Technical Contents

Engineering Guide: Abs Machining Locations

Engineering Insight: ABS Machining Locations Demand Absolute Precision

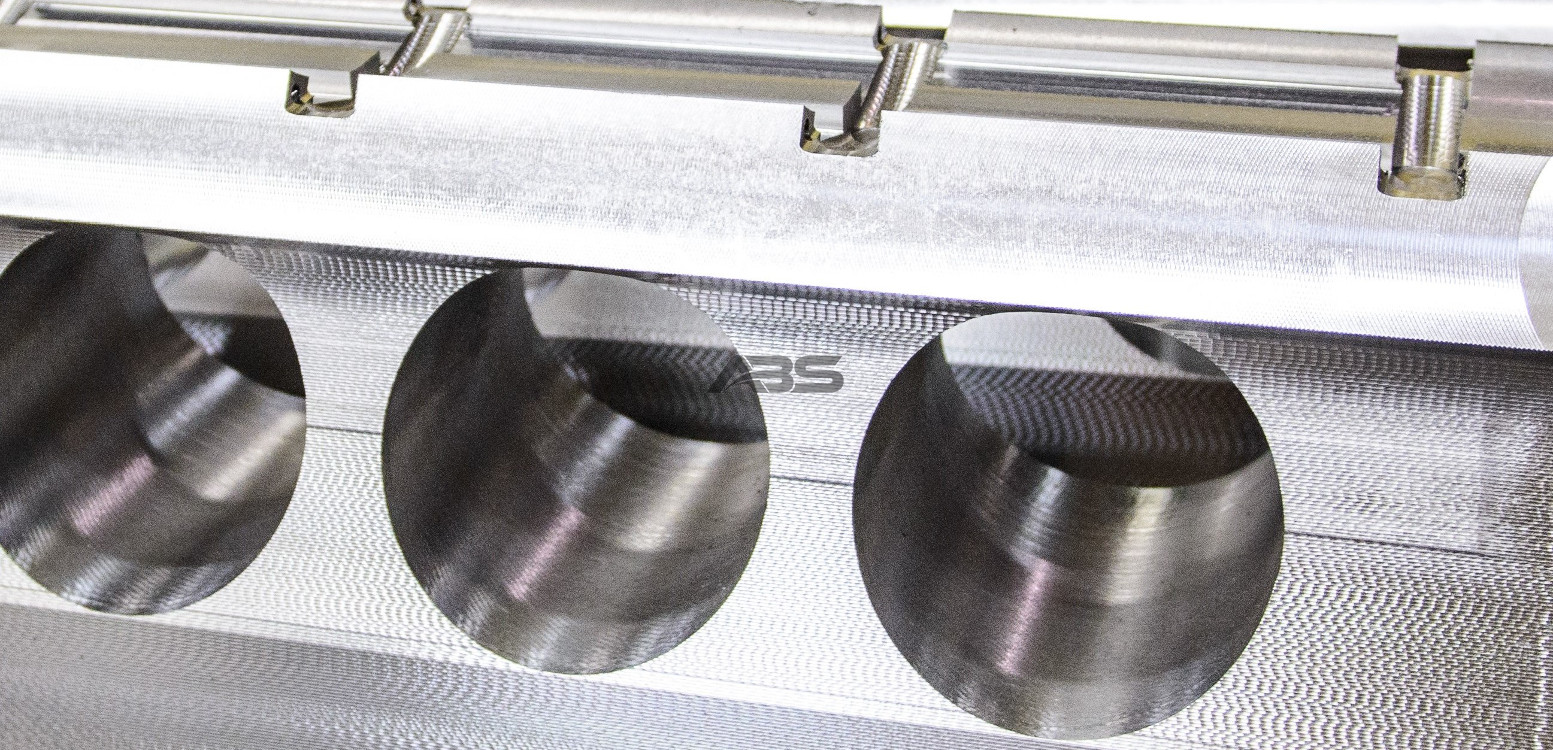

Achieving dimensional accuracy in ABS machining locations is non-negotiable for critical components in automotive, aerospace, and medical device manufacturing. ABS locations define the precise spatial relationship between mating parts, directly impacting assembly integrity, functional performance, and long-term reliability. Even micron-level deviations can cause catastrophic assembly failures, accelerated wear, or compromised safety margins in high-stress applications. At Wuxi Lead Precision Machinery, we understand that precision in these critical features transcends standard tolerancing; it requires deep material science knowledge, advanced process control, and unwavering commitment to repeatability. ABS locations often interface with dissimilar materials or complex geometries, making thermal management, residual stress control, and micro-surface finish paramount considerations during machining strategy development.

