Technical Contents

Engineering Guide: Custom Injection Molded Parts

Engineering Insight: The Critical Role of Precision in Custom Injection Molded Parts

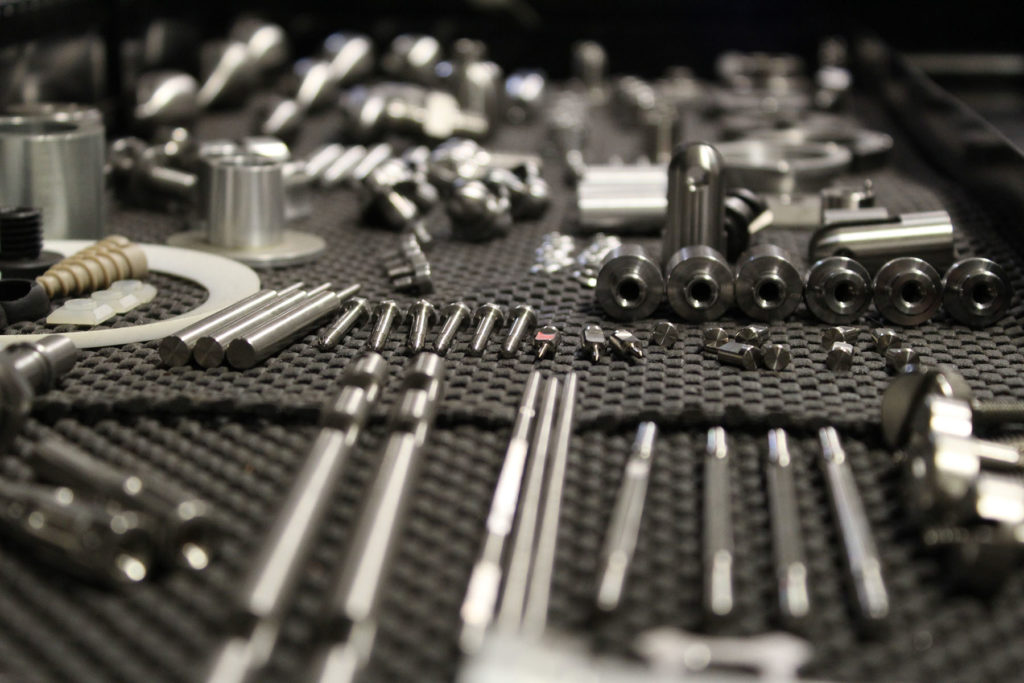

In the realm of high-performance manufacturing, custom injection molded parts are more than just components—they are engineered solutions that define the reliability, efficiency, and longevity of complex systems. At Wuxi Lead Precision Machinery, we understand that precision is not an optional enhancement but a foundational requirement, especially when serving industries such as aerospace, defense, and advanced automation where failure is not an option. Our decade-long expertise in custom metal manufacturing has been rigorously tested through contracts for Olympic-grade equipment and mission-critical military applications, reinforcing our commitment to uncompromising accuracy and repeatability.

