Technical Contents

Engineering Guide: Cnc Milling Vacancies

Engineering Insight: CNC Milling Vacancies and the Critical Role of Precision in Advanced Manufacturing

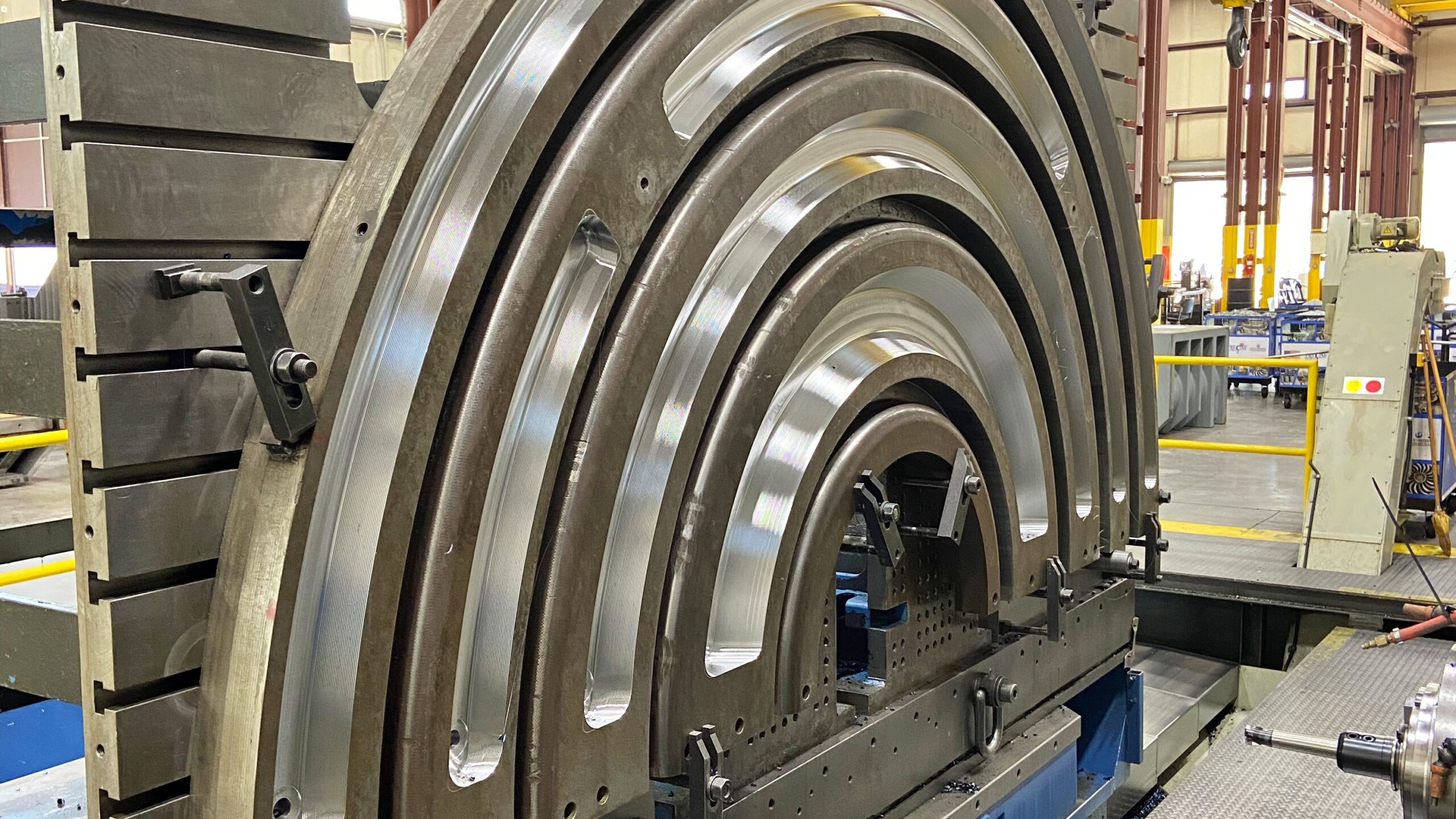

In the realm of high-end precision CNC machining, the term “CNC milling vacancies” does not refer to job openings, but rather to the strategic absence of material—intentional voids or cavities precisely milled into metal components during the manufacturing process. These vacancies are far from incidental; they are engineered features critical to the performance, weight distribution, thermal management, and structural integrity of advanced mechanical systems. At Wuxi Lead Precision Machinery, we understand that the precision with which these cavities are machined directly impacts the functionality and reliability of the final product, especially in sectors where tolerances are measured in microns.

