Technical Contents

Engineering Guide: Aluminum 3D Printing Service

Engineering Insight: Aluminum 3D Printing Service – The Role of Precision in Advanced Manufacturing

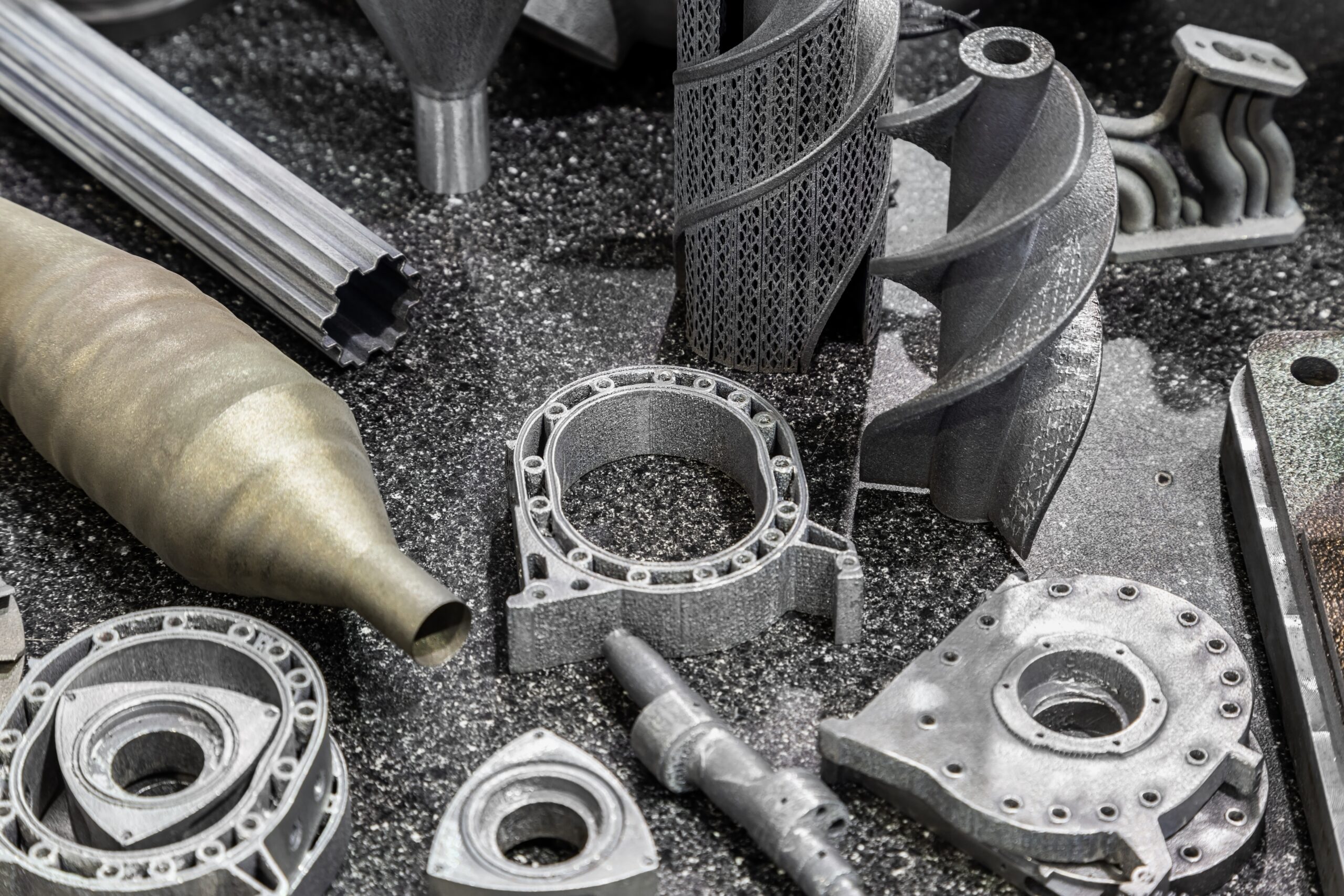

In the realm of custom metal manufacturing, aluminum 3D printing has emerged as a transformative technology, enabling complex geometries, lightweight structures, and rapid prototyping with exceptional material efficiency. However, the true value of aluminum additive manufacturing lies not just in its design freedom, but in the precision with which parts are produced. At Wuxi Lead Precision Machinery, we understand that in high-stakes industries such as aerospace, defense, and high-performance engineering, dimensional accuracy, surface integrity, and material consistency are non-negotiable.

