Technical Contents

Engineering Guide: Ribbed Moulding

Engineering Insight Precision Imperatives in Ribbed Moulding Fabrication

Ribbed moulding is far more than an aesthetic feature in high-performance metal components. Its primary engineering function lies in significantly enhancing structural rigidity while minimizing weight—a critical balance demanded by aerospace, defense, and advanced infrastructure applications. The geometric complexity of ribs introduces acute challenges in material flow, thermal management, and stress distribution during forming. Even minor deviations in rib profile, spacing, or base thickness can trigger catastrophic dimensional instability or fatigue failure under operational loads. Precision here is non-negotiable; it directly dictates component longevity and system safety. At Wuxi Lead Precision Machinery, we treat ribbed moulding as a high-stakes engineering discipline, not merely a shaping process.

The consequences of inadequate precision manifest rapidly. Inconsistent rib depth causes uneven stress concentration, accelerating crack propagation in dynamic environments. Poorly controlled wall thickness between ribs compromises thermal dissipation—critical for electronics housings or engine components—leading to overheating and premature failure. Surface finish irregularities at rib junctions create initiation points for corrosion, especially in marine or chemical exposure scenarios. These risks escalate exponentially when tolerances exceed ±0.05mm, a threshold where many standard manufacturers operate. Lead Precision’s CNC-driven approach maintains tolerances down to ±0.005mm, ensuring ribs perform their structural role predictably across temperature extremes and cyclic stresses. Our process integrates real-time thermal compensation algorithms and multi-axis in-process metrology, eliminating the “trial-and-error” common in conventional ribbed moulding.

This rigor stems from direct experience with zero-failure-critical sectors. We engineered ribbed structural supports for Beijing’s National Stadium roof system, where wind-load resistance demanded micron-level rib uniformity across 50-meter spans. Similarly, our components for classified defense systems undergo 100% volumetric inspection to verify rib integrity under simulated blast conditions. Such projects cement our understanding: ribbed moulding precision separates functional parts from mission-critical assets.

Our validated capabilities for complex ribbed geometries include:

| Parameter | Capability Range | Industry Benchmark |

|---|---|---|

| Rib Depth Tolerance | ±0.005 mm to ±0.02 mm | ±0.05 mm to ±0.1 mm |

| Minimum Rib Thickness | 0.3 mm (stainless steel) | 0.8 mm |

| Rib Spacing Accuracy | ±0.01 mm | ±0.05 mm |

| Surface Roughness (Ra) | 0.4 μm to 1.6 μm | 3.2 μm to 6.3 μm |

| Material Thickness Range | 0.5 mm to 12.0 mm | 1.0 mm to 8.0 mm |

Wuxi Lead Precision Machinery’s mastery of ribbed moulding is forged in environments where compromise is not an option. When your application demands ribs that actively contribute to structural resilience—not just passive form—our Olympic-proven and military-validated processes deliver the dimensional certainty your engineering integrity requires. Partner with us to transform ribbed moulding from a manufacturing challenge into a performance advantage.