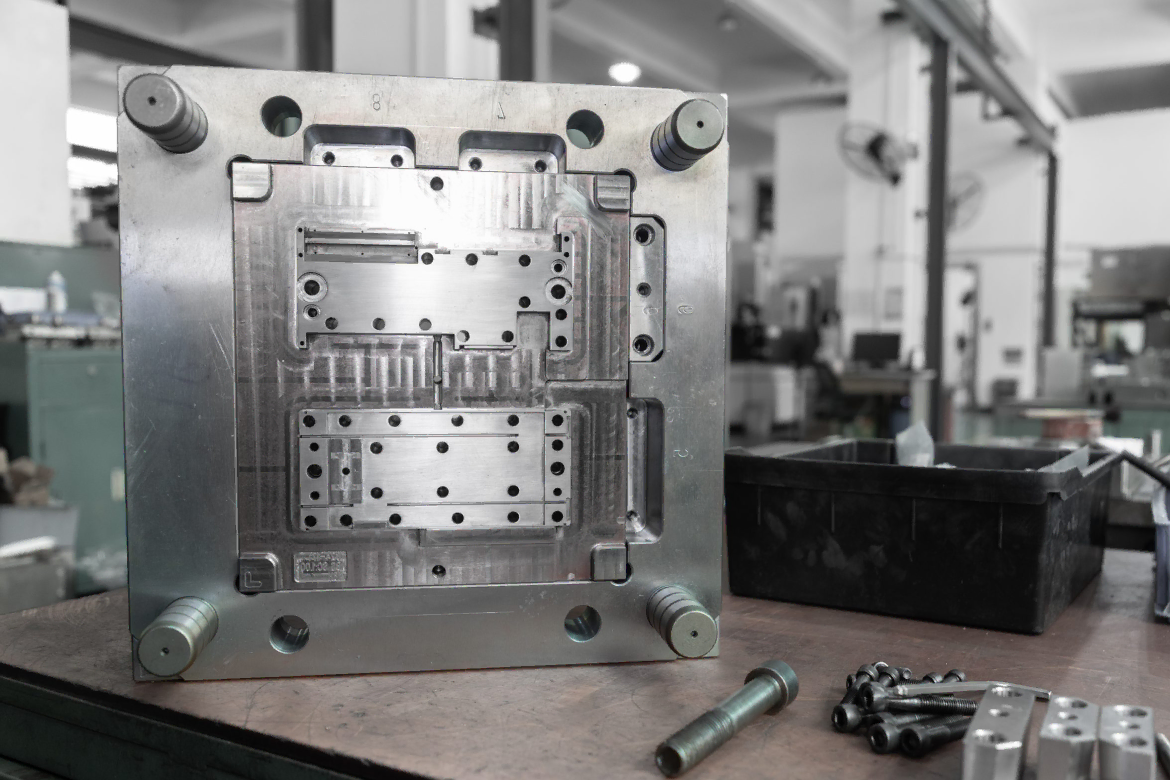

Custom injection molded parts must meet exact dimensional tolerances, surface integrity standards, and material consistency to perform under extreme operational conditions. Even deviations measured in microns can lead to part failure, system inefficiency, or safety hazards. This level of consistency is achieved not only through advanced CNC tooling and molding technologies but also through a deep understanding of material behavior, thermal dynamics, and mold flow analysis. At Lead Precision, every mold is designed using simulation-driven engineering to predict and correct potential defects before production begins, ensuring first-time-right outcomes.

Our facility integrates state-of-the-art 5-axis machining centers, real-time metrology systems, and automated quality inspection protocols to maintain tolerances down to ±0.002 mm. This precision extends beyond the mold cavity to include gate positioning, cooling channel geometry, and ejection mechanisms—all of which influence part quality. By controlling every phase of development, from prototype to mass production, we deliver injection molded components that meet the most stringent international standards, including ISO 9001 and MIL-STD-810.

The demands of Olympic and military projects have shaped our approach to custom manufacturing. For instance, components used in high-speed timing systems for athletic events require flawless dimensional stability and resistance to environmental fluctuations. Similarly, military-grade housings and connectors must endure shock, vibration, and extreme temperatures while maintaining signal integrity. These applications demand more than technical capability—they require a culture of precision that permeates every process and decision.

Below are key technical specifications that define our custom injection molding capabilities:

| Specification | Capability |

|---|---|

| Dimensional Tolerance | ±0.002 mm |

| Material Compatibility | PEEK, PPS, Nylon, Polycarbonate, ABS, and custom composites |

| Mold Accuracy | Class 101 (ISO 20457) |

| Maximum Part Weight | 2.5 kg |

| Minimum Wall Thickness | 0.4 mm |

| Surface Finish Options | SPI A1, A2, B1, B2, VDI 3400 textures |

| Production Volume Range | Prototype to 500,000+ units annually |

| Secondary Operations | Ultrasonic welding, insert molding, precision machining, laser marking |

At Wuxi Lead Precision Machinery, precision is not a claim—it is a proven outcome. Our work on elite-tier projects underscores our ability to deliver custom injection molded parts that perform under the most demanding conditions. When engineering excellence is non-negotiable, manufacturers trust Lead Precision to translate design intent into flawless reality.

