Technical Contents

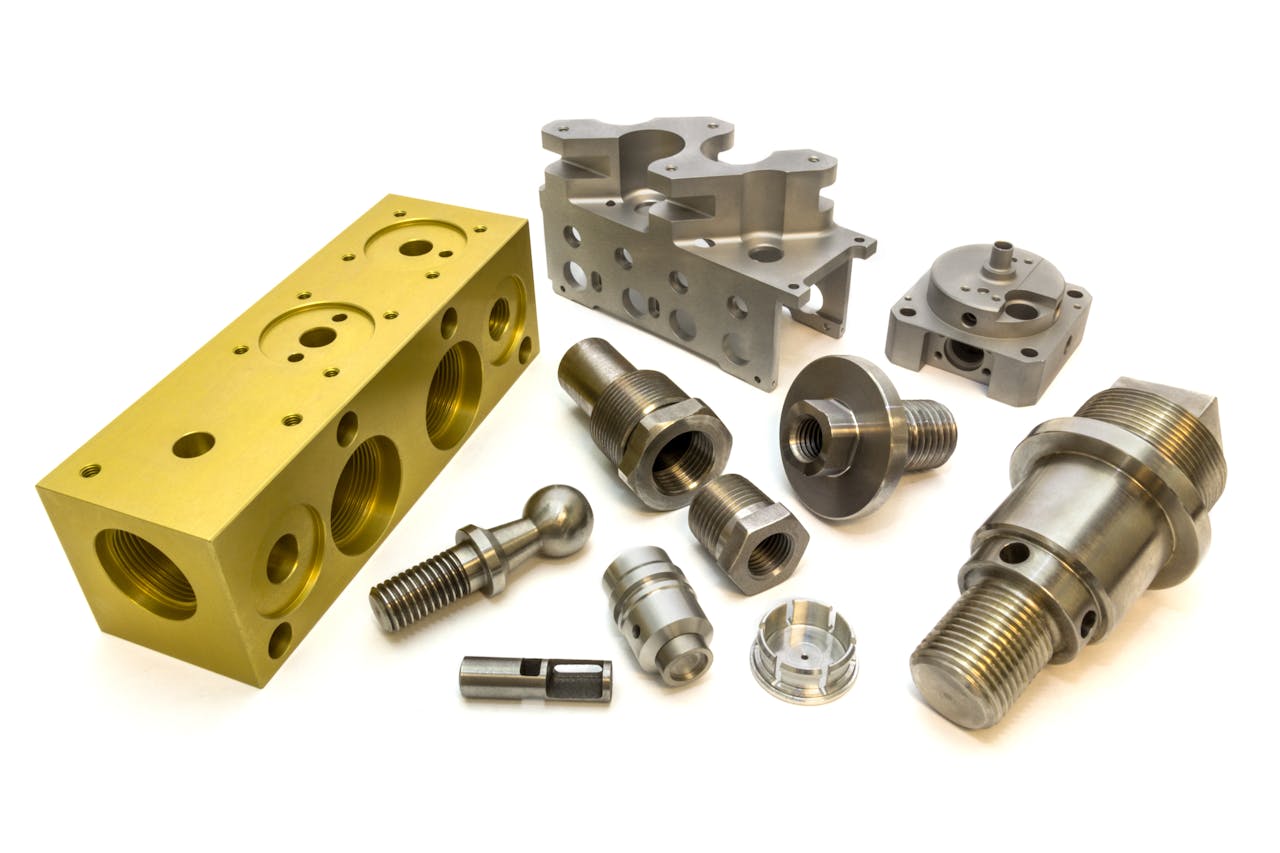

Engineering Guide: Custom Cnc Machining Parts

Engineering Insight: The Non-Negotiable Role of Precision in Custom CNC Machining Parts

Precision in custom CNC machining parts transcends mere specification adherence; it is the foundational element determining functional integrity, longevity, and safety in mission-critical applications. In high-performance sectors like aerospace, defense, and advanced medical technology, even micron-level deviations can trigger catastrophic system failures. Consider a turbine blade assembly: a tolerance stack-up exceeding 5μm may induce imbalance at 20,000 RPM, accelerating wear and risking structural collapse. Such scenarios underscore why precision engineering is not a cost center but a strategic investment in operational reliability. At Wuxi Lead Precision Machinery, we treat tolerances not as targets but as absolute boundaries, rigorously enforced through closed-loop metrology and process validation.

Our commitment to uncompromising precision is validated through demanding real-world deployments. We engineered critical components for the Beijing 2022 Winter Olympics ice-resurfacing fleet, where sub-10μm geometric accuracy ensured flawless ice consistency under extreme cold and vibration. Similarly, our collaboration with Tier-1 defense contractors required AS9100-certified production of missile guidance subsystems, where surface finishes and positional tolerances directly impacted targeting accuracy in high-G environments. These projects exemplify how military-grade and Olympic-scale applications demand more than standard machining—they require predictive process control, material science expertise, and zero-defect accountability at every micro-step.

