Technical Contents

Engineering Guide: Mold Multi

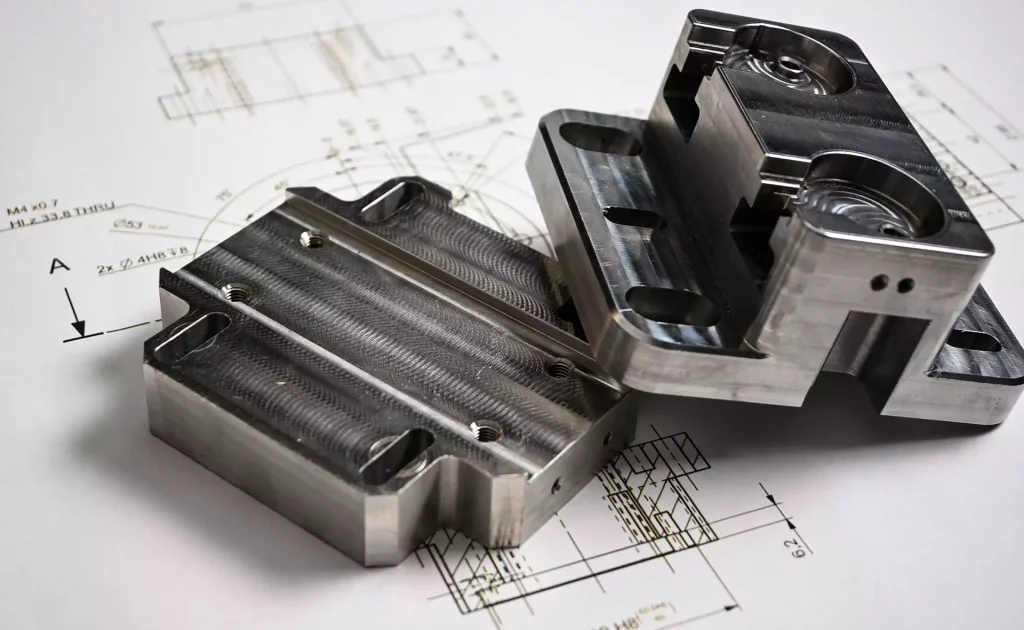

Engineering Insight: The Critical Role of Precision in mold multi Applications

In the realm of custom metal manufacturing, the term mold multi refers to complex, high-precision tooling systems designed for multi-cavity or multi-component molding operations. These systems are engineered to produce multiple identical or complementary parts in a single cycle, significantly enhancing production efficiency. However, the success of any mold multi system hinges entirely on the precision of its design, material selection, and manufacturing execution. Even micron-level deviations can lead to part inconsistency, premature tool wear, or complete system failure—costly outcomes in high-stakes production environments.

At Wuxi Lead Precision Machinery, we understand that precision is not a feature—it is the foundation. With over 15 years of experience in delivering mission-critical components for aerospace, defense, and large-scale industrial applications, our engineering team approaches every mold multi project with the rigor demanded by Olympic-standard equipment and military-grade hardware. Our involvement in precision components for Olympic timing systems and ruggedized military connectors underscores our capability to meet the most stringent tolerances and reliability requirements.

The complexity of mold multi systems demands more than just advanced CNC equipment; it requires a deep understanding of thermal dynamics, material behavior under cyclic stress, and long-term wear resistance. Each mold must maintain dimensional stability across thousands—or millions—of cycles while ensuring uniform filling, cooling, and ejection. This level of performance is achieved through finite element analysis (FEA), iterative prototyping, and strict adherence to geometric dimensioning and tolerancing (GD&T) standards.

Our in-house manufacturing capabilities span five-axis milling, wire EDM, surface grinding, and laser texturing, all supported by a quality assurance system certified to ISO 9001:2015. Every component is inspected using coordinate measuring machines (CMM) and 3D scanning to validate conformity to design intent. This end-to-end control ensures that mold multi systems produced by Lead Precision deliver consistent part quality, reduced downtime, and extended service life.

