Technical Contents

Engineering Guide: 6 Molding

Engineering Insight: The Critical Role of Precision in 6 Molding Processes

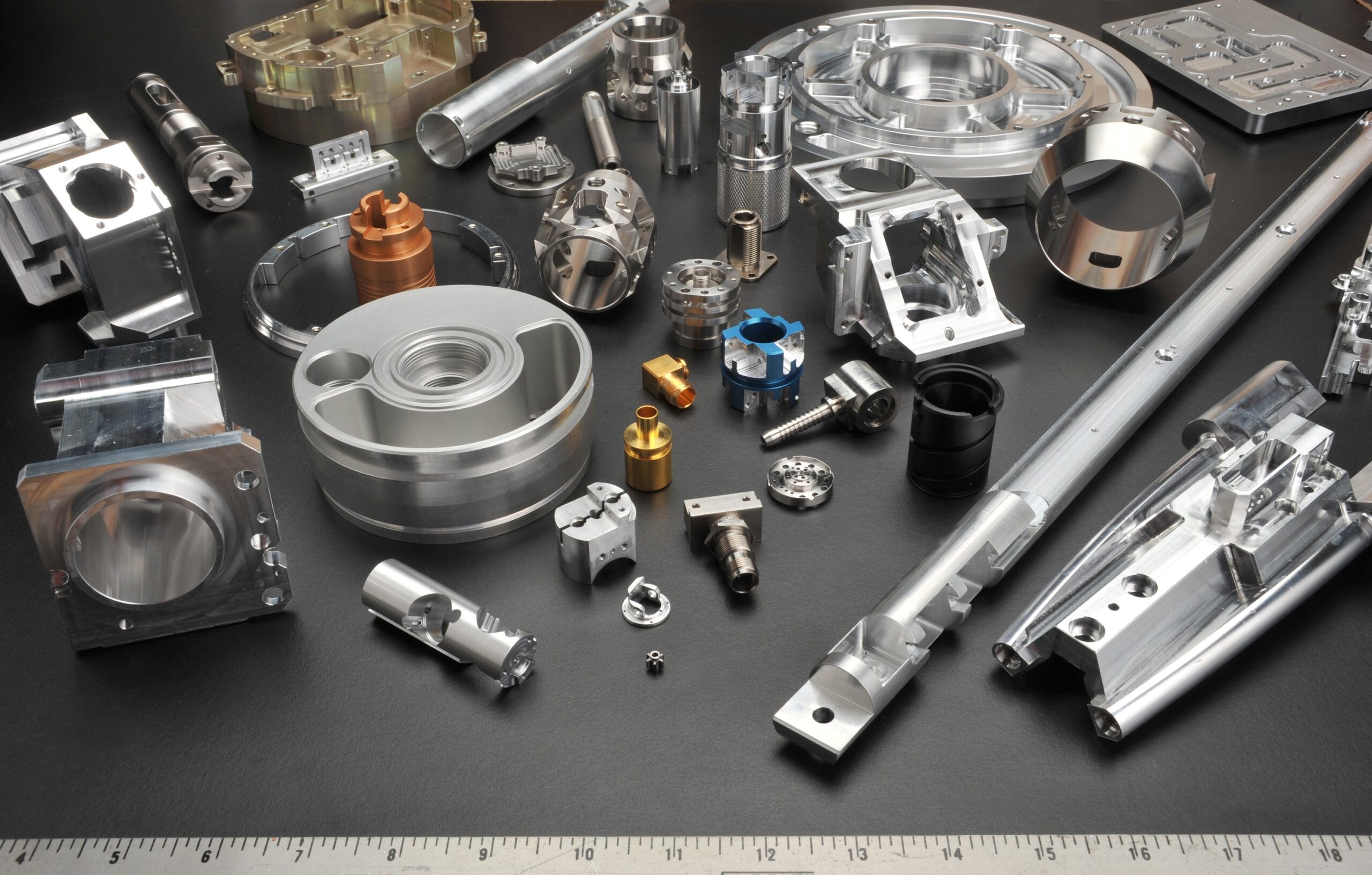

In the realm of advanced custom metal manufacturing, the term “6 molding” refers to a highly integrated approach that combines precision forming, machining, and assembly across six coordinated stages. This methodology is not merely a production sequence—it is an engineering philosophy rooted in consistency, tolerancing, and material integrity. At Wuxi Lead Precision Machinery, we define 6 molding as a benchmark for excellence, where every micron of deviation is accounted for, and every component is engineered to perform under extreme conditions.

