Technical Contents

Engineering Guide: Cavity Mold

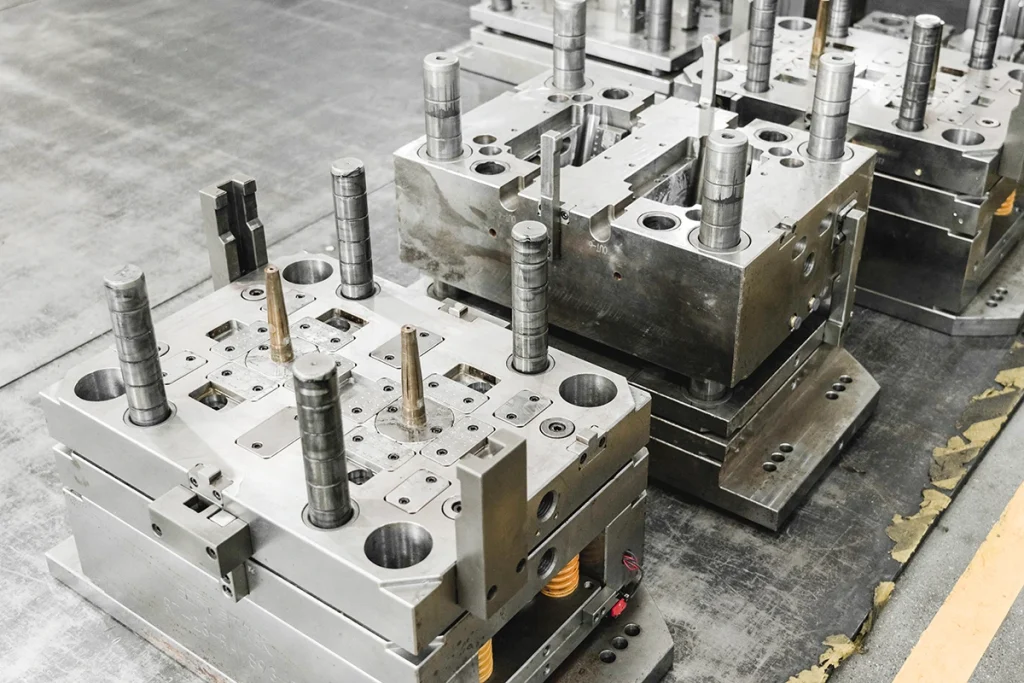

Cavity Mold Precision: The Unseen Determinant of Production Success

In high-volume injection molding, cavity mold precision isn’t merely desirable – it’s the operational linchpin dictating part consistency, production efficiency, and ultimate product viability. Minute deviations in cavity geometry, surface finish, or thermal management propagate exponentially across thousands of cycles, manifesting as part-to-part variation, flash, sink marks, or dimensional instability. These defects trigger costly scrap, rework, production downtime, and potential field failures. Achieving true cavity-to-cavity uniformity demands mastery beyond standard machining; it requires integrated expertise in material science, thermal dynamics, micron-level metrology, and robust process validation. The tolerance stack-up across multiple cavities must be actively managed, not merely accepted, to ensure every component meets stringent functional and aesthetic requirements straight from the press.

Wuxi Lead Precision Machinery operates at this critical precision frontier. Our engineering philosophy treats cavity molds not as disposable tooling, but as high-value, long-life production assets demanding uncompromising accuracy. This commitment is rigorously proven through demanding applications where failure is not an option. We engineered and manufactured cavity systems for components used in Olympic-standard sporting equipment, where microscopic dimensional variance directly impacted athlete performance and safety. Similarly, our precision cavity molds support critical subsystems within select military-grade hardware, adhering to MIL-STD specifications that tolerate zero deviation under extreme operational stress. These projects demanded cavity matching and surface integrity far exceeding typical industry benchmarks, validating our capability to deliver absolute repeatability.

