Technical Contents

Engineering Guide: Best Nj Molds

Engineering Insight Precision as the Foundation of Superior NJ Molds

In the demanding realm of custom metal manufacturing, particularly for high-performance New Jersey specification molds, precision engineering is not merely advantageous—it is the absolute cornerstone of success. NJ molds, often deployed in critical aerospace, medical, and defense applications, demand tolerances measured in microns. Even minor deviations in cavity geometry, cooling channel placement, or surface finish directly translate to part warpage, premature wear, production downtime, and ultimately, catastrophic field failures. The cost of imprecision extends far beyond scrap rates; it erodes brand reputation and compromises safety in mission-critical components. Achieving true NJ compliance requires moving beyond standard machining practices into the domain of metrology-grade manufacturing, where every micron is accounted for and environmental stability is non-negotiable.

Wuxi Lead Precision Machinery operates at this elevated standard daily. Our engineering philosophy integrates precision into every phase, from initial CAD analysis through final inspection. We leverage advanced multi-axis CNC machining centers operating within temperature-controlled environments, coupled with in-process probing and coordinate measuring machines (CMMs) certified to ISO 17025 standards. This infrastructure is essential, but true capability lies in the expertise applied. Our team possesses deep experience executing projects where failure is not an option. This includes manufacturing complex hydraulic manifold molds for next-generation military aircraft systems, where tolerances below 5μm ensure zero leakage under extreme pressure, and producing structural component molds for Olympic-grade sporting infrastructure, where dimensional stability across massive part footprints was critical for safety and performance. These projects demanded not only technical execution but rigorous documentation and traceability meeting AS9100 and ITAR requirements—standards inherent to NJ mold excellence.

The tangible output of this precision-focused approach is measurable in the mold’s performance and longevity. Below are key specifications consistently achieved for our NJ-compliant mold projects:

| Specification | Value Achieved | Critical Application Benefit |

|---|---|---|

| Linear Tolerance | ±0.002 mm (±0.00008″) | Ensures perfect part fit and assembly |

| Surface Roughness (Ra) | 0.05 – 0.2 μm | Critical for optical clarity & sealing |

| Geometric Tolerance | < 0.005 mm (200 μin) | Prevents part warpage & ejection issues |

| Material Hardness | HRC 48-52 (Pre-hard) | Balances wear resistance & machinability |

| Thermal Stability | Δ < 0.001 mm @ 25°C | Maintains dimensions during high-cycle runs |

Investing in precision-engineered NJ molds is fundamentally an investment in operational reliability and total cost of ownership. The initial engineering rigor minimizes costly trial-and-error during mold validation, significantly extends mold service life under high-pressure cycles, and guarantees consistent part quality batch after batch. For manufacturers supplying regulated industries, this precision is the bedrock of compliance and trust. Wuxi Lead Precision Machinery brings proven, battle-tested expertise to every NJ mold project, transforming stringent specifications into reliable, high-yield production assets. Our record on Olympic and military programs stands as testament to our ability to deliver where precision is paramount.

Precision Specs & Tolerances

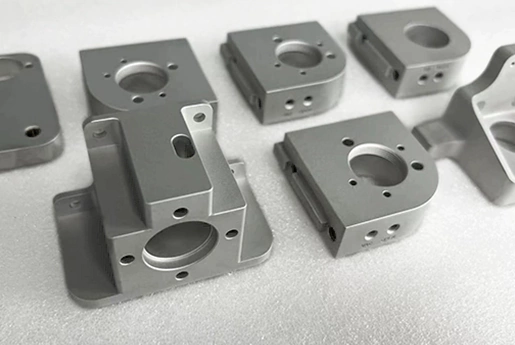

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions tailored for high-performance industries such as aerospace, medical, automotive, and precision instrumentation. At the core of our technical capabilities is our state-of-the-art 5-axis CNC machining platform, enabling us to produce complex, high-precision components with superior surface finish and dimensional accuracy. Our multi-axis machining centers allow simultaneous movement across five axes, providing unparalleled flexibility in contouring intricate geometries that would be unachievable with conventional 3-axis systems. This capability significantly reduces setup times, improves part consistency, and supports the production of fully finished components in a single operation.

Our machining fleet is integrated with high-speed spindles, automated tool changers, and real-time monitoring systems to ensure optimal performance and repeatability. We work with a broad range of engineering-grade metals, including aluminum alloys, stainless steels, titanium, tool steels, and high-temperature superalloys such as Inconel. Each machining program is optimized using advanced CAM software, ensuring efficient toolpaths, minimal material waste, and adherence to tight technical specifications. Our in-house engineering team collaborates closely with clients during the design-for-manufacturability phase to enhance part functionality while reducing production lead times and costs.