Material-specific challenges significantly influence ABS location precision. ABS plastics exhibit higher thermal expansion coefficients and lower rigidity compared to metals, demanding specialized fixturing to prevent distortion and meticulous control of cutting forces to avoid deflection or melting. Conventional metal machining parameters are insufficient; optimizing spindle speed, feed rate, and coolant strategy is essential to maintain dimensional stability and achieve the required geometric tolerances without inducing internal stresses that lead to post-machining drift. Our engineering team leverages decades of experience with polymer machining, developing proprietary techniques to counteract material-specific behaviors and ensure locations meet stringent GD&T requirements consistently.

Wuxi Lead Precision Machinery operates at the pinnacle of precision manufacturing, validated through demanding projects including Olympic venue structural components and classified military systems. These engagements required machining ABS locations within tolerances exceeding standard industry capabilities, often under extreme confidentiality and zero-defect mandates. Our success stems from integrating state-of-the-art equipment with rigorous process validation. Below are key specifications defining our capability envelope for critical location machining:

| Parameter | Value | Industry Standard Benchmark |

|---|---|---|

| Positioning Accuracy | ±0.001 mm (X, Y, Z) | ±0.005 mm |

| Repeatability | ±0.0005 mm | ±0.002 mm |

| Spindle Runout | < 0.0002 mm (T.I.R.) | < 0.001 mm |

| Thermal Compensation | Real-time, multi-point | Basic linear compensation |

| Surface Finish (Ra) | 0.2 – 0.8 µm (controlled) | 1.6 – 3.2 µm |

The consequences of imprecise ABS locations extend far beyond scrap parts; they risk entire system failures, costly field recalls, and reputational damage. Our approach combines advanced 5-axis machining centers with in-process probing and laser calibration, ensuring every location is verified against CAD models before part release. This level of control, forged through high-stakes projects for global defense and infrastructure leaders, is now available for your most demanding ABS machining requirements. Partner with Wuxi Lead Precision Machinery to transform your critical location specifications from engineering intent into flawless physical reality. Contact our engineering team to discuss your specific tolerancing challenges and material requirements.