Precision Specs & Tolerances

Advanced Manufacturing Capabilities for Precision Ribbed Moulding

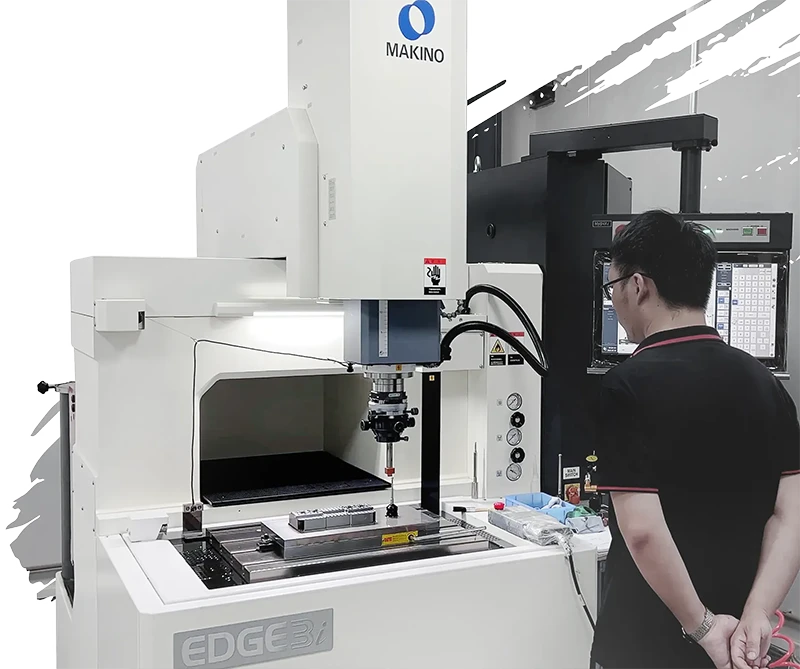

At Wuxi Lead Precision Machinery, we specialize in high-precision custom metal manufacturing, with a particular focus on complex ribbed moulding components used in aerospace, automotive, and industrial machinery applications. Our technical expertise is built around advanced 5-axis CNC machining systems, which enable us to produce intricately contoured rib structures with exceptional accuracy and surface integrity. These multi-axis platforms allow simultaneous machining from multiple angles, eliminating the need for multiple setups and significantly reducing cumulative error, part distortion, and lead times.

Our 5-axis CNC centers are equipped with high-speed spindles, automated tool changers, and real-time cutting condition monitoring. This ensures consistent material removal rates and optimal tool engagement, critical when machining deep, thin ribs in high-strength alloys such as titanium, aluminum 7075, and stainless steel 17-4 PH. The dynamic motion control of our machines supports continuous contouring, enabling smooth transitions across complex geometries typical in rib-reinforced structural panels and mould tooling.

To maintain the highest standards of dimensional accuracy, every component undergoes comprehensive quality verification using state-of-the-art Coordinate Measuring Machine (CMM) inspection. Our CMM systems are integrated into the production workflow, allowing for both first-article inspection and in-process checks. Utilizing tactile and optical probes, these systems capture thousands of data points to validate geometric dimensioning and tolerancing (GD&T), ensuring conformity to ISO 1101 and ASME Y14.5 standards. All inspection reports are documented and traceable, providing full transparency for audit and compliance purposes.

We are committed to delivering parts that meet or exceed the most stringent industry requirements. Our process control systems are supported by a climate-controlled metrology lab and regular machine calibration in accordance with ISO 10791 and ISO 230 standards. This holistic approach to quality ensures thermal stability, repeatability, and long-term process capability.

The table below outlines our standard achievable tolerances for ribbed moulding components under controlled production conditions.

| Feature | Standard Tolerance | High-Precision Option | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.010 mm | Up to 500 mm |

| Positional Tolerance | ±0.03 mm | ±0.015 mm | Relative to datum |

| Profile of Surface | 0.05 mm | 0.02 mm | Full form control |

| Rib Wall Thickness | ±0.05 mm | ±0.02 mm | Minimum 0.8 mm achievable |

| Angular Accuracy | ±0.05° | ±0.02° | Between features |

| Surface Finish (Ra) | 1.6 µm | 0.4 µm | As machined, no post-process |

Our technical capabilities are reinforced by a team of experienced process engineers who optimize toolpaths, select appropriate cutting strategies, and validate designs for manufacturability. This engineering-first approach ensures that every ribbed moulding component is produced with maximum efficiency, structural integrity, and dimensional fidelity.

Material & Finish Options

Material Selection for Precision Ribbed Moulding Components

Selecting the optimal material for ribbed moulding components is critical to achieving structural integrity, thermal performance, and longevity in demanding applications. Rib geometry amplifies stress concentrations, requiring materials with balanced strength, machinability, and corrosion resistance. At Wuxi Lead Precision Machinery, we engineer solutions where material properties directly align with your operational environment and performance targets.