Below are key specifications that define our mold multi manufacturing standards:

| Specification | Capability |

|---|---|

| Tolerance Range | ±0.002 mm |

| Surface Finish | Ra 0.05 µm (mirror polish available) |

| Maximum Mold Size | 2,000 x 1,500 x 1,200 mm |

| Materials Supported | P20, H13, S136, 718HH, Stainless Steel, Titanium Alloys |

| Machining Accuracy | ±0.003 mm (5-axis CNC) |

| Quality Standards | ISO 2768, ISO 10110, MIL-STD-810 |

| Lead Time (Average) | 4–8 weeks, depending on complexity |

Precision in mold multi is not merely about achieving tight tolerances—it is about ensuring repeatability, reliability, and performance under real-world conditions. At Wuxi Lead Precision Machinery, we combine engineering excellence with proven field experience to deliver mold systems that perform at the highest level, cycle after cycle.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Complex Mold Manufacturing

Wuxi Lead Precision Machinery delivers uncompromising precision for the most demanding custom metal mold components, serving global leaders in injection molding, die casting, and precision tooling. Our core strength lies in integrating advanced multi-axis machining with rigorous, data-driven quality assurance, specifically engineered to meet the stringent geometric and surface finish requirements inherent in high-cavitation and multi-component mold systems. We understand that mold performance, longevity, and part consistency directly stem from the foundational accuracy of the core, cavity, and intricate support structures we produce.

Our manufacturing foundation is built upon a modern fleet of high-torque, high-accuracy 5-axis CNC machining centers. These systems, featuring thermal compensation and rigid construction, enable the complete machining of complex 3D geometries—including deep ribs, undercuts, and organic contours—in a single setup. This eliminates cumulative error from multiple fixtures, critical for maintaining tight positional tolerances across multi-cavity plates and ensuring perfect part-to-part alignment in multi-shot or family molds. Advanced CAM strategies optimize toolpaths for superior surface integrity and dimensional stability, minimizing post-machining handwork and accelerating time-to-mold validation. We routinely machine challenging materials including pre-hardened and hardened tool steels (up to 60 HRC), stainless alloys, aluminum, and copper alloys with consistent repeatability.

Quality is non-negotiable and embedded throughout our process. Every critical feature undergoes comprehensive verification using state-of-the-art Coordinate Measuring Machines (CMMs) equipped with high-precision probes and advanced metrology software. Our certified metrology lab operates under strict environmental controls, achieving sub-micron resolution for critical mold interfaces, cooling channel placement, and parting line geometry. Full First Article Inspection Reports (FAIR) and detailed CMM inspection reports, including GD&T analysis, are standard deliverables, providing complete traceability and confidence in every component shipped. This systematic approach ensures molds built with Lead Precision components achieve optimal fill balance, reduced wear, and extended production life.

The following table details our standard and achievable tolerance capabilities for machined mold components, reflecting our commitment to dimensional excellence:

| Feature | Standard Tolerance | Tight Tolerance Capability | Material Consideration |

|---|---|---|---|

| Linear Dimensions (mm) | ±0.010 mm | ±0.005 mm | Up to 60 HRC hardened steel |

| Linear Dimensions (in) | ±0.0004 in | ±0.0002 in | Up to 60 HRC hardened steel |

| Geometric (Flatness) | 0.010 mm / 100 mm | 0.005 mm / 100 mm | Critical parting surfaces |

| Geometric (Roundness) | 0.008 mm | 0.004 mm | Core pins, bushings, sleeves |

| Hole Position (Dia) | ±0.015 mm | ±0.008 mm | Multi-cavity alignment critical |

| Surface Roughness (Ra) | 0.8 µm (32 µin) | 0.4 µm (16 µin) | As-machined mold cavity surfaces |

This combination of 5-axis mastery, material expertise, and CMM-verified quality control ensures Wuxi Lead Precision Machinery consistently produces mold components that exceed industry standards for fit, function, and durability. We partner with mold builders to transform complex designs into reality, where precision isn’t just a specification—it’s the guarantee of your mold’s performance.