Precision Specs & Tolerances

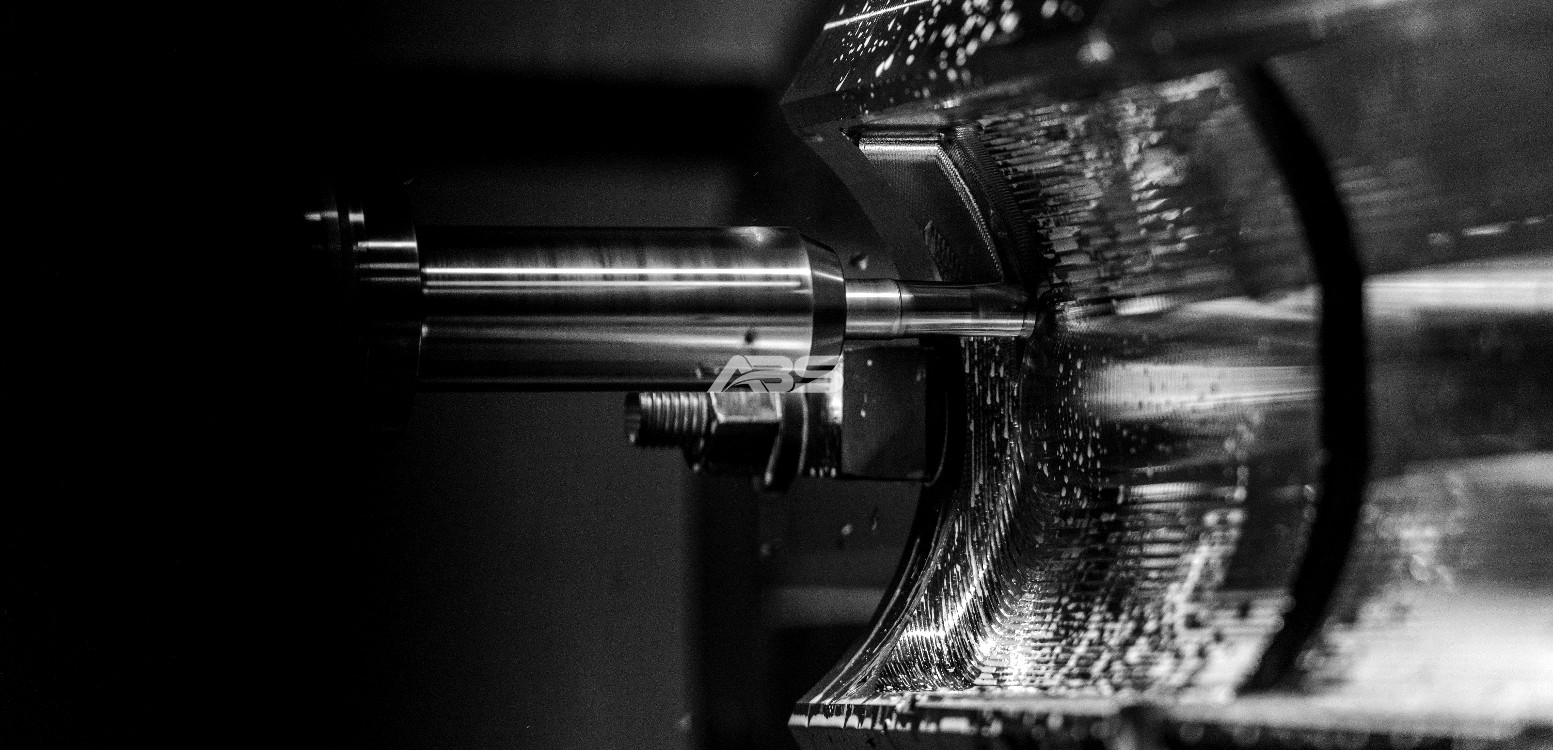

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions tailored for high-performance industries such as aerospace, medical, automation, and energy. At the core of our technical capabilities is a fully integrated 5-axis CNC machining platform, enabling us to produce complex, high-precision components with exceptional repeatability and surface finish. Our machining centers are equipped with state-of-the-art controls and tooling systems, allowing simultaneous multi-axis movement to access intricate geometries in a single setup. This reduces cumulative error, improves part accuracy, and significantly shortens lead times compared to conventional 3-axis methods.

Our 5-axis machining process supports a broad range of engineering-grade metals, including aluminum alloys, stainless steels, titanium, Inconel, and tool steels. Each job is supported by in-house CAD/CAM programming and toolpath optimization, ensuring efficient material removal and optimal surface integrity. We specialize in close-tolerance components with complex contours, undercuts, and organic shapes that are common in high-end industrial applications. Our facility maintains strict environmental controls and machine calibration schedules to ensure thermal stability and long-term dimensional consistency.

Quality assurance is embedded throughout our manufacturing workflow. Every critical dimension is verified using a Zeiss DuraMax and Contura G2 Coordinate Measuring Machine (CMM), providing traceable, high-resolution metrology data. Our inspection protocols follow ISO 10360 standards, and all reports are delivered with final shipments. In addition to first-article inspections, we implement in-process checks for high-volume runs, ensuring consistency across batches. All technicians are trained in GD&T (Geometric Dimensioning and Tolerancing), enabling precise interpretation of engineering intent.