Our expertise in CNC milling vacancies stems from over a decade of serving industries where failure is not an option—Olympic-grade sporting equipment, aerospace systems, and military defense technologies. In such applications, the geometry, surface finish, and dimensional accuracy of milled cavities must meet exacting standards. For example, in aerospace components, reducing mass through precision-milled internal channels must not compromise structural strength. Similarly, in high-performance optical mounts used in defense systems, cavities must align with sub-micron repeatability to ensure sensor accuracy under extreme conditions.

At Lead Precision, our 5-axis CNC milling centers, equipped with high-resolution probing systems and thermal compensation algorithms, enable us to produce complex internal geometries with tolerances as tight as ±0.002 mm. Our process begins with advanced CAM simulation to validate tool paths and avoid collisions, especially when accessing deep, narrow cavities. We utilize solid carbide micro-tools with adaptive feed controls to maintain surface integrity and dimensional consistency, even in hardened steels and exotic alloys such as Inconel 718 and titanium Grade 5.

Material selection and fixturing strategy are equally vital. We employ custom vacuum and modular clamping systems to minimize deformation during milling, ensuring that thin walls and deep pockets remain within specification. All finished components undergo full CMM inspection, with GD&T reports provided for traceability—essential for compliance in military (MIL-STD) and aerospace (AS9100) certifications.

The following table outlines key specifications achievable in our CNC milling vacancy operations:

| Parameter | Capability |

|---|---|

| Positional Accuracy | ±0.002 mm |

| Surface Finish (Ra) | As low as 0.4 μm |

| Minimum Cavity Depth | Up to 150 mm with aspect ratio 10:1 |

| Materials Processed | Aluminum 7075, Titanium Ti-6Al-4V, Inconel 718, Tool Steel (H13, S136) |

| Tolerance Class | IT6 to IT7 per ISO 286 |

| Machining Centers | 5-axis simultaneous, XYZABC configuration |

| Inspection Equipment | Zeiss CMM, Optical Comparator, Roughness Tester |

Our proven track record in delivering mission-critical components for Olympic athletes and defense contractors underscores our mastery in transforming design intent into precision reality. When engineering CNC milling vacancies, it is not merely about removing material—it is about achieving perfection in absence. At Wuxi Lead Precision Machinery, we ensure that every void is as precisely defined as the part itself.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Demanding Applications

Wuxi Lead Precision Machinery operates at the forefront of advanced CNC manufacturing, delivering exceptional precision and complexity for the most demanding aerospace, medical, and industrial components. Our core strength lies in integrating cutting-edge multi-axis technology with rigorous quality control protocols, ensuring every part meets exacting global standards and exceeds client expectations. This capability directly addresses critical challenges in high-mix, low-volume production environments where accuracy, repeatability, and geometric complexity are non-negotiable.

Our facility is anchored by a strategic fleet of high-performance 5-axis CNC machining centers, primarily featuring industry-leading Haas and DMG MORI models. These machines are not merely multi-axis capable; they deliver true simultaneous 5-axis interpolation, enabling the production of intricate organic shapes, deep cavities, and complex undercuts in a single setup. This eliminates cumulative errors from multiple fixtures, drastically reduces lead times, and significantly enhances part integrity. All equipment is maintained under strict preventative maintenance schedules and operated by Wuxi Lead-certified engineers with deep expertise in advanced CAM programming and high-precision machining strategies for exotic alloys, titanium, high-temp composites, and hardened steels.

Quality assurance is seamlessly integrated into our manufacturing workflow, not an afterthought. Every critical dimension and geometric feature undergoes comprehensive verification using state-of-the-art Coordinate Measuring Machines (CMMs), including Zeiss and Hexagon systems with sub-micron accuracy. Our AS9100-certified quality management system mandates full first-article inspection reports (FAIRs) and in-process checks against client-supplied GD&T specifications. This data-driven approach provides complete traceability and ensures statistical process control, minimizing scrap and guaranteeing conformance batch after batch. We leverage metrology data not just for pass/fail validation, but for continuous process refinement and predictive capability analysis.

The table below details our standard and precision tolerance capabilities across common material classes, reflecting our commitment to dimensional stability and surface finish excellence. These figures represent achievable results under controlled production conditions for qualified parts; specific project requirements are always evaluated during the quoting phase.

| Material Category | Standard Tolerance (mm) | Precision Tolerance (mm) | Typical Surface Finish (Ra µm) |

|---|---|---|---|

| Aluminum Alloys | ±0.025 | ±0.005 to ±0.010 | 0.8 – 1.6 |

| Carbon & Alloy Steels | ±0.025 | ±0.008 to ±0.015 | 0.8 – 3.2 |

| Stainless Steels | ±0.025 | ±0.008 to ±0.015 | 0.8 – 3.2 |

| Titanium Alloys | ±0.025 | ±0.010 to ±0.020 | 1.6 – 3.2 |

| Engineering Plastics | ±0.050 | ±0.020 to ±0.040 | 1.6 – 6.3 |

This combination of advanced 5-axis machining capacity, uncompromising CMM-based quality validation, and demonstrable tolerance mastery positions Wuxi Lead as a strategic partner for OEMs requiring zero-defect components. We transform complex designs into reality with the precision, reliability, and technical depth demanded by next-generation manufacturing challenges, directly supporting the high-caliber engineering roles within our organization. Partner with us to leverage capabilities that mitigate risk and accelerate your time-to-market.

