Technical Contents

Engineering Guide: Associated Production Services Inc

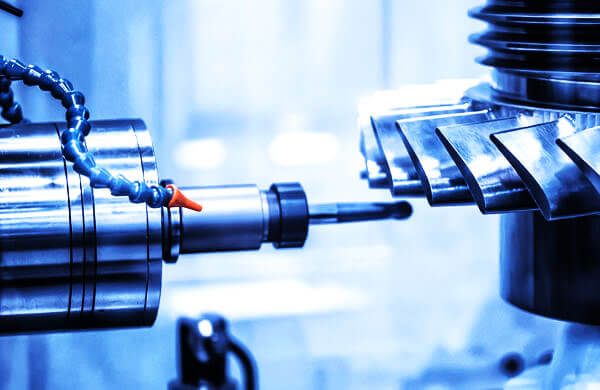

Engineering Insight: The Role of Precision in Custom Metal Manufacturing

In the realm of high-performance custom metal manufacturing, precision is not merely a quality metric—it is the foundational principle that defines reliability, functionality, and long-term value. For industries where failure is not an option—such as aerospace, defense, medical technology, and high-end industrial automation—micro-level deviations in component dimensions can cascade into system-wide inefficiencies or catastrophic failures. At Wuxi Lead Precision Machinery, we approach precision as both a technical requirement and an engineering philosophy, rooted in over two decades of delivering mission-critical components for clients with the most demanding specifications.

Our engineering team operates under the understanding that precision begins at the design phase. Close collaboration with clients ensures that tolerances, material behavior under load, thermal expansion, and surface finish requirements are all accounted for before a single tool engages the workpiece. This proactive engineering mindset allows us to anticipate challenges and optimize manufacturing sequences, minimizing variability and maximizing repeatability across production runs.

Wuxi Lead’s proven track record in supplying parts for Olympic-standard equipment and certified military applications underscores our capability to meet and exceed stringent international standards. Components manufactured for Olympic timing systems, for example, required micron-level tolerances to ensure flawless synchronization and data integrity under high-speed operation. Similarly, our work with defense contractors has involved producing ruggedized housings and actuation components that perform reliably in extreme environments—proof of our ability to balance precision with durability.

Our facility in Wuxi, China, is equipped with state-of-the-art CNC machining centers, coordinate measuring machines (CMM), and real-time in-process inspection systems. These tools enable us to maintain tolerances as tight as ±0.002 mm and surface finishes down to Ra 0.4 µm, ensuring that every component conforms to the most exacting blueprints. Moreover, our ISO 9001-certified quality management system provides a structured framework for continuous monitoring and process improvement.

Below is a summary of our core precision manufacturing capabilities:

| Specification | Performance Level |

|---|---|

| Dimensional Tolerance | ±0.002 mm |

| Surface Finish (Ra) | As low as 0.4 µm |

| Maximum Work Envelope | 2,500 mm × 1,200 mm × 800 mm |

| Material Compatibility | Aluminum, Stainless Steel, Titanium, Inconel, Brass, Engineering Plastics |

| Quality Certification | ISO 9001:2015 |

| Inspection Equipment | CMM, Optical Comparators, Laser Scanning |

| Production Capacity | Batch sizes from 1 to 10,000+ units |

Precision, in essence, is the convergence of advanced technology, rigorous process control, and engineering expertise. At Wuxi Lead Precision Machinery, we do not simply manufacture parts—we engineer confidence. For associated production services inc, partnering with a manufacturer that understands the gravity of precision ensures that every component delivered is not just dimensionally accurate, but functionally assured.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Complex Demands

Wuxi Lead Precision Machinery delivers uncompromising precision for high-complexity metal components through integrated advanced manufacturing and quality assurance systems. Our core strength lies in mastering geometrically intricate parts requiring multi-faceted machining in a single setup, eliminating cumulative errors inherent in traditional multi-stage processes. This capability is anchored by our strategic deployment of 5-axis CNC machining centers, enabling simultaneous cutting tool movement across X, Y, Z linear axes and two rotational axes (A and B). This configuration allows uninterrupted access to complex contours, undercuts, and organic shapes typical in aerospace structural components, medical implants, and energy sector turbine parts. Our DMG MORI and MAZAK 5-axis platforms feature Heidenhain controls, high-torque spindles (up to 24,000 RPM), and thermal compensation systems, ensuring micron-level stability during extended production runs of titanium, Inconel, aluminum alloys, and hardened steels. Material removal rates remain optimized without sacrificing surface integrity, critical for fatigue-critical applications.

Rigorous quality validation is non-negotiable. Every critical dimension undergoes verification via our Zeiss CONTURA G3 Coordinate Measuring Machine (CMM), operating under ISO 10360-2 standards within a climate-controlled metrology lab (20°C ±0.5°C). This system employs tactile and optical probing to generate comprehensive GD&T reports, validating form, position, and profile tolerances against CAD models. Statistical Process Control (SPC) data is integrated directly into production feedback loops, enabling real-time adjustments to maintain capability indices (Cp/Cpk >1.67) across high-volume batches. Our AS9100D-certified quality management system mandates full traceability from raw material certification through final inspection, with digital records archived for 15+ years.