Precision Specs & Tolerances

Technical Capabilities: Precision Metal Manufacturing for Demanding Applications

Wuxi Lead Precision Machinery delivers uncompromising precision in custom metal manufacturing, engineered to meet the stringent demands of aerospace, medical, and advanced industrial sectors. Our core strength lies in integrating advanced multi-axis machining with rigorous quality validation, ensuring every component adheres to exacting functional and geometric specifications. Unlike standard fabrication houses, we specialize in complex geometries requiring simultaneous 5-axis CNC milling and turning, eliminating secondary operations and maintaining micron-level accuracy across intricate features. This capability is critical for mission-critical parts where assembly integrity and performance under extreme conditions are non-negotiable.

Our 5-axis CNC machining centers feature high-torque spindles, expansive travel ranges (X: 1,200 mm / Y: 800 mm / Z: 750 mm), and dynamic tool changers supporting 40+ tool capacities. These systems execute continuous contouring of organic shapes, deep cavities, and undercuts in hardened alloys—including titanium, Inconel, and surgical-grade stainless steel—with minimal fixturing. The elimination of repositioning errors ensures geometric coherence across all datums, directly translating to reduced assembly time and enhanced end-product reliability for our clients. Material waste is minimized through optimized toolpath strategies, while high-speed machining protocols maintain surface integrity without thermal distortion.

Quality assurance is embedded at every phase, anchored by Zeiss CONTURA CMM systems operating under ISO 17025 standards. Each part undergoes full-spectrum inspection against 3D CAD models, with comprehensive reporting on dimensional conformance, GD&T callouts, and surface finish. Our CMM workflows include temperature-stabilized measurement environments, calibrated probes for micro-feature validation (down to 0.001 mm resolution), and automated reporting traceable to international standards. This end-to-end verification guarantees that tolerances are not merely claimed but empirically proven, providing clients with auditable confidence in batch consistency.

The following table details achievable tolerances for critical parameters, reflecting our standard production capabilities under controlled conditions:

| Parameter | Standard Tolerance | Precision Tolerance | Reference Standard |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.005 mm | ISO 2768-mK |

| Angular Features | ±0.1° | ±0.02° | ISO 2768-c |

| Positional GD&T | ±0.03 mm | ±0.008 mm | ASME Y14.5 |

| Surface Roughness | Ra 1.6 μm | Ra 0.4 μm | ISO 1302 |

| Concentricity | 0.05 mm | 0.01 mm | ISO 1101 |

These capabilities converge to solve high-stakes manufacturing challenges: reducing lead times for prototyping through single-setup machining, ensuring biocompatibility for medical implants via controlled surface finishes, and achieving weight-critical tolerances in aerospace structural components. We partner with clients during design for manufacturability (DFM) to optimize part geometry for precision execution, transforming complex concepts into certified, production-ready metal components. At Wuxi Lead, precision is not a claim—it is a documented, repeatable outcome.

Material & Finish Options

Material Selection for High-Performance Custom Injection Molded Parts

Selecting the appropriate material for custom injection molded parts is critical to ensuring performance, durability, and cost-efficiency in demanding industrial applications. At Wuxi Lead Precision Machinery, we specialize in precision metal components tailored to aerospace, automotive, medical, and industrial automation sectors. Our expertise in aluminum, steel, and titanium enables us to deliver molded parts that meet exacting standards for strength, weight, and environmental resistance.