Material & Finish Options

Material Selection in Precision CNC Milling: Aluminum, Steel, and Titanium

Selecting the appropriate material is a critical step in the CNC milling process, directly influencing part performance, durability, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in high-precision CNC milling of engineering-grade metals, with extensive expertise in aluminum, steel, and titanium. Each material offers distinct mechanical properties and is suited to specific industrial applications, from aerospace components to medical devices and automotive systems.

Aluminum is widely favored for its excellent strength-to-weight ratio, thermal conductivity, and machinability. It is particularly ideal for applications requiring lightweight yet durable parts, such as heat sinks, enclosures, and structural components in aerospace and electronics. The most commonly used grade in precision machining is 6061-T6, which provides good corrosion resistance and weldability. Due to its softness compared to steel and titanium, aluminum allows for faster machining speeds, reducing production time and tool wear.

Steel, particularly in its alloy and stainless forms, delivers superior strength, hardness, and wear resistance. Grades such as 4140, 17-4 PH, and 304/316 stainless steel are routinely used in high-stress environments, including oil and gas, defense, and heavy machinery. While steel is more challenging to machine due to its toughness and tendency to generate heat, our advanced CNC milling systems are optimized to maintain tight tolerances and surface integrity. Stainless steel variants also offer excellent corrosion resistance, making them suitable for medical and food-processing applications.

Titanium, especially Grade 5 (Ti-6Al-4V), is the material of choice for extreme performance conditions. Its exceptional strength-to-density ratio, biocompatibility, and resistance to high temperatures and corrosion make it indispensable in aerospace, military, and biomedical industries. However, titanium’s low thermal conductivity and high chemical reactivity require specialized tooling and cutting strategies. At Wuxi Lead, our engineers apply precise feed rates, coolant management, and high-performance carbide tools to ensure dimensional accuracy and surface quality when milling titanium components.

Common Material Properties for CNC Milling

| Material | Tensile Strength (MPa) | Hardness (HB) | Density (g/cm³) | Common Applications |

|---|---|---|---|---|

| Aluminum 6061-T6 | 310 | 95 | 2.70 | Aerospace, Electronics, Enclosures |

| Steel 4140 | 950 | 220 | 7.85 | Automotive, Tooling, Defense |

| Stainless 316 | 580 | 160 | 8.00 | Medical, Marine, Food Processing |

| Titanium Ti-6Al-4V | 900 | 360 | 4.43 | Aerospace, Biomedical, Racing |

Surface Finishing: Anodizing for Aluminum

Anodizing is a key post-processing technique for aluminum parts, enhancing surface durability, corrosion resistance, and aesthetic quality. The process creates a controlled oxide layer on the surface, which can be dyed in various colors for identification or branding. Type II (sulfuric acid) and Type III (hardcoat) anodizing are commonly used, with Type III providing thicker, wear-resistant coatings suitable for high-abrasion environments. At Wuxi Lead, we offer precision anodizing services with strict process control to ensure uniform coating thickness and adherence to international standards.

Material and finish selection must align with functional requirements, environmental exposure, and lifecycle demands. Our engineering team collaborates closely with clients to recommend optimal material-grade and surface treatment combinations, ensuring performance and reliability in every precision-machined component.

Manufacturing Process & QC

Precision CNC Milling Production Process: From Concept to Zero-Defect Delivery

At Wuxi Lead Precision Machinery, our CNC milling production process is engineered for uncompromising quality and efficiency, directly supporting the high-caliber talent we seek in CNC milling vacancies. We understand that exceptional parts begin long before the spindle engages. Our rigorously defined workflow—Design, Prototyping, Mass Production—ensures dimensional accuracy, material integrity, and flawless functionality, eliminating defects at the source. This systematic approach is not merely a procedure; it is the foundation of our reputation and the standard we expect from every engineer and machinist on our team.

The Design phase is where precision is conceptualized. Our engineering team collaborates closely with clients, utilizing advanced CAD/CAM software to develop models that prioritize manufacturability alongside function. Critical attention is given to Geometric Dimensioning and Tolerancing (GD&T), material selection based on metallurgical validation, and toolpath optimization. We conduct thorough Design for Manufacturing (DFM) analysis, identifying potential stress points, minimizing setup complexity, and ensuring thermal compensation strategies are embedded. This proactive engineering prevents 90% of potential production errors before metal is cut, setting the stage for success and demanding engineers who think critically about process integration.