The table below outlines the precision benchmarks we consistently achieve across our facility, reflecting capabilities honed through such high-stakes engagements:

| Specification Category | Capability Range | Measurement Standard | Application Relevance |

|---|---|---|---|

| Dimensional Tolerance | ±0.001 mm to ±0.005 mm | ISO 2768-mK | Aerospace hydraulic manifolds |

| Geometric Accuracy (GD&T) | ±0.002 mm (True Position) | ASME Y14.5-2018 | Satellite deployment mechanisms |

| Surface Roughness (Ra) | 0.2 μm to 0.8 μm | ISO 4287 | Medical implant interfaces |

| Material Complexity | Titanium, Inconel, PEEK | ASTM/AMS standards | Jet engine compressor blades |

| Traceability | Full lot-to-part digital | ITAR-compliant | Defense-critical assemblies |

Achieving this level of precision demands more than advanced machinery—it requires embedding quality into the engineering DNA. Our process begins with DFM analysis to preempt manufacturability risks, followed by in-process CMM verification at critical stages, and culminates in full first-article inspection reports traceable to NIST standards. For clients, this translates to reduced assembly scrap, extended service life, and compliance with stringent regulatory frameworks like ITAR and FAA Part 21.

When your application tolerates no margin for error, precision becomes the language of trust. Wuxi Lead Precision Machinery operates at this threshold daily, transforming complex engineering intent into flawless physical reality. Partner with us to ensure your custom CNC machining parts perform exactly as designed—wherever excellence is non-negotiable.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in precision CNC machining, engineered to meet the exacting demands of high-performance industries such as aerospace, medical, automation, and energy. At the core of our manufacturing excellence is a fully integrated 5-axis CNC machining platform, enabling us to produce highly complex geometries with superior accuracy and surface integrity. Unlike conventional 3-axis systems, our 5-axis machines allow simultaneous movement across all five axes, minimizing setup cycles and ensuring tight alignment across multi-faceted components. This capability significantly enhances part consistency, reduces lead times, and supports the production of intricate designs that would otherwise require multiple operations or custom fixtures.

Our machining centers are equipped with high-speed spindles, advanced tool management systems, and real-time monitoring software, ensuring optimal cutting performance and tool life. We work with a wide range of engineering-grade materials, including aluminum alloys, stainless steel, titanium, brass, PEEK, and other high-strength composites. Each machining process is supported by in-house CAD/CAM programming, allowing for seamless transition from design to production with full digital traceability. Our engineers collaborate closely with clients during the design-for-manufacturability (DFM) phase to optimize part geometry, material selection, and machining strategy—ensuring cost efficiency without compromising performance.

Quality assurance is embedded at every stage of production. All critical dimensions are verified using state-of-the-art Coordinate Measuring Machines (CMM) with multi-sensor technology, providing micron-level measurement accuracy. Our CMM inspection routines are fully programmable and repeatable, enabling 100% inspection of high-volume batches or detailed first-article reports for prototype validation. In addition to CMM, we employ optical comparators, surface roughness testers, and calibrated hand tools to validate dimensional conformity and surface finish specifications.

The following table outlines the standard tolerance capabilities achievable across common machining operations:

| Feature | Standard Tolerance | Precision Tolerance (Optional) |

|---|---|---|

| Linear Dimensions (mm) | ±0.05 mm | ±0.01 mm |

| Hole Diameter | ±0.05 mm | ±0.0125 mm |

| Positional Tolerance | ±0.05 mm | ±0.02 mm |

| Flatness | 0.05 mm | 0.01 mm |

| Perpendicularity | 0.05 mm | 0.02 mm |

| Surface Roughness (Ra) | 3.2 µm | 0.8 µm (machined), down to 0.2 µm (polished) |

| Angular Dimensions | ±0.1° | ±0.05° |

These tolerances are consistently maintained through environmental controls, preventive maintenance schedules, and operator training. All inspection data is documented and provided with shipments, ensuring full compliance with ISO 9001 standards and customer-specific quality requirements. Wuxi Lead Precision Machinery combines cutting-edge 5-axis technology with rigorous quality control to deliver custom CNC machined parts that meet the highest benchmarks in precision and reliability.

Material & Finish Options

Material Selection Fundamentals for Precision CNC Machined Components

Selecting the optimal material is critical for balancing performance, cost, and manufacturability in custom CNC machining. At Wuxi Lead Precision Machinery, our engineering team prioritizes material properties aligned with your functional requirements, environmental exposure, and lifecycle demands. Misalignment here directly impacts part longevity, assembly compatibility, and total project cost. We analyze stress loads, corrosion resistance, weight constraints, and regulatory standards before finalizing recommendations.