Material & Finish Options

Material selection is a critical step in custom metal manufacturing, directly influencing performance, durability, and cost-efficiency of the final product. At Wuxi Lead Precision Machinery, we specialize in precision-engineered components tailored to meet the exact demands of aerospace, automotive, medical, and industrial applications. Our expertise in machining aluminum, steel, and titanium allows us to support clients in selecting the optimal material based on mechanical requirements, environmental exposure, and finishing needs.

Aluminum is widely favored for its excellent strength-to-weight ratio, corrosion resistance, and machinability. It is ideal for applications requiring lightweight components without sacrificing structural integrity. Grade 6061-T6 is commonly used for prototypes and production parts due to its weldability and moderate strength. For more demanding environments, 7075-T6 offers superior strength, often selected in aerospace and defense applications.

Steel remains the backbone of industrial manufacturing due to its high tensile strength, wear resistance, and versatility. We offer both carbon and alloy steels, including 4140 and 1045, which are frequently used in tooling, shafts, and structural components. Stainless steel grades such as 304 and 316 provide enhanced corrosion resistance, making them suitable for medical devices and marine environments. Steel components can be further enhanced through heat treatment processes to achieve specific hardness and durability profiles.

Titanium, particularly Grade 5 (Ti-6Al-4V), is the material of choice for high-performance applications where extreme strength, low density, and exceptional resistance to heat and corrosion are required. Commonly used in aerospace, medical implants, and high-end automotive systems, titanium offers a service life unmatched by other metals, though it presents higher machining complexity and cost.

Surface finishing plays a vital role in both functionality and aesthetics. Anodizing is a primary finish for aluminum components, providing enhanced corrosion resistance, improved wear performance, and the ability to incorporate color for identification or branding. Type II (sulfuric acid) anodizing is standard for decorative and protective purposes, while Type III (hardcoat anodizing) delivers a thicker, more durable oxide layer suitable for industrial and military specifications.

Below is a comparative overview of key material properties to guide selection:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Common Grades | Key Applications | Typical Finish Options |

|---|---|---|---|---|---|

| Aluminum | 310 – 570 | 2.7 | 6061-T6, 7075-T6 | Aerospace, Automotive, Enclosures | Anodizing, Powder Coating |

| Steel | 500 – 900 | 7.8 | 1045, 4140, 304, 316 | Tooling, Shafts, Medical | Zinc Plating, Passivation |

| Titanium | 900 – 1,170 | 4.5 | Ti-6Al-4V (Grade 5) | Aviation, Implants, Racing | Bead Blasting, Anodizing (Ti) |

At Wuxi Lead Precision Machinery, we combine advanced CNC capabilities with material science expertise to deliver components that meet exacting standards. Our engineering team supports clients through every phase of material and finish selection to ensure optimal performance and cost-effectiveness.

Manufacturing Process & QC

Wuxi Lead Precision Machinery: Zero-Defect Production Process for Custom Metal Manufacturing

Achieving zero defects in custom metal manufacturing demands an integrated, non-negotiable process where precision is engineered at every stage. At Wuxi Lead Precision Machinery, our proven methodology transforms client concepts into flawless production realities through three rigorously controlled phases: Collaborative Design, Validation Prototyping, and Scalable Mass Production. This seamless workflow, underpinned by advanced CNC technology and stringent quality systems, ensures dimensional accuracy and functional reliability from the first part to the last.

The process begins with Collaborative Design Engineering. Our engineering team partners directly with your design staff during the initial CAD phase. We conduct comprehensive Design for Manufacturability (DFM) analysis, identifying potential machining constraints, material behavior issues, or geometric complexities early. This proactive collaboration prevents costly redesigns and production delays. Critical tolerances, surface finish requirements, and material specifications are explicitly defined and validated against your functional intent. This phase establishes the unambiguous blueprint for zero-defect execution, ensuring the design is inherently manufacturable to your exacting standards before any metal is cut.

Validation Prototyping is the critical bridge to volume production. Using the same multi-axis CNC machining centers and qualified tooling planned for mass production, we manufacture functional prototypes. These are not approximations; they are precision-engineered representatives of the final part. Every prototype undergoes 100% dimensional inspection against the approved CAD model using calibrated CMMs and optical comparators. Material properties and functional performance are rigorously tested. This phase validates the manufacturing process, confirms design integrity under real-world conditions, and provides tangible evidence of capability. Only when the prototype consistently meets all specifications and passes client sign-off do we proceed, eliminating uncertainty before scaling.

