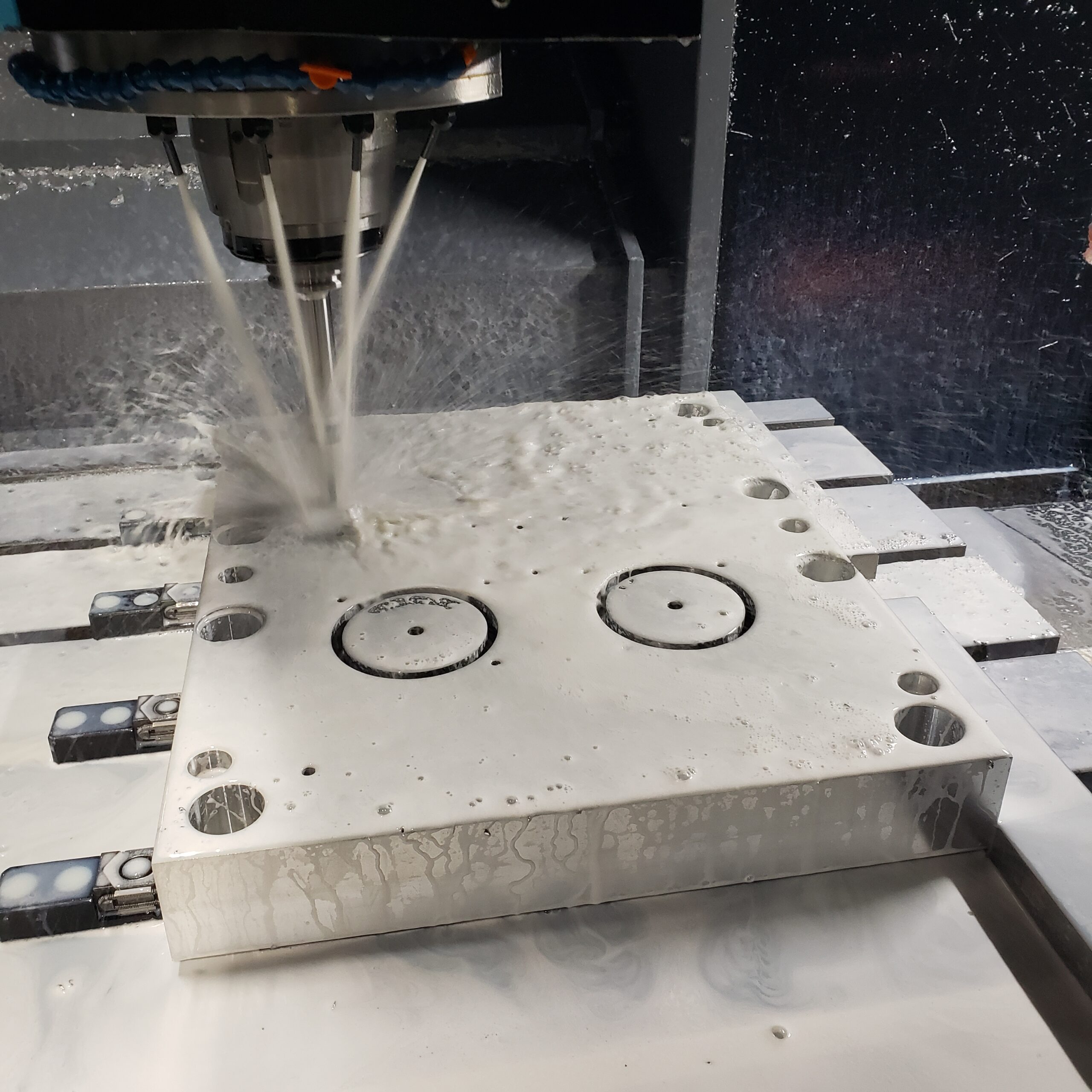

Our engineering philosophy centers on integrating precision at every stage of the prototype and mold development cycle. From initial CAD modeling to CNC machining, EDM processing, and final surface finishing, we maintain tight control over dimensional accuracy and material integrity. This ensures that each prototype not only mirrors the intended design but also serves as a reliable benchmark for mold validation. In plastic mold development, even sub-millimeter inconsistencies can lead to part warping, flash, or ejection failure—defects that are costly to correct at scale. By leveraging high-precision toolpaths, real-time metrology, and advanced simulation software, we preempt these challenges and deliver molds capable of sustaining high-cycle production with minimal wear.

