Technical Contents

Engineering Guide: Sheet Metal Former

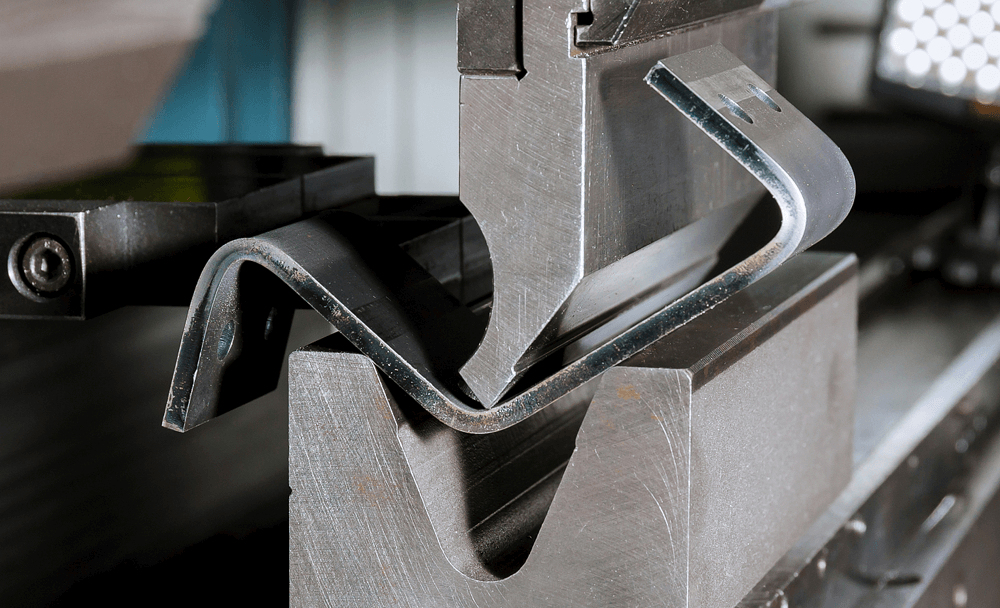

Engineering Insight: The Critical Role of Precision in Sheet Metal Forming

In high-end manufacturing, the performance of a sheet metal former is not merely a function of power or speed—it is defined by precision. At Wuxi Lead Precision Machinery, we understand that even micron-level deviations can cascade into structural, functional, and aesthetic failures in final components. This understanding drives our engineering philosophy: precision is non-negotiable. Whether producing enclosures for military communication systems or structural panels for Olympic-grade sports facilities, the integrity of every bend, fold, and contour must be repeatable, reliable, and exact.

Sheet metal forming involves complex stress dynamics, where material behavior under pressure must be predicted and controlled with high fidelity. Springback, material anisotropy, and tool wear are just a few variables that challenge dimensional consistency. Our sheet metal formers are engineered with advanced kinematic models and real-time feedback systems that dynamically adjust forming parameters. This closed-loop control ensures that each operation adheres to tight tolerances, often within ±0.1 mm, across diverse materials—from mild steel to high-strength aluminum alloys.

Wuxi Lead’s expertise in precision engineering is validated through mission-critical applications. We have supplied forming systems used in the construction of modular infrastructure for Olympic venues, where architectural panels required flawless surface finish and dimensional repeatability across thousands of units. Similarly, our machines have supported defense contractors in producing ruggedized housings for field-deployable electronics, meeting MIL-STD-810 specifications for durability and environmental resistance. These projects demand more than robust hardware—they require a deep understanding of material science, geometric complexity, and long-term process stability.

Our commitment to precision extends beyond the machine. Each sheet metal former is calibrated using laser interferometry and undergoes rigorous in-house testing before shipment. We integrate precision-ground tooling, high-resolution encoders, and servo-electric actuators to eliminate backlash and hysteresis—common sources of error in hydraulic or mechanically driven systems. The result is a forming solution capable of maintaining accuracy over millions of cycles, reducing scrap rates and increasing throughput in high-mix, low-volume production environments.

