Technical Contents

Engineering Guide: 1018 Carbon Steel Properties

Engineering Insight: 1018 Carbon Steel Properties and the Precision Imperative

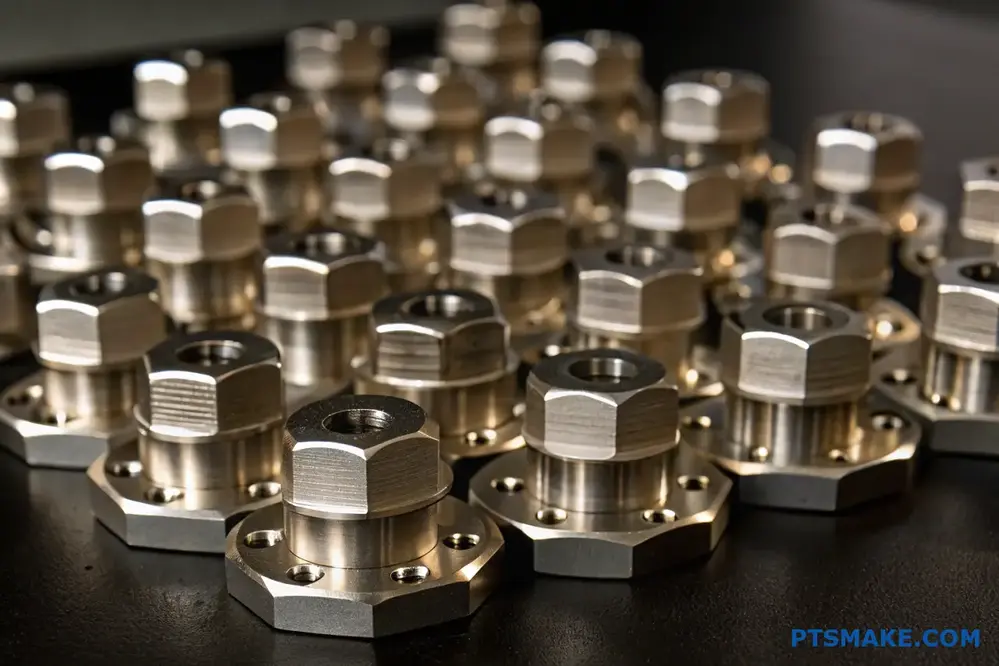

In the realm of custom metal manufacturing, 1018 carbon steel remains a cornerstone material due to its balanced mechanical properties, cost-effectiveness, and exceptional machinability. At Wuxi Lead Precision Machinery, our extensive experience in delivering mission-critical components for high-demand sectors—including Olympic infrastructure projects and military-grade equipment—has reinforced our understanding that material selection is only as effective as the precision with which it is processed. 1018 carbon steel, while widely accessible, demands exacting control during machining, forming, and finishing to achieve the performance standards required in advanced engineering applications.

1018 carbon steel is a low-carbon steel containing approximately 0.18% carbon, which grants it excellent ductility and weldability. Its relatively soft base structure allows for easy cold forming and threading, making it ideal for shafts, pins, fasteners, and structural components where moderate strength and high dimensional consistency are required. However, this very softness also means that without precise machining parameters—such as optimized feed rates, tool selection, and thermal management—parts can suffer from dimensional drift, surface imperfections, or inconsistent tolerances. In high-stakes environments like defense systems or precision-guided Olympic timing mechanisms, such deviations are unacceptable.

Our work on classified military subsystems and precision components for Olympic venue automation has taught us that repeatability and traceability are non-negotiable. When working with 1018 steel, we implement tight process controls including in-line metrology, CNC tool wear compensation, and post-machining stress-relief protocols to ensure that every component meets exacting GD&T specifications. Surface finish, straightness, and concentricity are monitored at micron-level accuracy, ensuring compatibility in high-cycle or load-sensitive assemblies.

