Technical Contents

Engineering Guide: Aluminum Printing

Engineering Insight Aluminum Additive Manufacturing Precision Requirements

Precision in aluminum additive manufacturing transcends mere dimensional accuracy; it defines functional integrity for mission-critical components. In aerospace, defense, and high-performance sporting goods, tolerances below 20 microns directly impact fatigue resistance, thermal management, and aerodynamic efficiency. Conventional casting or machining often introduces material inconsistencies or geometric limitations that additive processes overcome—but only when executed with uncompromising process control. At Wuxi Lead Precision Machinery, we treat micron-level repeatability as non-negotiable, not optional. Our engineering protocols stem from direct experience delivering components for Olympic-level equipment and Tier-1 military suppliers, where a single micron deviation can invalidate years of R&D investment.

Aluminum printing demands holistic precision management across powder metallurgy, thermal dynamics, and post-processing. Standard industrial systems frequently tolerate ±50–100μm deviations in complex geometries, but our clients require ±15μm consistency even in thin-walled, high-aspect-ratio structures. This necessitates real-time melt pool monitoring, inert gas purification to 10ppm oxygen levels, and stress-relief cycles calibrated to specific alloy microstructures. For instance, our work on titanium-aluminum compressor blades for a defense contractor required maintaining 0.02mm positional accuracy across 300mm spans—achieved through adaptive laser power modulation and in-situ metrology. Similarly, Olympic bobsled runners we produced demanded mirror-smooth surface finishes (Ra ≤ 0.8μm) without secondary polishing to minimize ice friction. Such outcomes rely on proprietary parameter libraries refined over 12,000+ production builds.

Our technical capabilities consistently exceed industry benchmarks, as demonstrated below:

| Parameter | Industry Standard | Lead Precision Capability |

|---|---|---|

| Layer Thickness | 30–50μm | 20–30μm |

| X-Y Accuracy | ±40μm | ±15μm |

| Z-Axis Accuracy | ±50μm | ±20μm |

| Build Volume (max) | 250x250x300mm | 400x400x500mm |

| Surface Roughness (as-built) | Ra 10–15μm | Ra 3–5μm |

| Oxygen Control | 100–200ppm | ≤10ppm |

Achieving this level of precision requires treating additive manufacturing as a closed-loop engineering system, not just a production step. Every build undergoes pre-print thermal simulation and post-build CT scanning to validate internal porosity levels below 0.1%. Our ISO 13485-certified facility integrates metrology data directly into parameter adjustments, ensuring batch-to-batch uniformity critical for serialized military hardware. When your application demands aluminum components that perform under extreme cyclic loads or thermal gradients, precision isn’t measured in microns alone—it’s quantified in mission success rates. Partner with engineers who’ve delivered under Olympic podium pressure and battlefield specifications. Contact Wuxi Lead Precision Machinery to transform your most demanding aluminum AM challenges into certified, flight-ready solutions.