For industries where failure is not an option, the sheet metal former must be more than a fabrication tool—it must be a precision instrument. At Wuxi Lead Precision Machinery, decades of refining this standard have positioned us as a trusted partner in advanced manufacturing. Our engineering heritage, proven in some of the world’s most demanding applications, ensures that every machine we deliver meets the uncompromising demands of modern industry.

| Specification | Detail |

|---|---|

| Positioning Accuracy | ±0.05 mm |

| Repeatability | ±0.02 mm |

| Maximum Forming Force | 1200 kN |

| Material Thickness Range | 0.5 – 6.0 mm |

| Control System | Siemens 840D Solution Line |

| Tooling Interface | Quick-change, precision-ground |

| Data Connectivity | OPC UA, Ethernet/IP, MQTT |

Precision Specs & Tolerances

Technical Capabilities

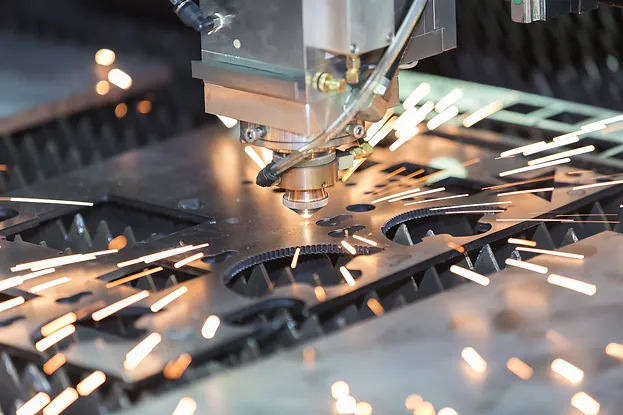

Wuxi Lead Precision Machinery delivers uncompromising precision in sheet metal forming through integrated advanced manufacturing systems. Our core strength lies in deploying state-of-the-art 5-axis CNC press brakes, enabling complex geometries and tight tolerances unattainable with conventional 3-axis machinery. These systems utilize simultaneous multi-axis control to execute intricate bends, coining operations, and flange formations in a single setup. This eliminates cumulative errors from repositioning, drastically reducing secondary operations while ensuring part consistency across high-volume production runs. Material handling is optimized via automated feeders and precision backgauges, supporting gauges from 0.5mm to 6.0mm in stainless steel, aluminum, and carbon steel alloys up to 3000mm in length.

Rigorous quality assurance is non-negotiable. Every critical dimension undergoes verification using Zeiss CONTURA G2 Coordinate Measuring Machines (CMM) with 0.0005mm probing accuracy. Our inspection protocol cross-references physical components against original CAD models, validating geometric dimensioning and tolerancing (GD&T) compliance. This closed-loop process ensures deviations are identified and corrected in real-time, preventing non-conforming parts from progressing downstream. Statistical process control (SPC) data is documented per ISO 9001 standards, providing full traceability for aerospace, medical, and industrial clients requiring auditable quality records.

The following table details our standard achievable tolerances for critical forming parameters. These specifications reflect our operational baseline under controlled workshop conditions (20±2°C); tighter tolerances are attainable for mission-critical applications through dedicated process validation.

| Parameter | Standard Tolerance | Material Thickness Range | Notes |

|---|---|---|---|

| Linear Dimension (Flat) | ±0.05 mm | 0.5–6.0 mm | Per ISO 2768-mK |

| Hole Position | ±0.10 mm | All | Relative to datum features |

| Bend Angle | ±0.5° | 0.8–4.0 mm | For angles 30°–150° |

| Bend Radius Consistency | ±0.15 mm | 1.0–3.0 mm | Within single part |

| Flatness | 0.10 mm/m | <3.0 mm | Measured per ASME Y14.5 |

| Edge Misalignment | ≤0.20 mm | All | After welding/assembly |

Our technical infrastructure ensures repeatability where competitors face limitations. The synergy between 5-axis forming and CMM validation minimizes scrap rates by up to 40% compared to traditional methods, directly impacting client cost structures. All operators undergo certified training in precision forming techniques and GD&T interpretation, ensuring human expertise complements machine capability. For projects demanding micron-level accuracy in enclosures, brackets, or structural components, Wuxi Lead provides documented process capability indices (Cp/Cpk ≥1.67) to guarantee performance against your engineering specifications. Partner with us to transform complex sheet metal designs into defect-free production realities.

