Technical Contents

Engineering Guide: Cnc Milling Metals

Engineering Insight: CNC Milling Metals – The Imperative of Precision

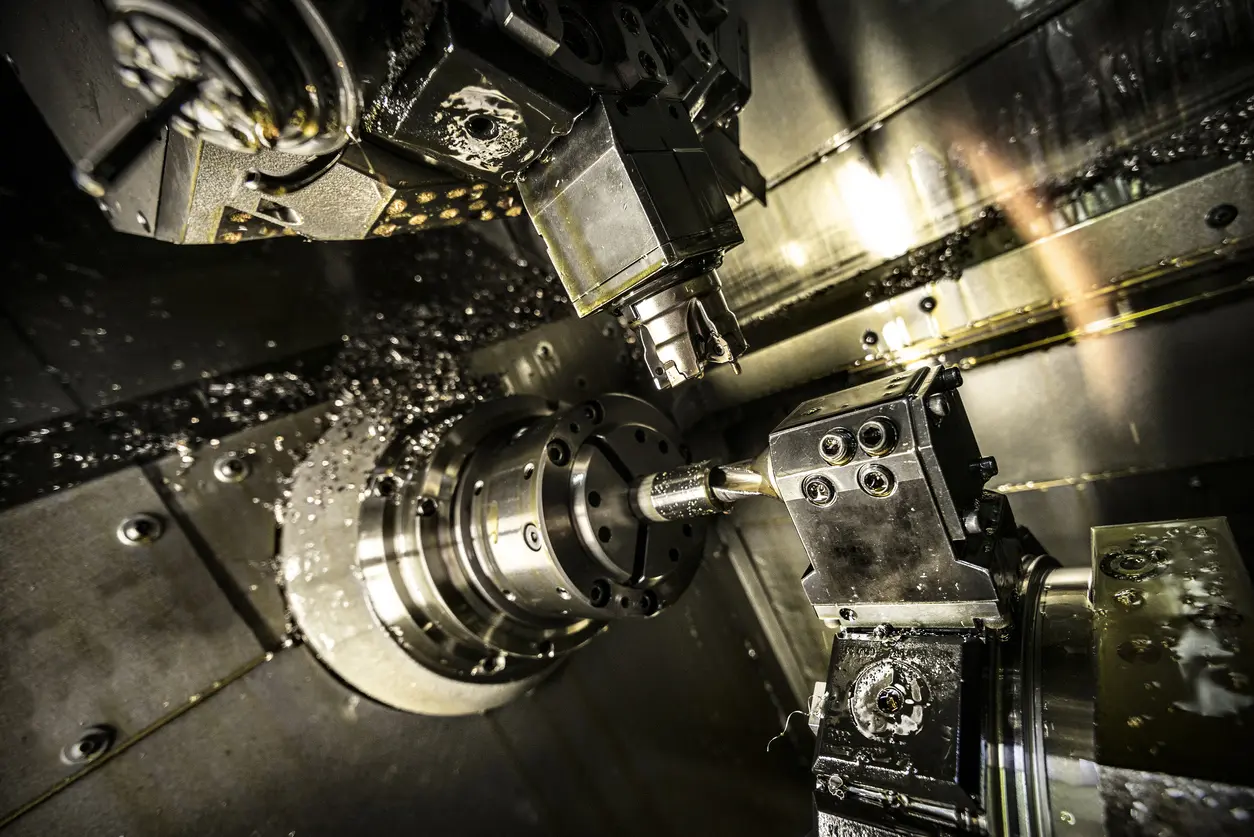

In the realm of advanced manufacturing, CNC milling metals stands as a cornerstone process for producing high-integrity components across aerospace, defense, medical, and high-performance industrial sectors. At Wuxi Lead Precision Machinery, we recognize that precision is not merely a target—it is a foundational requirement. The ability to maintain tight tolerances, ensure geometric accuracy, and deliver repeatable results defines the threshold between functional reliability and operational failure.

Precision in CNC milling metals begins with machine rigidity, thermal stability, and advanced control systems, but it extends far beyond hardware. It is embedded in process engineering, toolpath optimization, material science understanding, and real-time quality validation. At Lead Precision, our CNC milling operations are calibrated to achieve tolerances as tight as ±0.002 mm, supported by 5-axis simultaneous machining capabilities and in-process probing systems that ensure consistency across production runs.

