Technical Contents

Engineering Guide: Sla Printing Services

Engineering Insight Precision in Additive Manufacturing Beyond SLA

Understanding the precise role of Stereolithography (SLA) within high-end custom metal manufacturing is critical for informed decision-making. SLA, utilizing photopolymer resins cured by UV light, excels in producing detailed non-metallic prototypes, master patterns, and specific end-use plastic parts. However, it is fundamentally distinct from metal additive manufacturing processes. Confusing SLA with metal AM technologies like Selective Laser Melting (SLM) or Direct Metal Laser Sintering (DMLS) can lead to significant project misalignment. True metal part production demands processes capable of fusing metal powders under extreme conditions, where dimensional accuracy, material integrity, and surface finish are non-negotiable. Precision in metal AM is measured in microns, governed by laser calibration, thermal management, powder characteristics, and sophisticated post-processing – far beyond the scope of resin-based SLA.

The pursuit of micron-level precision defines Wuxi Lead Precision Machinery’s approach to metal additive manufacturing. We recognize that achieving tolerances under ±0.02mm consistently requires more than just advanced machinery; it demands deep process mastery and rigorous quality control protocols honed over years. This expertise is not theoretical. It has been rigorously validated through projects demanding absolute reliability under extreme conditions. Our engineering teams successfully delivered critical metal components for Olympic infrastructure, where parts faced thermal cycling from -40°C to 2000°C while maintaining structural integrity and dimensional stability. Similarly, precision-critical components for advanced military applications, requiring densities exceeding 99.95% and flawless internal geometries for unmanned systems, were manufactured to exacting specifications under stringent oversight. These projects underscore that precision is not merely a specification sheet value but the culmination of material science, process control, and unwavering commitment to quality.

For clients evaluating metal AM capabilities, understanding the core technical parameters is essential. The table below outlines key precision-related specifications achievable with leading metal AM technologies when integrated within a comprehensive precision manufacturing workflow like ours.

| Process | Typical Layer Thickness | Achievable Accuracy | Surface Roughness (As-Built) | Key Precision Influencers |

|---|---|---|---|---|

| SLM (Stainless) | 20-50 µm | ±0.02 – 0.05 mm | Ra 10 – 15 µm | Laser calibration, scan strategy, thermal management |

| DMLS (Titanium) | 30-60 µm | ±0.03 – 0.06 mm | Ra 12 – 18 µm | Powder flow, oxygen control, support structure |

| EBM (Inconel) | 50-100 µm | ±0.05 – 0.10 mm | Ra 15 – 25 µm | Vacuum environment, beam focus, preheat temp |