Precision in 6 molding is non-negotiable. Components produced through this process are often deployed in mission-critical environments—ranging from aerospace systems to defense applications—where failure is not an option. The accumulation of minor variances across multiple stages can result in catastrophic performance degradation. Therefore, our engineering protocols emphasize real-time metrology, closed-loop feedback systems, and adaptive tooling to maintain tolerances within ±0.002 mm. This level of control ensures that each molded stage aligns perfectly with the next, preserving geometric accuracy and functional reliability.

Our expertise in 6 molding has been rigorously tested through high-profile projects, including components certified for Olympic-standard equipment and precision subsystems adopted in military-grade hardware. These applications demanded not only adherence to international quality standards but also the ability to scale production without compromising repeatability. By integrating proprietary CNC algorithms and in-process inspection, Wuxi Lead has achieved a first-pass yield rate exceeding 98.7% across high-mix, low-volume production runs.

Material selection and thermal management are equally pivotal in 6 molding. We utilize advanced alloys such as 7075-T6 aluminum, Inconel 718, and maraging steel, all processed under controlled environments to minimize residual stress. Each molding phase is supported by finite element analysis (FEA) simulations, ensuring that deformation risks are predicted and mitigated before physical production begins.

The following table outlines key performance specifications achieved through our 6 molding process:

| Parameter | Specification |

|---|---|

| Dimensional Tolerance | ±0.002 mm |

| Surface Roughness (Ra) | 0.4 – 1.6 µm |

| Maximum Component Weight | 120 kg |

| Minimum Feature Resolution | 0.1 mm |

| Production Repeatability (CpK) | ≥1.67 |

| Materials Supported | Aluminum, Titanium, Stainless Steel, Inconel, Brass |

| Lead Time (Prototype) | 12–18 days |

| Quality Certification | ISO 9001:2015, AS9100D (Aerospace) |

Wuxi Lead Precision Machinery’s success in 6 molding stems from a fusion of empirical experience and cutting-edge technology. Our engineering team averages over 15 years of specialized manufacturing experience, with direct involvement in national defense initiatives and international sporting infrastructure. This depth of knowledge allows us to anticipate challenges before they arise, delivering not just parts—but performance-proven solutions.

Precision Specs & Tolerances

Technical Capabilities: Precision Metal Manufacturing for Demanding Applications

Wuxi Lead Precision Machinery delivers uncompromising accuracy in custom metal components through advanced multi-axis CNC machining and rigorous quality validation. Our core strength lies in mastering complex geometries inherent in high-integrity sectors like aerospace, medical devices, and energy systems. Central to this capability is our fleet of state-of-the-art 5-axis CNC machining centers, featuring simultaneous motion control across X, Y, Z, A, and B axes. This technology eliminates the need for multiple setups, ensuring critical feature relationships are maintained within micron-level tolerances while significantly reducing lead times and human error potential. Our engineers leverage proprietary fixturing strategies and adaptive toolpath generation to machine intricate contours, deep cavities, and thin-walled structures from challenging alloys including titanium, Inconel, and hardened tool steels. Material integrity is preserved through optimized cutting parameters and real-time process monitoring, preventing thermal distortion and ensuring dimensional stability throughout production.

Quality assurance is not an endpoint but an integrated process. Every component undergoes comprehensive Coordinate Measuring Machine (CMM) inspection using calibrated Zeiss and Hexagon systems. Our AS9100 and ISO 9001-certified protocols mandate full-surface scanning against 3D CAD models, validating geometric dimensioning and tolerancing (GD&T) compliance for form, position, and profile. Statistical process control (SPC) data is continuously analyzed to identify trends and drive proactive process refinement. This closed-loop methodology guarantees that tolerances are consistently achieved batch after batch, providing clients with absolute confidence in part interchangeability and functional performance.