Material & Finish Options

Material Selection for High-Precision Sheet Metal Forming

Selecting the appropriate material is critical in sheet metal forming, particularly when producing high-tolerance components for aerospace, automotive, and industrial equipment applications. At Wuxi Lead Precision Machinery, we emphasize material compatibility with forming processes to ensure dimensional accuracy, structural integrity, and long-term performance. The three primary materials used in precision sheet metal forming are aluminum, steel, and titanium, each offering distinct mechanical and chemical properties suited to specific operational demands.

Aluminum is widely favored for its excellent strength-to-weight ratio, corrosion resistance, and formability. It is ideal for applications where weight reduction is essential without sacrificing structural performance. Grades such as 5052, 6061, and 7075 are commonly used in sheet metal forming, with 5052 offering superior workability and 7075 providing higher strength for demanding environments. Aluminum’s low density and high thermal conductivity also make it suitable for heat dissipation components and enclosures.

Steel remains the backbone of industrial sheet metal fabrication due to its high tensile strength, durability, and cost-effectiveness. Cold-rolled steel (CRS) and stainless steel (particularly grades 304 and 316) are frequently selected. CRS provides excellent surface finish and dimensional consistency, making it ideal for painted or powder-coated enclosures. Stainless steel adds corrosion and heat resistance, with 316 offering enhanced performance in marine and chemical environments. However, steel’s higher yield strength requires more robust tooling and press force during forming.

Titanium is reserved for mission-critical applications in aerospace and medical industries. It offers an exceptional strength-to-density ratio and outstanding resistance to extreme temperatures and corrosion. While challenging to form due to its high springback and work hardening characteristics, titanium’s performance in harsh environments justifies its use in high-value components. Specialized forming techniques and tooling materials are required to maintain precision.

Surface finishing plays a vital role in enhancing both functionality and aesthetics. Anodizing is a commonly specified finish for aluminum parts. This electrochemical process thickens the natural oxide layer, significantly improving wear resistance, corrosion protection, and adhesion for paint or primers. Type II (sulfuric acid) anodizing provides a decorative and protective finish, while Type III (hard coat) anodizing delivers extreme durability for industrial use. Anodized surfaces can also be dyed for identification or branding purposes.

Below is a comparative overview of key material specifications relevant to sheet metal forming:

| Material | Typical Grades | Tensile Strength (MPa) | Density (g/cm³) | Formability | Common Applications |

|---|---|---|---|---|---|

| Aluminum | 5052, 6061, 7075 | 200–570 | 2.7 | Excellent | Enclosures, aerospace panels |

| Steel (CRS) | 1008, 1010 | 340–440 | 7.85 | Good | Industrial frames, chassis |

| Stainless | 304, 316 | 505–860 | 8.0 | Moderate | Medical, food processing |

| Titanium | Grade 2, Grade 5 | 345–1000 | 4.5 | Limited | Aerospace, defense systems |

Understanding material behavior under stress, thermal exposure, and environmental conditions ensures optimal part performance. At Wuxi Lead Precision Machinery, we support clients in selecting the right material and finish combination to meet both design intent and production efficiency.

Manufacturing Process & QC

Sheet Metal Former Production Process: Achieving Zero Defects

The path to flawless sheet metal components begins with rigorous process discipline. At Wuxi Lead Precision Machinery, our integrated workflow from Design through Prototyping to Mass Production is engineered for Zero Defects, ensuring your parts meet exacting specifications consistently. This systematic approach minimizes risk and maximizes yield for high-value manufacturing.

Design is the critical foundation. Our engineering team employs advanced CAD/CAM software for comprehensive part modeling and toolpath simulation. We conduct thorough tolerance stack-up analysis and material flow studies specific to your alloy and thickness. Finite Element Analysis (FEA) predicts potential deformation or springback, allowing us to preemptively adjust forming strategies. This virtual validation ensures the design is not only functional but inherently manufacturable within tight tolerances, eliminating conceptual flaws before metal is touched. Close collaboration with your design team during this phase is essential for optimal results.