Our expertise has been rigorously tested in mission-critical applications. We have supplied components for Olympic-standard sporting equipment where aerodynamic symmetry and weight distribution are paramount. Equally, our machining solutions have met stringent military specifications, where failure is not an option. These projects demand more than technical capability—they require a culture of precision that permeates every stage of production, from raw material selection to final inspection.

Material behavior during milling is a critical engineering consideration. Metals such as titanium, Inconel, aluminum alloys, and hardened steels each present unique challenges in terms of thermal expansion, chip evacuation, and tool wear. Our engineers employ adaptive machining strategies, including high-speed cutting (HSC) and trochoidal milling, to manage heat generation and maintain dimensional stability. Surface finishes down to 0.4 µm Ra are routinely achieved, minimizing the need for secondary operations.

Below is a summary of key performance specifications achieved through our CNC milling processes:

| Parameter | Specification |

|---|---|

| Positional Accuracy | ±0.002 mm |

| Repeatability | ±0.001 mm |

| Maximum Work Envelope | 1200 × 800 × 600 mm (5-axis) |

| Spindle Speed Range | 20,000 RPM (high-speed options) |

| Surface Finish (Typical) | 0.4 – 1.6 µm Ra |

| Materials Supported | Aluminum, Titanium, Inconel, Steel, Stainless Steel, Brass |

| Quality Standards | ISO 9001:2015, MIL-STD-810, AS9100 |

At Wuxi Lead Precision Machinery, precision is not an outcome—it is engineered. Our decades of experience in high-stakes manufacturing environments have refined our approach to CNC milling metals, ensuring that every component meets the highest standards of performance, reliability, and quality. For industries where precision defines success, we deliver with confidence.

Precision Specs & Tolerances

Technical Capabilities: Precision CNC Milling for Demanding Metal Applications

Wuxi Lead Precision Machinery delivers uncompromising precision in CNC milling of complex metal components for the world’s most demanding industries. Our core strength lies in integrating state-of-the-art multi-axis machining technology with rigorous, traceable quality control systems, ensuring every part meets exacting aerospace, medical, and defense specifications. We specialize in transforming challenging engineering designs into reality using advanced 5-axis CNC milling centers, primarily featuring DMG MORI and MAZAK platforms renowned for stability, accuracy, and thermal compensation. These machines enable simultaneous 5-axis interpolation, eliminating the need for multiple setups and significantly reducing cumulative error. This capability is essential for producing intricate geometries, deep cavities, undercuts, and organic forms found in turbine blades, surgical implants, and structural aerospace brackets from materials including titanium alloys, Inconel, aluminum 7075-T6, and hardened tool steels up to 60 HRC. Proven repeatability within tight tolerances is not an aspiration but a daily operational standard.

Our commitment to quality is embedded throughout the manufacturing process, anchored by comprehensive Coordinate Measuring Machine (CMM) inspection. Every critical feature undergoes meticulous verification using Zeiss and Hexagon GLOBAL S CMMs, operating within a temperature-controlled metrology lab. This ensures full dimensional and geometric compliance against the original CAD model and customer drawing requirements. Inspection reports are fully traceable, providing detailed GD&T analysis and surface finish verification, meeting stringent AS9100 and ISO 13485 documentation standards. This systematic approach guarantees that components not only meet print but also function flawlessly in their final assembly, minimizing scrap and rework for our partners.

The synergy between our advanced 5-axis machining capacity and rigorous CMM-based quality assurance delivers tangible value. Customers achieve significant reductions in lead times through consolidated operations, enhanced part integrity by eliminating secondary setup errors, and absolute confidence in component performance under extreme conditions. We understand that precision in high-value metal components is non-negotiable; it directly impacts safety, efficiency, and regulatory approval. Wuxi Lead operates as a true engineering partner, providing not just machining services but deep technical consultation on design for manufacturability (DFM) specific to complex metal milling, ensuring optimal results from prototype through high-volume production. Our facility is engineered for seamless global supply chain integration, offering consistent quality delivery to international clients.

The following table details our typical achievable precision capabilities across common metal alloys:

| Specification Category | Typical Achievable Tolerance | Notes |

|---|---|---|

| Dimensional (Linear) | ±0.005 mm (±0.0002″) | For features < 100 mm |

| ±0.010 mm (±0.0004″) | For features 100-300 mm | |

| Geometric (True Position) | Ø0.010 mm (Ø0.0004″) | Critical features, datum referenced |

| Ø0.020 mm (Ø0.0008″) | Standard features | |

| Surface Finish (Ra) | 0.4 – 0.8 µm (16 – 32 µin) | Milling, standard production |

| 0.2 µm (8 µin) | Achievable with fine finishing passes | |

| Angularity / Perpendicularity | ±0.005° | Over 100 mm length |

These capabilities, consistently proven through rigorous CMM validation, form the foundation of Wuxi Lead’s reputation for delivering mission-critical metal components where precision is paramount.