Aluminum alloys, particularly 6061-T6 and 7075-T6, dominate lightweight structural applications. Their high strength-to-weight ratio ensures rigidity in thin-walled rib designs while minimizing mass. Aluminum’s thermal conductivity aids heat dissipation in electronics housings or aerospace enclosures. However, untreated aluminum lacks surface hardness for high-wear interfaces, necessitating protective finishes. Steel variants like 304 stainless or 4140 alloy deliver superior strength and wear resistance for heavy-load industrial mouldings. Their density suits applications where mass stabilizes vibration, though corrosion resistance requires careful grade selection or coating. Titanium Ti-6Al-4V excels in extreme environments—marine, aerospace, or chemical processing—where unparalleled corrosion resistance and strength at elevated temperatures justify its premium cost. Its low thermal expansion maintains rib dimensional stability under thermal cycling but demands specialized CNC tooling to manage work hardening.

Surface finishing is non-negotiable for ribbed geometries. Anodizing transforms aluminum’s surface into a durable, non-conductive ceramic layer. Type II (sulfuric acid) anodizing provides moderate wear resistance and dye compatibility for aesthetic or identification purposes. For critical rib interfaces exposed to abrasion or electrical arcing, Type III (hardcoat) anodizing delivers 50–70 μm thickness with Rockwell C60+ hardness, preserving intricate rib detail while resisting galling. Note that steel and titanium require alternative processes: steel benefits from passivation or electroless nickel plating, while titanium often uses inert anodizing for color-coding without enhancing wear resistance.

Material performance specifications guide high-stakes decisions. Refer to the comparative data below:

| Material | Yield Strength (MPa) | Density (g/cm³) | Corrosion Resistance | Typical Rib Applications |

|---|---|---|---|---|

| Aluminum 6061-T6 | 276 | 2.70 | Moderate (enhanced with anodizing) | Lightweight enclosures, heat sinks, rail components |

| Steel 304 SS | 215 | 8.00 | High (chloride-prone) | Industrial frames, hydraulic manifolds, marine hardware |

| Titanium Ti-6Al-4V | 880 | 4.43 | Exceptional | Aerospace brackets, medical implants, offshore connectors |

Material choice impacts CNC machining strategy. Aluminum allows aggressive feeds for cost efficiency in complex ribs. Steel requires rigid setups to prevent deflection in deep ribs. Titanium mandates lower cutting speeds and specialized toolpaths to avoid heat buildup. Always integrate finish requirements early—hard anodizing tolerances affect rib root radii and edge definition. Partner with our engineering team to validate material-finish synergy for your ribbed component’s lifecycle demands. We ensure your selection optimizes performance, manufacturability, and total cost of ownership.

Manufacturing Process & QC

Design Phase: Precision Engineering for Ribbed Moulding

The foundation of flawless ribbed moulding production begins with a comprehensive design phase, where engineering precision meets functional requirements. At Wuxi Lead Precision Machinery, our design team leverages advanced CAD/CAM software to develop detailed 3D models tailored to client specifications. Each ribbed moulding profile is analyzed for structural integrity, thermal distribution, and material flow dynamics to ensure optimal performance during extrusion or stamping. Finite Element Analysis (FEA) is routinely applied to simulate stress points and deformation risks, allowing for preemptive design corrections. Close collaboration with clients ensures dimensional accuracy, surface finish requirements, and compatibility with downstream assembly processes. Tolerances are defined down to ±0.02 mm, and all design outputs are validated through internal Design for Manufacturability (DFM) reviews before progression.

Prototyping: Validating Form, Fit, and Function

Once the design is finalized, a functional prototype is produced using high-precision CNC machining or rapid tooling methods. This stage is critical for verifying the geometric accuracy and mechanical behavior of the ribbed profile under real-world conditions. Prototypes undergo rigorous testing, including dimensional inspection via coordinate measuring machines (CMM), surface roughness evaluation, and mechanical load testing. Any deviations are documented and addressed through iterative refinements. Client feedback is integrated at this stage to confirm alignment with application needs. Only after full approval—ensuring form, fit, and function are met—does the project advance to mass production. This controlled validation process eliminates costly errors and establishes a benchmark for quality consistency.