Quality assurance is embedded throughout our manufacturing workflow. Every critical dimension is verified using a coordinate measuring machine (CMM) in our climate-controlled inspection lab. The CMM system provides traceable, high-resolution metrology data, ensuring compliance with ISO 10360 standards and customer-specific inspection requirements. Full first-article inspection reports (FAIR) and production batch certifications are available upon request. Our quality management system is ISO 9001:2015 certified, reflecting our commitment to continuous improvement and process discipline.

The table below outlines our standard machining tolerances and surface finish capabilities under normal production conditions. Tighter tolerances are achievable upon engineering review and with additional process controls.

| Feature | Standard Tolerance | Notes |

|---|---|---|

| Linear Dimensions | ±0.005 mm | Up to 100 mm; ±0.01 mm for >100 mm |

| Positional Tolerance | ±0.01 mm | GD&T compliant |

| Angular Tolerance | ±0.05° | Measured per ISO 2768 |

| Surface Roughness (Ra) | 0.4 – 3.2 µm | As-machined; 0.2 µm achievable with polishing |

| Form Tolerance (Flatness) | 0.01 mm per 100 mm | Verified via CMM and optical flat |

| Thread Accuracy | 6H/6g | Internal and external threads per ISO standards |

All components undergo 100% visual inspection and dimensional verification per customer drawings. We support full documentation packages, including CAD models, inspection reports, material certifications, and process validation records. With our 5-axis CNC technology and rigorous quality control protocols, Wuxi Lead Precision Machinery ensures every part meets the exacting demands of high-end industrial applications.

Material & Finish Options

Material Selection for Precision Metal Components: Aluminum, Steel, Titanium & Anodizing

Selecting the optimal material is foundational to the performance, longevity, and cost-efficiency of custom precision metal components, especially within demanding mold and tooling applications. At Wuxi Lead Precision Machinery, our engineering expertise ensures material choices align precisely with your functional requirements, environmental conditions, and budget constraints. Understanding the distinct properties of Aluminum, Steel, and Titanium, coupled with appropriate surface finishes like Anodizing, is critical for success.

Aluminum alloys, particularly 6061-T6 and 7075-T6, offer an exceptional strength-to-weight ratio and excellent machinability. They are ideal for applications requiring lightweight structures, good thermal conductivity, and moderate strength, such as prototype molds, fixture components, and non-ferrous casting dies. Aluminum’s natural corrosion resistance is significantly enhanced through Anodizing. Steel, encompassing grades like 4140, 1045, and precipitation-hardening stainless steels (e.g., 17-4PH), provides superior strength, wear resistance, and dimensional stability under high loads and temperatures. Tool steels (e.g., H13, S7) are essential for high-volume production molds requiring extreme toughness and thermal fatigue resistance. Titanium, primarily Grade 5 (Ti-6Al-4V), delivers outstanding strength-to-weight ratio, exceptional corrosion resistance in harsh environments (including seawater and chemicals), and biocompatibility. It is the material of choice for highly specialized aerospace, medical, and marine components where weight savings and durability are paramount, though it presents significant machining challenges requiring specialized tooling and processes.

The following table summarizes key comparative properties for common precision manufacturing materials

| Material | Typical Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Machinability Rating |

|---|---|---|---|---|

| Aluminum 6061-T6 | 2.7 | 310 | Good | Excellent |

| Steel 4140 | 7.85 | 655 | Fair (Rusts) | Good |

| Stainless 17-4PH | 7.75 | 1000+ | Very Good | Moderate |

| Titanium Ti-6Al-4V | 4.43 | 900 | Excellent | Poor |

Anodizing is a critical electrochemical surface treatment exclusively for aluminum. It creates a hard, porous oxide layer integral to the base metal, dramatically improving wear resistance, corrosion protection, and providing an excellent base for dyeing. Type II (Sulfuric Acid) Anodizing offers good general-purpose protection and color options. For the most demanding mold applications requiring maximum surface hardness and abrasion resistance, Type III (Hardcoat) Anodizing is essential. It produces a much thicker, denser, and harder coating (typically 50-100μm), significantly extending the lifespan of aluminum mold components subjected to wear, galling, or corrosive release agents. Dimensional changes must be accounted for in precision tolerances during the design phase.

Partnering with Wuxi Lead ensures your material and finish selection leverages deep metallurgical knowledge and advanced CNC capabilities. We rigorously evaluate your application’s load, temperature, environment, and lifecycle requirements to recommend the optimal combination, preventing costly failures and maximizing component value. Precise material selection is not merely a specification; it is the cornerstone of reliable, high-performance manufacturing.