Material & Finish Options

When selecting materials for precision CNC milling in high-performance applications, Aluminum, Steel, and Titanium stand out as the most widely used metals due to their distinct mechanical properties, machinability, and suitability for specific industrial environments. At Wuxi Lead Precision Machinery, we understand that optimal material choice directly impacts part functionality, longevity, and cost-efficiency. This guide outlines key characteristics of these metals and the role of surface finishes such as anodizing in enhancing performance.

Aluminum is favored in aerospace, automotive, and electronics industries for its excellent strength-to-weight ratio, thermal conductivity, and corrosion resistance. Grade 6061-T6 is particularly popular due to its weldability and moderate strength, while 7075-T6 offers higher strength for demanding structural applications. Aluminum’s low density and ease of machining make it ideal for complex geometries and high-volume production runs. However, its lower wear resistance compared to steel necessitates protective finishes in abrasive environments.

Steel, especially in alloy and stainless forms, provides superior strength, durability, and wear resistance. 4140 alloy steel is commonly used in tooling and high-stress components, while 304 and 316 stainless steels offer excellent corrosion resistance, making them suitable for medical, food processing, and marine applications. Despite being more challenging to machine than aluminum, modern CNC technology allows precise cutting of steel with tight tolerances. Post-machining heat treatments can further enhance hardness and structural integrity.

Titanium, particularly Grade 5 (Ti-6Al-4V), is the material of choice in aerospace, medical implants, and high-performance automotive sectors. It offers an exceptional strength-to-density ratio and outstanding resistance to corrosion, even in extreme environments. However, titanium’s low thermal conductivity and high chemical reactivity require specialized tooling and slower machining parameters to prevent work hardening and tool wear. Despite higher material and processing costs, its performance benefits justify its use in mission-critical components.

Surface finishing plays a crucial role in extending component life and improving aesthetics. Anodizing, primarily applied to aluminum, creates a durable, corrosion-resistant oxide layer that can be dyed for identification or branding. Type II (sulfuric acid) and Type III (hardcoat) anodizing offer varying levels of thickness and hardness, with Type III suitable for high-wear applications. While anodizing does not apply to steel or titanium, these metals benefit from alternatives such as passivation, plating, or coating.

Below is a comparative overview of key material properties relevant to CNC milling:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Common Grades | Typical Applications | Machinability Rating |

|---|---|---|---|---|---|

| Aluminum | 2.7 | 310 (6061-T6) | 6061, 7075 | Aerospace, Electronics | Excellent |

| Steel (Alloy) | 7.8 | 655 (4140) | 4140, 4340 | Tooling, Automotive | Moderate |

| Stainless Steel | 8.0 | 505 (304) | 304, 316 | Medical, Marine | Fair |

| Titanium | 4.5 | 900 (Ti-6Al-4V) | Gr 2, Gr 5 | Aerospace, Medical Implants | Poor to Moderate |

Selecting the right material requires balancing performance requirements, environmental exposure, and production costs. At Wuxi Lead Precision Machinery, we support clients in making informed decisions through expert consultation and advanced CNC capabilities tailored to each metal’s unique behavior.