Mass Production: Zero-Defect Manufacturing Execution

Mass production of ribbed moulding components is executed on automated, high-speed lines equipped with real-time monitoring systems. Our facility utilizes closed-loop process control to maintain strict adherence to dimensional and surface quality standards. Each production run begins with first-article inspection, followed by in-process checks at defined intervals. Statistical Process Control (SPC) data is continuously logged to detect trends and prevent non-conformance. All operators are trained in Six Sigma methodologies, and our ISO 9001-certified quality management system ensures full traceability from raw material to final shipment. End-of-line inspection includes 100% visual checks and random sampling for metallurgical verification. The result is a zero-defect output, delivering consistent, high-integrity components at scale.

Typical Production Specifications for Ribbed Moulding

| Parameter | Specification |

|---|---|

| Material Options | Aluminum 6063, 6061, 7075; Stainless Steel 304, 316 |

| Standard Tolerances | ±0.02 mm (dimensional), ±0.05 mm (profile) |

| Surface Finish | Matte, Anodized (clear/hard), Powder Coated |

| Minimum Rib Height | 0.8 mm |

| Maximum Profile Length | 6,000 mm (custom lengths available) |

| Production Lead Time | 15–25 days (including prototyping) |

| Quality Standards | ISO 9001:2015, RoHS, SPC-controlled |

| Packaging | Anti-corrosion film, custom palletization |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised Ribbed Moulding Excellence

At Wuxi Lead Precision Machinery, we engineer ribbed moulding solutions where dimensional accuracy and structural integrity are non-negotiable. Our 15-year specialization in high-tolerance metal fabrication ensures your rib profiles meet exacting functional and aesthetic requirements, whether for architectural cladding, aerospace components, or industrial enclosures. Generic manufacturers compromise on repeatability; we deploy advanced 5-axis CNC milling and Swiss-type turning systems calibrated to ±0.005mm, eliminating common defects like rib distortion or surface micro-fractures. This precision translates directly to reduced assembly failures, seamless finishing compatibility, and extended product lifecycle—critical for clients operating in regulated or high-stress environments.

Our process begins with a rigorous Design for Manufacturability (DFM) review, where our engineering team collaborates to optimize rib geometry, material selection, and toolpath strategies. We prioritize minimizing secondary operations through integrated machining sequences, ensuring consistent wall thickness and rib alignment across complex contours. Below are key capabilities defining our ribbed moulding output:

| Specification | Capability | Industry Standard Comparison |

|---|---|---|

| Tolerance Control | ±0.005mm (5 microns) | Typical: ±0.025mm |

| Material Range | Aluminum 6061-T6, 7075; Stainless 304/316; Titanium Gr5 | Limited alloys common |

| Max Work Envelope | 1,200 x 800 x 600mm | Often < 800mm in Z-axis |

| Surface Finish | Ra 0.4µm (as-machined); Anodizing/PVD ready | Ra 1.6µm typical |

| Lead Time (Prototype) | 12–18 business days | 25+ days industry average |

This technical rigor is backed by full material traceability, in-process CMM verification at critical stages, and compliance with ISO 9001:2015 and AS9100D standards. We understand that a single rib deviation can cascade into field failures—our zero-defect philosophy means we treat every component as mission-critical.

Initiate your project with a partner who treats your specifications as engineering mandates, not suggestions. Contact our precision engineering team directly at [email protected] to submit your technical drawings and receive a DFM analysis within 48 hours. Include your target tolerances, annual volume, and material requirements for a tailored capability assessment. For urgent RFQs, reference “Ribbed Moulding Priority” in your subject line to expedite technical review.

Wuxi Lead Precision Machinery delivers more than parts—we deliver dimensional certainty. Let our CNC expertise become your competitive advantage. Reach out today to finalize specifications and secure production capacity. Your ribbed moulding challenges demand exacting solutions; we provide them.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.