Technical Contents

Engineering Guide: Copper Machined Parts

Engineering Insight: Precision Imperatives in Copper Machined Parts

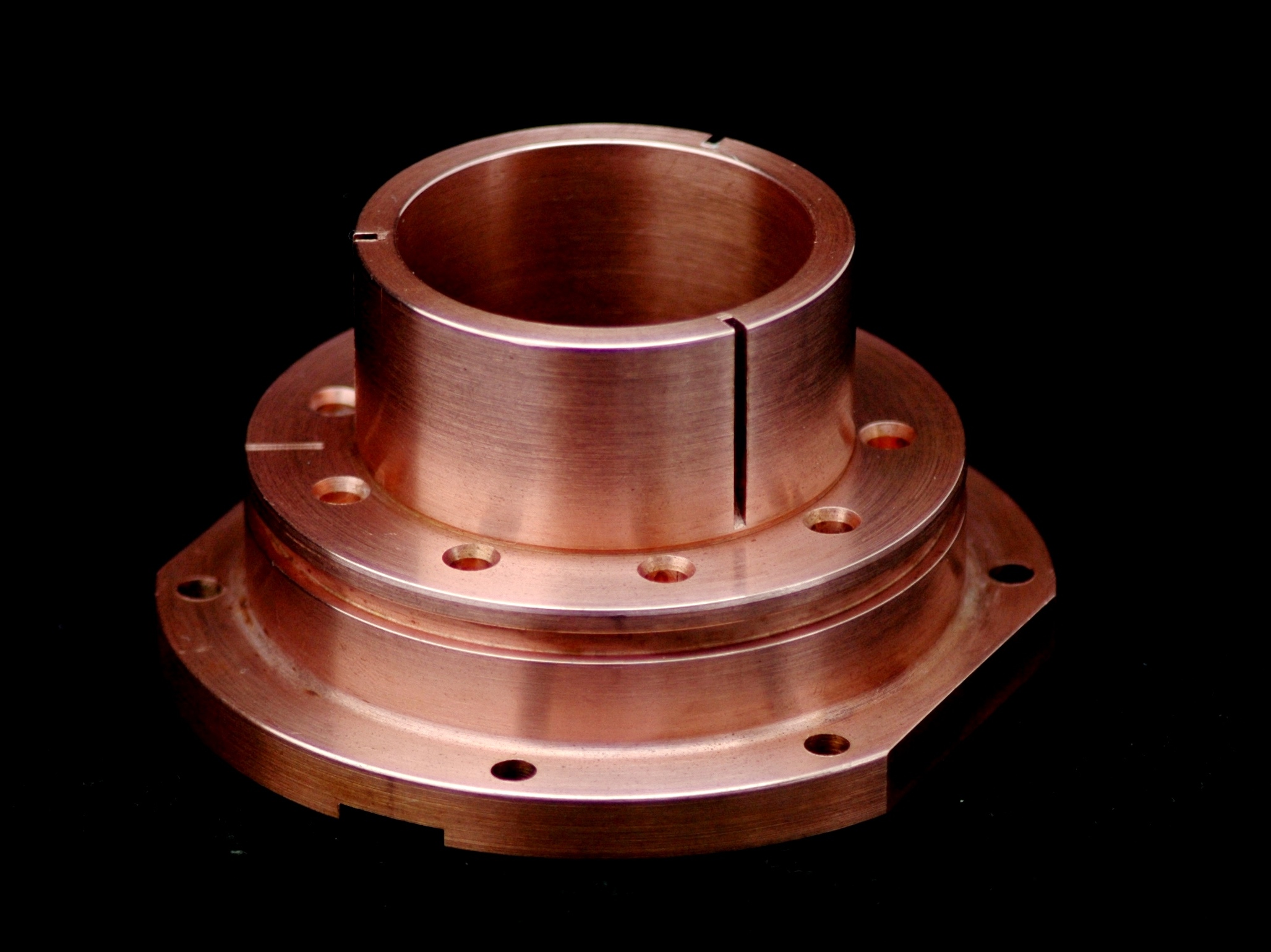

Copper’s exceptional thermal and electrical conductivity make it indispensable for high-performance applications in aerospace, defense, and advanced electronics. However, its inherent softness, gummy texture, and high thermal expansion coefficient present formidable machining challenges. Conventional CNC processes often induce burring, dimensional drift, or surface defects, directly compromising part functionality. At Wuxi Lead Precision Machinery, we recognize that precision in copper machining transcends tight tolerances—it demands holistic control over material behavior, thermal management, and microstructural integrity. A deviation of even 5 microns can disrupt thermal pathways in satellite components or induce signal loss in 5G infrastructure. Our approach integrates adaptive cutting strategies, cryogenic cooling, and real-time in-process metrology to neutralize copper’s volatility, ensuring geometric accuracy and surface finishes that meet MIL-STD-883 and ISO 2768-mK standards.