The following table details our standard achievable tolerances for critical machining parameters, reflecting our commitment to exceeding industry benchmarks:

| Parameter | Standard Capability | High-Precision Capability | Measurement Method |

|---|---|---|---|

| Linear Dimension (mm) | ±0.010 | ±0.005 | CMM / High-Precision Micrometer |

| Angular Tolerance (°) | ±0.05 | ±0.02 | CMM / Sine Bar |

| Positional Tolerance (mm) | ±0.012 | ±0.008 | CMM |

| Surface Roughness (Ra) | 0.8 μm | 0.4 μm | Profilometer |

| Flatness (mm/m) | 0.015 | 0.008 | CMM / Optical Flat |

These specifications are validated under controlled environmental conditions (20°C ±0.5°C) and represent our baseline for production runs. For mission-critical applications, we collaborate with clients during the design phase to establish enhanced tolerance zones and specialized inspection protocols, ensuring manufacturability without compromising functionality. Our investment in Siemens-controlled 5-axis platforms, coupled with CMM traceability to national standards, transforms engineering intent into physically flawless components. This precision foundation directly supports clients in reducing assembly scrap, accelerating time-to-market, and achieving superior product reliability in the field. Partner with Wuxi Lead to convert your most challenging metal fabrication requirements into certified, high-yield realities.

Material & Finish Options

Material Selection for High-Precision Metal Components in 6 Molding Applications

Selecting the appropriate material is critical in high-end metal manufacturing, especially within the context of 6 molding processes where dimensional accuracy, structural integrity, and surface finish are paramount. At Wuxi Lead Precision Machinery, we specialize in custom metal components engineered for performance-driven industries such as aerospace, medical devices, and advanced automation. Our expertise enables clients to make informed decisions between aluminum, steel, and titanium—three of the most widely used materials in precision manufacturing.

Aluminum is often the preferred choice when weight reduction and corrosion resistance are key requirements. Its high strength-to-density ratio, excellent thermal conductivity, and machinability make it ideal for complex molds and housings. When paired with anodizing, aluminum achieves enhanced surface hardness and wear resistance. Type II and Type III (hard coat) anodizing are commonly applied, with the latter offering a durable, non-conductive surface capable of withstanding harsh environments.

Steel, particularly tool steel and stainless steel variants, delivers superior durability and resistance to deformation under high stress and temperature. This makes it suitable for long-run molding applications where tool longevity is essential. While steel does not anodize like aluminum, it can be treated with passivation, nitriding, or coated with PVD/CVD layers to improve surface performance. Its inherent rigidity ensures minimal deflection during precision operations, a critical factor in maintaining tight tolerances.

Titanium stands at the pinnacle of performance materials, offering an exceptional strength-to-weight ratio and outstanding resistance to corrosion, even in extreme conditions. Though more challenging to machine and higher in cost, titanium is indispensable in aerospace and medical implant manufacturing. It does not support conventional anodizing for decorative or protective purposes in the same way as aluminum, but electrochemical treatments can produce functional oxide layers that improve biocompatibility and wear behavior.

Each material presents distinct advantages, and the final selection depends on application-specific demands such as load, environment, lifecycle, and regulatory compliance. Our engineering team at Wuxi Lead Precision Machinery supports clients through material evaluation, prototyping, and finish selection to ensure optimal performance and cost-efficiency.

The following table summarizes key mechanical and finishing properties of these materials:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Common Finishes | Max Operating Temp (°C) | Typical Applications |

|---|---|---|---|---|---|

| Aluminum 6061-T6 | 310 | 2.7 | Anodizing (Type II/III), Powder Coat | 120 | Molds, brackets, enclosures |

| Steel (4140) | 655 | 7.85 | Passivation, Nitriding, Chrome Plating | 480 | Tooling, shafts, high-load parts |

| Titanium (Ti-6Al-4V) | 900 | 4.43 | Electrochemical Oxidation, Bead Blast | 600 | Aerospace, medical implants, marine |

Material selection is not merely a technical decision—it is a strategic one. At Wuxi Lead Precision Machinery, we combine metallurgical insight with precision manufacturing to deliver components that meet the highest industrial standards.

