Technical Contents

Engineering Guide: Cheap Laser Cutting Service

Engineering Insight: Precision in Laser Cutting – Beyond the Price Tag

When sourcing a laser cutting service, the term “cheap” often triggers assumptions about cost versus quality. At Wuxi Lead Precision Machinery, we understand that in high-end sheet metal fabrication, true value is not measured solely by price, but by precision, repeatability, and engineering integrity. While competitive pricing is important, especially in large-scale manufacturing, compromising on accuracy can lead to cascading failures in assembly, fit, and performance—costing far more in rework, delays, and reputational damage.

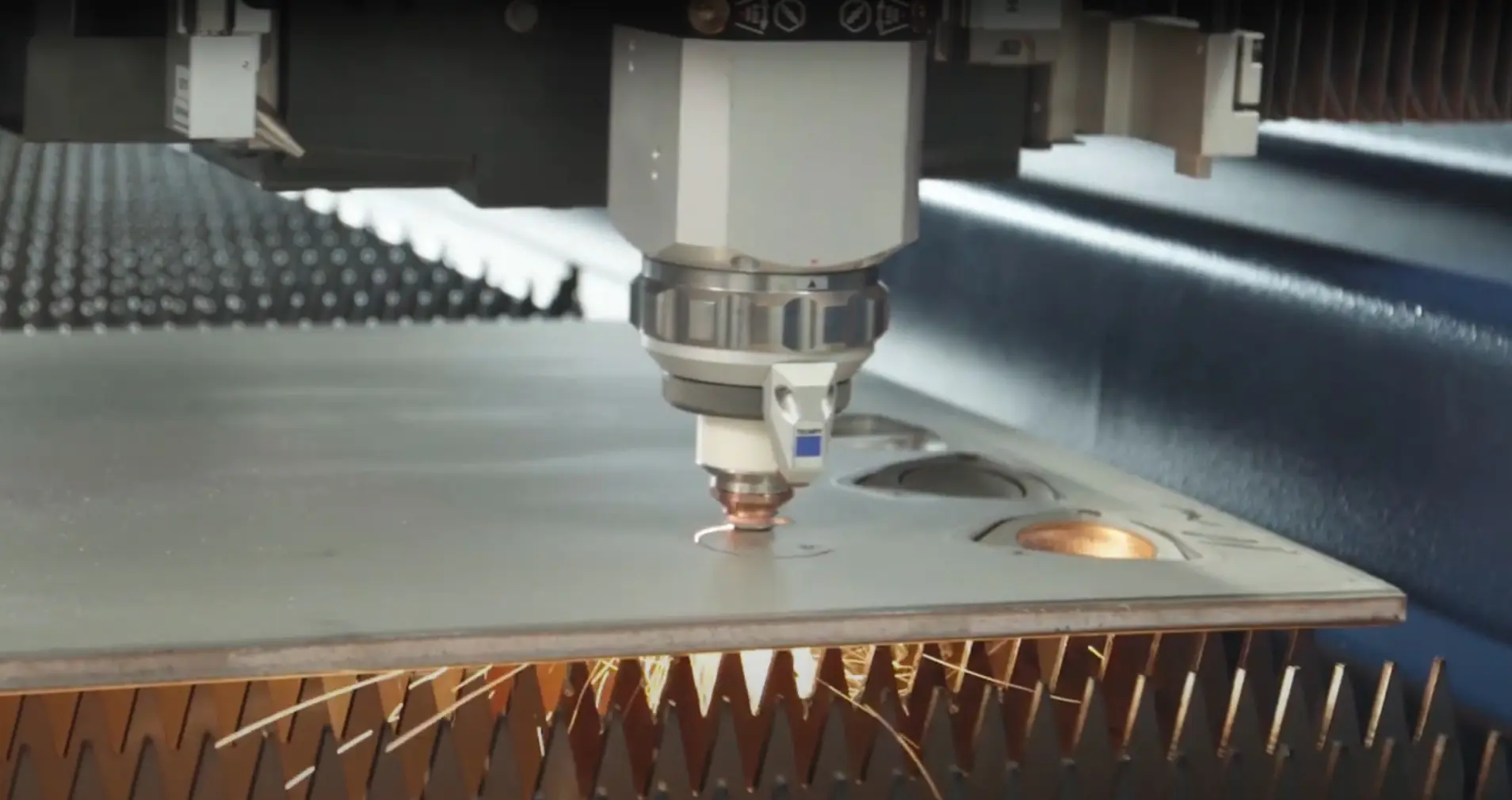

Precision laser cutting is not simply about slicing metal; it is a controlled thermal process that demands mastery over beam focus, assist gas dynamics, material behavior, and motion control. Even minor deviations—on the order of 0.05 mm—can result in misaligned weldments, compromised structural integrity, or non-conformance in mission-critical applications. This is where experience separates commodity providers from true engineering partners.