Precision Specs & Tolerances

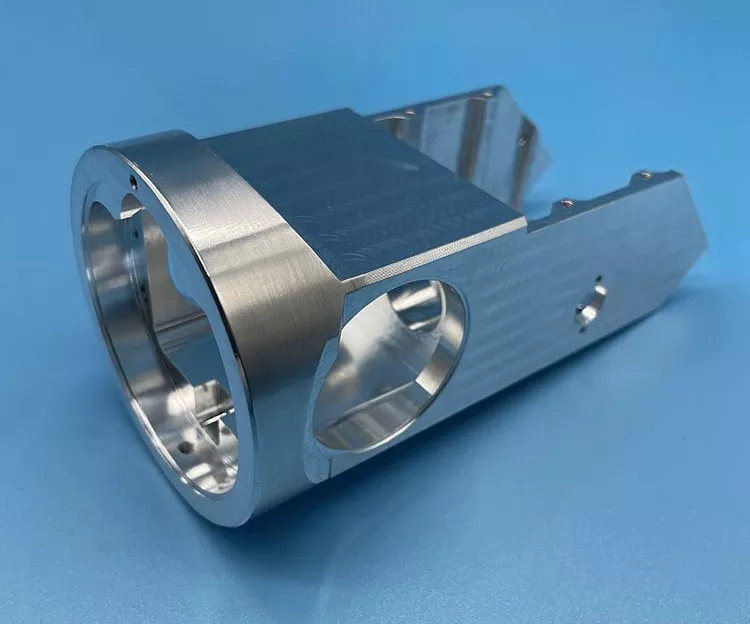

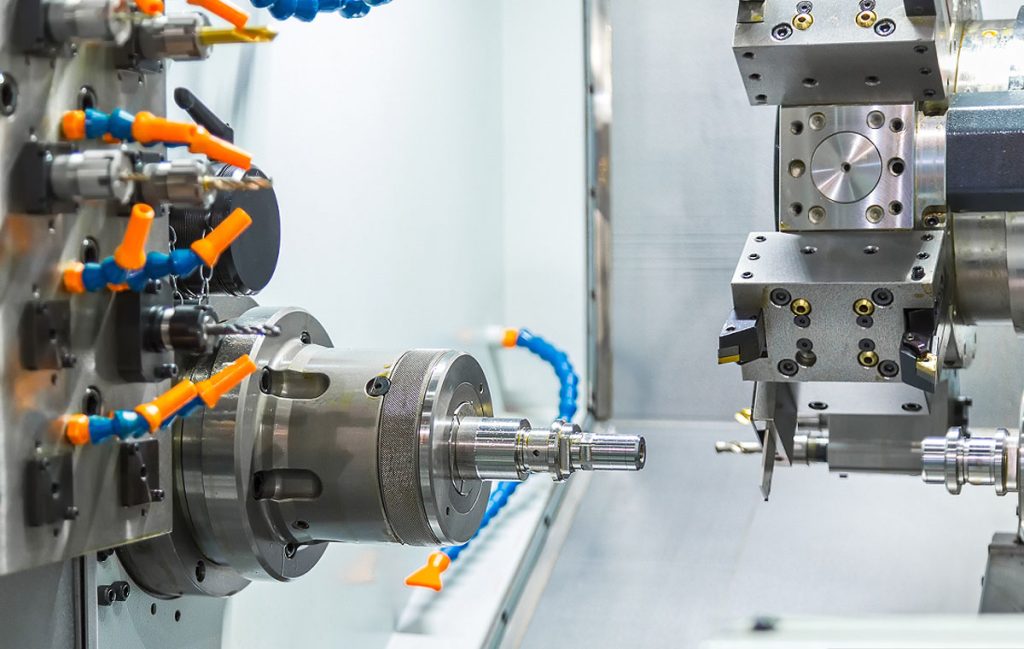

Wuxi Lead Precision Machinery delivers advanced manufacturing solutions for high-performance aluminum components, serving industries where precision, reliability, and repeatability are mission-critical. Our technical capabilities are anchored in state-of-the-art 5-axis CNC machining systems, enabling us to produce complex geometries with exceptional accuracy and surface finish. These multi-axis platforms allow simultaneous movement across five planes, eliminating the need for multiple setups and significantly reducing cumulative error. This capability is particularly vital in aluminum printing applications, where thin walls, deep cavities, and organic forms demand continuous tool engagement and dynamic cutting angles.

Our 5-axis machining centers are equipped with high-speed spindles, automated tool changers, and real-time monitoring systems to maintain consistent performance across production runs. The integration of advanced CAM software ensures optimal toolpath generation, minimizing cycle times while maximizing material removal rates—especially critical when working with aluminum’s high thermal conductivity and tendency toward chatter. We specialize in processing aerospace-grade aluminum alloys such as 6061, 7075, and 2024, as well as custom alloys requiring tight thermal and dimensional control.