Wuxi Lead Precision Machinery’s expertise is forged through decades of delivering mission-critical components for Olympic-grade equipment and military defense systems. These applications demand more than standard compliance—they require performance under extreme conditions, absolute reliability, and zero margin for error. Our involvement in such projects has refined our ability to manage complex geometries, exotic alloys, and stringent surface finish requirements—all of which translate directly into superior prototype and mold outcomes for our commercial and industrial clients.

We treat every prototype as a proof of concept and every mold as a long-term production asset. This mindset drives our investment in state-of-the-art 5-axis machining centers, cavity pressure monitoring systems, and climate-controlled inspection environments. Our engineers work in closed-loop collaboration with clients to validate design intent, optimize gate locations, and simulate mold flow—ensuring that the first shot is as close to perfect as possible.

The following table outlines key specifications that define our prototype and plastic mold capabilities:

| Specification | Capability |

|---|---|

| Tolerance Range | ±0.002 mm |

| Maximum Mold Size | 1200 × 800 × 700 mm |

| Material Compatibility | P20, 718H, NAK80, H13, Stainless Steel, Aluminum |

| Surface Finish Options | Mirror polish (SPI A1), texture (MT-11000), matte |

| Lead Time (Prototype) | 10–18 days |

| Mold Lifetime | 500,000+ cycles (optimized steel selection) |

| Quality Assurance | CMM, 3D scanning, first-article inspection |

Precision in prototype and plastic mold development is not an isolated technical step—it is the cornerstone of manufacturing excellence. At Wuxi Lead Precision Machinery, our proven track record in high-demand sectors underscores our ability to deliver not just parts, but performance you can trust.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Complex Mold & Prototype Demands

Wuxi Lead Precision Machinery delivers uncompromising precision for demanding prototype and plastic injection mold manufacturing within the custom metal sector. Our core strength lies in integrating advanced multi-axis machining with rigorous, data-driven quality control, ensuring components meet the exacting geometric and dimensional requirements critical for mold performance and part consistency. We specialize in transforming complex CAD models into high-integrity metal components where tight tolerances, intricate contours, and superior surface finishes are non-negotiable.

Our foundation is a modern fleet of high-performance 5-axis CNC machining centers. These systems provide simultaneous, coordinated motion across all five axes, enabling the precise machining of highly complex geometries in a single setup. This capability is essential for producing core/cavity inserts, lifters, slides, and intricate mold bases with undercuts, deep ribs, or organic shapes that would be impossible or prohibitively expensive with 3-axis methods. The elimination of multiple setups drastically reduces cumulative error, improves positional accuracy between features, shortens lead times, and enhances overall part integrity. Our machines achieve sub-micron level repeatability, utilizing high-rigidity spindles and thermal compensation systems to maintain dimensional stability throughout extended production runs, even for challenging materials like hardened tool steels, aluminum alloys, and high-temperature superalloys.

Quality assurance is not a final step but an integrated process. Every critical dimension and geometric feature undergoes comprehensive verification using state-of-the-art Coordinate Measuring Machines (CMMs). Our Zeiss and Hexagon CMMs, calibrated to ISO 10360 standards, provide traceable, micron-level measurement accuracy across the entire work envelope. Utilizing advanced probing systems and PC-DMIS software, we perform full First Article Inspections (FAI) and implement Statistical Process Control (SPC) during production. This generates detailed inspection reports with GD&T analysis, ensuring absolute conformance to your engineering specifications and providing the data transparency required for critical mold applications. This rigorous QC protocol guarantees that every component leaving our facility meets the stringent demands for mold fit, function, and longevity.

The following table outlines our standard achievable tolerance capabilities for machined features, reflecting the precision attainable through our combined 5-axis machining and CMM validation processes. Tighter tolerances are achievable based on specific geometry, material, and feature size.

| Feature Type | Standard Tolerance Range | Tight Tolerance Capability |

|---|---|---|

| Linear Dimensions | ±0.010 mm | ±0.005 mm |

| Hole Position | ±0.015 mm | ±0.008 mm |

| Hole Diameter | ±0.010 mm | ±0.005 mm |

| Flatness | 0.010 mm / 100 mm | 0.005 mm / 100 mm |

| Perpendicularity | 0.015 mm | 0.008 mm |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm |

This commitment to measurable precision, from complex 5-axis fabrication through metrology-grade inspection, ensures Wuxi Lead delivers mold components and prototypes that perform reliably in the most demanding production environments, minimizing tryout time and maximizing part quality for your end product.