Aluminum is widely favored for its excellent strength-to-weight ratio and thermal conductivity. It is particularly suitable for lightweight structural components and heat-sensitive applications. The 6061 and 7075 aluminum alloys offer high machinability and corrosion resistance, making them ideal for complex molds and housings. When paired with anodizing, aluminum achieves enhanced surface hardness and wear resistance, while allowing for color coding and aesthetic customization.

Steel, particularly tool steel and stainless steel variants, provides superior durability and resistance to deformation under high pressure and temperature. Grades such as P20, H13, and 420 stainless steel are commonly used in injection molds requiring long service life and tight tolerances. Steel’s high hardness ensures dimensional stability over thousands of cycles, making it the preferred choice for high-volume production runs. Surface treatments such as nitriding or chrome plating further extend tool life and reduce friction.

Titanium stands out for its exceptional strength-to-density ratio and outstanding corrosion resistance, especially in aggressive environments. While more challenging to machine, titanium’s performance in high-stress, high-temperature conditions justifies its use in critical aerospace and medical components. Grade 5 (Ti-6Al-4V) is the most widely used titanium alloy in precision manufacturing due to its weldability and fatigue resistance.

Anodizing is a key finishing process for aluminum components, forming a protective oxide layer that improves surface hardness, wear resistance, and dielectric properties. Type II (sulfuric acid) anodizing is standard for decorative and moderate protection needs, while Type III (hardcoat anodizing) delivers a thicker, more durable layer suitable for industrial and military applications. Anodized finishes can be dyed in various colors for identification or branding without compromising performance.

Below is a comparative overview of key material properties for custom injection molded parts:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Corrosion Resistance | Typical Applications | Common Finishes |

|---|---|---|---|---|---|

| Aluminum 6061 | 310 | 2.7 | Good | Enclosures, heat sinks, molds | Anodizing, powder coating |

| Steel P20 | 980 | 7.8 | Moderate | Injection molds, tooling blocks | Nitriding, chrome plating |

| Steel 420 | 1,200 | 7.7 | High | Medical molds, precision tools | Polishing, passivation |

| Titanium Ti-6Al-4V | 950 | 4.4 | Excellent | Aerospace, medical implants | Anodizing, plasma coating |

At Wuxi Lead Precision Machinery, we guide clients through material and finish selection based on application requirements, environmental exposure, and lifecycle expectations. Our engineering team ensures optimal performance through precise material pairing and advanced surface treatments.

Manufacturing Process & QC

Precision Execution: From Concept to Zero-Defect Injection Molded Components

Our rigorously controlled production sequence for custom metal injection molded parts ensures absolute fidelity to your specifications, eliminating costly errors before full-scale manufacturing begins. This integrated approach—Design, Prototyping, Mass Production—is engineered for zero defects through systematic validation and process control. We begin with collaborative design review, applying deep metallurgical and molding expertise to optimize geometry, material selection, and manufacturability. Our engineers conduct comprehensive Design for Manufacturing (DFM) analysis, identifying potential stress points, ejection challenges, or porosity risks inherent in complex metal injection molding (MIM). This phase leverages advanced simulation software to predict material flow, shrinkage, and thermal behavior, ensuring the digital model translates flawlessly to physical reality. Early intervention here prevents 90% of downstream failures, saving significant time and investment.

Prototyping is not merely a form check but a critical process validation step. Using production-intent tooling and your specified metal alloy feedstock, we produce functional prototypes under actual molding parameters. Each prototype undergoes rigorous metrology, including CMM inspection against CAD data and material testing for density, hardness, and microstructure. This phase validates the DFM adjustments and fine-tunes sintering profiles. Only when dimensional accuracy, mechanical properties, and surface finish meet or exceed your requirements do we authorize tooling for mass production. This disciplined iteration guarantees the production process is locked before committing to high-volume runs.

Mass production operates under our Zero Defects Manufacturing System. Every molding cycle is monitored in real-time via integrated sensors tracking pressure, temperature, and injection speed. Statistical Process Control (SPC) charts continuously analyze critical dimensions from in-process samples, triggering immediate corrective action if trends approach tolerance limits. 100% automated vision inspection screens for surface anomalies, while random destructive testing verifies internal integrity per ASTM standards. Our cleanroom-class molding environment and ISO 9001-certified procedures ensure consistency across batches. This closed-loop system, combined with operator expertise, delivers parts where conformance is non-negotiable, not aspirational.