Quality assurance is embedded into every phase of production. Each component undergoes comprehensive inspection using a Zeiss DuraMax and Contura G2 Coordinate Measuring Machine (CMM), ensuring metrological validation of critical dimensions, geometric tolerances, and surface integrity. Our CMM systems operate under temperature-controlled conditions to eliminate thermal drift, delivering measurement repeatability within ±0.0001 mm. In addition to first-article inspection, we perform in-process and final inspections on all high-precision runs, with full traceability maintained through digital quality records.

The following table outlines the standard tolerances we consistently achieve in aluminum machining operations:

| Feature | Standard Tolerance | High-Precision Capability |

|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.005 mm |

| Positional Tolerance | ±0.02 mm | ±0.008 mm |

| Flatness | 0.02 mm per 100 mm | 0.005 mm per 100 mm |

| Circular Runout | 0.015 mm | 0.003 mm |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm |

| Angular Tolerance | ±0.05° | ±0.01° |

These specifications reflect our commitment to exceeding industry benchmarks in custom aluminum manufacturing. Whether producing prototypes or high-volume production parts, Wuxi Lead Precision Machinery combines cutting-edge equipment with rigorous quality control to deliver components that meet exacting engineering requirements. Our technical team collaborates closely with clients during design for manufacturability (DFM) reviews, ensuring optimal part performance while minimizing cost and lead time. With full in-house capability from CNC programming to final inspection, we provide a seamless, scalable solution for advanced aluminum printing and precision machining needs.

Material & Finish Options

Material Selection Guide for High-Precision CNC Machined Components

The term aluminum printing is a misnomer in industrial manufacturing; aluminum components are exclusively produced through subtractive methods like CNC machining, not additive printing. At Wuxi Lead Precision Machinery, we emphasize precise material selection as the foundation of performance-critical parts. Aluminum alloys dominate aerospace, automotive, and electronics due to their optimal strength-to-weight ratio and thermal conductivity. Steel offers unmatched durability for structural applications, while titanium provides exceptional corrosion resistance and biocompatibility for medical or marine use. Each material demands tailored machining strategies to achieve micron-level tolerances and surface integrity.

Aluminum 6061-T6 and 7075-T6 are industry standards. 6061 balances weldability and moderate strength, ideal for brackets and housings. 7075 delivers aerospace-grade strength but requires slower machining speeds to prevent work hardening. Steel variants like 304 stainless excel in high-stress environments but generate significant heat during cutting, necessitating rigid toolpaths and coolant optimization. Titanium Grade 5 (Ti-6Al-4V) demands specialized tooling and low RPMs to avoid galling, though its fatigue resistance justifies the machining complexity for critical components. Material choice directly impacts lead time, tool wear, and final part cost—factors we rigorously model during our quoting phase.

Anodizing is non-negotiable for aluminum end-use parts exposed to environmental stress. Type II (sulfuric acid) anodizing creates a 5–25μm decorative and corrosion-resistant layer, while Type III (hardcoat) yields 25–125μm thickness for extreme abrasion resistance. Both processes enhance paint adhesion but require precise voltage control to avoid micro-cracking. Note: Anodizing cannot be applied to steel or titanium; these materials rely on passivation (steel) or plasma electrolytic oxidation (titanium) for surface protection.

Our engineering team evaluates five core parameters when advising clients: operational temperature range, load dynamics, environmental exposure, regulatory compliance (e.g., ASTM, ISO), and lifecycle cost. Below is a comparative reference for common alloys:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Machinability Rating | Relative Cost |

|---|---|---|---|---|---|

| Aluminum 6061-T6 | 2.7 | 310 | Good | 9/10 | + |

| Aluminum 7075-T6 | 2.8 | 572 | Moderate | 7/10 | ++ |

| Steel 304 | 8.0 | 505 | Moderate | 6/10 | + |

| Titanium Ti-6Al-4V | 4.4 | 900 | Excellent | 3/10 | ++++ |

Selecting the optimal material-finishing combination prevents field failures and reduces total ownership costs. For instance, anodized 7075 aluminum outperforms steel in weight-sensitive drone arms, while titanium’s bioinertness makes it irreplaceable for surgical implants. Wuxi Lead’s CNC machining centers—including 5-axis DMG MORI and Makino systems—are calibrated to handle these materials with zero rework tolerance. We recommend initiating projects with our material consultation to align specifications with your functional requirements and production volume. Contact our engineering team for application-specific feasibility analysis and finish recommendations.