Material & Finish Options

Material selection is a critical phase in the development of high-performance prototype and plastic mold components. At Wuxi Lead Precision Machinery, we understand that the right combination of base material and surface treatment directly influences part durability, dimensional stability, and production efficiency. For custom metal manufacturing applications, aluminum, steel, and titanium stand out as the most widely used materials due to their distinct mechanical properties and compatibility with precision machining processes.

Aluminum is often the preferred choice for prototyping and mold applications where lightweight construction and excellent thermal conductivity are essential. Its low density and high strength-to-weight ratio make it ideal for molds requiring rapid heat dissipation, such as in plastic injection molding. Additionally, aluminum is highly machinable, reducing lead times and tool wear during production. However, it is less wear-resistant than steel, making it better suited for low- to medium-volume runs.

Steel, particularly tool steels like P20, H13, and S136, offers superior hardness, wear resistance, and longevity. These properties make steel the standard for high-volume plastic molds where surface finish consistency and structural integrity are paramount. While steel is more challenging to machine and heavier than aluminum, its extended service life justifies the investment in large-scale manufacturing environments. Stainless steel variants also provide excellent corrosion resistance, essential for molds exposed to aggressive resins or humid conditions.

Titanium, though less common in standard mold fabrication, is selected for highly specialized applications demanding extreme strength, corrosion resistance, and performance at elevated temperatures. Its biocompatibility and resistance to chemical degradation make it suitable for medical and aerospace mold tooling. However, titanium’s high cost and machining complexity typically limit its use to niche, high-value components.

Surface finishing, particularly anodizing, plays a pivotal role in enhancing the functional and aesthetic qualities of aluminum molds. Anodizing creates a durable, corrosion-resistant oxide layer that improves wear resistance and allows for color coding or branding through dye integration. Type II (sulfuric acid) and Type III (hardcoat) anodizing are commonly applied, with the latter offering superior thickness and hardness for industrial tooling. While anodizing is specific to aluminum, steel components benefit from alternatives such as nitriding, chrome plating, or polishing to achieve similar performance enhancements.

Below is a comparative overview of key material properties relevant to prototype and plastic mold applications.

| Material | Tensile Strength (MPa) | Hardness (HRC) | Thermal Conductivity (W/m·K) | Common Applications | Suitable Finishes |

|---|---|---|---|---|---|

| Aluminum (6061) | 310 | 15–20 (HB) | 167 | Prototypes, low-volume molds | Anodizing (Type II/III), polishing |

| Steel (P20) | 950–1100 | 28–32 | 30 | Medium- to high-volume molds | Nitriding, chrome plating, polishing |

| Steel (H13) | 1550 | 45–50 | 28 | High-stress, hot-runner molds | Nitriding, PVD coating |

| Titanium (Ti-6Al-4V) | 900–1000 | 36–40 | 7 | Aerospace, medical tooling | Anodizing (medical grade), coating |

Selecting the optimal material and finish requires a thorough understanding of production volume, environmental exposure, and performance demands. Wuxi Lead Precision Machinery provides expert consultation to ensure your prototype or mold system delivers precision, reliability, and cost-efficiency across its lifecycle.

Manufacturing Process & QC

Wuxi Lead Precision Machinery: Integrated Production Process for Zero Defect Plastic Mold & Prototype Manufacturing

Achieving zero defects in custom plastic mold and prototype manufacturing demands a rigorously controlled, end-to-end process. At Wuxi Lead Precision Machinery, we integrate deep engineering expertise with advanced metrology to ensure every component meets exacting specifications from initial concept through high-volume production. Our methodology eliminates costly iterations and supply chain disruptions, delivering production-ready quality on schedule.

The process begins with collaborative Design Engineering. Our CNC and mold design specialists work directly with client CAD data, applying decades of shop-floor experience to optimize geometry for manufacturability, material behavior, and tool longevity. Critical factors like gate location, cooling channel efficiency, and ejection dynamics are simulated using advanced mold flow analysis software. We enforce strict Geometric Dimensioning and Tolerancing (GD&T) standards and conduct Design for Manufacturing (DFM) reviews to preempt potential defects before metal is cut. This phase establishes the non-negotiable quality baseline.

Precision Prototyping transforms the validated design into a tangible, functional reality. Utilizing our multi-axis CNC milling and wire EDM centers, we produce prototype molds or direct functional prototypes in the intended production resin. Every critical feature undergoes 100% inspection against the master CAD model using calibrated Coordinate Measuring Machines (CMM) and optical comparators. We perform rigorous 72-hour thermal stability testing on mold prototypes and conduct first-article inspections on plastic parts, verifying dimensions, surface finish, and structural integrity. This stage is not merely validation; it is the critical proving ground where potential defects are identified and resolved under controlled conditions, ensuring the design is truly production-viable.