Manufacturing Process & QC

Wuxi Lead Precision Machinery: Precision CNC Milling Metals Production Process

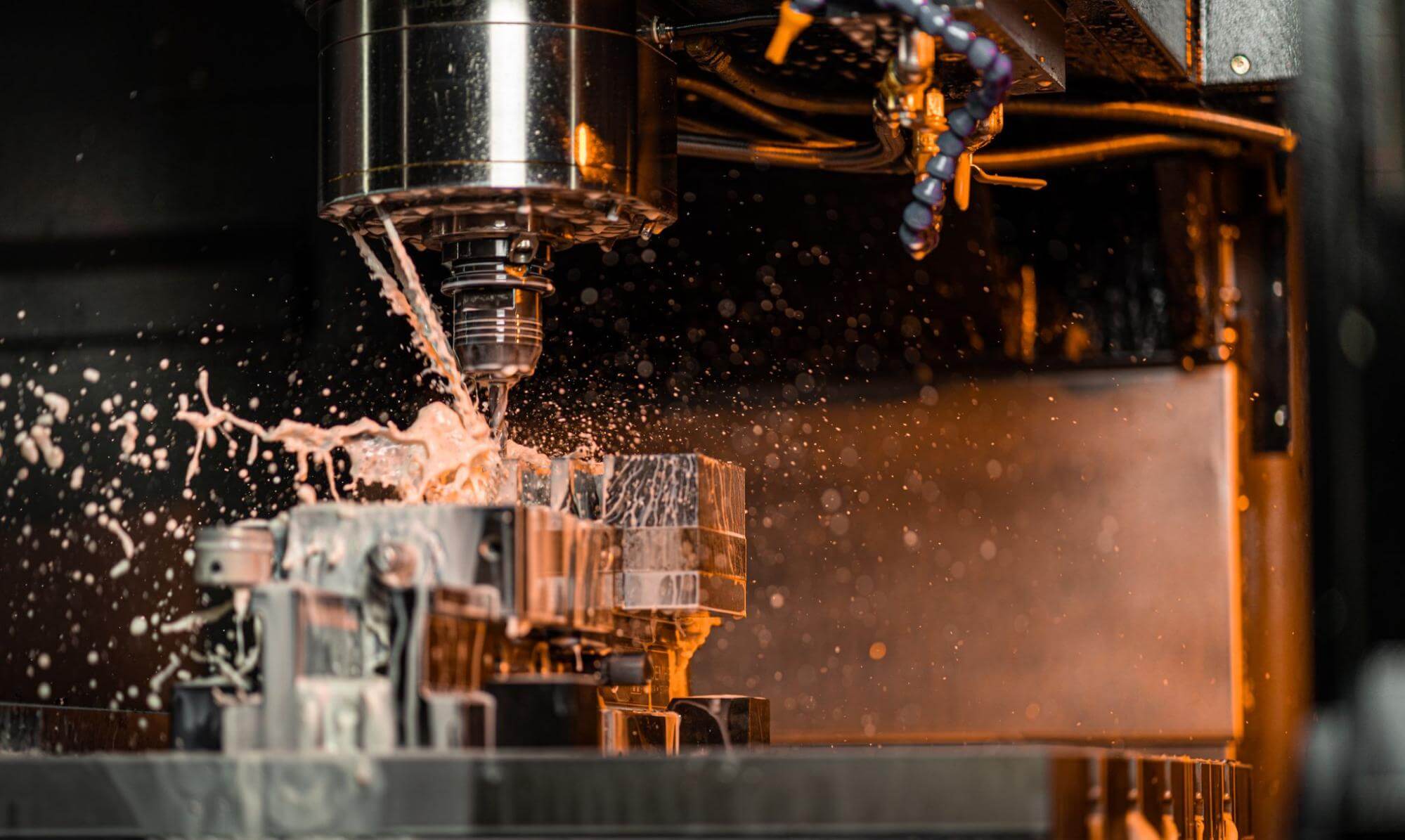

Achieving zero-defect outcomes in high-end CNC milling of metals demands a rigorously controlled, integrated production process. At Wuxi Lead Precision Machinery, we execute this through three critical, interdependent phases: Design Optimization, Precision Prototyping, and Scalable Mass Production. Each phase incorporates proactive quality assurance, eliminating defects before they occur rather than relying solely on end-of-line inspection.

The process begins with collaborative Design for Manufacturability (DFM) analysis. Our engineering team works directly with client CAD models, scrutinizing geometric complexity, material suitability, and tolerance stack-ups specific to metals like aerospace-grade aluminum alloys, titanium, and hardened stainless steels. We identify potential machining challenges—thin walls, deep cavities, or critical intersecting features—and propose refinements before metal is cut. This phase ensures the design is not just functional but inherently manufacturable to micron-level precision, preventing costly iterations later. Material certification and traceability protocols are established here, aligning with AS9100 or ISO 9001 requirements as mandated by the application.

Prototyping is not merely a validation step; it is the cornerstone of our zero-defect strategy. Using the same HAAS and DMG MORI 5-axis vertical machining centers intended for production, we manufacture initial units under identical process parameters. Advanced 3D scanning and CMM inspection verify dimensional accuracy against the optimized design in real-time. Any deviation triggers immediate root-cause analysis—adjusting toolpaths, refining fixturing, or optimizing coolant strategies—before committing to volume. This iterative prototyping phase typically resolves over 90% of potential production issues, ensuring the process window is fully validated and robust.