Manufacturing Process & QC

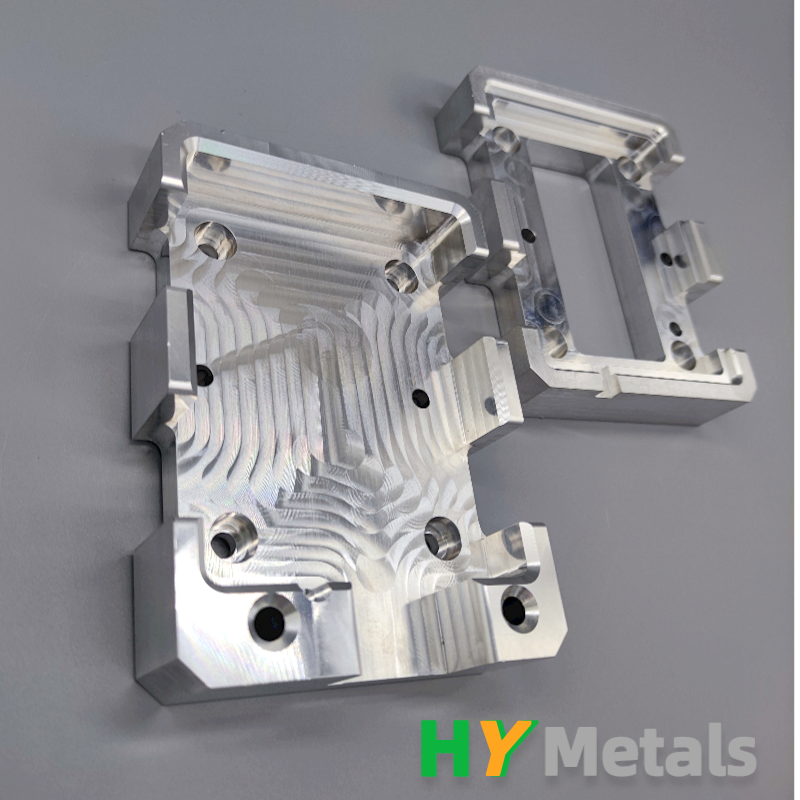

Design: Precision Engineering at the Foundation

The journey of aluminum printing begins with design, where engineering excellence meets functional intent. At Wuxi Lead Precision Machinery, we collaborate closely with clients to transform conceptual ideas into manufacturable, high-performance components. Utilizing advanced CAD/CAM software and finite element analysis (FEA), our engineering team optimizes part geometry for structural integrity, thermal performance, and weight efficiency. Special attention is given to material behavior during the printing phase, including thermal expansion, residual stress, and layer adhesion. Design for Additive Manufacturing (DfAM) principles are rigorously applied to minimize support structures, reduce post-processing effort, and ensure dimensional accuracy. Every design undergoes a comprehensive review cycle, including tolerance stack-up analysis and manufacturability validation, to eliminate potential flaws before physical production begins.

