Technical Contents

Engineering Guide: Mold Products

Engineering Insight: Precision as the Foundation of Mold Product Excellence

In custom metal manufacturing, mold products represent the critical interface between design intent and physical reality. The dimensional accuracy and surface integrity achieved during mold production directly dictate the quality, consistency, and functional performance of every component produced. For high-value applications across aerospace, medical devices, and advanced consumer goods, precision is not merely desirable; it is a non-negotiable requirement governing assembly success, product lifespan, and end-user safety. Minute deviations in mold geometry propagate exponentially during high-volume production, leading to part rejection, costly downtime, and compromised brand reputation. Achieving true precision demands more than advanced machinery; it requires integrated expertise spanning material science, thermal dynamics, and meticulous process control from initial design through final inspection.

Wuxi Lead Precision Machinery operates at this demanding threshold of capability. Our engineering team possesses deep specialization in overcoming the inherent challenges of mold manufacturing, particularly thermal distortion during extended production cycles and the stringent surface finishes required for optical or sealing surfaces. We implement rigorous metrology protocols at every stage, utilizing coordinate measuring machines (CMM) and optical comparators calibrated to national standards, ensuring traceability and repeatability. This systematic approach guarantees that tolerance bands are consistently met, not just on the first article but across the entire production run. Our facility leverages multi-axis CNC machining centers with sub-micron positional accuracy, specifically configured for the complex geometries and hardened tool steels prevalent in high-performance molds.

The following specifications reflect the precision benchmarks consistently achieved by Lead Precision for critical mold components:

| Specification Parameter | Typical Capability Range | Measurement Standard |

|---|---|---|

| Linear Dimensional Tolerance | ±0.002 mm to ±0.005 mm | ISO 2768-mK / Custom |

| Geometric Tolerance (GD&T) | ±0.003 mm (Position) | ASME Y14.5-2018 |

| Surface Roughness (Ra) | 0.05 µm to 0.4 µm | ISO 4287 / Custom Finish |

| Mirror Polish Achievability | SPI A-1 (Optical Grade) | SPI Standards |

| Thermal Stability (Post-Treatment) | < 5 µm distortion @ 100°C | In-house Thermal Cycling Test |

This level of precision is proven in environments where failure is unacceptable. Lead Precision has successfully delivered mission-critical mold components verified for use in systems supporting Olympic timing equipment, where microsecond accuracy is paramount, and specialized defense applications demanding absolute reliability under extreme operational stress. These projects underscore our capacity to meet and exceed the most exacting international standards through disciplined engineering and uncompromising process execution. For manufacturers requiring molds that deliver flawless parts run after run, Lead Precision provides the technical foundation where precision is engineered into every micron. Contact our engineering team to discuss how our precision manufacturing protocols can secure your next critical project.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers precision-engineered mold products through advanced custom metal manufacturing capabilities, serving high-demand industries such as automotive, aerospace, medical, and consumer electronics. At the core of our technical excellence is a fully integrated 5-axis CNC machining platform, enabling the production of complex geometries with superior surface finishes and tight tolerances. Our facility in Wuxi, China, operates under ISO-compliant standards, ensuring consistent repeatability and adherence to international quality benchmarks.