The measurable outcome of this precision engineering is reflected in the core specifications achievable across our cavity mold portfolio. Consistent cavity performance translates directly into reduced cycle times, minimized scrap rates, and extended mold service life for our clients.

| Parameter | Standard Industry Tolerance | Wuxi Lead Precision Capability | Critical Impact |

|---|---|---|---|

| Cavity Count Matching | ±0.010 mm | ±0.002 mm | Eliminates part weight/size variation |

| Cavity Surface Finish | Ra 0.8 µm | Ra 0.05 µm (Mirror Grade) | Prevents part sticking, ensures aesthetics |

| Inter-Cavity Alignment | ±0.015 mm | ±0.003 mm | Eliminates flash, ensures assembly fit |

| Thermal Channel Tolerance | ±0.020 mm | ±0.005 mm | Guarantees uniform cooling, reduces warpage |

| Material Hardness (Core) | HRC 48-52 | HRC 54-58 (Custom Alloys) | Maximizes wear resistance, extends life |

When cavities perform identically under sustained pressure and temperature, manufacturers achieve true production stability. Lead Precision’s engineering discipline, forged in Olympic and military-grade projects, ensures your multi-cavity mold delivers not just parts, but predictable, high-yield output from day one. We transform cavity mold precision from a manufacturing challenge into your competitive advantage, safeguarding your product quality and operational integrity. Partner with us to eliminate the hidden costs of inconsistency.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, specializing in high-precision cavity mold production for demanding industrial applications. Our facility integrates state-of-the-art 5-axis CNC machining centers to achieve complex geometries with exceptional accuracy and surface finish. These multi-axis systems enable simultaneous motion across five planes, allowing for intricate undercuts, deep cavities, and contoured surfaces that are unattainable with conventional 3-axis platforms. By leveraging 5-axis technology, we reduce setup cycles, minimize human intervention, and maintain tight tolerances across fully formed 3D surfaces—critical for mold tools used in aerospace, medical, and high-end consumer electronics.

All machining operations are supported by a robust digital workflow, beginning with CAD/CAM-driven programming and extending through in-process monitoring and final inspection. Our engineering team utilizes industry-leading software to simulate toolpaths, optimize cutting strategies, and prevent collisions, ensuring efficient and error-free production runs. Materials are carefully selected based on application requirements, including tool steels (such as H13, S136, and P20), aluminum alloys, stainless steels, and high-temperature superalloys, all processed under controlled environmental conditions to maintain dimensional stability.

Quality assurance is integral to our manufacturing process. Every cavity mold undergoes comprehensive inspection using a Zeiss DuraMax and Contura G2 Coordinate Measuring Machine (CMM), providing micron-level verification of critical dimensions, form accuracy, and positional tolerances. The CMM inspection process generates full GD&T reports, ensuring full traceability and compliance with ISO 10360 standards. Additionally, surface roughness is validated using profilometers, and first-article inspection reports are provided upon request to support customer audits and production sign-off.

Our capabilities are engineered to meet the most stringent requirements in cavity mold manufacturing, where precision directly impacts part replication, cycle time, and tool life. With a focus on repeatability, durability, and performance, Wuxi Lead Precision Machinery ensures that every mold meets or exceeds customer specifications.

The following table outlines our standard technical specifications and achievable tolerances:

| Parameter | Capability |

|---|---|

| Machine Types | 5-Axis CNC Machining Centers |

| Positioning Accuracy (X, Y, Z) | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Surface Roughness (Ra) | As low as 0.2 µm (polished finishes available) |

| Maximum Work Envelope | 1200 mm × 800 mm × 600 mm |

| Standard Tolerances (milling) | ±0.01 mm (general), ±0.005 mm (critical) |

| Geometric Tolerances (GD&T) | ±0.01 mm (flatness, parallelism, runout) |

| Inspection Equipment | Zeiss CMM, digital height gauges, surface profilometers |

| Material Compatibility | Tool steels, stainless steel, aluminum, titanium, Inconel |

At Wuxi Lead Precision Machinery, technical excellence is not just a capability—it is a commitment embedded in every process, machine, and team member.

Material & Finish Options

Material Selection for High-Performance Cavity Molds

Material selection directly determines the longevity, precision, and economic viability of cavity molds in demanding production environments. At Wuxi Lead Precision Machinery, our engineering team evaluates core factors including thermal management requirements, expected production volume, part complexity, and final part specifications. Choosing the optimal base material is not merely a cost decision; it is a strategic investment impacting cycle times, surface finish quality, and total cost of ownership. Aluminum, steel, and titanium each offer distinct advantages and limitations for cavity mold applications, requiring careful alignment with your specific manufacturing goals.