The following table outlines our standard machining tolerances for custom metal components. These values represent our typical production capability; tighter tolerances are achievable upon engineering review and with appropriate design consideration.

| Feature | Standard Tolerance | Notes |

|---|---|---|

| Linear Dimensions (up to 100 mm) | ±0.010 mm | Tighter tolerances available on request |

| Linear Dimensions (100–300 mm) | ±0.015 mm | Depends on material and geometry |

| Linear Dimensions (300–600 mm) | ±0.025 mm | Requires process validation |

| Hole Diameter (reamed) | +0.010 / -0.000 mm | Up to 20 mm diameter |

| Positional Tolerance | ±0.015 mm | Per GD&T, relative to datum |

| Surface Roughness (Ra) | 0.8 µm (typical) | Can achieve 0.4 µm with fine finishing |

| Angular Features | ±0.05° | On 5-axis simultaneous machining |

| Flatness (per 100 mm) | 0.015 mm | On stress-relieved materials |

All tolerances are subject to design feasibility and material stability. We recommend early design consultation to optimize manufacturability and cost-efficiency. Wuxi Lead Precision Machinery combines advanced 5-axis technology with rigorous quality control to deliver precision components that meet the most demanding technical requirements.

Material & Finish Options

Material Selection for Precision Metal Components

Material selection directly impacts performance, cost, and manufacturability in high-tolerance CNC machining. At Wuxi Lead Precision Machinery, we prioritize pairing your application requirements with optimal metals and finishes to ensure durability, efficiency, and value. Below, we detail critical considerations for aluminum, steel, and titanium—three cornerstone materials in custom metal manufacturing—alongside anodizing solutions for enhanced functionality.

Aluminum dominates aerospace, automotive, and electronics due to its strength-to-weight ratio, thermal conductivity, and corrosion resistance. Grade 6061-T6 offers excellent machinability for structural components, while 7075-T6 provides superior strength for high-stress applications like drone frames or defense hardware. Its low density reduces fuel consumption in transportation, but note that aluminum’s softness necessitates careful toolpath planning to avoid burring. We recommend it for parts requiring tight tolerances under 0.005mm where weight savings are non-negotiable.

Steel variants deliver unmatched hardness and load-bearing capacity. 4140 alloy steel excels in shafts and gears needing fatigue resistance, while 304 stainless steel is ideal for medical or marine environments demanding corrosion immunity. However, steel’s abrasiveness accelerates tool wear, increasing production costs. For mission-critical components like hydraulic manifolds, we leverage our hardened carbide tooling and coolant systems to maintain ±0.002mm precision without compromising surface integrity.