Precision in aluminum 3D printing is multifaceted. It begins with laser focus control and layer resolution, extends through thermal management during build cycles, and culminates in post-processing techniques such as heat treatment, stress relieving, and precision machining. Even minor deviations in any of these stages can result in part failure under operational stress. This is why our engineering team employs closed-loop monitoring systems and in-situ metrology to ensure every build adheres to strict tolerances, typically within ±0.05 mm for critical features.

Our expertise in precision aluminum 3D printing has been rigorously tested in projects for Olympic-level sports equipment and military-grade components. For instance, we supported the development of custom aluminum lattice structures for lightweight racing components used in international competitions, where every gram and micron impacts performance. Similarly, our work with defense contractors has involved producing mission-critical housings and heat exchangers that must perform reliably under extreme environmental conditions.

These applications demand more than just advanced machinery—they require deep process knowledge, rigorous quality control, and a culture of engineering excellence. At Wuxi Lead, we combine state-of-the-art metal additive systems with decades of CNC and precision machining heritage, ensuring that every 3D-printed aluminum part meets or exceeds international standards such as ISO 9001 and AS9100.

Below are key technical specifications for our aluminum 3D printing service, reflecting our commitment to precision and performance.

| Parameter | Specification |

|---|---|

| Material | AlSi10Mg, AlSi7Mg, Scalmalloy® (on request) |

| Build Volume | Up to 250 x 250 x 300 mm |

| Layer Thickness | 20–60 μm |

| Typical Accuracy | ±0.05 mm (for features < 100 mm) |

| Surface Roughness (as-built) | Ra 8–12 μm |

| Post-Processing Options | Hot Isostatic Pressing (HIP), T6 Heat Treatment, CNC Machining, Polishing |

| Density | >99.9% (fully dense, defect-controlled) |

| Lead Time (standard) | 7–10 working days (including QA) |

At Wuxi Lead Precision Machinery, we don’t just print aluminum parts—we engineer performance. Our integration of additive manufacturing with precision subtractive techniques ensures that every component is not only geometrically complex but dimensionally reliable. In industries where failure is not an option, precision is the foundation of trust.

Precision Specs & Tolerances

Technical Capabilities: Precision Aluminum Additive Manufacturing

Wuxi Lead Precision Machinery delivers mission-critical aluminum components through integrated metal additive and subtractive manufacturing. Our technical foundation combines advanced laser powder bed fusion (LPBF) systems with 5-axis CNC machining and metrology-grade quality control. This end-to-end process ensures geometric integrity, surface finish, and dimensional accuracy unattainable through standalone 3D printing. Aluminum alloys (including AlSi10Mg, AlSi7Mg, and certified aerospace grades) are processed under controlled inert atmospheres to eliminate oxidation and porosity, meeting stringent AMS and ASTM standards for structural applications.

Precision Post-Processing Integration

As-printed aluminum parts inherently require precision finishing to achieve functional tolerances. Our facility employs HAAS and DMG MORI 5-axis CNC centers for critical post-processing operations. This includes precision milling of sealing surfaces, bearing seats, and datum features; thread forming; and complex contour finishing. The seamless transition from additive build to subtractive refinement eliminates tolerance stack-up errors and ensures compatibility with legacy assemblies. Heat treatment (T6 solutionizing and aging) is performed in-house under NADCAP-accredited procedures, optimizing mechanical properties while minimizing distortion.

Metrology-Driven Quality Assurance

Every component undergoes a defined inspection protocol. Critical dimensions are validated via Zeiss METROTOM 800 CT scanning for internal defect analysis, while geometric deviations are quantified using Hexagon Leitz PMM-C 3D CMMs. All measurements reference the original CAD model with GD&T callouts, generating full-first-article inspection (FAI) reports per AS9102. Surface roughness is certified to Ra ≤ 0.8 µm on machined features, and porosity levels are maintained below 0.1% through real-time melt pool monitoring during printing.

Dimensional Tolerance Specifications

The following table defines achievable tolerances for aluminum components after integrated additive-subtractive processing. Tight tolerances require specific geometric considerations and may impact lead time.

| Feature Category | Standard Tolerance (mm) | Tight Tolerance (mm) | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.05 | ±0.025 | Up to 150 mm; ±0.0015 mm/mm beyond |

| Hole Diameter | +0.05 / -0.00 | +0.025 / -0.00 | Reamed or honed features only |

| Flatness | 0.05 per 100 mm | 0.02 per 100 mm | Critical sealing surfaces |

| Positional Tolerance | ±0.05 | ±0.02 | Relative to primary datums |

| Surface Roughness (CNC) | Ra 1.6 | Ra 0.8 | Measured per ISO 4287 |

These specifications reflect capabilities under controlled production conditions. Tolerances for thin-walled structures (<2 mm) or extreme aspect ratios require engineering review. All processes are documented under ISO 9001:2015 and IATF 16949 quality management systems, with full material traceability from powder lot to finished part. Wuxi Lead’s integrated workflow transforms as-printed aluminum builds into certified, assembly-ready components for aerospace hydraulic systems, medical implants, and high-performance automotive subsystems.