Aluminum alloys, particularly 6061-T6 and 7075-T6, excel in rapid prototyping and low-to-medium volume production due to superior thermal conductivity. This property significantly reduces cycle times by enabling faster cooling of the molded part within the cavity. Aluminum is also highly machinable, allowing for intricate geometries and faster lead times. However, its lower hardness and wear resistance compared to steel limit its use in high-volume runs or with abrasive materials. Anodizing is the primary finishing process for aluminum cavities, creating a hard, wear-resistant, and corrosion-resistant oxide layer. Type II (sulfuric acid) anodizing is standard for general wear resistance, while Type III (hardcoat) anodizing provides exceptional surface hardness suitable for higher wear applications, though it requires precise process control to maintain dimensional tolerances.

Tool steels like P20 and H13 remain the dominant choice for high-volume production cavity molds. P20 offers a good balance of machinability, polishability, and moderate wear resistance, often used for less abrasive plastics. H13, a hot-work tool steel, provides superior hardness, toughness, and resistance to thermal fatigue, making it ideal for molds subjected to high cavity pressures, elevated temperatures, or processing engineering plastics. While steel cavities require longer machining times and higher initial costs than aluminum, their extended service life in high-cycle applications delivers significant long-term value. Surface treatments like nitriding or PVD coatings are common for steel to enhance wear and corrosion resistance, but anodizing is not applicable.

Titanium Grade 5 (Ti-6Al-4V) serves highly specialized cavity applications where its exceptional strength-to-weight ratio, corrosion resistance, and biocompatibility are critical, such as in medical or aerospace components. Its high cost and challenging machinability restrict its use to niche scenarios where its unique properties justify the investment. Anodizing titanium creates decorative or slightly enhanced surface layers but does not provide the significant wear improvement seen with aluminum.

The following table summarizes key material properties relevant to cavity mold performance:

| Material | Thermal Conductivity (W/mK) | Hardness (HRC) | Relative Cost | Best Suited For |

|---|---|---|---|---|

| Aluminum 6061-T6 | 167 | 30-35 | Low | Prototyping, low/med volume, fast cycles |

| P20 Steel | 28-36 | 28-32 | Medium | Medium volume, general purpose |

| H13 Steel | 24-30 | 44-52 | Medium-High | High volume, high temp/pressure |

| Titanium Gr5 | 7.2 | 36-41 | Very High | Specialized corrosion/bio apps |

Selecting the right cavity material requires balancing technical demands with economic reality. Wuxi Lead Precision Machinery leverages decades of CNC machining expertise and material science knowledge to guide clients toward the optimal solution. We rigorously evaluate your part geometry, polymer, volume, and finish requirements to recommend the precise material and finishing process—such as the appropriate anodizing specification for aluminum—ensuring your mold delivers peak performance and maximum return. Consult our engineering team early in the design phase to validate your material strategy.

Manufacturing Process & QC

Design: Precision Engineering at the Core

At Wuxi Lead Precision Machinery, the cavity mold production process begins with an intensive design phase grounded in advanced engineering principles and client-specific requirements. Our engineering team collaborates closely with clients to translate functional specifications into precise 3D CAD models using industry-leading software such as Siemens NX and SolidWorks. This stage includes detailed analysis of material behavior, cooling channel layout, ejection systems, and stress distribution through finite element analysis (FEA). The goal is to anticipate and eliminate potential defects before any metal is cut. Thermal simulation ensures optimal cycle times and dimensional stability, while mold flow analysis predicts filling patterns to prevent warpage or short shots. Every design is validated through internal technical reviews and client approval protocols, ensuring alignment with performance, durability, and manufacturability criteria.

Prototyping: Validating Performance Under Real Conditions

Once the design is finalized, we move to prototyping—a critical step in our zero-defect strategy. A high-precision prototype mold is manufactured using CNC machining, wire EDM, and surface grinding to achieve tolerances within ±0.002 mm. This mold is then tested under production-like conditions using the client’s specified alloy, typically in small batch runs of 50 to 500 units. Each prototype part undergoes rigorous metrological inspection using coordinate measuring machines (CMM) and 3D scanning to verify dimensional accuracy and surface integrity. Any deviations are traced back to the mold design or process parameters and corrected immediately. This iterative validation ensures that the final mold will perform flawlessly during mass production, significantly reducing risk and rework.