Manufacturing Process & QC

Precision Metal Molding: From Design to Zero-Defect Mass Production

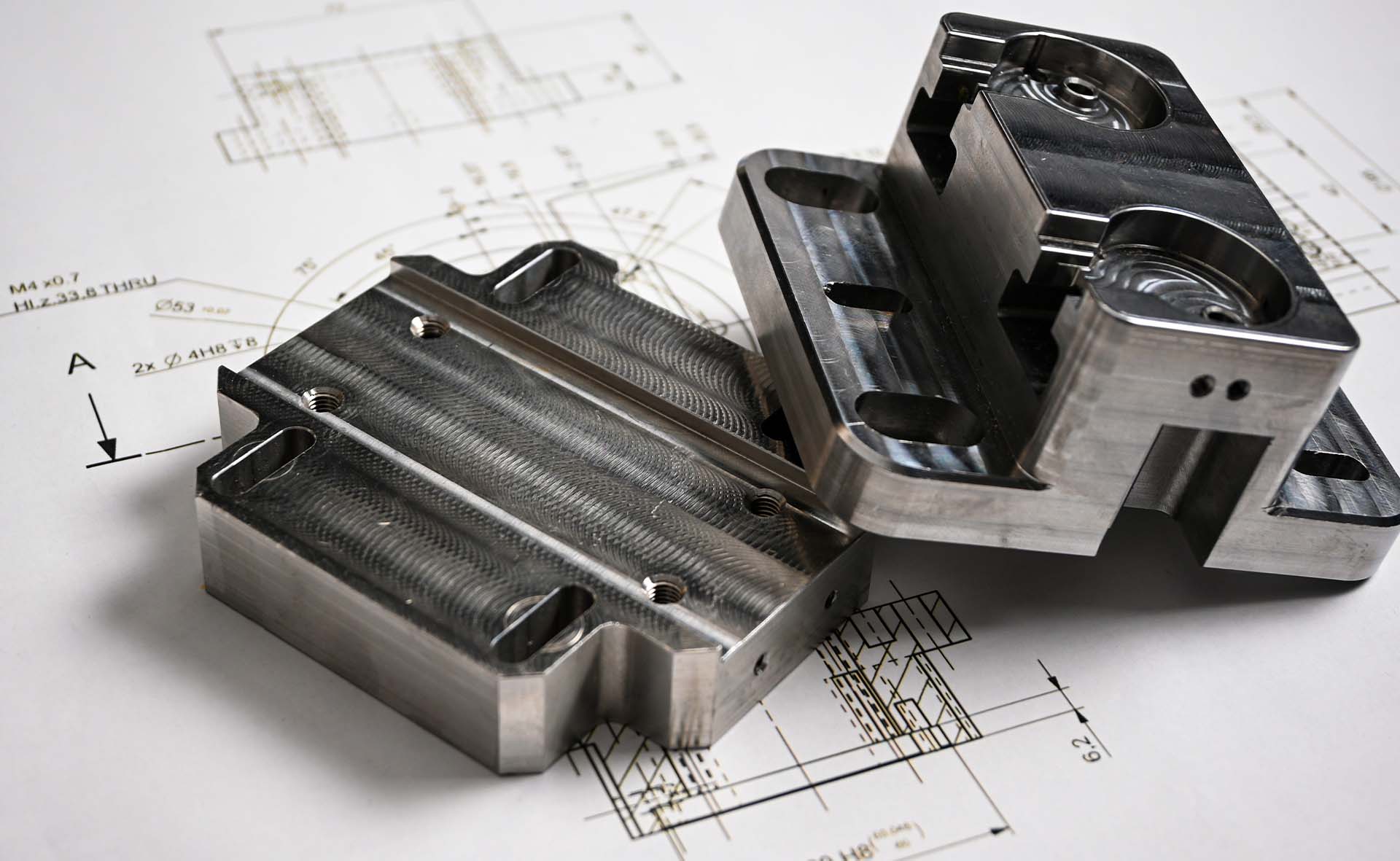

At Wuxi Lead Precision Machinery, our Six-Axis Precision Molding process delivers uncompromising quality for complex metal components. This integrated methodology ensures zero defects from initial concept through high-volume production, leveraging advanced engineering and rigorous validation. The journey begins with collaborative design engineering. Our team conducts in-depth Design for Manufacturability (DFM) analysis, utilizing 3D CAD/CAM simulations to optimize part geometry, material flow, and stress distribution. Finite Element Analysis (FEA) identifies potential weak points, allowing iterative refinement before tooling commences. This phase is critical for eliminating inherent design flaws that could compromise structural integrity or dimensional accuracy in the final part.

Prototyping transitions validated designs into physical reality under controlled conditions. Using high-fidelity soft tooling or rapid CNC-machined prototypes, we produce initial units for comprehensive metrology. Every critical dimension is verified against CAD models using coordinate measuring machines (CMM) and optical scanners, generating traceable inspection reports. Material properties undergo destructive and non-destructive testing to confirm compliance with ASTM or ISO standards. Client feedback is incorporated during this stage, ensuring functional performance aligns with application requirements before committing to production tooling. This iterative validation prevents costly errors in mass production.