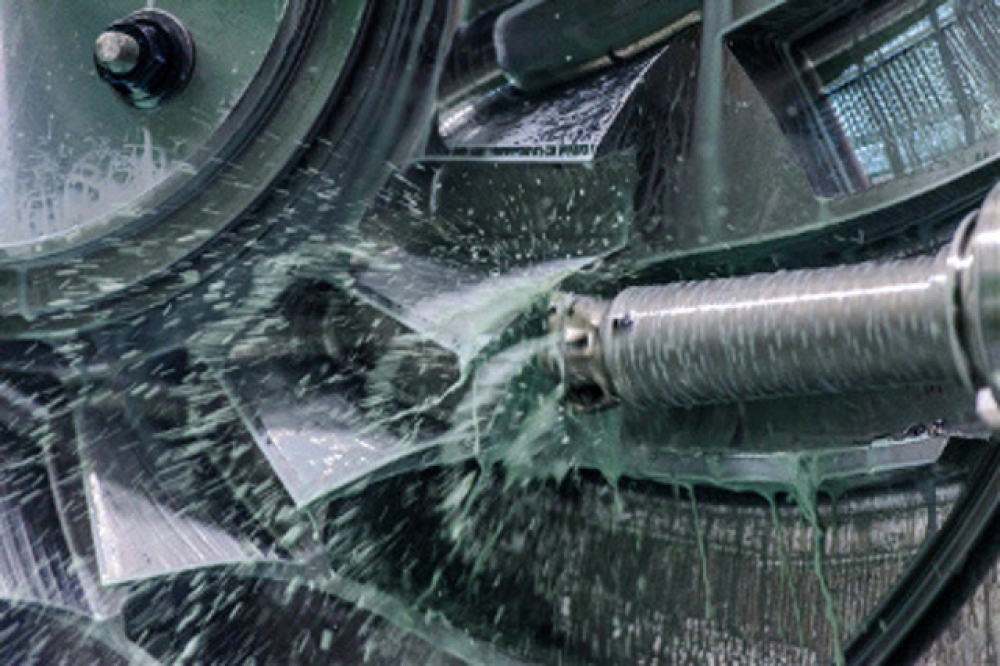

Titanium (Grade 5/Ti-6Al-4V) is the premium choice for extreme conditions—think jet engine mounts or surgical implants. Its biocompatibility and resistance to 600°C+ temperatures justify higher costs, but its low thermal conductivity complicates machining. Chips weld to cutters if speeds/feed rates aren’t meticulously calibrated. Our 5-axis CNC centers with rigid tapping capabilities prevent galling, ensuring seamless production of complex geometries.

Anodizing transforms aluminum surfaces beyond aesthetics. Type II (sulfuric acid) anodizing provides standard corrosion resistance for enclosures, while Type III (hardcoat) anodizing achieves 50–70 µm thickness for wear-resistant hydraulic pistons or rail components. This electrolytic process seals pores, boosting hardness to 60 HRC without dimensional changes—critical for press-fit assemblies. Always specify anodizing before machining; we integrate it into our workflow to avoid post-process rework.

Material Comparison for Critical Applications

| Material | Key Grades | Tensile Strength (MPa) | Density (g/cm³) | Best For |

|---|---|---|---|---|

| Aluminum | 6061-T6, 7075 | 310–572 | 2.7 | Lightweight structural parts |

| Steel | 4140, 304 SS | 655–965 | 7.8 | High-strength mechanical systems |

| Titanium | Ti-6Al-4V | 900–1,170 | 4.4 | Extreme-environment components |

Selecting the right material-finishing combination prevents over-engineering and reduces total cost of ownership. At Wuxi Lead, our engineering team collaborates with you from DFM analysis to final inspection, ensuring your material choice aligns with functional demands and production scalability. Contact us to discuss how our ISO 9001-certified processes optimize your next precision metal project.

Manufacturing Process & QC

The production process at Wuxi Lead Precision Machinery follows a rigorously structured workflow designed to ensure precision, consistency, and zero defects across all ABS machining projects. Our approach integrates advanced engineering with real-time quality verification, beginning with design and culminating in high-volume manufacturing. Each phase is optimized for performance, repeatability, and compliance with international standards.

Design serves as the foundation of every successful manufacturing initiative. Our engineering team collaborates closely with clients to analyze technical drawings, material specifications, and functional requirements. Using industry-leading CAD/CAM software, we develop 3D models and simulate machining paths to optimize tool engagement, cycle time, and dimensional accuracy. Finite element analysis (FEA) is applied when necessary to predict thermal and mechanical behavior under operational conditions. This digital validation ensures that design intent is fully realized before any physical prototype is produced.

Prototyping follows design finalization and functions as both a validation and refinement stage. We produce initial ABS-machined components using precision CNC milling and turning centers with sub-micron tolerance capabilities. These prototypes undergo comprehensive inspection via coordinate measuring machines (CMM), optical comparators, and surface profilometers to verify geometric accuracy and surface finish. Functional testing is conducted in simulated operating environments to assess fit, durability, and performance. Feedback from this stage is systematically integrated into process adjustments, ensuring that any potential deviation is corrected prior to scale-up.

Mass production is executed only after formal client approval and internal process sign-off. Our automated production lines operate under strict statistical process control (SPC), with real-time monitoring of critical parameters such as spindle load, tool wear, and environmental conditions. Every component is traceable through our digital manufacturing execution system (MES), which logs machine data, inspection results, and operator inputs. In-process inspections occur at predefined intervals, while final quality audits are conducted on 100% of critical dimensions for high-risk features. This layered approach to quality assurance ensures zero-defect delivery across batches of any size.