Furthermore, while 1018 steel is not typically used in high-stress or high-wear applications without case hardening or surface treatment, its response to such processes is highly dependent on initial dimensional precision. We routinely apply carburizing or nitriding to enhance surface hardness while maintaining a tough core—processes that require uniform starting geometry to achieve predictable case depth and minimal distortion.

The table below outlines key mechanical and physical properties of 1018 carbon steel, as processed under controlled conditions typical of Wuxi Lead’s production environment.

| Property | Value |

|---|---|

| Carbon Content | 0.18% |

| Tensile Strength (Ultimate) | 440 MPa (63.8 ksi) |

| Yield Strength | 370 MPa (53.7 ksi) |

| Elongation at Break | 15% (in 2 in) |

| Hardness (Brinell) | 126 HB |

| Density | 7.87 g/cm³ |

| Machinability Rating | 72% (relative to AISI 1112) |

| Modulus of Elasticity | 205 GPa (29.7 x 10⁶ psi) |

| Typical Applications | Shafts, pins, bolts, low-load gears, fixtures |

At Wuxi Lead Precision Machinery, we treat every 1018 steel component not as a commodity, but as an engineered system element. Our legacy in delivering precision under extreme specifications underscores our belief: the true value of a material is realized not in its datasheet, but in the accuracy of its execution.

Precision Specs & Tolerances

Technical Capabilities for Precision 1018 Carbon Steel Manufacturing

Wuxi Lead Precision Machinery delivers exceptional value in custom 1018 carbon steel components by directly addressing the material’s inherent characteristics through advanced manufacturing and rigorous quality control. While 1018 steel offers excellent machinability, weldability, and cost-effectiveness for structural and mechanical applications, its lower carbon content presents specific challenges for high-tolerance work. Variability in dimensional stability during machining and potential for minor warpage post-processing demand sophisticated process control. Our integrated approach leverages cutting-edge technology and metrology to consistently overcome these challenges, ensuring parts meet the most stringent aerospace, automation, and precision equipment specifications.

Our core capability centers on state-of-the-art 5-axis CNC machining centers, primarily DMG MORI and Makino platforms. This technology is critical for 1018 steel work. Complex geometries requiring multiple setups on 3-axis machines introduce cumulative alignment errors and extended lead times. Our 5-axis systems machine intricate features in a single setup, eliminating repositioning errors and significantly reducing thermal distortion risks inherent in prolonged machining cycles of this relatively soft material. High-speed spindles and optimized toolpaths ensure superior surface finishes while minimizing heat generation, a key factor in maintaining the dimensional integrity of 1018 steel parts. We employ specialized cutting strategies and tooling designed explicitly for low-carbon steels to prevent built-up edge and achieve consistent burr-free results, even on thin-walled sections.

Quality assurance is non-negotiable. Every critical 1018 steel component undergoes comprehensive validation using our Zeiss and Hexagon CMMs, operating under strict ISO 17025 guidelines with NIST-traceable calibration. These systems provide full 3D metrology-grade validation, capturing hundreds of data points to verify complex contours, positional tolerances, and geometric dimensioning and tolerancing (GD&T) callouts far beyond simple caliper checks. This level of inspection is essential for detecting subtle warpage or distortion in 1018 steel that might escape less rigorous checks, ensuring absolute conformance to your engineering drawings before shipment. Our CMM reports provide full traceability and detailed analysis, offering confidence in every part delivered.

The table below outlines the precision tolerances we consistently achieve on 1018 carbon steel components, reflecting our capability to exceed standard industry expectations for this material:

| Feature | Typical Industry Standard (1018 Steel) | Wuxi Lead Precision Capability (1018 Steel) |

|---|---|---|

| Linear Dimension (in) | ±0.005 | ±0.0005 (up to ±0.0002 on critical features) |

| Linear Dimension (mm) | ±0.13 | ±0.013 (up to ±0.005 on critical features) |

| Angular Tolerance | ±0.5° | ±0.1° |

| Positional Tolerance | ±0.008 | ±0.001 |

| Surface Roughness (Ra) | 63-125 μin | 32 μin (standard), down to 8 μin |

| Geometric Tolerances | Per ISO 2768-mK | Per drawing GD&T (RFS, MMC, LMC fully validated) |

This combination of advanced 5-axis machining, material-specific process expertise, and uncompromising CMM inspection allows Wuxi Lead to transform the inherent properties of 1018 carbon steel into a reliable asset for your precision applications. We eliminate downstream rework and assembly issues by guaranteeing dimensional accuracy and stability from the first article through full production, providing true manufacturing partnership for demanding B2B projects.

