Technical Contents

Engineering Guide: 2 Axis Cnc Machine

Engineering Insight: The Critical Role of Precision in 2-Axis CNC Machines

In the realm of precision CNC machining, the 2-axis CNC machine remains a foundational technology for high-volume turning operations, particularly in sectors where repeatability, accuracy, and efficiency are non-negotiable. While advancements have introduced multi-axis systems, the 2-axis configuration—typically comprising X and Z axes—continues to deliver exceptional performance in turning applications, especially when engineered to exacting standards. At Wuxi Lead Precision Machinery, we recognize that precision is not merely a specification; it is the cornerstone of reliability, performance, and long-term value in industrial manufacturing.

The core function of a 2-axis CNC machine is to rotate the workpiece (via the spindle) while a cutting tool moves linearly along the X (radial) and Z (axial) axes to shape the material. Despite its apparent simplicity, achieving micron-level tolerances consistently demands advanced engineering, superior component quality, and rigorous calibration. Thermal stability, spindle runout, guideway precision, and servo control responsiveness all contribute to the final part accuracy. Even minor deviations in any of these parameters can compound over production runs, leading to scrap, rework, or field failures—unacceptable outcomes in aerospace, defense, and medical applications.

Wuxi Lead Precision Machinery brings over two decades of experience in designing and manufacturing high-precision CNC equipment trusted in mission-critical environments. Our engineering teams have supported projects aligned with Olympic-standard timing systems and precision components for military-grade instrumentation, where failure is not an option. These experiences have ingrained a culture of uncompromising quality, traceable processes, and continuous improvement across our product line. Our 2-axis CNC machines are built with hardened linear guideways, high-frequency spindles, and closed-loop feedback systems to maintain ±0.005 mm positional accuracy across extended operations.

We understand that precision is not only about hardware. It extends to control algorithms, vibration damping, tool wear compensation, and environmental adaptability. Our machines integrate with advanced CNC controllers that allow real-time monitoring and adaptive correction, ensuring that every part meets the required geometric and surface finish specifications. This holistic approach to precision engineering enables manufacturers to achieve Six Sigma levels of process capability, reducing waste and increasing throughput.

Below are key technical specifications representative of our high-precision 2-axis CNC turning centers:

| Specification | Value |

|---|---|

| Maximum Spindle Speed | 6,000 RPM |

| Spindle Taper | ISO 30 |

| X-Axis Travel | 200 mm |

| Z-Axis Travel | 500 mm |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Control System | Fanuc 0i-TF or Siemens 828D |

| Tool Magazine Capacity | 8–12 stations (optional) |

| Rapid Traverse (X/Z) | 30 / 36 m/min |

| Machine Weight | 3,200 kg |

In industries where precision defines performance, the 2-axis CNC machine—when engineered to the highest standards—remains an indispensable asset. At Wuxi Lead Precision Machinery, we combine proven mechanical design with cutting-edge control technology to deliver machines that perform reliably under the most demanding conditions.