The following table details achievable tolerance benchmarks across common feature types, reflecting our standard production capabilities under controlled environmental conditions. These values represent typical performance; tighter tolerances are attainable for specific applications through process refinement.

| Feature Type | Standard Tolerance | Tight Tolerance Capability | Reference Standard |

|---|---|---|---|

| Linear Dimensions (mm) | ±0.010 | ±0.003 | ISO 2768-mK |

| Hole Diameter (mm) | H7 (+0.015/0) | H5 (+0.004/0) | ISO 286-2 |

| Positional Tolerance (mm) | ±0.020 | ±0.005 | ISO 1101 |

| Flatness (mm) | 0.020 per 100mm | 0.005 per 100mm | ISO 128-24 |

| Surface Roughness (Ra) | 0.8 µm | 0.2 µm | ISO 1302 |

This technical foundation ensures that components manufactured at Wuxi Lead meet the stringent functional and reliability demands of Tier 1 suppliers across defense, semiconductor equipment, and life sciences sectors. We partner with clients during design for manufacturability (DFM) reviews to optimize part geometry for our capabilities, reducing cost and lead time while guaranteeing first-article conformance. Our engineering team provides actionable feedback on tolerance stack-ups and material selection, transforming complex designs into producible, high-yield realities. This end-to-end precision engineering approach minimizes downstream assembly issues and accelerates time-to-market for your most challenging products.

Material & Finish Options

Material selection is a foundational step in precision metal manufacturing, directly influencing component performance, durability, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in custom fabrication using three core metals: aluminum, steel, and titanium. Each material offers distinct mechanical and thermal properties, making them suitable for specific industrial applications ranging from aerospace and automotive to medical and energy systems.

Aluminum is widely preferred for its excellent strength-to-weight ratio, corrosion resistance, and machinability. It is particularly advantageous in applications where weight reduction is critical without compromising structural integrity. The 6061 and 7075 aluminum alloys are among the most commonly used due to their balanced mechanical properties and weldability. Aluminum also responds exceptionally well to anodizing, a key surface treatment that enhances wear and corrosion resistance while allowing for aesthetic customization through color dyeing.

Steel, particularly in its stainless (e.g., 304, 316) and alloy (e.g., 4140, 4340) forms, provides superior strength, hardness, and thermal stability. Stainless steel variants offer excellent resistance to oxidation and chemical exposure, making them ideal for medical devices, food processing equipment, and marine environments. Alloy steels are frequently selected for high-stress mechanical components such as shafts, gears, and tooling due to their enhanced toughness and fatigue resistance. While steel does not anodize, it can be treated with passivation, plating, or powder coating to improve surface performance.

Titanium stands at the premium end of material options, offering an unmatched strength-to-density ratio and extraordinary resistance to corrosion, especially in saline and high-temperature environments. Grade 5 (Ti-6Al-4V) is the most widely used titanium alloy in aerospace and biomedical implants due to its biocompatibility and ability to maintain integrity under extreme conditions. Though more challenging and costly to machine, titanium’s long-term reliability in critical applications justifies its use where performance outweighs cost considerations.

Anodizing is a key finishing process offered for aluminum components. This electrochemical treatment thickens the natural oxide layer, significantly improving surface hardness and wear resistance. Type II (sulfuric acid) anodizing is standard for decorative and moderate protection needs, while Type III (hardcoat anodizing) delivers a thicker, denser layer suitable for industrial and military specifications. Anodized finishes are non-conductive and can be dyed in a range of colors for part identification or branding.

The following table summarizes key properties of the primary materials we work with:

| Material | Typical Alloys | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Common Applications |

|---|---|---|---|---|---|

| Aluminum | 6061, 7075 | 2.7 | 310–570 | High | Aerospace, automotive, enclosures |

| Stainless Steel | 304, 316 | 8.0 | 505–620 | Very High | Medical, marine, food processing |

| Alloy Steel | 4140, 4340 | 7.8 | 655–1000 | Moderate | Tooling, shafts, structural parts |

| Titanium | Grade 5 (Ti-6Al-4V) | 4.4 | 900–1000 | Exceptional | Aerospace, implants, racing |

Selecting the right material and finish requires a thorough understanding of operational demands. At Wuxi Lead Precision Machinery, we support clients through material consultation, prototyping, and full-scale production to ensure optimal performance and value.

Manufacturing Process & QC

Precision Manufacturing Process: From Concept to Zero Defects Fulfillment

At Wuxi Lead Precision Machinery, our production process is engineered for uncompromising quality and reliability, specifically designed to meet the stringent demands of high-end industrial clients like Associated Production Services Inc. We integrate advanced engineering rigor with meticulous execution across three critical phases, ensuring every component achieves zero defects before shipment. This systematic approach minimizes risk and maximizes value for your supply chain.