Our expertise is validated through mission-critical projects where failure is non-negotiable. We engineered timing system components for the Beijing Winter Olympics, where sub-millisecond synchronization relied on copper parts machined to ±0.001mm tolerances under extreme thermal cycling. Similarly, our work on classified defense projects—including radar waveguides and propulsion subsystems—demonstrates our capability to maintain repeatability in copper alloys under stringent ITAR protocols. This experience translates to your production: we anticipate micro-deformations during fixturing, optimize toolpath dynamics to prevent built-up edge, and implement post-machining stress-relief protocols that eliminate latent distortion.

For your reference, key copper alloys and their precision machining parameters are summarized below. Note that achieving the stated tolerances requires specialized tooling geometries and spindle harmonics tuned to each alloy’s unique response.

| Alloy Designation | Common Name | Key Applications | Max Achievable Tolerance | Critical Machining Consideration |

|---|---|---|---|---|

| C11000 | Electrolytic Tough Pitch | Busbars, Connectors | ±0.005mm | High thermal conductivity demands aggressive chip evacuation to prevent work hardening |

| C10100 | Oxygen-Free High Conductivity | Vacuum Systems, MRI Coils | ±0.002mm | Sensitivity to oxidation requires inert atmosphere during finishing |

| C18150 | Chromium Copper | Welding Electrodes, RF Components | ±0.001mm | Beryllium content necessitates strict dust control per OSHA standards |

Precision copper machining is not merely a technical exercise—it is a safeguard for your product’s operational lifespan. At Wuxi Lead, every spindle rotation, coolant pressure adjustment, and probe calibration is engineered to transform copper’s challenges into your competitive advantage. Our 15-year legacy in Olympic and defense-tier manufacturing ensures your parts perform flawlessly, whether embedded in a satellite array or a next-generation semiconductor tool. Partner with us to convert material potential into engineered certainty.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced manufacturing solutions for high-performance copper machined parts, leveraging state-of-the-art 5-axis CNC machining technology to meet the stringent demands of aerospace, medical, energy, and industrial automation sectors. Copper, known for its excellent thermal and electrical conductivity, presents unique machining challenges due to its softness, ductility, and tendency to work-harden. Our technical expertise is engineered to overcome these challenges through optimized toolpaths, precision coolant delivery, and specialized tooling strategies that maintain dimensional accuracy while preserving material integrity.

Our 5-axis CNC machining centers provide unparalleled flexibility in producing complex geometries with tight tolerances and superior surface finishes. With simultaneous multi-axis motion, we eliminate the need for multiple setups, reducing lead times and enhancing repeatability. This capability is particularly critical when machining intricate copper components such as heat exchanger manifolds, electrical connectors, and RF shielding housings, where angular features and deep cavities are common. The integration of high-torque spindles and rigid machine structures ensures stable cutting performance, minimizing vibration and tool deflection during prolonged operations.

Quality assurance is embedded throughout our production process. Every copper machined part undergoes rigorous inspection using coordinate measuring machines (CMM) to validate conformance to design specifications. Our CMM systems are calibrated to international standards and operated by certified metrology technicians, enabling micron-level verification of critical dimensions, geometric tolerances, and surface profiles. In addition to first-article inspection, we conduct in-process and final inspections to ensure consistency across production runs. Data from CMM reports are documented and archived for full traceability, supporting compliance with ISO 9001 and customer-specific quality requirements.

Material selection is another cornerstone of our technical capability. We source high-purity copper (C10100, C11000) as well as high-strength alloys such as beryllium copper (C17200) and tellurium copper (C14500), tailored to the functional needs of the application. Each material is tested upon receipt and processed under controlled environmental conditions to prevent oxidation and contamination.

The following table outlines the standard technical specifications we achieve for copper machined parts:

| Specification | Capability |

|---|---|

| Maximum Work Envelope (XYZ) | 1200 mm × 800 mm × 600 mm |

| Positional Tolerance | ±0.005 mm |

| Dimensional Tolerance (Standard) | ±0.025 mm |

| Dimensional Tolerance (Tight) | ±0.005 mm |

| Surface Roughness (Ra) | As low as 0.4 µm |

| Geometric Tolerance (GD&T) | ±0.01 mm (per ASME Y14.5) |

| CMM Measurement Accuracy | ±0.0015 mm (2σ) |

| Lead Time (Prototype) | 7–12 days |

| Lead Time (Production) | 15–25 days |

Wuxi Lead Precision Machinery combines cutting-edge equipment, rigorous quality control, and deep material expertise to deliver copper machined parts that meet the highest standards of precision and reliability.