Precision Specs & Tolerances

Technical Capabilities: Advanced Precision Manufacturing

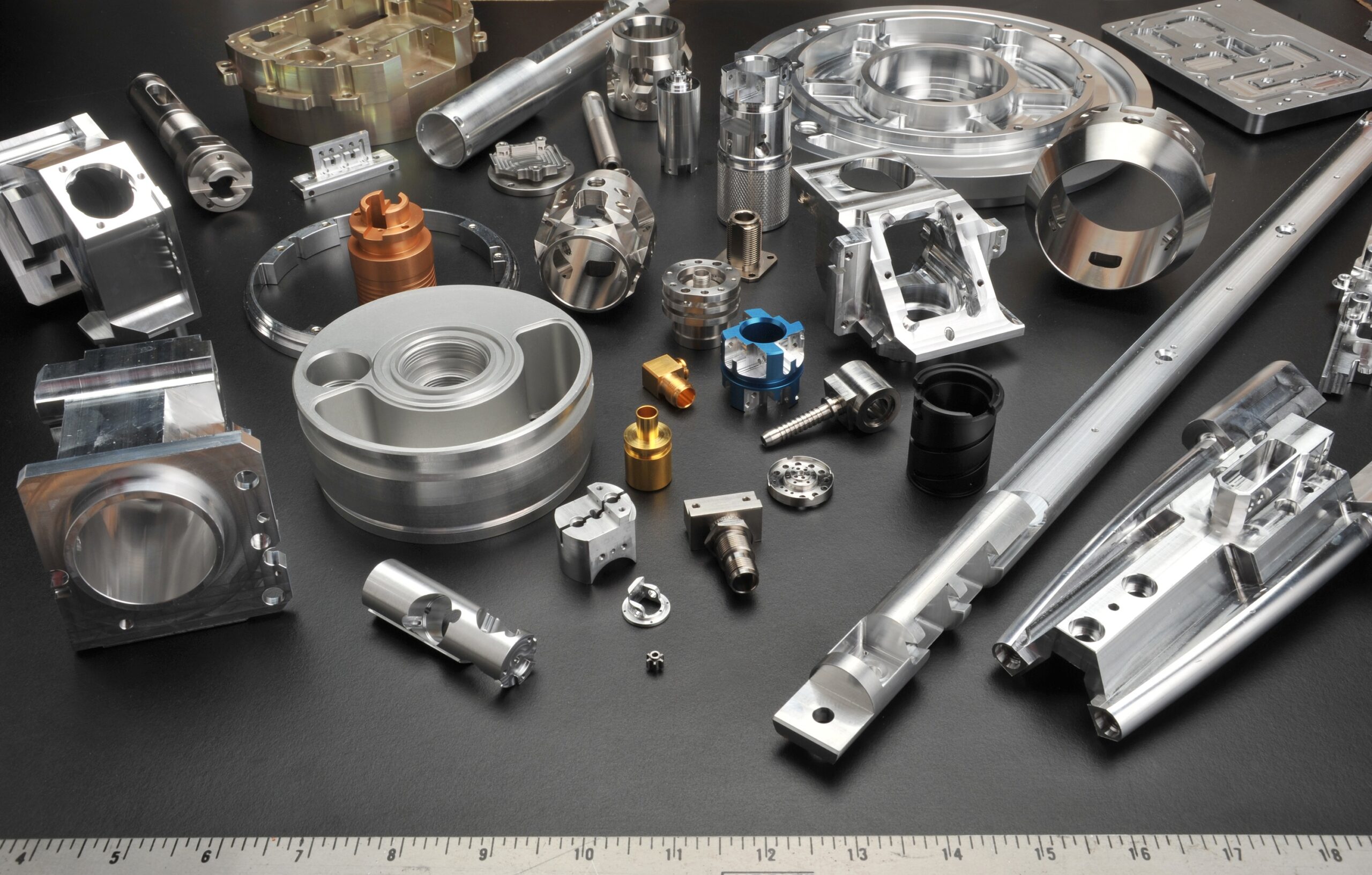

Wuxi Lead Precision Machinery clarifies a critical industry distinction upfront. While basic 2-axis CNC lathes exist for simple turning operations, our core manufacturing excellence and competitive advantage reside firmly in sophisticated multi-axis technology. We specialize in high-complexity components demanding tight tolerances and intricate geometries, capabilities inherently beyond the scope of 2-axis systems. Our production floor is anchored by state-of-the-art 5-axis CNC machining centers, enabling us to deliver the precision and efficiency required for the most demanding aerospace, medical, and energy sector applications. This strategic focus ensures clients receive solutions optimized for part consolidation, reduced setup times, and superior surface finishes on complex 3D contours – outcomes unattainable with limited-axis machinery.