Material & Finish Options

Understanding 1018 Carbon Steel in Precision Manufacturing

In the landscape of custom metal manufacturing, material selection directly influences performance, cost-efficiency, and long-term reliability. Among the most widely used low-carbon steels, 1018 carbon steel stands out for its balanced mechanical properties and excellent machinability. At Wuxi Lead Precision Machinery, we recognize that informed material decisions are critical for high-precision components across industries such as automation, automotive, and industrial equipment.

1018 carbon steel contains approximately 0.18% carbon, contributing to its softness and ductility. This composition allows for easy cold forming, threading, and precision machining—making it ideal for shafts, pins, fixtures, and other custom-engineered parts. Its low carbon content also enables effective case hardening, where the surface is hardened while the core remains tough, offering a strategic advantage in wear-prone applications.

While not inherently corrosion-resistant, 1018 steel can be paired with protective finishes such as zinc plating, black oxide, or powder coating to enhance durability in harsh environments. Unlike aluminum or titanium, 1018 does not offer natural oxidation resistance, so finish selection becomes a crucial part of the design process when exposure to moisture or chemicals is expected.

When comparing materials, 1018 steel bridges the gap between cost and functionality. It is stronger than most aluminum alloys but less dense than stainless steel or titanium, offering a favorable strength-to-cost ratio. However, for applications requiring high corrosion resistance or extreme strength-to-weight ratios, materials like 6061-T6 aluminum or Grade 5 titanium may be more suitable despite their higher cost and more complex machining requirements.

Anodizing, a common finish for aluminum, is not applicable to carbon steel due to fundamental differences in material chemistry. Instead, steel components rely on electroplating, passivation, or coating methods to improve surface performance. Understanding these limitations ensures realistic expectations during the design and procurement phases.

At Wuxi Lead, we support clients in selecting the optimal material and finish combination based on functional requirements, environmental exposure, and production volume. Our precision CNC machining capabilities are tailored to handle 1018 steel with tight tolerances and repeatable accuracy, ensuring consistency across high-volume runs.

Below is a comparative overview of 1018 carbon steel against common alternative materials used in custom manufacturing.

| Property | 1018 Carbon Steel | 6061-T6 Aluminum | Grade 5 Titanium (Ti-6Al-4V) |

|---|---|---|---|

| Tensile Strength (MPa) | 440 | 310 | 900 |

| Yield Strength (MPa) | 370 | 276 | 830 |

| Hardness (Brinell) | 126 | 95 | 360 |

| Density (g/cm³) | 7.87 | 2.70 | 4.43 |

| Machinability Rating | 70% | 90% | 30% |

| Corrosion Resistance | Low (requires coating) | Moderate (anodizable) | High |

| Typical Applications | Shafts, fasteners, gears | Enclosures, brackets | Aerospace, medical implants |

Material selection is not a one-size-fits-all decision. 1018 carbon steel remains a cornerstone in industrial manufacturing due to its versatility and cost-effectiveness. When paired with the right finishing process and precise machining, it delivers reliable performance for a broad range of engineering challenges.

Manufacturing Process & QC

Production Process: Achieving Zero Defects with 1018 Carbon Steel

The journey from concept to flawless 1018 carbon steel component at Wuxi Lead Precision Machinery begins with rigorous engineering design. Our engineers meticulously analyze the part geometry, functional requirements, and the inherent properties of 1018 steel. Understanding its moderate strength, excellent machinability in the annealed condition, and susceptibility to warpage during aggressive machining is critical. We leverage advanced CAD/CAM software to optimize toolpaths, minimize stress concentrations, and account for the material’s predictable but limited hardenability. This phase includes comprehensive tolerance stack-up analysis and material flow simulation to preempt potential defects like dimensional drift or surface imperfections inherent to low-carbon steels. Design validation ensures manufacturability aligns precisely with 1018’s capabilities before any metal is cut.