The process begins with collaborative Design Integration and Validation. Our engineering team partners directly with your design data, conducting thorough Design for Manufacturability (DFM) analysis. We scrutinize material selection, geometric complexity, and tolerance stack-ups to identify potential production challenges early. Utilizing advanced CAD/CAM simulation software, we virtually validate toolpaths and machining sequences, ensuring optimal process stability. This proactive phase prevents costly errors downstream by confirming feasibility and optimizing the manufacturing strategy before any material is cut, aligning perfectly with your zero-defect objectives from inception.

Prototyping and Process Qualification follows, serving as the critical bridge to mass production. We produce functional prototypes using the exact materials and intended production equipment. Each prototype undergoes rigorous First Article Inspection (FAI) per AS9102 standards, verifying all critical dimensions, surface finishes, and material properties against your specifications. Dimensional inspection utilizes calibrated Coordinate Measuring Machines (CMM) and optical comparators. This phase validates the machining process capability, confirms fixture integrity, and allows for minor iterative refinements. Only after achieving 100% conformance and securing your formal approval do we lock the production process parameters.

Zero Defects Mass Production leverages the validated process under stringent statistical process control (SPC). Every production run initiates with a comprehensive setup verification. Real-time monitoring of key process parameters (cutting forces, temperatures, tool wear) occurs throughout machining. In-process inspections at defined intervals, coupled with 100% critical feature verification via automated vision systems or CMM, ensure continuous adherence to specifications. Full material traceability is maintained from raw stock to finished part. Final inspection employs multi-stage protocols including dimensional checks, visual examination under controlled lighting, and mandatory client-specific testing. This integrated quality management system, certified to ISO 9001:2015, guarantees consistent output where defects are systematically prevented, not merely detected.

Our production capabilities consistently deliver the precision required for complex aerospace, medical, and energy sector components. Key performance metrics are demonstrated below:

| Parameter | Capability | Measurement Standard |

|---|---|---|

| Dimensional Tolerance | ±0.005 mm (0.0002″) | ISO 2768-mK / ASME Y14.5 |

| Surface Roughness (Ra) | As low as 0.2 µm (8 µin) | ISO 4287 / ASME B46.1 |

| In-Process Inspection | 100% Critical Features | Client-Specific FAI Plan |

| Final Inspection Rate | 100% Dimensional Verification | Calibrated CMM / Optical |

| Material Traceability | Full Lot-to-Part Chain | MTRs Integrated into ERP |

This disciplined progression from validated design through qualified prototyping to rigorously controlled mass production forms the foundation of our zero-defect commitment. Wuxi Lead Precision Machinery ensures your components arrive not just on time, but with the absolute precision and reliability your high-value applications demand.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery for precision-driven, high-integrity metal manufacturing solutions tailored to the most demanding industrial applications. At Lead Precision, we specialize in delivering custom metal components and assemblies that meet exacting standards in aerospace, energy, automation, and advanced equipment manufacturing. Our commitment to engineering excellence, combined with state-of-the-art CNC capabilities and rigorous quality control, ensures that every part we produce exceeds expectations for performance, durability, and repeatability.

When you collaborate with us, you gain more than a supplier—you gain a strategic manufacturing partner with deep technical expertise and a proven track record in complex, low-to-medium volume production. Our facility in Wuxi, China, is equipped with advanced multi-axis CNC machining centers, high-precision turning and milling equipment, and comprehensive inspection systems, enabling us to handle intricate geometries and tight tolerances with unwavering consistency. We work with a wide range of engineering-grade metals, including aluminum alloys, stainless steels, titanium, and exotic materials, ensuring compatibility with your performance requirements.

Our engineering team works closely with clients from design through final production, offering Design for Manufacturability (DFM) analysis, rapid prototyping, and scalable production planning. This collaborative approach minimizes lead times, reduces costs, and ensures seamless integration into your supply chain. Whether you require one-off prototypes or high-mix production runs, our agile manufacturing model adapts to your project’s unique demands.

We maintain full compliance with international quality standards, including ISO 9001:2015, and employ in-process and final inspections using coordinate measuring machines (CMM), optical comparators, and surface finish testers. Every component is traceable, documented, and certified to meet your specifications.

Below are key capabilities that define our production excellence:

| Capability | Specification |

|---|---|

| CNC Machining | 3-axis to 5-axis milling, turning, mill-turn |

| Tolerances | ±0.005 mm (±0.0002″) |

| Maximum Work Envelope | 1200 x 800 x 600 mm (47 x 31.5 x 23.6 in) |

| Materials | Aluminum, Stainless Steel, Titanium, Brass, Copper, Inconel, Tool Steels |

| Finishing Options | Anodizing, Passivation, Powder Coating, Plating, Bead Blasting |

| Quality Standards | ISO 9001:2015, Full First Article Inspection Reports, PPAP, FAI |

| Lead Times | Prototype: 7–14 days; Production: 15–30 days (varies by complexity) |

At Wuxi Lead Precision Machinery, we understand that your success depends on reliability, precision, and partnership. Let us become an extension of your engineering and production team. Contact us today at [email protected] to discuss your next project. Our engineers are ready to review your designs, provide technical feedback, and deliver a manufacturing solution that drives performance and value. Partner with Lead Precision—where precision meets performance.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.