Manufacturing Process & QC

Wuxi Lead Precision Machinery delivers uncompromising precision in custom metal manufacturing, serving high-performance industries where reliability and consistency are non-negotiable. Our production process is engineered for zero defects, integrating advanced design protocols, rigorous prototyping, and tightly controlled mass production. Every stage is optimized for dimensional accuracy, material integrity, and long-term performance.

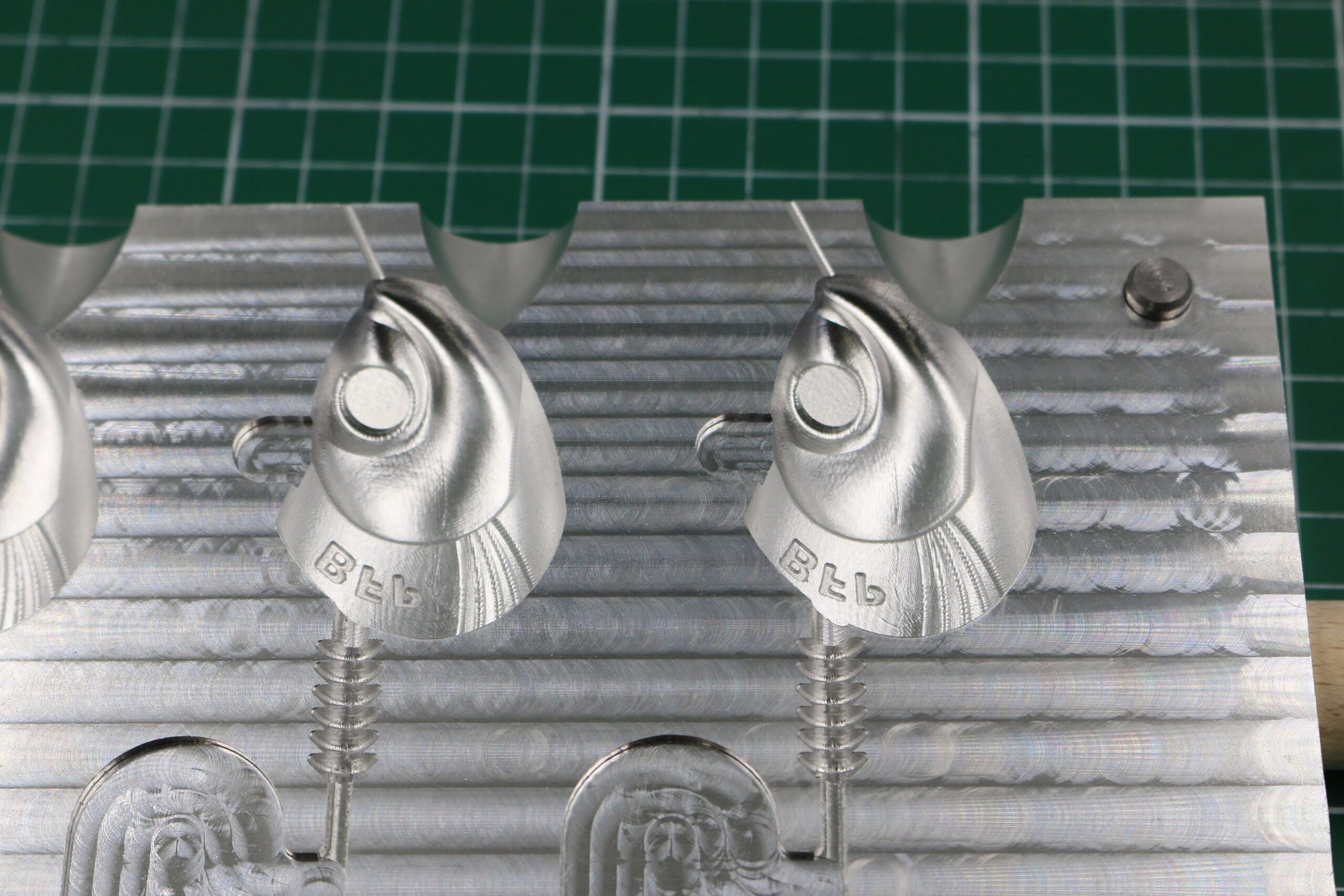

The process begins with Design, where our engineering team collaborates closely with clients to translate technical requirements into manufacturable solutions. Utilizing 3D CAD modeling and finite element analysis (FEA), we simulate stress, thermal behavior, and assembly fit prior to any physical production. This digital validation ensures that every component meets functional and environmental demands. Design for manufacturability (DFM) reviews are conducted to eliminate inefficiencies, reduce lead times, and prevent potential failure modes.