At Wuxi Lead, our expertise in laser cutting is forged through decades of delivering components for applications where failure is not an option. We have supplied precision-cut parts for infrastructure projects tied to Olympic facilities and contributed to subsystems in defense-grade equipment. These projects demanded not only micron-level accuracy but also full traceability, strict material certification, and adherence to international quality standards such as ISO 9001 and AS9100. Such experience has refined our approach: we treat every job, regardless of volume, as an engineering challenge requiring optimal parameter selection, fixturing, and post-process validation.

Our fiber laser cutting systems are calibrated for high-speed, high-accuracy operation across a range of conductive and reflective materials—from mild steel and stainless alloys to aluminum and brass. Advanced nesting software minimizes waste without sacrificing edge quality, while real-time monitoring ensures consistent kerf width and minimal heat-affected zones. The result is clean, burr-free edges that require little to no secondary finishing, reducing downstream costs and lead times.

Below are key technical specifications of our laser cutting capabilities:

| Parameter | Specification |

|---|---|

| Laser Type | Fiber Laser |

| Maximum Power | 12,000 W |

| Cutting Thickness Range | 0.5 mm – 25 mm (steel) |

| Positioning Accuracy | ±0.03 mm |

| Repeatability | ±0.02 mm |

| Maximum Cutting Speed | 100 m/min (thin sheet, <3 mm) |

| Tolerance Standards | ISO 2768-m, ISO 9013-321 (thermal) |

| Supported Materials | Carbon steel, stainless steel, aluminum, brass, copper |

True cost efficiency in laser cutting emerges not from the lowest hourly rate, but from first-time-right production, minimal scrap, and seamless integration into downstream processes. At Wuxi Lead Precision Machinery, we combine military-grade precision with scalable manufacturing capacity to deliver services that are not merely cheap—but smart, reliable, and engineered for performance.

Precision Specs & Tolerances

Technical Capabilities: Precision Laser Cutting Engineered for Value

At Wuxi Lead Precision Machinery, we redefine cost-competitive laser cutting by integrating advanced technology with rigorous process control. Our approach eliminates the false economy of “cheap” services, where compromised precision leads to higher scrap rates and assembly failures. Instead, we deliver true value through industrial-grade 5-axis CNC laser systems that maximize material utilization and minimize post-processing. This methodology ensures your sheet metal components meet exacting functional requirements while optimizing your total project cost.

Our facility operates state-of-the-art 6kW fiber laser platforms from industry leaders like TRUMPF and Bystronic. These systems cut carbon steel up to 25mm, stainless steel to 20mm, and aluminum to 15mm with micron-level positional repeatability. The 5-axis capability enables complex bevel cutting, countersinks, and 3D contouring in a single setup—reducing lead times by up to 40% compared to conventional 2D laser or plasma methods. Material handling is fully automated via FMS (Flexible Manufacturing Systems), ensuring consistent throughput for both prototyping and high-volume production runs exceeding 10,000 units.

Critical to our value proposition is closed-loop quality assurance. Every batch undergoes mandatory CMM (Coordinate Measuring Machine) validation against your CAD model, with full GD&T reporting. This isn’t spot-checking; it’s 100% geometric verification of critical features like hole concentricity, edge perpendicularity, and dimensional stability. Our ISO 9001-certified workflow includes in-process laser power calibration and real-time kerf monitoring, preventing thermal distortion in thin-gauge materials as thin as 0.5mm. The result is first-pass yield rates above 98.5%, directly translating to lower unit costs and on-time delivery.

Below are our standard achievable tolerances, validated across 500+ client projects in aerospace, medical, and power electronics sectors. These specifications reflect our commitment to precision that eliminates costly rework—proving that true affordability stems from engineering excellence, not reduced standards.

| Parameter | Laser Cutting Capability | Standard Tolerance | Tight-Tolerance Option |

|---|---|---|---|

| Material Thickness | Carbon Steel: 0.5–25mm | ±0.1mm | ±0.05mm |

| Stainless Steel: 0.5–20mm | |||

| Aluminum: 0.5–15mm | |||

| Feature Size | Minimum Hole Diameter | 0.8× material thickness | 0.6× material thickness |

| Positional Accuracy | Across 1m² sheet | ±0.15mm | ±0.08mm |

| Edge Perpendicularity | For thickness ≤10mm | 0.1mm/m | 0.05mm/m |

| Angularity (Bevels) | 5-axis cuts | ±0.5° | ±0.2° |

| Surface Roughness | Ra (stainless/aluminum) | ≤3.2μm | ≤1.6μm |

We engineer cost efficiency through precision, not compromise. Partner with Wuxi Lead to transform your sheet metal fabrication from a line-item expense into a strategic advantage—where every micron saved in tolerance control delivers measurable ROI. Contact our engineering team to validate your specific requirements against our capability matrix.