Our 5-axis machining capability represents the pinnacle of modern subtractive manufacturing. Simultaneous five-axis motion allows a single workpiece setup to access virtually all critical features, eliminating cumulative errors from multiple fixtures. This is essential for producing monolithic structural components, turbine blades, complex hydraulic manifolds, and surgical implants where geometric integrity is non-negotiable. We leverage advanced machine tools with high-resolution linear scales, thermal compensation systems, and rigid spindle configurations to maintain micron-level accuracy throughout extended production runs. Material versatility spans aerospace-grade titanium and Inconel to medical stainless steels and high-performance polymers, all processed under stringent environmental controls.

Quality assurance is inseparable from our machining process. Every critical dimension and geometric feature undergoes rigorous validation using Zeiss CONTURA and GLOBAL S-coordinate measuring machines (CMMs). Our certified metrology lab operates under ISO 17025 guidelines, providing full first-article inspection reports (FAIRs) and comprehensive production lot verification. This closed-loop system – integrating 5-axis machining with CMM validation – guarantees conformance to the most exacting engineering specifications, including AS9100 and ISO 13485 requirements. Statistical process control (SPC) data is continuously monitored, ensuring capability indices (Cp/Cpk) consistently exceed industry benchmarks.

The following table details the precision tolerances achievable through our integrated 5-axis machining and metrology system. These figures represent our standard production capability under controlled conditions for qualified materials and geometries; tighter tolerances are attainable for specific applications through process optimization.

| Feature Category | Standard Capability | Measurement Method |

|---|---|---|

| Linear Dimension | ±0.005 mm (±0.0002″) | CMM / High-Precision Micrometer |

| Geometric Tolerance (GD&T) | 0.010 mm (0.0004″) | CMM (Per ASME Y14.5) |

| Angular Tolerance | ±0.005° | CMM / Precision Angle Gauge |

| Surface Roughness (Ra) | 0.4 µm (16 µin) | Profilometer |

| Positional Tolerance | 0.008 mm (0.0003″) | CMM |

This documented capability, proven across thousands of production parts, underscores Wuxi Lead’s commitment to delivering precision beyond basic machining. We transform complex engineering challenges into reliable, high-integrity components through the synergistic application of 5-axis technology and uncompromising metrological validation. Partner with us for applications where dimensional certainty directly impacts performance and safety.

Material & Finish Options

Material Selection for 2-Axis CNC Machining: Aluminum, Steel, and Titanium

Selecting the appropriate material for 2-axis CNC machining is critical to ensuring performance, durability, and cost-efficiency in precision components. At Wuxi Lead Precision Machinery, we specialize in high-accuracy machining of engineering-grade metals, with proven expertise in aluminum, steel, and titanium. Each material offers distinct mechanical properties, machinability characteristics, and compatibility with surface treatments such as anodizing—making informed selection essential for optimal results.

Aluminum is one of the most widely used materials in precision CNC applications due to its excellent strength-to-weight ratio, thermal conductivity, and corrosion resistance. It is particularly favored in aerospace, automotive, and electronics industries where lightweight structural integrity is paramount. The 6061 and 7075 aluminum alloys are commonly machined on 2-axis CNC lathes, offering good machinability and weldability. Aluminum is highly compatible with anodizing, a process that enhances surface hardness and wear resistance while allowing for color customization. Type II (sulfuric acid) and Type III (hardcoat) anodizing are standard options, with the latter providing superior durability for high-stress environments.

Steel, particularly alloy and stainless variants, is selected when higher strength, wear resistance, and structural reliability are required. Materials such as 4140 alloy steel and 304/316 stainless steel are routinely processed on our 2-axis CNC machines. These steels maintain dimensional stability under load and exhibit excellent performance in corrosive or high-temperature environments. While steel is less amenable to anodizing than aluminum, it can be treated with alternatives such as passivation, electroplating, or powder coating to improve surface protection and aesthetics. Machining steel requires robust tooling and precise parameter control due to its higher hardness and tendency to generate heat.