Prototyping transforms validated designs into tangible reality under controlled conditions. Using the same high-precision 5-axis CNC mills deployed in full production, we manufacture initial units with meticulous attention to setup and measurement. Every prototype undergoes comprehensive First Article Inspection (FAI) per AS9102 standards, including full CMM reporting, surface finish verification, and material property checks. This phase is crucial for validating tooling, fixturing, and the final machining strategy. Feedback loops between our skilled machinists, quality technicians, and design engineers are immediate, allowing rapid iteration. Only when the prototype meets or exceeds all specifications—proven through documented evidence—does the process advance. This stage exemplifies the problem-solving expertise required for our CNC milling roles.

Mass Production leverages the perfected process for consistent, high-volume output. Our state-of-the-art facility employs real-time Statistical Process Control (SPC), with in-process inspections at critical control points and 100% automated vision or laser scanning for key features on high-mix lines. Tool wear is monitored continuously via sensor integration, triggering automatic compensation or replacement. Every component undergoes final inspection against the approved prototype baseline. Our commitment to Zero Defects is quantifiable and driven by a culture where every team member owns quality.

Wuxi Lead Precision Zero-Defect Production Specifications

| Parameter | Specification | Verification Method |

|---|---|---|

| Process Capability (Cpk) | ≥ 1.67 (Six Sigma Level) | SPC Control Charts, Real-Time Monitoring |

| Dimensional Accuracy | ± 0.002 mm (Standard) | CMM, Optical Comparators |

| Surface Finish (Ra) | As low as 0.4 µm | Profilometer, Visual Standards |

| FAI Compliance | 100% AS9102 Adherence | Comprehensive FAI Report |

| In-Process Inspection | Min. 5% per batch (Critical Features 100%) | Automated Gauging, Operator Checks |

This seamless transition from Design through Prototyping to Mass Production, governed by stringent specifications and a relentless focus on prevention, defines Wuxi Lead’s operational excellence. It creates an environment where precision engineers thrive, solving complex challenges within a system built for perfection. We seek CNC milling professionals who are not just operators, but integral contributors to this zero-defect ecosystem, ensuring every part shipped meets the exacting demands of aerospace, medical, and advanced industrial applications. Join us to master and advance the pinnacle of precision manufacturing.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched CNC Milling Expertise

At Wuxi Lead Precision Machinery, we understand that in high-end manufacturing, precision, reliability, and consistency are non-negotiable. As a leader in precision CNC machining based in Wuxi, China, we specialize in delivering custom-engineered components that meet the most demanding specifications across aerospace, medical, automation, and advanced industrial sectors. Our commitment to excellence is reflected not only in our advanced manufacturing capabilities but in our collaborative approach to partnership.

If you are seeking a trusted provider for CNC milling services, look no further. Our state-of-the-art facility is equipped with high-performance 3-axis, 4-axis, and 5-axis CNC milling centers, enabling us to produce complex geometries with micron-level accuracy. With decades of combined engineering experience and a culture rooted in continuous improvement, we ensure every component we deliver exceeds expectations for quality, performance, and on-time delivery.

Our integrated quality control system utilizes coordinate measuring machines (CMM), optical comparators, and surface roughness testers to verify conformance to tight tolerances. Whether you require low-volume prototypes or high-volume production runs, our agile manufacturing processes are designed to scale with your needs while maintaining full traceability and compliance with international standards, including ISO 9001:2015.

We recognize that every client has unique requirements. That’s why we offer end-to-end support—from design consultation and material selection to post-processing and global logistics. Our engineering team works closely with your R&D and production departments to optimize part design for manufacturability, reduce lead times, and lower total cost of ownership.

To ensure transparency and efficiency, we provide real-time project tracking, detailed inspection reports, and responsive communication at every stage of production. When you partner with Wuxi Lead Precision Machinery, you gain more than a supplier—you gain a strategic ally committed to your success.

Explore the full potential of precision CNC milling with a team that values accuracy as much as you do.

| Specification | Capability |

|---|---|

| Milling Axes | 3-axis, 4-axis, 5-axis |

| Maximum Work Envelope | 1200 mm × 800 mm × 600 mm |

| Tolerance | ±0.005 mm |

| Surface Finish | As low as Ra 0.4 μm |

| Materials Supported | Aluminum, Stainless Steel, Titanium, Brass, PEEK, Delrin, and other engineering-grade alloys and polymers |

| Quality Standards | ISO 9001:2015 certified, Full inspection reporting |

| Lead Times | Prototype: 7–10 days; Production: 15–25 days (varies by complexity) |

Contact us today to discuss your CNC milling requirements. Send your drawings, specifications, or project inquiries to [email protected] and let our engineers provide a detailed quote and technical feedback within 24 hours. At Wuxi Lead Precision Machinery, we don’t just manufacture parts—we build precision partnerships.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.