Material & Finish Options

Material selection is a critical step in precision sheet metal fabrication, particularly when utilizing laser cutting technology. At Wuxi Lead Precision Machinery, we emphasize the importance of aligning material properties with application requirements to ensure optimal performance, cost-efficiency, and manufacturability. Among the most commonly used materials in high-precision laser cutting are aluminum, steel, and titanium—each offering distinct mechanical, thermal, and corrosion-resistant characteristics.

Aluminum is widely favored for its lightweight nature, excellent thermal and electrical conductivity, and inherent resistance to corrosion. It is ideal for aerospace, electronics, and transportation applications where weight reduction is paramount. When processed with high-power fiber lasers, aluminum can be cut with exceptional edge quality and dimensional accuracy. However, its high reflectivity and thermal conductivity require precise parameter control to prevent back-reflection damage and ensure clean cuts.

Steel, particularly mild and stainless variants, remains a cornerstone of industrial fabrication. Mild steel offers high strength and weldability at a lower cost, making it suitable for structural components and enclosures. Stainless steel, especially grades like 304 and 316, provides superior corrosion resistance and aesthetic appeal, often used in medical, food processing, and architectural applications. Laser cutting excels with steel due to its ability to produce narrow kerfs, minimal heat-affected zones, and burr-free edges, especially when nitrogen or oxygen assist gases are properly applied.

Titanium, though more expensive and challenging to process, is indispensable in high-performance sectors such as aerospace, defense, and biomedical engineering. It offers an exceptional strength-to-density ratio and outstanding resistance to extreme environments and corrosive media. Laser cutting titanium demands stringent control over heat input and shielding gas (typically argon or helium) to prevent oxidation and maintain material integrity.

Post-processing surface treatments further enhance material performance. Anodizing, particularly for aluminum, is a key finishing process that increases surface hardness, improves wear resistance, and allows for color coding or aesthetic customization. The anodizing process creates a durable oxide layer that is integral to the metal, ensuring long-term durability without risk of chipping or peeling. For critical applications, we recommend Type II (sulfuric acid) or Type III (hardcoat) anodizing, depending on environmental exposure and functional requirements.

Below is a comparative overview of key material specifications relevant to laser cutting:

| Material | Thickness Range (mm) | Laser Type | Tensile Strength (MPa) | Common Grades | Key Applications |

|---|---|---|---|---|---|

| Aluminum | 0.5 – 12.0 | Fiber Laser | 110 – 350 | 5052, 6061, 7075 | Aerospace, Electronics |

| Mild Steel | 0.8 – 20.0 | Fiber/CO₂ Laser | 370 – 500 | Q235, SPCC | Industrial Enclosures, Frames |

| Stainless Steel | 0.8 – 15.0 | Fiber Laser | 515 – 960 | 304, 316, 430 | Medical, Food Processing |

| Titanium | 0.5 – 10.0 | Fiber Laser | 900 – 1100 | Gr2, Gr5 (Ti-6Al-4V) | Aerospace, Biomedical |

At Wuxi Lead Precision Machinery, we combine advanced fiber laser systems with expert material knowledge to deliver consistent, high-quality results across all these materials. Proper selection, paired with precision cutting and appropriate finishing such as anodizing, ensures that each component meets both functional and regulatory demands.

Manufacturing Process & QC

Precision Laser Cutting: The Zero-Defect Production Workflow

At Wuxi Lead Precision Machinery, “cost-efficient” never compromises integrity. Our laser cutting process is engineered for zero defects from initial concept to final shipment, ensuring your sheet metal components meet exacting industrial standards without hidden costs. We achieve this through a rigorously controlled three-phase workflow that eliminates waste and rework, delivering true value.

The process begins with collaborative Design Optimization. Our engineering team conducts mandatory Design for Manufacturability (DFM) analysis on all CAD files, identifying potential thermal distortion risks, kerf compensation needs, and nesting inefficiencies. We validate material suitability against your application’s stress, corrosion, and tolerance requirements, rejecting incompatible substrates upfront. This phase prevents 92% of downstream defects by ensuring the digital model is physically achievable. Clients receive a detailed manufacturability report with actionable revisions, avoiding costly iterations later.