Aluminum alloys dominate aerospace, automotive, and electronics due to their exceptional strength-to-weight ratio and thermal conductivity. 6061-T6 offers versatile machinability and weldability for structural components, while 7075-T6 delivers superior strength for high-stress applications like landing gear fittings. Aluminum’s natural corrosion resistance is often enhanced through finishing processes, but its lower hardness requires careful toolpath planning to prevent burring during high-speed milling.

Carbon and stainless steels provide unmatched durability for heavy industrial machinery, tooling, and marine hardware. 4140 alloy steel excels in high-wear scenarios requiring heat treatment, whereas 303 and 304 stainless grades ensure corrosion resistance in chemical or saline environments. Steel’s higher density and abrasiveness necessitate rigid machine setups and specialized tooling to maintain tight tolerances—particularly critical for hydraulic manifolds or valve bodies where micro-defects cause system failure.

Titanium Grade 5 (6Al-4V) is indispensable for medical implants and aerospace critical components where biocompatibility, extreme temperature resilience, and fatigue resistance are non-negotiable. Its low thermal conductivity demands precise coolant management during machining to avoid work hardening, while its high cost justifies near-net-shape strategies to minimize material waste. Titanium’s performance premium is justified only when aluminum or steel cannot meet operational extremes.

Surface finishing, particularly anodizing, transforms aluminum’s functional and aesthetic properties. Type II (sulfuric acid) anodizing provides moderate corrosion resistance and dye compatibility for consumer electronics housings. Type III (hardcoat) anodizing creates a wear-resistant ceramic layer exceeding 60 HRC hardness for hydraulic pistons or military hardware. Incorrect anodizing parameters—such as excessive voltage or inadequate sealing—cause micro-cracking that compromises corrosion barriers. Our integrated finishing facility controls every variable to meet MIL-A-8625 or ISO 10074 specifications.

Material selection must be a collaborative engineering decision, not a procurement checkbox. Below are key comparative specifications to guide initial feasibility assessment.

| Material | Key Grades | Tensile Strength (MPa) | Common Applications | Machinability Rating |

|---|---|---|---|---|

| Aluminum | 6061-T6, 7075-T6 | 310, 572 | Enclosures, brackets, drone frames | Excellent (A) |

| Stainless Steel | 303, 304, 4140 | 620, 505, 655 | Valves, shafts, surgical tools | Moderate (B) |

| Titanium | Grade 5 (6Al-4V) | 900 | Aircraft fittings, prosthetics | Poor (D) |

Partnering with an experienced CNC manufacturer early in design prevents costly material-related rework. Wuxi Lead’s material science expertise ensures your selection optimizes performance while leveraging our high-precision milling, turning, and finishing capabilities for flawless execution.

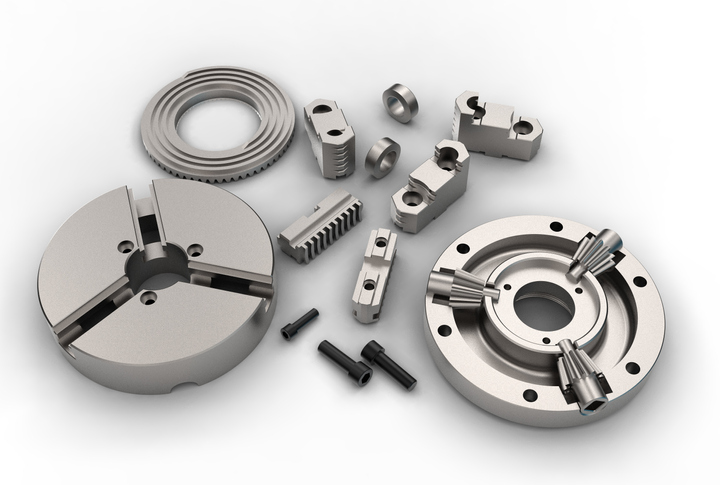

Manufacturing Process & QC

At Wuxi Lead Precision Machinery, our custom CNC machining process is engineered for precision, consistency, and zero-defect delivery. We adhere to a structured workflow that spans from initial design to prototyping and full-scale production, ensuring every component meets the highest standards of quality and performance.

The process begins with design analysis and engineering validation. Our team collaborates closely with clients to review CAD models, material specifications, tolerances, and functional requirements. Using advanced simulation software, we conduct a comprehensive design for manufacturability (DFM) assessment to identify potential issues early, optimize toolpaths, and ensure the design aligns with precision machining capabilities. This phase reduces costly revisions and accelerates time to market.