Transitioning to Zero-Defect Mass Production leverages the perfected process parameters established during prototyping. Our automated production cells, monitored by real-time sensor networks, maintain precise control over injection pressure, temperature profiles, and cycle times. Statistical Process Control (SPC) charts track critical dimensions continuously, with automatic process correction initiated at the first sign of deviation. Every production run includes in-process inspections at defined intervals and final batch validation against the approved prototype. Material traceability and full documentation are maintained throughout, providing an immutable quality record. This closed-loop system guarantees consistent output meeting the tightest tolerances, eliminating scrap and rework.

Key process metrics demonstrating our zero-defect commitment are maintained across all phases:

| Phase | Typical Lead Time | Critical Tolerance Capability | Primary Validation Method |

|---|---|---|---|

| Design Engineering | 5-10 Business Days | N/A (Specification Setting) | DFM Report, Mold Flow Analysis |

| Precision Prototyping | 15-25 Days | ±0.01 mm | CMM Full Scan, First Article |

| Mass Production | 30-60 Days (Tool) | ±0.005 mm | SPC Monitoring, Batch CMM Audit |

Wuxi Lead’s integrated approach—where design insight informs prototyping, and prototyping rigor defines production—forms the foundation of our zero-defect guarantee. We do not merely manufacture molds and parts; we engineer assured outcomes, delivering production-ready precision that secures your supply chain and elevates your product quality. Partner with us for manufacturing certainty.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Prototype & Plastic Mold Manufacturing

At Wuxi Lead Precision Machinery, we specialize in delivering high-precision custom metal manufacturing solutions tailored to the exacting demands of global industries. As a trusted partner in prototype development and plastic mold production, we combine advanced CNC machining, expert tooling design, and rigorous quality control to transform your concepts into high-performance, production-ready components. Whether you’re in automotive, medical, electronics, or industrial equipment, our engineering-first approach ensures your project moves from design to delivery with precision, speed, and reliability.

Our facility in Wuxi, China, is equipped with state-of-the-art machinery and staffed by a team of seasoned engineers and technicians who understand the complexities of precision manufacturing. We don’t just build molds—we engineer solutions. From initial 3D modeling and material selection to final inspection and shipment, every stage of production is optimized for accuracy and repeatability. Our ISO-certified processes and in-house capabilities allow us to control quality at every touchpoint, reducing lead times and minimizing risk for our clients.

When you partner with Lead Precision, you gain more than a supplier—you gain a strategic manufacturing ally. We work closely with design and engineering teams worldwide to provide early-stage feedback, design for manufacturability (DFM) analysis, and rapid prototyping services that accelerate time-to-market. Our expertise in high-cavity molds, hot runner systems, and micro-molding enables us to support both low-volume prototypes and high-volume production runs with equal excellence.

We understand that in today’s competitive landscape, consistency, communication, and technical capability are non-negotiable. That’s why we maintain transparent project tracking, real-time updates, and direct engineering support throughout the lifecycle of your project. Our clients value not only our technical precision but also our commitment to long-term collaboration and continuous improvement.

For your next prototype or plastic mold project, trust a partner that delivers precision, performance, and partnership in every component we produce.

| Specification | Detail |

|---|---|

| Material Range | P20, 718, 8407, H13, S136, 420SS, Aluminum (7075, 6061), Brass |

| Tolerance | Up to ±0.002 mm |

| Mold Base Standards | LKM, FUTABO, DME, HASCO |

| Surface Finishes | SPI #A1–A3, B1–B3, C1–C3, VDI 3400, Texturing, Polishing |

| Lead Time (Prototype) | 15–25 days (depending on complexity) |

| Lead Time (Production Mold) | 25–45 days |

| Maximum Mold Size | 1200 × 800 × 800 mm |

| Annual Capacity | 500+ molds per year |

| Quality Standards | ISO 9001:2015, Full First Article Inspection (FAI) Reports |

| Secondary Services | Heat Treatment, Nitriding, EDM, CNC Finishing, Assembly |

Contact us today at [email protected] to discuss your project requirements. Our engineering team is ready to provide a detailed quotation, DFM feedback, and technical support to ensure your design is optimized for performance and manufacturability. Let Wuxi Lead Precision Machinery be your trusted partner in precision manufacturing.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.