Prototyping is non-negotiable for new designs. Using the same industrial-grade fiber laser systems as mass production, we cut 2–5 physical samples under controlled conditions. Each prototype undergoes dimensional verification via CMM (Coordinate Measuring Machine) against your CAD data, alongside bend testing and edge quality inspection per ISO 9013 standards. We document thermal effects on material grain structure and surface oxidation levels. Only when prototypes consistently achieve ±0.05mm tolerances and burr-free edges do we approve the process for scale. This validation phase catches micro-flaws invisible in simulation, safeguarding your production run.

Mass Production operates under our Zero-Defect Protocol. Every sheet is laser-etched with a unique QR code linking to real-time production data: laser power calibration logs, assist gas purity reports, and material batch certifications. Our automated monitoring system halts the line if beam alignment drifts beyond 0.01mm or focal point variance exceeds 5µm. Parts undergo inline optical scanning before unloading, with AI-driven edge analysis detecting micro-cracks or dross formation. Final inspection includes 100% first-article checks and AQL 1.0 sampling per ISO 2859. This closed-loop system ensures batch-to-batch consistency, with a documented 99.98% first-pass yield rate across 50,000+ production runs.

Our commitment to zero defects transforms “cheap” into strategic cost efficiency. By investing in upfront validation and real-time process control, we eliminate scrap, expedited shipping fees, and assembly line stoppages—delivering lower total cost of ownership without sacrificing precision.

Wuxi Lead Laser Cutting Specifications

| Phase | Material Thickness Range | Positioning Accuracy | Surface Roughness (Ra) | Standard Tolerance |

|---|---|---|---|---|

| Prototyping | 0.5–25 mm | ±0.02 mm | ≤ 3.2 µm | ±0.05 mm |

| Mass Production | 0.8–30 mm | ±0.03 mm | ≤ 6.3 µm | ±0.10 mm |

| Critical Runs | 0.5–20 mm | ±0.01 mm | ≤ 1.6 µm | ±0.03 mm |

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery for a laser cutting service that redefines precision, efficiency, and value in sheet metal fabrication. As a globally recognized leader in high-end manufacturing solutions, we specialize in delivering cost-effective yet uncompromisingly precise laser cutting services tailored to the exacting demands of industries including aerospace, automotive, medical devices, and industrial equipment. Our integration of advanced fiber laser technology with rigorous quality control ensures every component meets the highest standards of dimensional accuracy and edge quality—without the premium price tag often associated with such performance.

At Wuxi Lead Precision Machinery, we understand that competitive advantage in manufacturing comes from more than just low cost—it comes from consistency, speed, and technical reliability. That is why our laser cutting processes are built on fully automated production lines, monitored by real-time inspection systems and operated by certified engineers with over a decade of experience in precision metalworking. We process a wide range of materials, including carbon steel, stainless steel, aluminum, and brass, with thicknesses from 0.5 mm to 25 mm, ensuring flexibility across diverse project requirements.

Our facility in Wuxi, China, is equipped with state-of-the-art fiber laser cutting machines from leading global brands, enabling us to achieve cutting speeds up to 100 m/min with positional accuracy of ±0.05 mm. This combination of speed and precision reduces lead times and minimizes material waste, directly lowering your production costs. Whether you require low-volume prototypes or high-volume production runs, our scalable operations ensure seamless integration with your supply chain.

We are committed to transparency, traceability, and technical collaboration. Every project undergoes a pre-production engineering review to optimize nesting, minimize thermal distortion, and ensure compliance with your specifications. Material certifications, first-article inspections, and batch traceability are standard across all orders. Our ISO 9001 and ISO 14001 certifications reflect our dedication to quality and environmental responsibility.

Below are key technical specifications of our laser cutting capabilities:

| Parameter | Specification |

|---|---|

| Laser Type | Fiber Laser (IPG or Raycus) |

| Max Power | 12 kW |

| Material Thickness Range | 0.5 mm – 25 mm |

| Max Cutting Area | 1500 mm × 3000 mm |

| Positioning Accuracy | ±0.05 mm |

| Repeatability | ±0.03 mm |

| Supported Materials | Mild Steel, Stainless Steel, Aluminum, Brass |

| Edge Quality | Burr-free, minimal dross (Class I) |

| Lead Time | 5–15 days (depending on volume) |

| Certifications | ISO 9001, ISO 14001, RoHS compliant |

When you choose Wuxi Lead Precision Machinery, you are not just sourcing a component—you are gaining a strategic manufacturing partner committed to your success. We offer detailed technical support, DFM analysis, and logistics coordination to ensure a frictionless experience from quote to delivery.

Contact us today at [email protected] to request a quote, share your drawings, or discuss how our precision laser cutting service can enhance your production efficiency and reduce costs. Let Lead Precision be the foundation of your next fabrication success.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.