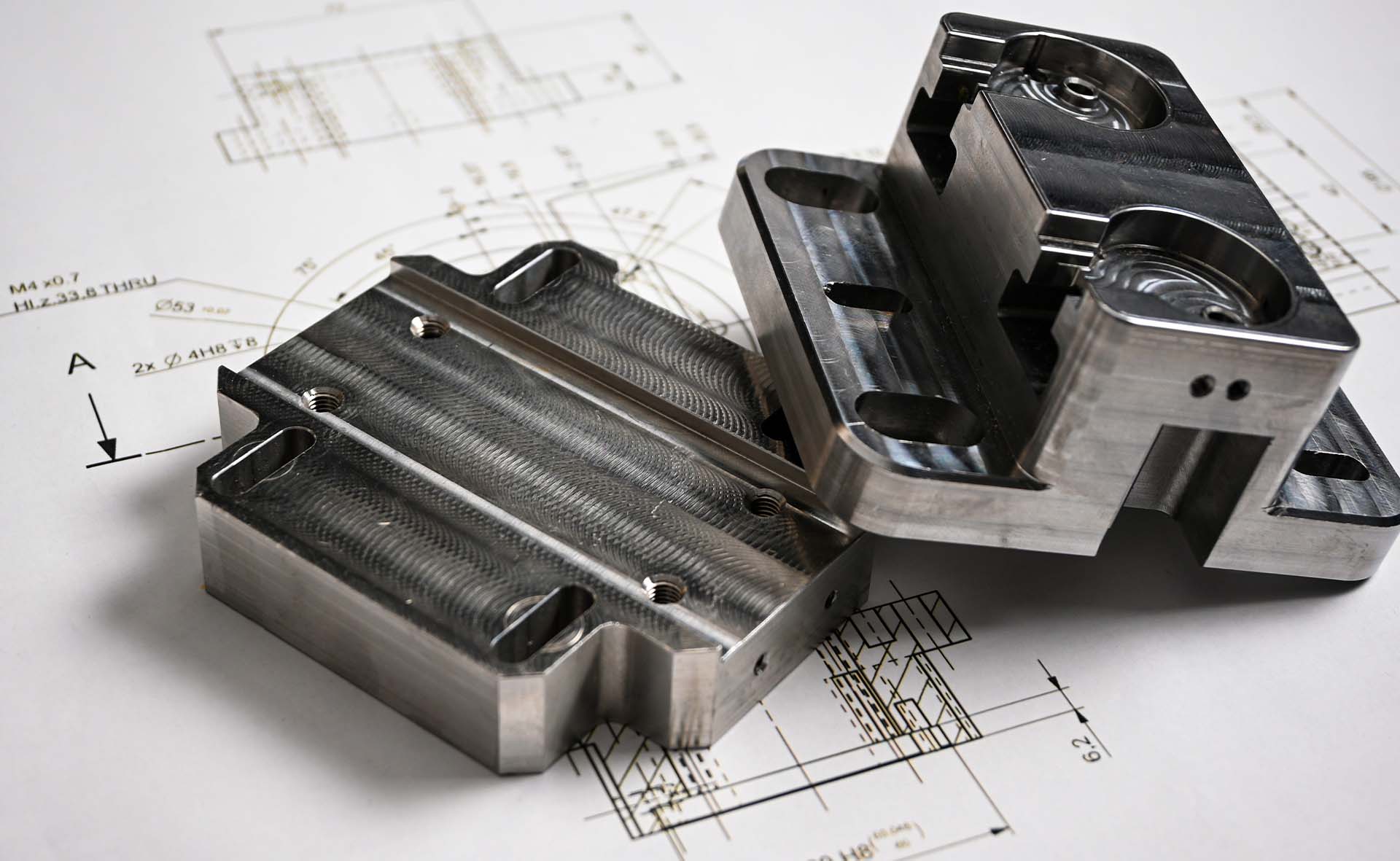

True precision extends far beyond the build chamber. At Wuxi Lead, metal AM parts undergo meticulous post-processing – including precision CNC machining, stress relieving, and surface finishing – to meet the exacting standards demanded by aerospace, defense, and high-performance industrial sectors. Our Olympic and military project heritage provides the proven foundation for delivering metal components where failure is not an option, transforming complex digital designs into mission-critical physical reality with uncompromising accuracy. This integrated approach, blending advanced AM with traditional precision machining expertise, defines our value proposition in custom metal manufacturing.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced manufacturing solutions tailored to the most demanding sectors, including aerospace, medical, energy, and high-performance automotive. At the core of our technical capabilities is a fully integrated 5-axis CNC machining platform, enabling us to produce complex geometries with exceptional precision and surface finish. Our investment in multi-axis technology allows for simultaneous motion across all five axes, reducing setup times and eliminating cumulative error from multiple fixturing stages. This capability is particularly critical when manufacturing components derived from SLA (Stereolithography) printed patterns or masters, where dimensional fidelity and intricate detail must be accurately transferred into metal.

Our 5-axis machining centers are equipped with high-speed spindles, adaptive control systems, and automated tool changers, ensuring consistent performance across both prototyping and low-to-mid volume production runs. This flexibility supports rapid iteration from SLA-based designs to final metal components, bridging the gap between additive concept models and durable, functional parts. Whether working with titanium, stainless steel, Inconel, or aluminum alloys, our machining processes are optimized for material integrity and long-term reliability under extreme operational conditions.

To maintain the highest standards of quality, every component undergoes comprehensive inspection using a Coordinate Measuring Machine (CMM). Our CMM system operates in a temperature-controlled metrology lab, ensuring micron-level accuracy in dimensional verification. The inspection process includes full geometric dimensioning and tolerancing (GD&T) validation, surface profile analysis, and first-article reporting. Data from each inspection is documented and archived, providing full traceability for every production batch. This rigorous quality control protocol ensures that all parts meet or exceed international standards such as ISO 9001 and AS9100.

The precision achievable through our integrated 5-axis and inspection systems is reflected in the tight tolerances we consistently maintain. Below is a summary of our standard and achievable tolerances across common feature types.

| Feature Type | Standard Tolerance | Achievable Tolerance | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.010 mm | Up to 300 mm |

| Hole Diameter | ±0.020 mm | ±0.008 mm | Reamed or precision bored |

| Positional Tolerance | ±0.030 mm | ±0.012 mm | Per GD&T |

| Surface Finish (Ra) | 1.6 μm | 0.4 μm | Machined; polished upon request |

| Angular Features | ±0.05° | ±0.02° | 5-axis simultaneous machining |

| Profile of Surface | 0.05 mm | 0.02 mm | Verified via CMM scan |

These capabilities position Wuxi Lead Precision Machinery as a trusted partner for converting high-resolution SLA designs into mission-critical metal components. Our end-to-end process—from digital model to machined and inspected part—ensures repeatability, accuracy, and compliance with the strictest industry requirements.