Material & Finish Options

Material Selection for High-Performance Machined Components: Beyond Copper

While copper possesses excellent electrical and thermal conductivity, it is fundamentally suboptimal for precision structural machined parts due to its inherent softness, low strength, and significant thermal expansion. At Wuxi Lead Precision Machinery, we prioritize material integrity and functional performance. For demanding applications requiring dimensional stability, strength, and durability under load or thermal cycling, aluminum alloys, stainless steels, and titanium alloys are the industry-standard choices. Selecting the correct base material is critical for part longevity, performance, and cost-effectiveness. Copper alloys like beryllium copper are reserved for specific electrical contact or spring applications, not general structural components; using pure copper for such roles invites premature failure.

Aluminum alloys offer an exceptional strength-to-weight ratio and are highly machinable, making them ideal for aerospace brackets, heat sinks, and housings where weight reduction is paramount. Stainless steels, particularly grades 303, 304, and 17-4 PH, provide superior corrosion resistance, high strength, and wear properties essential for medical instruments, fluid handling systems, and marine hardware. Titanium alloys, though more challenging to machine, deliver unmatched strength-to-weight ratios combined with exceptional corrosion resistance and biocompatibility, critical for aerospace components, high-end medical implants, and chemical processing equipment. Material choice directly impacts machining complexity, lead time, and final cost. Our engineering team rigorously evaluates your application’s environmental exposure, load requirements, and regulatory standards to prescribe the optimal material.

Surface finishing significantly enhances functional performance and longevity. Anodizing is exclusively applicable to aluminum, creating a hard, corrosion-resistant oxide layer that can be dyed for identification. It improves wear resistance and electrical insulation but does not benefit steel or titanium. For stainless steel components, passivation is essential to remove free iron and maximize corrosion resistance; electropolishing provides further enhancement. Titanium typically requires specialized cleaning or acid etching, with anodizing used primarily for color coding rather than significant wear improvement. Selecting the wrong finish for a material wastes resources and compromises part function.

The following table summarizes key properties and considerations for primary structural materials:

| Material Category | Key Properties | Typical Applications | Critical Machining Notes |

|---|---|---|---|

| Aluminum Alloys (e.g., 6061, 7075) | High strength-to-weight ratio, excellent thermal/electrical conductivity, good machinability | Aerospace brackets, heat sinks, enclosures, automotive components | Requires sharp tools, high speeds, coolant control to prevent built-up edge and chatter; 7075 is harder to machine than 6061 |

| Stainless Steels (e.g., 303, 304, 17-4 PH) | High strength, excellent corrosion resistance, good wear properties | Medical devices, valves, pumps, marine hardware, food processing | Work hardens rapidly; requires rigid setup, lower speeds, high feed rates, appropriate tool geometry; 303 machines easiest, 17-4 PH hardest |

| Titanium Alloys (e.g., Ti-6Al-4V) | Exceptional strength-to-weight ratio, outstanding corrosion resistance, biocompatible | Aerospace structural parts, medical implants, chemical processing | Low thermal conductivity causes heat buildup; requires low cutting speeds, high feed rates, copious coolant, sharp tools; prone to galling |

Material and finish selection is not arbitrary. It requires deep understanding of the operational environment and manufacturing constraints. Wuxi Lead Precision Machinery leverages decades of CNC machining expertise to guide clients toward the optimal technical and economic solution. Consult our engineering team during the design phase to ensure your material specification aligns with performance demands and manufacturability, avoiding costly revisions and delays. Precision begins with the right foundation.

Manufacturing Process & QC

Design: Engineering Precision from Concept to Blueprint

At Wuxi Lead Precision Machinery, the production of copper machined parts begins with a rigorous design phase grounded in collaboration and precision engineering. Our engineering team works closely with clients to analyze functional requirements, environmental conditions, and integration needs. Copper, known for its excellent thermal and electrical conductivity, presents unique machining challenges due to its softness and high ductility. To address this, we utilize advanced CAD/CAM software to simulate material behavior and optimize toolpaths, ensuring dimensional accuracy and surface integrity. Design for manufacturability (DFM) reviews are conducted to eliminate potential flaws early, reducing cycle times and material waste. Every design is validated against international standards and customer-specific tolerances, typically ranging from ±0.005 mm to ±0.025 mm, depending on part complexity.