Throughout the entire production cycle, Wuxi Lead maintains full compliance with ISO 9001:2015 and IATF 16949 standards. Our facility is equipped with climate-controlled metrology labs and redundant calibration systems to sustain measurement integrity. Continuous improvement is driven by data analytics and root cause analysis, enabling proactive correction of potential process drift.

Below are key specifications for our ABS machining capabilities:

| Parameter | Specification |

|---|---|

| Material Compatibility | ABS (Acrylonitrile Butadiene Styrene) |

| Tolerance Range | ±0.005 mm to ±0.025 mm |

| Surface Finish (Ra) | 0.8 µm to 3.2 µm |

| Maximum Work Envelope | 1200 x 800 x 600 mm |

| CNC Machining Centers | 5-axis, 4-axis, 3-axis vertical milling |

| Quality Standards | ISO 9001:2015, IATF 16949, SPC, CMM reports |

| Production Capacity | Prototype to 50,000+ units annually |

| Lead Time (Prototype) | 7–12 days |

| Lead Time (Mass Production) | 15–30 days (varies by volume) |

This end-to-end process ensures that every ABS-machined component meets the highest standards of precision, reliability, and performance.

Why Choose Wuxi Lead Precision

Elevate Your ABS Alloy Machining Capabilities with Lead Precision

Precision machining of Aluminum-Brass-Steel (ABS) alloys demands uncompromising technical expertise and process stability. At Wuxi Lead Precision Machinery, we specialize in high-tolerance ABS component manufacturing for aerospace, medical, and semiconductor industries where material integrity directly impacts product performance. Unlike generic plastic ABS, our focus on metal ABS alloys ensures superior thermal conductivity, mechanical strength, and dimensional stability under extreme operational conditions. Partnering with us mitigates supply chain risks while accelerating your time-to-market through integrated engineering support and rigorous quality validation.

Our ISO 9001-certified facility in Wuxi, China, combines 15+ years of metallurgical insight with advanced 5-axis CNC technology. We maintain strict control over material sourcing from certified global suppliers, ensuring consistent alloy composition and traceability. Every ABS component undergoes multi-stage inspection using Zeiss CMMs and optical comparators, validating geometric accuracy against ASME Y14.5 standards. This disciplined approach eliminates costly rework and guarantees seamless integration into your final assemblies.

Critical ABS Machining Specifications

| Parameter | Capability Range | Industry Standard Compliance |

|---|---|---|

| Material Groups | 6061-T6, 7075-T7351 Aluminum; C36000 Brass; 4140 Steel | AMS, ASTM, MIL-SPEC |

| Tolerance Range | ±0.005 mm (±0.0002″) | GD&T Level A |

| Max Part Size | 1200 x 800 x 600 mm (47 x 31 x 24″) | N/A |

| Surface Finish | Ra 0.4 µm (16 µin) to Ra 1.6 µm (63 µin) | ISO 1302 |

| Lead Time (Prototype) | 10-15 business days | N/A |

We recognize that ABS alloy selection directly influences fatigue resistance and thermal management in mission-critical applications. Our engineering team collaborates from initial design review to final production, optimizing toolpaths for minimal residual stress and burr-free edges. This proactive partnership reduces material waste by up to 22% compared to conventional machining approaches while ensuring repeatability across volumes from 1 to 10,000+ units. All processes adhere to stringent IP protection protocols, with NDAs standard for every engagement.

Choosing Wuxi Lead Precision means investing in measurable outcomes: 99.8% first-pass yield rates, full material certification documentation, and responsive technical escalation paths. Our clients consistently achieve 30% faster validation cycles due to our integrated metrology workflow and real-time production data transparency. For complex ABS components where micron-level deviations compromise system functionality, our facility delivers the reliability your engineering team requires.

Initiate a technical dialogue today to discuss your ABS machining challenges. Contact our engineering team directly at [email protected] with your part specifications and volume requirements. We will provide a detailed capability assessment within 24 business hours, including feasibility analysis and optimized cost-per-part projection. Let Lead Precision become your strategic manufacturing partner for uncompromised ABS alloy performance.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.