Material & Finish Options

When selecting materials for high-performance 3D printed components, aluminum stands out as a leading choice in aerospace, automotive, and industrial applications due to its exceptional strength-to-weight ratio, thermal conductivity, and corrosion resistance. At Wuxi Lead Precision Machinery, we specialize in advanced aluminum 3D printing services using premium-grade alloys optimized for complex, lightweight, and durable parts. Our expertise extends across multiple metal materials, including aluminum, steel, and titanium, each offering distinct advantages depending on application requirements.

Aluminum alloys, particularly AlSi10Mg and AlSi7Mg, are widely used in laser powder bed fusion (LPBF) processes. These alloys provide excellent castability, high thermal conductivity, and good mechanical properties after heat treatment. AlSi10Mg is ideal for components requiring high strength, low weight, and resistance to thermal fatigue—common in engine parts, heat exchangers, and structural aerospace elements. AlSi7Mg offers similar benefits with slightly improved ductility, making it suitable for dynamic load-bearing applications.

For applications demanding higher strength and wear resistance, steel variants such as 316L stainless steel and 17-4 PH precipitation-hardening steel are recommended. 316L provides superior corrosion resistance and is often used in marine and medical environments. 17-4 PH delivers high tensile strength and can be heat-treated to achieve hardness levels exceeding 40 HRC, making it ideal for tooling and high-stress mechanical parts.

Titanium, specifically Grade 5 (Ti6Al4V), is selected when maximum strength-to-density ratio and biocompatibility are critical. Commonly used in aerospace and medical implants, titanium offers outstanding performance under extreme conditions but comes at a higher material and processing cost.

Post-processing plays a vital role in enhancing both performance and aesthetics. Anodizing is a key surface treatment for aluminum components, providing improved corrosion resistance, wear protection, and electrical insulation. Type II and Type III (hardcoat) anodizing are available based on functional needs. Type II offers moderate thickness and dyeing capability for identification or branding, while Type III delivers thicker, harder coatings for industrial wear resistance.

Below is a comparison of key material properties relevant to 3D printed components:

| Material | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Density (g/cm³) | Common Applications |

|---|---|---|---|---|---|

| AlSi10Mg | 400–450 | 250–300 | 8–12 | 2.67 | Aerospace, automotive, heat exchangers |

| AlSi7Mg | 380–430 | 240–280 | 10–14 | 2.66 | Lightweight structural parts |

| 316L Stainless Steel | 550–600 | 290–320 | 40–50 | 8.00 | Medical, marine, chemical processing |

| 17-4 PH Steel | 1000–1200 | 850–1000 | 10–15 | 7.75 | Tooling, aerospace, defense |

| Ti6Al4V | 900–950 | 800–850 | 10–12 | 4.43 | Aircraft, medical implants, racing |

At Wuxi Lead Precision Machinery, we guide clients through material and finish selection to ensure optimal performance, durability, and cost-efficiency. Our engineering team supports every stage—from design validation to post-processing—ensuring your aluminum 3D printed components meet the highest industrial standards.

Manufacturing Process & QC

Precision Aluminum 3D Printing: From Concept to Zero-Defect Production

At Wuxi Lead Precision Machinery, our aluminum 3D printing service transforms complex designs into mission-critical components through a rigorously controlled three-stage workflow. This process ensures metallurgical integrity, dimensional accuracy, and absolute compliance with aerospace, medical, and industrial standards. Every phase integrates proactive quality assurance to eliminate defects before they occur.

The journey begins with Design for Additive Manufacturing (DfAM) Optimization. Our engineering team collaborates with clients to refine geometries for laser powder bed fusion, leveraging topology optimization and thermal simulation. We validate support structures, overhang angles, and thermal stress distribution using EOSPRINT and ANSYS software. This phase prevents warpage, residual stress, and porosity by ensuring the design aligns with aluminum alloy behavior during melting and solidification. Critical parameters like scan strategy and layer thickness are predetermined to achieve target surface finishes below 15μm Ra.