Mass Production leverages the perfected process blueprint. Our fully automated cells, featuring robotic pallet changers and in-process probing, maintain consistent environmental and operational conditions. Real-time tool wear monitoring, thermal compensation systems, and automated first-article inspection after every 50 parts guarantee sustained adherence to specifications. Crucially, our zero-defect framework integrates Statistical Process Control (SPC) data from every machine, enabling predictive adjustments. Final inspection employs multi-sensor CMMs and surface roughness testers, with full traceability from raw material batch to finished component. This closed-loop system ensures every part meets the exacting standards demanded by aerospace, medical, and semiconductor industries.

The following table summarizes our core production capabilities for critical metal components:

| Specification Category | Capability Range | Typical Application Standard |

|---|---|---|

| Material Compatibility | Aluminum 6061/7075, Titanium Grade 5, Stainless Steel 303/316/17-4PH, Inconel 718 | Aerospace, Medical Implants |

| Dimensional Tolerance | ±0.005 mm (±0.0002″) for critical features | AS9100, ISO 2768-mK |

| Surface Finish (Ra) | 0.8 μm to 3.2 μm achievable; 0.4 μm possible with secondary processes | ISO 1302, Aerospace Spec |

| Max Work Envelope | 1000 x 600 x 500 mm (XYZ) | Large Structural Components |

| Process Cycle Time Reduction | 15-25% via optimized toolpath & automation | Cost-Sensitive Production |

This integrated approach—where design foresight, prototyping rigor, and production intelligence converge—transforms zero defects from an aspiration into a measurable, repeatable outcome. Wuxi Lead delivers not just parts, but guaranteed performance and supply chain reliability for your most demanding metal components.

Why Choose Wuxi Lead Precision

When it comes to high-performance CNC milling of metals, precision, repeatability, and material integrity are non-negotiable. At Wuxi Lead Precision Machinery, we specialize in delivering advanced CNC machining solutions tailored to the most demanding industrial applications. Our expertise spans aerospace, automotive, medical device manufacturing, and energy sectors, where component reliability directly impacts system performance and safety. If your operation requires micron-level accuracy, superior surface finishes, and strict adherence to engineering tolerances, partnering with Lead Precision is the strategic advantage you need.

Our CNC milling capabilities are built on a foundation of state-of-the-art equipment, rigorous quality control, and a team of engineers with deep metallurgical and machining process knowledge. We work with a wide range of engineering metals, including aluminum alloys, stainless steels, titanium, Inconel, brass, and hardened tool steels. Each project is approached with a focus on optimizing tool paths, minimizing thermal deformation, and ensuring dimensional stability across production runs—whether prototyping or high-volume manufacturing.

We understand that no two applications are identical. That’s why our engineering team collaborates closely with clients from design review through final inspection. We offer Design for Manufacturability (DFM) analysis to reduce costs, improve lead times, and enhance part functionality. Our 5-axis CNC milling centers provide exceptional flexibility for complex geometries, deep cavities, and tight-tolerance features that challenge conventional machining.

Our facility is ISO 9001:2015 certified, equipped with coordinate measuring machines (CMM), optical comparators, and surface roughness testers to ensure every component meets or exceeds specifications. With real-time process monitoring and full traceability, we deliver consistency you can rely on—batch after batch.

Below are key technical specifications of our CNC milling capabilities:

| Parameter | Specification |

|---|---|

| Machine Types | 3-axis, 4-axis, 5-axis CNC milling centers |

| Maximum Work Envelope | 1200 mm × 800 mm × 600 mm |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Spindle Speed | Up to 24,000 rpm |

| Tool Capacity | Up to 30-tool automatic tool changer |

| Materials Processed | Aluminum, steel, stainless steel, titanium, Inconel, brass, copper, tool steel |

| Tolerance Range | ±0.01 mm (standard), down to ±0.005 mm (tight-tolerance) |

| Surface Finish | As low as Ra 0.4 µm (polished finishes available) |

| Quality Standards | ISO 9001:2015, full inspection reporting, PPAP, FAI support |

Partnering with Wuxi Lead Precision Machinery means gaining a manufacturing ally committed to technical excellence and operational transparency. We don’t just produce parts—we engineer solutions that enhance your product performance and streamline your supply chain.

For detailed technical consultations, project quotes, or to send CAD/CAM files for evaluation, contact us today at [email protected]. Let us demonstrate how precision engineering and responsive service can elevate your next metal milling project.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.