Once the design is finalized, we proceed to prototyping. Prototypes are manufactured using the same high-precision CNC equipment intended for mass production, including 3-axis, 4-axis, and 5-axis machining centers. This ensures dimensional accuracy and surface finish consistency from prototype to final part. Each prototype undergoes rigorous inspection using coordinate measuring machines (CMM), optical comparators, and surface roughness testers. Feedback from prototype testing is integrated swiftly, allowing for rapid iterations until the part meets all functional and aesthetic criteria.

With prototype approval, we transition seamlessly into mass production. Our production floor is equipped with automated CNC systems, robotic part handling, and real-time monitoring to maintain throughput and precision. Every stage of machining—milling, turning, drilling, and finishing—is controlled via ISO-certified processes. We implement Statistical Process Control (SPC) to monitor critical dimensions continuously, ensuring process stability and early detection of variation.

Quality assurance is embedded at every step. In-process inspections, first-article inspections (FAI), and final batch audits are standard. All components are traceable through our digital quality management system, which logs material certifications, machine parameters, and inspection reports. This level of documentation ensures full compliance with aerospace, medical, and industrial standards.

Our commitment to zero defects is driven by precision engineering, advanced metrology, and a culture of continuous improvement. By integrating design, prototyping, and production under one roof, Wuxi Lead ensures unmatched consistency, reliability, and delivery performance for every custom CNC machining project.

| Specification | Detail |

|---|---|

| Machining Types | 3-axis, 4-axis, 5-axis CNC milling, CNC turning, multi-axis milling-turning |

| Materials | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Titanium, Brass, PEEK, Delrin |

| Tolerance | ±0.005 mm (±0.0002″) standard; tighter upon request |

| Surface Finish | As-machined: Ra 3.2 μm; polished to Ra 0.4 μm |

| Max Work Envelope | 1200 x 800 x 600 mm (47 x 31 x 24 in) |

| Quality Standards | ISO 9001:2015, ISO 13485 (medical), AS9100 (aerospace) |

| Inspection Equipment | CMM, optical comparator, surface roughness tester, micrometers, calipers |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Mission-Critical CNC Machining Excellence

Your engineering team demands components that perform flawlessly under extreme conditions. Generic machining services introduce unacceptable risk—dimensional drift, material inconsistencies, or delayed deliveries that derail production schedules. At Wuxi Lead Precision Machinery, we engineer certainty into every custom CNC part. Our ISO 9001-certified facility in China merges German-engineered machinery with rigorously trained technicians to deliver precision where it matters most. We specialize in low-volume, high-complexity components for aerospace, medical device, and energy sectors—parts where tolerances tighter than ±0.005mm and material integrity are non-negotiable.

Our integrated manufacturing ecosystem eliminates traditional supply chain vulnerabilities. From titanium aerospace brackets to corrosion-resistant marine valve components, we control every variable: raw material traceability, in-process metrology, and final inspection using Zeiss CMMs. This disciplined approach ensures first-article approval rates exceeding 98% and on-time delivery performance above 99.2%. We invest in your success through collaborative engineering reviews—identifying manufacturability improvements that reduce costs without compromising function.

Technical Capabilities at a Glance

| Parameter | Specification |

|——————–|—————————————-|

| Materials | Aluminum 7075-T6, Titanium Grade 5, Inconel 718, Stainless 316L, PEEK, Brass C360 |

| Tolerances | ±0.005mm (standard), ±0.002mm (precision) |

| Max Work Envelope | 1200 x 800 x 650 mm (5-axis milling) |

| Surface Finish | Ra 0.4 µm to Ra 3.2 µm (customizable) |

| Lead Times | 15–30 days (complex prototypes to production) |

| Certifications | ISO 9001:2015, AS9100D, NADCAP (pending) |

Choosing a machining partner is a strategic decision that impacts product reliability and time-to-market. Wuxi Lead Precision provides more than parts—we deliver engineering partnership. Our team engages early in your design phase, offering DFM insights that prevent costly revisions. Real-time production tracking via our secure client portal ensures transparency, while dedicated project managers act as your single point of accountability from RFQ to shipment.

The next project deadline won’t wait. Submit your technical drawings and requirements to [email protected] today. Our engineering team will respond within 4 business hours with a detailed manufacturability assessment and competitive quotation. Specify your target tolerance class and material certification requirements to accelerate the review process. For urgent RFQs, include “Priority Engineering Review” in the subject line.

Trust Wuxi Lead Precision Machinery to transform your most demanding designs into precision reality. We don’t just meet specifications—we engineer confidence into every component. Contact us now to secure capacity for your Q3–Q4 production runs. Your breakthrough project deserves nothing less.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.