Prototyping: Validating Performance Before Scale

Once the design is finalized, we move to the prototyping stage—critical for verifying form, fit, and function. Using high-speed CNC milling and turning centers equipped with specialized tooling for copper alloys, we produce initial samples within tight timelines. These prototypes undergo comprehensive inspection using coordinate measuring machines (CMM), optical comparators, and surface roughness testers. We evaluate critical dimensions, geometric tolerances (GD&T), and surface finish, ensuring compliance with specifications. Feedback from client testing is integrated swiftly, allowing for iterative refinements. This phase not only confirms design integrity but also validates process parameters such as spindle speed, feed rate, and coolant application—key factors in preventing material deformation and burring in copper.

Mass Production: Consistency, Control, and Zero Defects

With prototype approval, we transition to mass production under a fully documented quality management system compliant with ISO 9001:2015. Our CNC machining cells operate under real-time monitoring, with automated tool wear compensation and in-process gauging to maintain consistency across batches. Each copper component is machined from certified raw materials, traceable to mill certificates, ensuring material integrity. To uphold our zero-defect commitment, we implement Statistical Process Control (SPC) and First Article Inspection (FAI) protocols. Final inspection includes 100% visual checks and sampling-based dimensional verification. Non-conforming parts are immediately quarantined and analyzed through root cause correction processes.

Typical Production Specifications for Copper Machined Parts

| Parameter | Specification Range |

|---|---|

| Material Types | C11000 (ETP), C10100 (Oxygen-Free), C18000 (Copper-Clad) |

| Tolerance | ±0.005 mm to ±0.025 mm |

| Surface Roughness (Ra) | 0.4 µm to 3.2 µm |

| Maximum Part Size | 500 mm × 350 mm × 200 mm |

| Minimum Feature Size | 0.5 mm (holes, slots) |

| Production Volume Range | 1 – 50,000+ units per order |

| Lead Time (Mass Production) | 15–25 days (after prototype approval) |

Through seamless integration of design intelligence, prototyping validation, and disciplined production control, Wuxi Lead ensures every copper machined part meets the highest standards of precision and reliability.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised Copper Machining Excellence

Copper’s exceptional thermal and electrical conductivity make it indispensable for high-performance applications in aerospace thermal management, medical device electrodes, and semiconductor tooling. Yet its softness, high thermal diffusivity, and susceptibility to galling present formidable machining challenges. At Wuxi Lead Precision Machinery, we transform these complexities into competitive advantages through purpose-built CNC processes engineered exclusively for copper alloys. Our decades of metallurgical expertise ensure dimensional stability, surface integrity, and material property retention—critical for components where conductivity consistency directly impacts system performance.

We deploy dedicated CNC Swiss-type and 5-axis milling centers with specialized toolpath strategies to mitigate heat generation and prevent work hardening. Rigorous in-process metrology using Zeiss CMMs and optical comparators verifies tolerances down to ±0.005 mm while maintaining surface finishes as fine as Ra 0.4 µm. Every operation adheres to ISO 9001:2015 protocols, with full traceability from raw material certification to final inspection. Our facility’s controlled environment minimizes thermal drift during machining—a non-negotiable requirement for copper’s high expansion coefficient. Below are core capabilities defining our copper machining mastery:

| Spec Parameter | Capability | Notes |

|---|---|---|

| Material Grades | C10100, C11000, C18150, C18200 | Including oxygen-free and beryllium-copper |

| Tolerance Range | ±0.005 mm to ±0.025 mm | Verified per ASME Y14.5 |

| Surface Finish | Ra 0.4 µm to Ra 1.6 µm | Achieved without secondary polishing |

| Max Part Dimensions | Ø300 mm x 500 mm | For complex geometries |

| Secondary Processes | Passivation, plating, laser marking | In-house coordination |

Beyond technical execution, we integrate seamlessly into your engineering workflow. Our team collaborates during DFM stages to optimize part geometry for copper’s behavior, reducing scrap rates by up to 30% versus conventional approaches. Real-time production dashboards provide visibility into your order status, while our rapid prototyping cell delivers functional samples in 7–10 days—accelerating your time-to-market without compromising quality. For volume production, our automated bar-feeding systems ensure consistent throughput with minimal human intervention, critical for maintaining conductivity uniformity across batches.

The cost of copper component failure extends far beyond rework—it jeopardizes system reliability in life-science instruments or energy infrastructure. Partnering with Lead Precision means aligning with a supplier whose process controls are validated by Tier-1 aerospace and medical OEMs. We don’t just machine copper; we engineer conductivity.

Initiate your precision copper project with engineering rigor that matches your application’s demands. Contact our technical sales team at [email protected] to discuss material selection, tolerance validation, or rapid prototyping for your next-generation design. Specify “Copper Machining Guide Inquiry” in your subject line for priority engineering consultation. Let Lead Precision become your definitive solution for copper components where performance cannot be compromised.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.