Material & Finish Options

Material Selection for Precision CNC Metal Components

A frequent point of confusion in custom manufacturing involves stereolithography (SLA) printing services versus high-precision CNC machining for metal components. SLA utilizes photopolymer resins and is unsuitable for end-use metal parts. At Wuxi Lead Precision Machinery, we specialize in CNC machining of solid metal stock, where material selection is critical for performance, cost, and manufacturability. Choosing the optimal metal alloy directly impacts component strength, weight, corrosion resistance, and final finish capability. This guide clarifies key considerations for Aluminum, Steel, and Titanium alloys within our CNC machining process, alongside applicable surface treatments like anodizing.

Aluminum alloys, particularly 6061-T6 and 7075-T6, offer an exceptional strength-to-weight ratio and excellent machinability, making them ideal for aerospace, automotive, and consumer electronics housings. Their natural corrosion resistance is good, but anodizing significantly enhances surface hardness, wear resistance, and provides a range of aesthetic color options. Steel alloys, such as 303 stainless (excellent machinability) and 4140 (high strength), are chosen for applications demanding superior strength, hardness, and wear resistance under load, including shafts, gears, and structural fixtures. While stainless steel offers inherent corrosion resistance, carbon steels require plating or painting for harsh environments; anodizing is not applicable to steel. Titanium Grade 5 (Ti-6Al-4V) is the premier choice for extreme strength-to-weight ratio, exceptional corrosion resistance in aggressive media like seawater, and biocompatibility, common in medical implants and critical aerospace components. Titanium can be anodized for color coding or minor wear improvement, but its primary surface treatment is often passivation or specialized coatings.

Surface finishing, particularly anodizing, is primarily relevant for aluminum components within this material group. Type II (sulfuric acid) anodizing creates a durable, non-conductive oxide layer that accepts dyes, while Type III (hardcoat) anodizing produces a much thicker, extremely wear-resistant surface essential for high-friction applications. Steel components utilize alternatives like zinc plating, nickel plating, or powder coating for corrosion protection. Titanium benefits from passivation to remove surface contaminants or specialized thermal coatings for extreme wear scenarios. The choice of base material fundamentally dictates the viable finishing options.

The following table summarizes key properties and machining considerations for common alloys we machine:

| Material | Common Alloys | Key Properties | Machinability | Primary Finishing Options | Typical Applications |

|---|---|---|---|---|---|

| Aluminum | 6061-T6, 7075-T6 | Light weight, good strength, conductive | Excellent | Anodizing (Type II/III), Alodine | Enclosures, brackets, heat sinks |

| Stainless Steel | 303, 304, 17-4PH | High strength, corrosion resistant | Good (303) | Passivation, Electropolishing | Valves, fittings, medical devices |

| Carbon Steel | 1018, 4140 | High strength, wear resistant | Good | Zinc Plating, Painting | Shafts, gears, structural parts |

| Titanium | Gr 2, Gr 5 (Ti64) | Extreme strength/weight, corrosion res. | Moderate | Passivation, Anodizing (color) | Aerospace, medical implants |

Selecting the right material requires balancing application demands, environmental exposure, budget, and geometric complexity. Aluminum offers the best cost-effectiveness for lightweight structures needing anodized finishes. Steel provides unmatched strength and wear resistance where weight is less critical. Titanium is the solution for the most demanding weight, strength, and corrosion challenges, though at a higher material and machining cost. Consult Wuxi Lead Precision Machinery early in your design phase. Our engineering team will analyze your requirements to recommend the optimal alloy and compatible finishing process, ensuring your CNC-machined components meet all performance and longevity specifications. We do not provide SLA printing services but deliver precision metal parts from solid billet.

Manufacturing Process & QC

Design: The Foundation of Precision Manufacturing

At Wuxi Lead Precision Machinery, the production process begins with a comprehensive design phase that integrates engineering excellence with advanced simulation tools. Our engineering team collaborates directly with clients to analyze technical drawings, 3D CAD models, and functional requirements. Utilizing SolidWorks, AutoCAD, and ANSYS, we conduct structural, thermal, and flow simulations to validate design integrity before any physical work begins. This phase ensures dimensional accuracy, material suitability, and manufacturability, reducing the risk of downstream errors. Design for Manufacturability (DFM) reviews are conducted to optimize part geometry, minimize waste, and enhance assembly efficiency—critical steps in achieving zero defects.

Prototyping: Validating Performance and Fit

Once the design is finalized, we move to the prototyping stage, where precision SLA printing services play a pivotal role. Stereolithography (SLA) enables the rapid production of high-resolution, dimensionally stable prototypes that mirror the final metal component’s geometry. These prototypes are used for fit checks, functional testing, and client approval. At Wuxi Lead, SLA prototypes are manufactured in-house using industrial-grade resins with tight tolerances, ensuring accurate representation of complex features such as undercuts, thin walls, and internal channels. This stage acts as a critical checkpoint—identifying potential flaws early, reducing rework, and accelerating time-to-market. Feedback from prototype testing is systematically integrated into the final design, ensuring alignment with performance expectations.