Mass production deploys hardened steel molds within our climate-controlled facility, monitored by real-time process control systems. Each molding cycle adheres to strictly defined parameters, with automated sensors tracking temperature, pressure, and cycle time. Statistical Process Control (SPC) charts continuously analyze output, triggering immediate corrective actions if deviations exceed ±0.005mm tolerance thresholds. 100% inline optical inspection systems scan every component for surface defects, dimensional variances, or material inconsistencies, rejecting non-conforming units before they progress. Final parts undergo batch-level certification, including material traceability documentation and full-first-article inspection (FAI) reports per AS9102 standards.

Our Six-Axis Molding capabilities support demanding aerospace, medical, and energy sector applications. Key technical specifications are maintained across all production runs:

| Parameter | Capability Range | Tolerance Control | Material Compatibility |

|---|---|---|---|

| Part Complexity | Up to 6-axis forming | ±0.005 mm (critical) | Titanium, Inconel, Stainless Steel, Aluminum Alloys |

| Wall Thickness | 0.2 mm – 12.0 mm | ±0.02 mm (nominal) | |

| Production Volume | 1 – 500,000+ units | Cpk ≥ 1.67 | |

| Cycle Time | 15 – 180 seconds | Real-time monitored |

This closed-loop process—design rigor, prototype validation, and intelligent mass production—ensures zero-defect deliverables. By embedding quality at every phase, Wuxi Lead minimizes scrap, accelerates time-to-market, and guarantees components that perform reliably in mission-critical applications. Partner with us to transform precision metal molding challenges into competitive advantage. Contact our engineering team for a process audit tailored to your specifications.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Custom Metal Manufacturing

At Wuxi Lead Precision Machinery, we specialize in delivering precision-engineered metal components tailored to the exacting demands of global industries. With decades of experience in CNC machining and custom metal fabrication, we have established ourselves as a trusted partner for high-end manufacturing solutions. Our commitment to quality, consistency, and technical excellence makes us the ideal choice for companies seeking a reliable supplier in the competitive landscape of industrial production.

Our facility in Wuxi, China, is equipped with state-of-the-art CNC machining centers, advanced quality inspection systems, and a team of skilled engineers who oversee every stage of production. We understand that in high-performance applications—ranging from aerospace and medical devices to automation and energy systems—precision is non-negotiable. That’s why we implement strict process controls, ISO-compliant workflows, and full traceability to ensure every component meets or exceeds customer specifications.

When you partner with Lead Precision, you gain more than a manufacturer—you gain a collaborative engineering resource. From initial design consultation to prototyping, volume production, and logistics support, we work closely with your team to optimize manufacturability, reduce lead times, and control costs without compromising on quality. Our agile production model allows for both low-volume, high-mix runs and high-volume continuous manufacturing, giving you the flexibility your business demands.

We serve clients across North America, Europe, and Asia, supporting industries where performance and reliability are paramount. Our quality management system is ISO 9001 certified, and we routinely comply with international standards including RoHS, REACH, and ITAR where applicable. Whether you require tight-tolerance milling, complex turning operations, or multi-axis machining, our capabilities are built to meet the most challenging requirements.

Below are key technical specifications that define our manufacturing capacity:

| Specification | Capability |

|---|---|

| Maximum Machining Size | 1200 mm × 800 mm × 650 mm |

| Tolerance Control | ±0.005 mm (standard), down to ±0.001 mm (precision) |

| Materials Processed | Aluminum Alloys, Stainless Steel, Titanium, Brass, Copper, Tool Steels, Plastics |

| CNC Equipment | 3-axis, 4-axis, 5-axis Machining Centers; CNC Turning Centers |

| Surface Finishes | As-machined, Anodizing, Plating, Powder Coating, Passivation |

| Quality Inspection | CMM, Optical Comparator, Surface Roughness Tester, Caliper/Micrometer Checks |

| Production Volume | Prototype to High-Volume Serial Production |

| Lead Times | 10–25 days (standard), expedited options available |

We invite you to experience the Lead Precision difference. Contact us today at [email protected] to discuss your next project. Our engineering team is ready to collaborate on design optimization, material selection, and production planning to ensure your components are manufactured to the highest standards of precision and reliability. Let us become your long-term manufacturing partner—driving performance, efficiency, and success in every part we produce.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.