Prototyping follows as a closed-loop validation step. Using certified AlSi10Mg or Scalmalloy® powders, we produce functional prototypes on EOS M 400-4 systems. Each build undergoes real-time melt pool monitoring via integrated cameras and sensors, detecting anomalies like spatter or incomplete fusion. Post-build, prototypes are rigorously inspected: CT scanning validates internal integrity, CMM measurements confirm ±0.05mm tolerances, and tensile testing verifies mechanical properties against ASTM F3318. Iterations are minimal—typically one to two cycles—due to our predictive DfAM foundation. This phase de-risks mass production by certifying process stability.

Mass Production scales validated parameters under our Zero Defects framework. Production occurs in ISO Class 7 cleanrooms with humidity-controlled argon atmospheres to prevent oxide inclusions. In-process monitoring includes layer-wise thermal imaging and powder bed quality checks, triggering automatic corrections for deviations. Post-processing adheres to strict protocols: HIP treatment eliminates micro-porosity, precision CNC machining achieves critical datums, and vibratory finishing ensures surface consistency. Final inspection combines automated optical scanning with destructive testing of sacrificial coupons from each build. Traceability is maintained via blockchain-secured digital logs, linking every part to its powder lot, machine calibration data, and inspection reports.

This integrated approach ensures that 99.8% of parts meet first-article approval standards. By embedding quality at every transition—from design validation to serial production—we deliver aluminum components with the reliability demanded by high-stakes applications.

Key Aluminum 3D Printing Specifications

| Parameter | Specification | Standard Compliance |

|————————-|———————————–|———————|

| Material | AlSi10Mg, Scalmalloy® | AMS 7000, ASTM F3318|

| Layer Thickness | 20–60 μm | EOS Process Specs |

| Build Volume | 400 x 400 x 400 mm | Machine Capability |

| Dimensional Accuracy | ±0.05 mm (typical) | ISO 2768-mK |

| Surface Roughness (as-built) | 12–25 μm Ra | ISO 4287 |

| Density | >99.95% | ASTM B311 |

| Tensile Strength | 480 MPa (Scalmalloy®) | AMS 4998 |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Aluminum 3D Printing Excellence

At Wuxi Lead Precision Machinery, we don’t just deliver parts—we deliver precision-engineered solutions tailored to the exacting demands of high-performance industries. As a leading provider of custom metal manufacturing in China, we specialize in advanced aluminum 3D printing services that combine cutting-edge technology, rigorous quality control, and deep engineering expertise. When you choose to partner with us, you gain more than a supplier; you gain a strategic manufacturing ally committed to accelerating your innovation and ensuring your components meet the highest standards of performance and reliability.

Our aluminum 3D printing capabilities are built on state-of-the-art metal additive manufacturing platforms, including selective laser melting (SLM) and direct metal laser sintering (DMLS). These technologies allow us to produce complex, lightweight geometries that are impossible to achieve with traditional machining—ideal for aerospace, automotive, energy, and medical applications where performance, weight reduction, and thermal efficiency are critical. We work exclusively with high-grade aluminum alloys such as AlSi10Mg and AlSi7Mg, known for their excellent strength-to-weight ratio, thermal conductivity, and corrosion resistance.

Every project at Lead Precision begins with collaboration. Our engineering team works closely with your design and R&D departments to optimize part geometry for additive manufacturing, ensuring structural integrity, manufacturability, and cost-efficiency. From rapid prototyping to full-scale production, we maintain tight tolerances, superior surface finishes, and full material traceability. Our in-house post-processing capabilities—including heat treatment, stress relieving, CNC machining, and surface finishing—ensure your components meet or exceed industry specifications.

We understand that in high-end manufacturing, consistency and compliance are non-negotiable. That’s why our facility operates under ISO 9001-certified quality management systems, with rigorous inspection protocols using coordinate measuring machines (CMM), optical scanning, and metallurgical analysis. Whether you require a single prototype or a high-volume production run, you can trust Lead Precision to deliver on time, every time.

Below are key technical specifications for our aluminum 3D printing service:

| Parameter | Specification |

|---|---|

| Material Options | AlSi10Mg, AlSi7Mg |

| Build Volume | Up to 250 x 250 x 300 mm |

| Layer Thickness | 20–60 μm |

| Typical Tolerance | ±0.1 mm |

| Surface Roughness (as-built) | Ra 12–18 μm |

| Post-Processing | Heat Treatment, CNC Machining, Polishing, Anodizing |

| Quality Standards | ISO 9001, Full Material & Dimensional Reports |

Lead Precision is engineered for partnership. We believe that the future of manufacturing is collaborative, agile, and precision-driven. If you’re developing next-generation components that demand advanced aluminum 3D printing, we invite you to start the conversation today. Contact us at [email protected] to discuss your project, request a quote, or receive technical support from our engineering team. Let’s build the future—together.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.