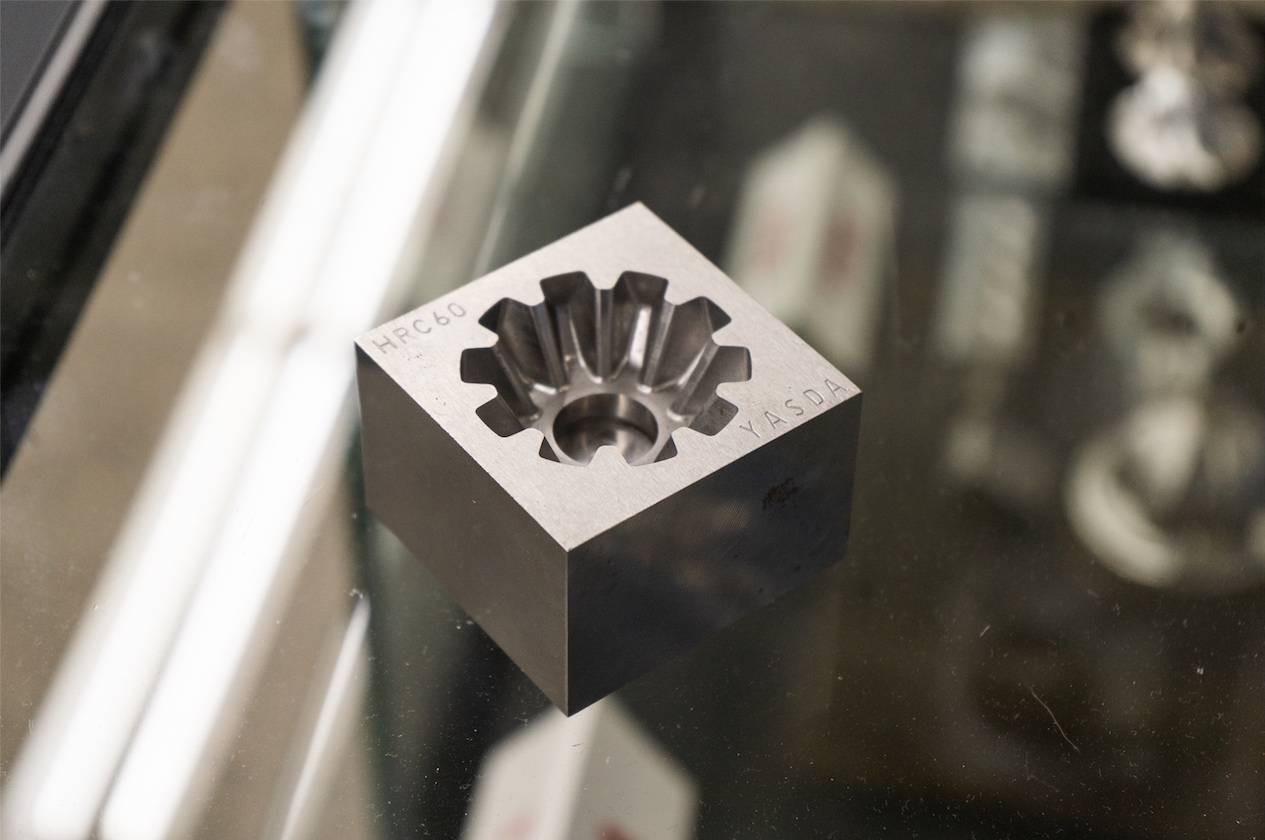

The 5-axis CNC machining centers utilized in our production process allow simultaneous movement across five axes, significantly enhancing machining accuracy and reducing setup times. This capability supports the creation of intricate mold cavities, core components, and electrode structures with minimal human intervention, reducing the risk of error and improving throughput. Advanced toolpath strategies and high-speed cutting techniques ensure optimal material removal rates while preserving dimensional integrity. Materials commonly processed include P20 and H13 tool steels, aluminum alloys, stainless steels, and high-temperature superalloys, all machined to exact customer specifications.

Quality assurance is rigorously maintained through a comprehensive inspection protocol anchored by Coordinate Measuring Machine (CMM) technology. Each mold component undergoes full dimensional validation using Zeiss and Mitutoyo CMM systems, providing micron-level verification of critical features. These inspections generate detailed reports traceable to individual work orders, supporting full documentation for customer audits and regulatory compliance. In addition to CMM, our quality control includes surface roughness testing, hardness verification, and first-article inspection processes, ensuring every product meets or exceeds design intent.

Our technical expertise extends beyond machining to include mold design support, material selection guidance, and manufacturability analysis. By collaborating early in the product development cycle, we help customers optimize designs for performance, longevity, and cost-efficiency. All programming is conducted using industry-leading CAD/CAM software, enabling seamless translation from 3D models to finished parts with precise tool engagement and collision avoidance.

The following table outlines the standard technical specifications and achievable tolerances for our mold product manufacturing:

| Parameter | Standard Capability | Tight Tolerance Option |

|---|---|---|

| Positional Tolerance | ±0.010 mm | ±0.005 mm |

| Linear Dimension Tolerance | ±0.012 mm | ±0.008 mm |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm (polished finish) |

| Angular Tolerance | ±0.05° | ±0.02° |

| Form Tolerance (Flatness) | 0.015 mm over 100 mm | 0.008 mm over 100 mm |

| Feature Repeatability | ±0.008 mm | ±0.004 mm |

| Max Work Envelope (5-axis) | 1,200 x 800 x 750 mm | Custom upon request |

Wuxi Lead Precision Machinery combines state-of-the-art equipment, rigorous quality control, and deep technical knowledge to deliver mold products that perform reliably under high-cycle production environments. Our capabilities are designed to meet the evolving demands of precision manufacturing with consistency, speed, and engineering integrity.