Prototyping: Validating Performance and Precision

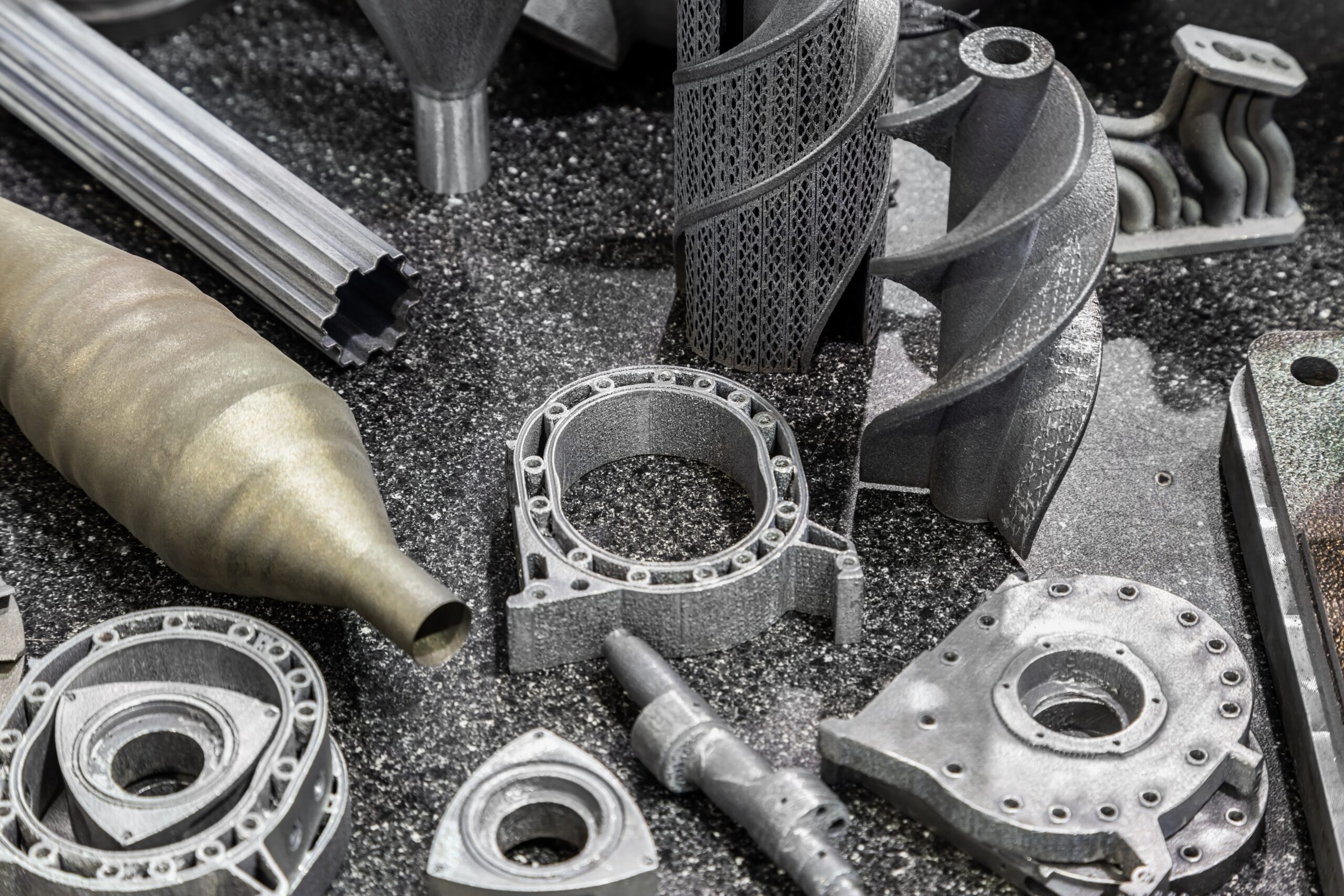

Once the design is finalized, we proceed to prototyping using state-of-the-art metal additive manufacturing systems. Our aluminum printing process leverages Selective Laser Melting (SLM) technology, enabling the fabrication of complex geometries unachievable through traditional machining. Prototypes are produced using high-purity aluminum alloys such as AlSi10Mg, known for excellent castability, thermal conductivity, and mechanical strength. Each prototype undergoes full metrological inspection using coordinate measuring machines (CMM) and 3D scanning to verify conformity to design specifications. Functional testing, including pressure, fatigue, and thermal cycling, is conducted to validate real-world performance. This phase is critical for identifying and correcting design or process deviations, ensuring that only fully qualified parts advance to mass production.