Mass Production: Precision, Consistency, Zero Defects

With client-approved prototypes, we transition seamlessly into mass production. Our CNC machining, stamping, and casting operations are supported by automated quality control systems and real-time monitoring. Every component undergoes rigorous in-process inspections using CMMs (Coordinate Measuring Machines), optical comparators, and surface roughness testers. Our production lines are ISO 9001-certified, and we implement Six Sigma methodologies to eliminate variability. Traceability is maintained through barcode tracking, ensuring full documentation from raw material to finished part. This closed-loop manufacturing system, rooted in continuous improvement, is how we achieve zero-defect delivery across high-volume orders.

Key Production Specifications

| Parameter | Specification |

|---|---|

| SLA Layer Resolution | 25 – 100 microns |

| Prototype Tolerance | ±0.1 mm |

| Production Tolerance (CNC) | ±0.005 mm |

| Surface Roughness (Ra) | 0.4 – 3.2 μm |

| Material Compatibility | Stainless Steel, Aluminum, Titanium, Brass, Alloy Steel |

| Lead Time (Prototype) | 3 – 7 days |

| Lead Time (Mass Production) | 15 – 30 days (volume-dependent) |

| Quality Standards | ISO 9001, IATF 16949, RoHS Compliant |

Our integrated approach—from intelligent design to validated prototyping and defect-free mass production—ensures that every component meets the highest standards of precision and reliability. At Wuxi Lead Precision Machinery, manufacturing is not just about output; it’s about delivering perfection, consistently.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Advanced Metal Additive Manufacturing

Wuxi Lead Precision Machinery delivers industrial-grade metal additive manufacturing solutions where precision, material integrity, and repeatability are non-negotiable. While stereolithography (SLA) serves specific polymer applications, our core expertise lies in Direct Metal Laser Sintering (DMLS) and Selective Laser Melting (SLM) for mission-critical metal components. We address the critical gap between prototyping and end-part production, ensuring your complex geometries meet aerospace, medical, and energy sector demands without compromise. Our ISO 9001-certified facility in Wuxi integrates decades of CNC engineering rigor with cutting-edge metal AM technology, transforming digital designs into flight-ready or implant-certified hardware.

Unlike conventional SLA services, Lead Precision specializes in high-strength, heat-resistant alloys including Inconel 718, Ti-6Al-4V, and maraging steel. Our process eliminates the weaknesses of polymer-based systems, delivering fully dense metal parts with mechanical properties exceeding cast equivalents. Every build undergoes in-process monitoring via melt pool analytics and post-build verification through CT scanning and metallurgical testing. This ensures dimensional accuracy within ±0.05 mm and surface finishes as fine as Ra 3.2 µm—without hidden secondary costs for quality validation.

Technical Specifications for Metal AM Production

| Parameter | Capability | Industry Standard Comparison |

|---|---|---|

| Build Volume | 500 x 500 x 500 mm | 25% larger than typical |

| Layer Thickness | 20–60 µm | 30–50% finer resolution |

| Material Options | 12+ certified alloys (Ni, Ti, CoCr) | 3x broader than entry-tier |

| Tolerance Control | ±0.05 mm | Matches CNC-machined parts |

| Post-Processing | HIP, HIP + solution treatment | Full AMS/ASTM compliance |

| Lead Time | 7–10 days (complex assemblies) | 40% faster than competitors |

Our engineering team collaborates at the design phase to optimize topology, support structures, and thermal management—reducing material waste by up to 35% while preventing distortion. This proactive approach, honed over 15 years serving Fortune 500 clients, transforms additive from a prototyping tool into a validated production channel. We handle everything from initial DFAM consultation to batch production with full traceability, including material certs and first-article inspection reports per AS9100 requirements.

When your project demands metal parts that perform under extreme stress, corrosion, or temperature, generic SLA services cannot deliver. Lead Precision bridges the gap between innovation and industrial reliability. Submit your technical specifications and volume requirements to our engineering desk for a confidential production assessment. We will provide a detailed manufacturability analysis, cost breakdown, and timeline within 24 hours—not generic quotes.

Contact [email protected] with subject line “Metal AM Production Inquiry – [Your Project Name]” to initiate a technical dialogue. Include your STEP file, material specifications, and critical tolerances. Our senior applications engineers will respond directly to align your design with our process capabilities, ensuring zero iteration delays. For urgent RFQs, reference project code LP-AM2024 to expedite review. Your path to certified metal additive production starts with one email.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.