Material & Finish Options

Material Selection for Precision Mold Manufacturing

Selecting optimal materials for mold production directly impacts tool longevity, part quality, and production economics. At Wuxi Lead Precision Machinery, we prioritize metallurgical alignment with your application’s thermal, mechanical, and environmental demands. Below we detail critical considerations for aluminum, steel, and titanium alloys, alongside anodizing as a key surface enhancement for aluminum molds.

Aluminum alloys like 7075-T6 offer exceptional thermal conductivity and machinability, reducing cycle times in high-volume plastic injection molding. They excel in prototypes and low-to-medium production runs where rapid heat dissipation is critical. However, aluminum lacks the wear resistance required for abrasive polymers or extended service. For such cases, tool steels become essential. H13 steel dominates hot-runner and die-casting molds due to its superior thermal fatigue resistance and toughness at elevated temperatures. Pre-hardened P20 steel suits medium-run plastic molds requiring balanced machinability and polishability. When extreme abrasion resistance is non-negotiable—as in glass-filled polymer molding—D2 or S7 tool steels provide exceptional hardness retention but demand specialized heat treatment. Titanium alloys, particularly Grade 5 (Ti-6Al-4V), serve niche applications requiring corrosion immunity in chemical processing molds or ultra-lightweight aerospace tooling. Its low thermal conductivity necessitates careful thermal management but justifies use where weight or reactivity are primary constraints.

The following specifications guide material comparison for mold cores and cavities:

| Material | Key Grades | Hardness (HRC) | Thermal Conductivity (W/m·K) | Best Application Context |

|---|---|---|---|---|

| Aluminum | 7075-T6, 6061-T6 | 15-30 | 130-150 | Rapid prototyping, low-run molds |

| Tool Steel | H13, P20, D2 | 45-60 | 25-35 | High-volume plastic, die casting |

| Titanium Alloy | Ti-6Al-4V | 32-36 | 6-7 | Corrosive environments, aerospace |

Anodizing significantly enhances aluminum molds by converting the surface into a hard, corrosion-resistant aluminum oxide layer. Type II (sulfuric acid) anodizing provides moderate wear resistance (5-25μm thickness) and dye compatibility for visual identification. For molds facing abrasive polymers or stringent wear demands, Type III (hardcoat) anodizing achieves 25-50μm thickness with hardness exceeding 60 HRC. This process improves release properties, reduces galling, and extends service life by 30-50% compared to bare aluminum. Crucially, anodizing must follow precision machining and stress-relief annealing to prevent dimensional distortion. Note that anodizing applies exclusively to aluminum; steel molds require alternative treatments like nitriding or PVD coatings, while titanium typically uses plasma electrolytic oxidation.

Material selection is never one-size-fits-all. We collaborate with clients to analyze polymer chemistry, cycle counts, and thermal profiles—ensuring your mold substrate and finish deliver maximum ROI. Wuxi Lead’s metallurgical team validates every specification against ISO 9001-certified processes, guaranteeing dimensional stability from first cut to final polish. Consult our engineers to match your project’s exact requirements with the optimal material-finish combination.

Manufacturing Process & QC

The production process for high-precision mold products at Wuxi Lead Precision Machinery follows a rigorously controlled sequence: Design, Prototyping, and Mass Production. Each phase is engineered to ensure dimensional accuracy, material integrity, and functional reliability, culminating in a Zero Defects outcome for our global manufacturing clients.

Design begins with comprehensive collaboration between our engineering team and the client. Utilizing advanced CAD/CAM software, we translate conceptual requirements into detailed 3D models. Finite Element Analysis (FEA) and mold flow simulations are applied to predict performance under operational conditions, optimizing wall thickness, cooling channels, and gating systems. Design for Manufacturability (DFM) reviews ensure that every geometry is not only functional but also producible within tight tolerances. This stage establishes the foundation for defect prevention by identifying potential risks before any metal is cut.