Mass Production: Scalable Excellence with Zero Defects

Transitioning to mass production, Wuxi Lead implements a fully controlled manufacturing environment designed for repeatability and quality assurance. Our production cells operate under strict environmental controls, with real-time monitoring of laser power, scan speed, layer thickness, and inert gas purity. Each build is supported by in-situ process monitoring, including layer-wise imaging and thermal tracking, to detect anomalies instantly. Post-processing follows a standardized sequence: controlled cooling, support removal, heat treatment (T6 temper as required), CNC machining for critical surfaces, and surface finishing (shot peening, anodizing, or polishing). Every component undergoes 100% inspection, with non-destructive testing (NDT) methods such as X-ray and ultrasonic testing applied to mission-critical parts.

Material and Process Specifications

| Parameter | Specification |

|---|---|

| Material | AlSi10Mg, Al6061, Al7075 (custom alloys on request) |

| Build Volume | Up to 500 x 500 x 400 mm |

| Layer Thickness | 20–60 μm |

| Positional Accuracy | ±0.05 mm / 100 mm |

| Surface Roughness (as-printed) | Ra 8–12 μm |

| Post-Processing Options | CNC machining, heat treatment, anodizing, polishing |

| Quality Standards | ISO 9001:2015, AS9100D (aerospace compliance) |

Through integrated design validation, precision prototyping, and defect-free mass production, Wuxi Lead ensures every aluminum-printed component meets the highest standards of performance, reliability, and consistency.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Advanced Aluminum Additive Manufacturing

The term “aluminum printing” often misrepresents the sophisticated industrial process required for high-integrity metal components. True aluminum additive manufacturing, specifically Direct Metal Laser Sintering (DMLS), demands precision engineering, rigorous material science, and deep process control – far beyond basic prototyping. At Wuxi Lead Precision Machinery, we transform this complex capability into a reliable, scalable production solution for demanding industries like aerospace, medical devices, and high-performance automotive. We eliminate the risk and uncertainty associated with adopting metal AM by providing engineered excellence from concept to certified part.

Lead Precision delivers more than machines; we provide a fully integrated manufacturing ecosystem. Our DMLS systems, developed and calibrated within our ISO 9001:2015 certified facility, are optimized for consistent production of complex aluminum geometries impossible with traditional CNC or casting. We address the core challenges: minimizing material waste, achieving near-net-shape accuracy to reduce secondary machining, and ensuring mechanical properties meet stringent aerospace and medical standards. Our engineering team collaborates closely with your design and production staff from the initial feasibility assessment through to final part validation, embedding manufacturability into your design process.

Our core DMLS capability for aluminum alloys is defined by repeatable, industrial-grade specifications:

| Parameter | Specification | Significance |

|---|---|---|

| Material | AlSi10Mg (Aerospace Grade) | Excellent castability, high strength, low weight |

| Density | ≥ 99.95% | Near-full density ensures structural integrity |

| Tensile Strength | ≥ 480 MPa | Meets critical performance requirements |

| Elongation | ≥ 10% | Essential ductility for safety-critical parts |

| Layer Thickness | 20-60 μm | Precision surface finish and detail resolution |

| Build Volume | Up to Ø250 x 325 mm | Accommodates production-scale part batches |

Partnering with Lead Precision means accessing a strategic manufacturing advantage. We mitigate your technical risk through our proprietary process monitoring and in-situ quality control systems, ensuring every build layer meets exacting tolerances. Our post-processing expertise – including stress-relieving, precision CNC finishing, and surface treatments – guarantees parts arrive ready for integration, not just printing. We understand your production timeline and quality audits are non-negotiable; our systems are built for 24/7 industrial operation with minimal downtime.

Do not compromise on the integrity of your critical aluminum components. Wuxi Lead Precision Machinery provides the engineering rigor, certified processes, and responsive partnership required to successfully implement aluminum additive manufacturing as a core production technology. Contact our engineering sales team directly to discuss your specific application challenges and production volumes. Initiate your project with confidence: Email [email protected] today for a confidential technical consultation and capability review. Let us demonstrate how our precision manufacturing solutions become your competitive edge.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.