Titanium, especially Grade 5 (Ti-6Al-4V), offers an exceptional balance of strength, corrosion resistance, and biocompatibility, making it ideal for aerospace, medical, and high-performance automotive applications. However, titanium presents challenges in 2-axis CNC machining due to its low thermal conductivity and high chemical reactivity with cutting tools. Specialized carbide tooling, lower cutting speeds, and consistent coolant application are necessary to prevent work hardening and tool wear. Titanium does not support conventional anodizing like aluminum, but it can undergo specialized surface treatments such as thermal oxidation or plasma electrolytic oxidation to enhance surface properties.

The table below summarizes key mechanical and machining characteristics of these materials:

| Material | Tensile Strength (MPa) | Hardness (HB) | Machinability Rating | Anodizing Compatibility | Common Grades |

|---|---|---|---|---|---|

| Aluminum | 310 (6061-T6) | 95 | Excellent | High (Type II & III) | 6061, 7075 |

| Steel (Alloy) | 655 (4140) | 200 | Moderate | Low | 4140, 4340 |

| Stainless Steel | 580 (304) | 180 | Moderate to Poor | None | 304, 316 |

| Titanium | 900 (Ti-6Al-4V) | 340 | Poor | Specialized only | Gr 2, Gr 5 |

Material choice directly impacts tool life, cycle time, and final part performance. At Wuxi Lead Precision Machinery, we support clients in selecting the optimal material and finish combination based on functional requirements, environmental exposure, and production volume. Our engineering team provides consultation to ensure every 2-axis CNC machined component meets exacting industry standards.

Manufacturing Process & QC

Precision Production Process for 2-Axis CNC Machines at Wuxi Lead

Achieving zero defects in precision 2-axis CNC machining demands a rigorously controlled production process, seamlessly integrating design validation, iterative prototyping, and scalable mass production. At Wuxi Lead Precision Machinery, this integrated workflow is foundational to delivering components meeting the most stringent aerospace, medical, and semiconductor industry tolerances. Our process begins with comprehensive design analysis, where CAD models undergo rigorous simulation for manufacturability, stress points, and thermal behavior specific to 2-axis kinematics. Material selection is optimized for the application, considering thermal expansion coefficients and machinability to prevent dimensional drift during production. Critical tolerances are cross-verified against customer specifications and our machine capabilities, ensuring the design is inherently producible within our zero-defect framework before any metal is cut.

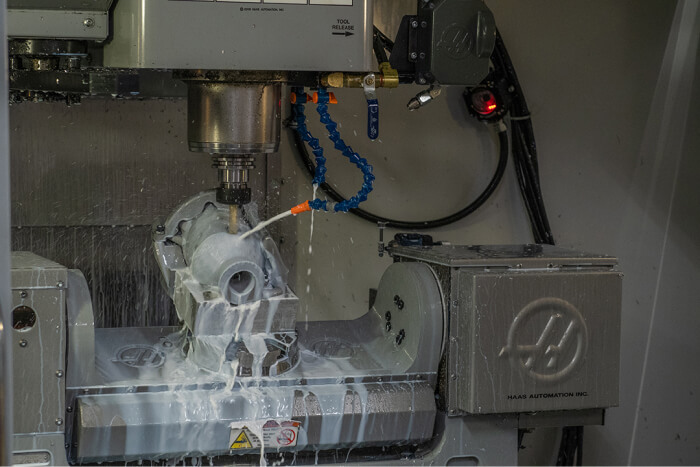

Prototyping serves as the critical validation phase, transforming digital designs into tangible components under production-intent conditions. We utilize dedicated high-precision 2-axis CNC machines within our controlled environment for initial runs, employing the exact tooling, fixturing, and cutting parameters planned for volume production. Every prototype undergoes meticulous first-article inspection using calibrated CMMs and optical comparators, measuring all critical dimensions against the CAD model. Dimensional deviations, surface finish quality, and material integrity are analyzed. Any discrepancies trigger immediate root cause analysis and process refinement—adjusting tool paths, spindle speeds, or coolant strategies—before progression. This iterative loop continues until 100% conformance is consistently achieved, proving the process robustness.