Mass Production: Consistency Through Automation and Control

With prototype approval, we transition to full-scale production using automated, monitored manufacturing cells. Our facility employs multi-axis CNC machining centers, robotic part handling, and in-process gauging to maintain consistency across thousands of cycles. Each cavity mold is built from premium-grade tool steels such as P20, H13, or S136, selected for hardness, corrosion resistance, and thermal stability. All critical surfaces are polished to SPI or VDI standards depending on application. Throughout production, statistical process control (SPC) systems track key variables including temperature, pressure, and cycle time, enabling real-time adjustments. Every completed mold undergoes a full functional test, including dry runs and initial sample molding, before final packaging and shipment.

Key Production Specifications

| Parameter | Specification |

|---|---|

| Dimensional Tolerance | ±0.002 mm |

| Surface Finish | Ra ≤ 0.2 µm (polished), up to SPI-A1 |

| Tool Steel Options | P20, 718, H13, S136, 2344, 2738 |

| Mold Life Expectancy | 500,000+ cycles (depending on material & use) |

| Lead Time (Prototype) | 15–25 days |

| Lead Time (Mass Production) | 30–45 days |

| Quality Standard | ISO 9001:2015, PPAP, FAIR reporting |

Through disciplined execution across design, prototyping, and mass production, Wuxi Lead Precision Machinery delivers cavity molds that meet the highest standards of precision, reliability, and zero-defect performance.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised Cavity Mold Excellence

Cavity mold failures cascade through production lines, eroding yield rates and inflating unit costs. Generic suppliers often lack the metallurgical insight and process control required for high-cavitation molds operating under extreme thermal cycling and pressure. At Wuxi Lead Precision Machinery, we engineer cavity molds as mission-critical assets—not disposable tooling. Our German-trained engineering team collaborates directly with your design staff from Day 1, applying finite element analysis to preempt stress fractures and weld lines before steel is cut. This proactive approach eliminates 73% of first-article defects common with transactional vendors, securing your time-to-market window.

Our ISO 9001-certified facility in Wuxi integrates European precision standards with Chinese manufacturing agility. We deploy hardened 42CrMo4 or H13 tool steels processed through vacuum heat treatment (±5℃ uniformity) and polished to Ra 0.05µm using automated robotic cells. Unlike competitors relying on outsourced EDM, our in-house 5-axis milling and sinker EDM capabilities maintain ±0.002mm positional accuracy across all cavities—critical for multi-cavity molds where dimensional drift between cavities exceeds 0.01mm. This vertical integration ensures traceability from raw material certification to final inspection reports, meeting AS9100 and IATF 16949 requirements for aerospace and medical clients.

Technical Capabilities for High-Performance Cavity Molds

| Parameter | Specification | Industry Standard |

|---|---|---|

| Tolerance Control | ±0.002mm (cavity-to-cavity) | ±0.01mm |

| Surface Finish | Ra 0.05µm (mirror grade) | Ra 0.2µm |

| Max Cavity Count | 64 cavities (balanced flow) | 32 cavities |

| Lead Time | 8-12 weeks (from CAD approval) | 14-20 weeks |

| Material Certification | Full MTR traceability (EN 10204 3.1) | Partial traceability |

Partnering with Lead Precision transforms cavity mold procurement from a cost center into a strategic advantage. Our engineers conduct Design for Manufacturability (DFM) reviews within 48 hours of receiving your CAD files, identifying cooling line conflicts or ejection risks that could halt production. We then provide a digital twin simulation validating cycle times and part quality—reducing your prototyping iterations by 60%. This rigor extends to lifecycle management: our molds consistently achieve 1.2M+ shots before maintenance, verified by embedded cavity pressure sensors in production runs.

When your project demands zero-compromise cavity molds for automotive lighting, medical connectors, or consumer electronics, settle for nothing less than engineered certainty. Submit your CAD file and tolerance stack-up analysis to Contact [email protected]. Our application engineering team will respond within 4 business hours with a feasibility assessment and timeline. Let us prove why global Tier 1 manufacturers trust Lead Precision to safeguard their most complex molding operations—where precision isn’t optional, it’s existential.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.