Prototyping follows the finalized design and serves as a physical validation step. Using CNC milling, wire EDM, and surface grinding, we produce a single mold set under production-intent conditions. This prototype is subjected to rigorous metrological inspection using coordinate measuring machines (CMM) and 3D laser scanning to verify conformity to specifications. Functional testing includes trial runs on client-specified presses to evaluate ejection behavior, cycle time, and part consistency. Any deviations are traced to root causes and corrected through iterative refinement. This stage is critical in verifying process stability and eliminating latent design flaws.

Mass Production is initiated only after prototype approval and process validation. Our automated production lines integrate high-speed CNC machining centers, robotic part handling, and real-time in-process gauging. Each mold component is tracked via a digital manufacturing execution system (MES), ensuring full traceability of materials, tooling, and inspection data. Statistical Process Control (SPC) monitors key parameters such as temperature, pressure, and cycle duration, enabling predictive adjustments before out-of-tolerance conditions occur. Final inspection includes hardness testing, surface roughness analysis, and assembly verification under load conditions.

Throughout all phases, our ISO 9001-certified quality management system enforces strict adherence to protocols. The result is a seamless transition from concept to volume output, with every mold meeting the Zero Defects standard required by automotive, medical, and consumer electronics industries.

| Specification | Detail |

|---|---|

| Tolerance Range | ±0.002 mm |

| Surface Roughness (Ra) | 0.05 – 0.8 µm |

| Materials Used | P20, H13, S136, 718H, Stainless Steel, Aluminum |

| Machining Methods | CNC Milling, Wire EDM, Surface Grinding, Boring |

| Inspection Equipment | CMM, 3D Laser Scanner, Optical Comparator, Hardness Tester |

| Lead Time (Prototype) | 15–25 days |

| Lead Time (Mass Production) | 30–60 days (varies by complexity) |

| Quality Standard | ISO 9001:2015, PPAP, FAI, SPC compliant |

Why Choose Wuxi Lead Precision

Elevate Your Mold Production Through Precision Engineering Partnership

In the demanding realm of custom metal mold manufacturing, dimensional accuracy and material integrity directly dictate production yield, part quality, and operational lifespan. Generic solutions often fail under the thermal and mechanical stresses of high-volume molding cycles, leading to costly downtime and compromised end products. Wuxi Lead Precision Machinery exists to eliminate these risks through engineered excellence, transforming your mold specifications into resilient, high-performance assets. Our decades of specialization in complex CNC-machined mold components for aerospace, medical, and automotive sectors ensure your tooling meets the most stringent global standards from inception to cyclical production.

We integrate advanced 5-axis milling, sinker EDM, and wire EDM capabilities within a single controlled environment, maintaining traceability and consistency across every machining phase. Our engineers collaborate with your team during the design-for-manufacturability stage, identifying potential thermal distortion or wear points before metal is cut. This proactive approach minimizes iteration cycles and accelerates time-to-market without sacrificing micron-level precision. Material selection is equally critical; we rigorously qualify alloys like H13, S7, and maraging steels for optimal hardness, thermal conductivity, and fatigue resistance under your specific operating conditions.

The technical foundation of our partnership is demonstrated in the capabilities table below, reflecting our commitment to measurable outcomes:

| Capability | Specification | Impact on Your Production |

|---|---|---|

| Dimensional Tolerance | ±0.002 mm (±0.00008″) | Eliminates flash, reduces secondary finishing |

| Surface Finish | Ra 0.05 µm (2 µin) | Extends mold life, ensures part clarity |

| Material Certification | Full heat-treated traceability | Guarantees metallurgical integrity under stress |

| Lead Time for Complex Cores | 12–18 days | Accelerates validation and ramp-up phases |

| In-Process Metrology | 100% CMM verification | Prevents defects before assembly |

This level of control is non-negotiable when your reputation hinges on zero-defect output. Partnering with Lead Precision means embedding our engineering rigor into your supply chain—transforming molds from consumable tools into strategic production assets. We do not merely fulfill orders; we solve the unspoken challenges of thermal cycling, ejection dynamics, and cavity pressure distribution that erode profitability in high-stakes manufacturing.

Initiate your precision molding project with a partner who treats your tolerances as our mandate. Contact our engineering team directly at [email protected] to submit your technical package for immediate review. Include your target cycle count, material requirements, and critical dimensions for a tailored capability assessment within 24 business hours. Let us demonstrate how precision machining discipline becomes your competitive advantage. Your next-generation mold solution begins with a single email.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.