Prototyping transforms the validated design into physical reality under controlled conditions. Using our high-precision CNC sheet metal formers, we produce initial samples with the exact tooling and parameters intended for production. Each prototype undergoes stringent metrology, including CMM inspection and first-article reporting against your GD&T requirements. This phase identifies subtle interactions between material behavior, tooling, and machine dynamics that simulation alone cannot capture. Any deviations trigger immediate process refinement – adjusting bend sequences, pressures, or backgauge positions – before committing to full-scale manufacturing. Prototyping is not a cost center; it is the essential safeguard against costly production errors.

Mass Production leverages the perfected process within a Zero Defects framework. Our automated production cells, featuring state-of-the-art CNC sheet metal formers, execute the validated program with micron-level repeatability. Real-time process monitoring tracks critical parameters like ram position, force, and material feed. Statistical Process Control (SPC) charts provide instant feedback, enabling proactive adjustments. Every component undergoes 100% in-process checks at key stages, not just final inspection. This integrated quality system, combined with operator expertise and rigorous machine calibration, guarantees conformance batch after batch. Zero Defects is achieved through prevention, not detection.

Critical Production Specifications Enabling Zero Defects

| Parameter | Specification | Zero Defects Impact |

|---|---|---|

| Positional Accuracy | ±0.01 mm | Eliminates misalignment in multi-bend parts |

| Repeatability | ±0.005 mm | Ensures identical geometry across all units |

| Force Control Range | 1-1000 kN (±0.5%) | Prevents material cracking or insufficient forming |

| Backgauge Resolution | 0.001 mm | Guarantees precise bend line placement |

| Real-time SPC Monitoring | Full process parameters | Enables immediate correction of drift |

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery for Advanced Sheet Metal Forming Solutions

When your manufacturing operations demand precision, reliability, and innovation in sheet metal forming, partnering with Wuxi Lead Precision Machinery ensures a competitive advantage. As a leading manufacturer in the sheet metal fabrication industry, we specialize in high-performance sheet metal formers engineered for complex applications across aerospace, automotive, energy, and industrial equipment sectors. Our machines are built to deliver micron-level accuracy, long-term durability, and seamless integration into automated production lines.

At Wuxi Lead, we understand that every client has unique production requirements. That’s why our engineering team works closely with you from concept to commissioning, offering customized solutions tailored to your material specifications, forming complexity, and throughput targets. Whether you require incremental forming, deep drawing, or high-speed progressive forming, our technology adapts to your process with superior control and minimal material waste.

Our commitment extends beyond machinery supply. We provide comprehensive technical support, including on-site installation, operator training, and lifecycle maintenance services. With a global service network and real-time remote diagnostics, we ensure maximum uptime and optimal performance of your equipment. Our in-house R&D center continuously innovates to meet evolving industry standards, ensuring that your investment remains future-ready.

Choosing Wuxi Lead means aligning with a partner who values precision as much as you do. We adhere to strict ISO 9001 quality management protocols, and every machine undergoes rigorous testing before shipment. From compact benchtop models to large-scale industrial systems, our sheet metal formers are designed for repeatability, safety, and energy efficiency.

To explore how our sheet metal forming technology can elevate your production capabilities, contact us today. Our engineering team is ready to discuss your application, provide a detailed feasibility analysis, and deliver a solution that meets your exact specifications.

| Specification | Detail |

|---|---|

| Maximum Forming Force | Up to 2000 kN |

| Material Thickness Range | 0.1 – 6.0 mm |

| Forming Speed | Adjustable up to 30 strokes/min |

| Control System | Siemens or Mitsubishi CNC |

| Positioning Accuracy | ±0.02 mm |

| Machine Frame | High-rigidity steel with vibration damping |

| Tooling Interface | Quick-change modular system |

| Safety Compliance | CE, ISO 13849-1 |

| Power Supply | 380V / 50Hz (custom voltages available) |

| Connectivity | Ethernet, USB, optional Industry 4.0 integration |

For technical inquiries, project consultations, or to request a quotation, reach out to our sales engineering team at [email protected]. Let Wuxi Lead Precision Machinery be your trusted partner in advanced sheet metal fabrication.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.