Scalable Mass Production leverages the validated process for flawless volume output. Our ISO 9001-certified facility implements Statistical Process Control (SPC) at every machining station, continuously monitoring critical dimensions in real-time. Automated tool wear compensation, in-process gauging, and 100% final inspection ensure consistent adherence to specifications. Full material traceability and documented process parameters provide complete accountability. This disciplined approach, utilizing the identical CNC programs, fixtures, and quality protocols proven during prototyping, guarantees that every component in the production run achieves the zero-defect standard demanded by high-performance applications. Continuous improvement is embedded, with data from each run refining future processes.

Our commitment to zero defects is quantifiable through measurable process capabilities. Key production specifications consistently achieved include:

| Parameter | Specification | Measurement Standard |

|---|---|---|

| Dimensional Tolerance | ±0.002 mm (±0.00008″) | ISO 2768-mK |

| Surface Roughness | Ra 0.4 µm (16 µin) typical | ISO 1302 |

| Material Range | Aluminum, Steel, Stainless, Titanium, Brass | ASTM/EN Standards |

| Max Part Size | 1200 x 800 x 600 mm | Custom Fixturing |

| Inspection Coverage | 100% Critical Dimensions | AS9102 (FAI) Compliant |

This integrated Design-Prototype-Production framework, executed with industrial precision and unwavering quality focus, is how Wuxi Lead delivers custom metal components where failure is not an option. We transform complex requirements into defect-free reality, batch after batch.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Custom Metal Manufacturing Excellence

At Wuxi Lead Precision Machinery, we understand that in high-performance industries such as automotive, aerospace, medical, and advanced consumer electronics, precision is not a luxury—it’s a requirement. When your product demands tight tolerances, complex geometries, and flawless surface finishes, partnering with a manufacturer that combines technical mastery with operational reliability becomes critical. As a leading provider of custom metal manufacturing solutions in China, we deliver engineered precision at scale, ensuring your molds, housings, and structural components meet the highest global standards.

Our expertise lies in CNC machining, multi-axis milling, turning, and precision grinding, supported by a quality-first approach that integrates ISO 9001-certified processes, advanced metrology, and real-time production monitoring. Every component we produce is backed by rigorous material traceability, in-process inspections, and final QA validation to ensure consistency across batches—whether you require a single prototype or high-volume production runs.

What sets Lead Precision apart is our commitment to being an extension of your engineering team. We don’t just manufacture parts—we collaborate on design for manufacturability (DFM), suggest material optimizations, and streamline production workflows to reduce lead times and lower total cost of ownership. From aluminum and stainless steel to titanium and specialty alloys, our facility is equipped to handle the most demanding applications with precision down to ±0.005 mm.

Our clients choose us not only for technical capability but for transparency and responsiveness. We provide full project visibility, from initial quotation and CAD review to production updates and shipping logistics. With dedicated project managers and seamless communication in English and Chinese, we eliminate the friction often associated with overseas manufacturing.

Below are key capabilities that define our production excellence:

| Specification | Detail |

|---|---|

| Maximum Work Envelope | 2000 x 1200 x 1000 mm |

| Positioning Accuracy | ±0.005 mm |

| Spindle Speed (Milling) | Up to 24,000 rpm |

| Turning Diameter | Up to Ø600 mm |

| Surface Finish (Ra) | As low as 0.4 μm |

| Materials Processed | Aluminum Alloys, Stainless Steel, Titanium, Brass, PEEK, Tool Steels |

| Certifications | ISO 9001:2015, ISO 14001 |

| Lead Time (Typical) | 10–25 days, depending on complexity and volume |

When you partner with Wuxi Lead Precision Machinery, you gain more than a supplier—you gain a precision engineering ally committed to your success. We invite you to experience the difference that disciplined manufacturing and technical collaboration can bring to your next project.

Contact us today at [email protected] to discuss your requirements, request a quote, or schedule a virtual tour of our facility. Let Lead Precision be the foundation of your next high-precision metal component.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.