Mass production leverages the validated process parameters within a closed-loop manufacturing system designed for sustained zero defects. Our 2-axis CNC machines operate under continuous environmental monitoring and real-time process control. In-process gauging checks critical features during machining, automatically triggering corrective actions or halting production if deviations exceed micro-tolerance thresholds. Every component undergoes 100% final inspection against the approved prototype and drawing, utilizing automated vision systems alongside manual verification for complex geometries. Statistical process control (SPC) data is analyzed daily to identify any emerging trends, enabling proactive maintenance and process optimization. This unwavering focus on process stability and verification ensures consistent output meeting ±0.002mm tolerances and superior surface finishes, guaranteeing first-pass yield and eliminating scrap.

Wuxi Lead 2-Axis CNC Machine Core Production Specifications

| Specification | Performance Value | Relevance to Zero Defects |

|---|---|---|

| Positioning Accuracy | ±0.0015 mm | Ensures consistent feature placement across all parts |

| Repeatability | ±0.0008 mm | Guarantees identical results in high-volume runs |

| Spindle Runout | ≤ 0.001 mm (TIR) | Critical for micron-level surface finish and hole accuracy |

| Thermal Compensation | Active, Real-time | Maintains dimensional stability during extended runs |

| In-Process Gauging | Integrated Metrology | Enables immediate correction before defects propagate |

| Surface Finish (Ra) | Down to 0.2 µm | Meets stringent aerospace and medical requirements |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched 2-Axis CNC Machining Excellence

At Wuxi Lead Precision Machinery, we understand that in high-stakes manufacturing environments, precision, reliability, and repeatability are non-negotiable. As a leading innovator in the field of precision CNC machining, we specialize in advanced 2-axis CNC machines engineered for industries where tight tolerances and consistent output define success. From aerospace components to medical device manufacturing, our 2-axis CNC solutions deliver the performance and durability your operations demand.

Our engineering philosophy centers on integrating robust mechanical design with intelligent control systems. Each 2-axis CNC machine is built using high-grade cast iron beds, precision-ground linear guides, and high-torque servo motors, ensuring minimal vibration and maximum stability during extended production cycles. The result is a machine that maintains micron-level accuracy across thousands of parts, reducing scrap rates and increasing throughput.

What sets Wuxi Lead Precision Machinery apart is our commitment to customization and long-term partnership. We don’t just sell machines—we deliver tailored solutions. Whether you require integration with automated loading systems, specialized tooling setups, or custom control interfaces, our engineering team works closely with you to configure a machine that aligns precisely with your production workflow. Our in-house R&D department continuously refines motion algorithms and thermal compensation systems, ensuring our machines perform consistently under real-world shop floor conditions.

We serve global clients across Europe, North America, and Southeast Asia, supporting industries that require uncompromising quality. Our service network includes remote diagnostics, on-site technical support, and comprehensive operator training programs. When you partner with us, you gain more than a supplier—you gain a committed engineering ally invested in your operational success.

Below are the core specifications of our flagship 2-axis CNC machine model, LP-CNC200, designed for high-precision turning and grinding applications.

| Specification | Detail |

|---|---|

| Axis Configuration | X-Z (2-axis) |

| Maximum Spindle Speed | 6,000 RPM |

| Spindle Motor Power | 15 kW |

| X-Axis Travel | 300 mm |

| Z-Axis Travel | 500 mm |

| Positioning Accuracy | ±0.003 mm |

| Repeatability | ±0.002 mm |

| Control System | Fanuc 31i or Siemens 840D (optional) |

| Tool Magazine Capacity | 12 stations (optional up to 24) |

| Rapid Traverse (X/Z) | 30 / 40 m/min |

| Machine Dimensions (L×W×H) | 2,800 × 1,900 × 1,850 mm |

| Weight | Approx. 4,200 kg |

Every machine we build reflects our dedication to precision, durability, and technological innovation. We invite forward-thinking manufacturers to collaborate with us and elevate their production capabilities. For detailed technical consultations, custom quotes, or to schedule a virtual demonstration, contact us today at [email protected]. Let Wuxi Lead Precision Machinery be the foundation of your next-generation manufacturing success.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.