Key production capabilities enabling this precision are maintained across all phases:

| Parameter | Capability | Verification Method |

|---|---|---|

| Dimensional Tolerance | ±0.005mm to ±0.05mm (based on geometry) | CMM, Optical Comparators |

| Material Options | 17-4PH, 316L, 420SS, Custom Alloys | Spectrographic Analysis, Tensile Testing |

| Part Complexity | High (undercuts, thin walls ≥0.5mm) | DFM Simulation, Prototype Validation |

| Surface Finish | As-sintered Ra 1.6μm to Polished Ra 0.1μm | Profilometry, Visual Standards |

| Production Volume | 1,000 to 1,000,000+ parts | Real-time SPC, Batch Traceability |

This seamless workflow, governed by data-driven decisions and uncompromising quality gates, transforms your design into a reliable, high-performance component. Wuxi Lead Precision Machinery guarantees not just parts, but assured functionality—eliminating scrap, rework, and supply chain disruption for your critical applications.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Custom Injection Molded Parts

At Wuxi Lead Precision Machinery, we specialize in delivering high-precision custom injection molded parts tailored to the exact demands of advanced manufacturing industries. As a trusted leader in custom metal manufacturing, our engineering-driven approach ensures that every component we produce meets stringent standards for quality, repeatability, and performance. Whether you’re developing mission-critical parts for aerospace, medical devices, automotive systems, or industrial automation, partnering with us means gaining a strategic advantage in precision, speed, and reliability.

Our state-of-the-art facility in Wuxi, China, is equipped with advanced CNC machining centers, high-speed molding technologies, and real-time quality inspection systems. We combine decades of metallurgical expertise with cutting-edge process control to deliver injection molded parts in a wide range of engineering-grade metals and alloys. From initial design consultation and mold development to full-scale production and post-processing, our team manages every phase with meticulous attention to detail.

We understand that in high-end manufacturing, tolerances matter. That’s why our custom injection molding process supports micron-level accuracy, complex geometries, and superior surface finishes—ensuring your parts perform exactly as intended. Our materials portfolio includes stainless steel, titanium, tool steel, and specialty alloys, all processed under ISO 9001-certified protocols to guarantee consistency and traceability.

Our commitment extends beyond manufacturing. We act as an extension of your engineering team, offering Design for Manufacturability (DFM) analysis, rapid prototyping, and scalable production solutions that reduce time-to-market and lower total cost of ownership. With a responsive global supply chain and in-house tooling capabilities, we support both low-volume pilot runs and high-volume production with equal efficiency.

When you choose Wuxi Lead Precision Machinery, you’re not just sourcing parts—you’re gaining a long-term manufacturing partner dedicated to innovation, precision, and excellence.

Below are key technical specifications that define our custom injection molding capabilities:

| Specification | Capability |

|---|---|

| Material Options | Stainless Steel (316L, 17-4PH), Titanium, Tool Steel, Cobalt-Chrome, Custom Alloys |

| Tolerance | ±0.003 mm (±0.0001″) |

| Part Weight Range | 0.1 g to 200 g |

| Surface Finish | Ra 0.4 µm to Ra 3.2 µm (custom finishes available) |

| Production Volume | Prototype to High-Volume (10,000+ units/month) |

| Secondary Operations | CNC Machining, Heat Treatment, Passivation, Laser Marking |

| Quality Standards | ISO 9001:2015, Full First Article Inspection (FAI), SPC Monitoring |

Contact us today to discuss your next project. Send your design files and requirements to [email protected] and receive a detailed technical review and quotation within 24 hours. Let Wuxi Lead Precision Machinery be your trusted partner in precision manufacturing.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.