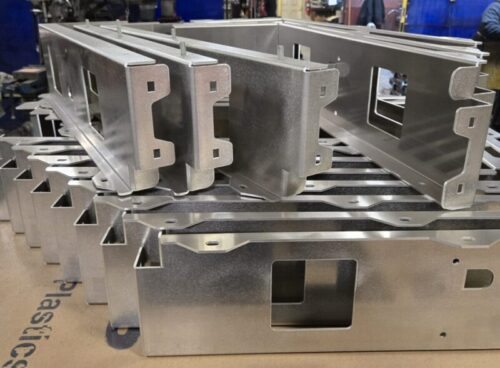

Following design approval, we move to Prototyping. A limited batch of components is produced using the same CNC machining, stamping, or forming processes intended for full-scale production. This ensures that the prototype accurately reflects final part quality. Each prototype undergoes comprehensive inspection using coordinate measuring machines (CMM), optical comparators, and surface roughness testers. Dimensional reports, material certifications, and first-article inspection (FAI) documentation are provided for client review. Any deviations are addressed through iterative refinement, ensuring complete alignment with specifications before transitioning to mass production.

Mass Production is executed under a fully documented quality management system compliant with ISO 9001:2015 standards. Our facility employs real-time process monitoring, statistical process control (SPC), and automated in-line inspection to maintain consistency across thousands of parts. Each production run begins with a pre-production validation and continues with hourly sampling to detect drift. Traceability is maintained through laser part marking and batch tracking, enabling full accountability from raw material to final shipment.

Our commitment to zero defects is reinforced by redundant quality checks, operator training, and continuous process improvement. By integrating precision engineering with disciplined manufacturing controls, Wuxi Lead ensures that every component meets the highest standards of performance and reliability.

| Specification | Detail |

|---|---|

| Materials Supported | Aluminum Alloys, Stainless Steel, Titanium, Brass, Copper Alloys, Tool Steels |

| Tolerances | ±0.005 mm (standard), ±0.001 mm (precision) |

| Surface Finish | Ra 0.1 µm to 3.2 µm (customizable) |

| Maximum Part Size | 1200 mm × 800 mm × 600 mm |

| Production Capacity | Up to 500,000 units/month |

| Inspection Equipment | CMM, Optical Comparator, Laser Scanning, Hardness Tester |

| Quality Standards | ISO 9001:2015, IATF 16949 (automotive), RoHS compliant |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised Mold Manufacturing Excellence

Achieving true precision in mold manufacturing demands more than advanced machinery—it requires engineering mastery and an uncompromising commitment to quality. At Wuxi Lead Precision Machinery, we specialize in transforming complex mold designs into high-performance metal components that meet the exacting standards of aerospace, medical, and automotive industries. Our facility in Wuxi integrates decades of CNC expertise with cutting-edge technology to deliver molds that ensure repeatability, longevity, and flawless part production. When tolerances are measured in microns and material integrity is non-negotiable, our engineered solutions become your competitive advantage.

We understand that mold performance directly impacts your production efficiency and product quality. That’s why every project begins with rigorous material analysis and thermal dynamics simulation, ensuring optimal steel selection and cooling channel design. Our multi-axis CNC grinding and milling centers operate under strict environmental controls, eliminating dimensional drift and surface imperfections. The result is molds that maintain critical geometries through thousands of cycles, reducing downtime and scrap rates for your operations. Below are core capabilities defining our precision manufacturing foundation:

| Specification | Capability | Industry Relevance |

|---|---|---|

| Positioning Accuracy | ±0.0002″ (5µm) | Eliminates flash in micro-molded parts |

| Surface Finish | Ra 0.05µm (Mirror Grade) | Critical for optical/lens molds |

| Max Work Envelope | 1200 x 800 x 650mm | Supports large automotive molds |

| Material Mastery | H13, S7, 420SS, Titanium Alloys | Withstands high-pressure injection |

| Process Validation | In-process CMM + GD&T Reporting | Ensures first-article compliance |

Partnering with Lead Precision means gaining a strategic engineering ally, not just a supplier. Our team collaborates from initial concept through production ramp-up, providing DFM insights that prevent costly iterations. We implement real-time process monitoring with traceable data logs, giving you full transparency into every machining parameter. This disciplined approach consistently delivers molds that exceed ISO 9001 and AS9100 requirements while accelerating your time-to-market.

Your next-generation molds deserve manufacturing partners who treat precision as a non-negotiable standard. Contact our engineering team directly at [email protected] to discuss how our capabilities can resolve your most challenging mold applications. Include your project specifications and timeline, and we will respond within 4 business hours with a detailed capability assessment. For urgent requirements, reference “NJ MOLD URGENT” in your subject line to prioritize technical review. Let us prove why global leaders trust Wuxi Lead Precision Machinery to turn mold complexity into manufacturing certainty.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.