Following design validation, prototyping transitions theory into tangible verification. Utilizing our high-precision CNC milling and turning centers, we produce initial samples under controlled conditions mirroring planned mass production. This stage is pivotal for 1018, where subtle variations in feed rates or coolant application can impact surface finish or dimensional stability. Each prototype undergoes exhaustive metrology: CMM verification against nominal CAD data, surface roughness testing, and critical feature inspection. We specifically validate how the annealed 1018 responds to our machining parameters, confirming minimal thermal distortion and verifying that the final dimensions remain within the tight tolerances demanded by high-end applications. Any deviations trigger immediate process refinement, ensuring the production blueprint is perfected.

This rigor transitions directly into mass production, where our Zero Defects philosophy is executed through integrated, multi-stage inspection and continuous statistical process control. Every 1018 carbon steel batch undergoes incoming material certification checks against ASTM A29 standards. During machining, automated in-process gaging monitors critical dimensions in real-time on the shop floor. Post-machining, 100% first-article inspection is standard, followed by rigorous sampling plans based on AQL 0.65 for critical features. Final inspection employs calibrated CMMs, optical comparators, and surface profilometers to validate all specifications. Crucially, we implement SPC charts tracking key process variables (e.g., tool wear, dimensional drift) specific to 1018’s behavior, enabling proactive correction before non-conformities occur. This closed-loop system, combined with operator certification and traceability from raw bar to finished part, guarantees consistent output meeting the most stringent aerospace, medical, and automation industry requirements.

Key mechanical properties of ASTM A29 1018 carbon steel essential for process planning are summarized below:

| Property | Typical Value Range | Standard Test Method |

|---|---|---|

| Tensile Strength | 400 – 470 MPa | ASTM A370 |

| Yield Strength (Min) | 310 MPa | ASTM A370 |

| Elongation in 2″ (Min) | 15% | ASTM A370 |

| Brinell Hardness (HB) | 126 – 140 | ASTM E10 |

| Machinability Rating | 72% (Relative to 1212) | – |

| Carbon Content | 0.15% – 0.20% | ASTM E415 |

Our integrated Design-Prototyping-Production workflow, deeply informed by 1018 carbon steel’s specific characteristics and governed by uncompromising Zero Defects protocols, ensures Wuxi Lead delivers custom components with unparalleled dimensional accuracy, structural integrity, and surface quality for demanding global OEMs.

Why Choose Wuxi Lead Precision

When it comes to high-performance, cost-effective materials in precision manufacturing, 1018 carbon steel remains a cornerstone for industrial applications. At Wuxi Lead Precision Machinery, we understand the unique balance of machinability, strength, and weldability that 1018 carbon steel offers. As a trusted partner in custom metal manufacturing, we specialize in transforming this versatile low-carbon steel into precision-engineered components tailored to your exact specifications.

Our expertise extends beyond standard fabrication. We integrate advanced CNC machining, precision turning, milling, and automated quality control systems to ensure every component meets rigorous dimensional and performance standards. Whether you’re producing shafts, pins, gears, or structural components, 1018 carbon steel provides a reliable base material due to its uniform composition and excellent response to heat treatment and surface finishing.

At Wuxi Lead, we don’t just manufacture parts—we engineer solutions. Our team collaborates closely with global clients to optimize designs for manufacturability, reduce lead times, and maintain consistent quality across production runs. With ISO 9001-certified processes and in-house material traceability, we ensure full compliance with international standards, giving you confidence in every shipment.

To support your project needs, below are the key mechanical and chemical properties of 1018 carbon steel processed under controlled conditions:

| Property | Value |

|---|---|

| Carbon Content | 0.18% |

| Tensile Strength | 440 MPa (63.8 ksi) |

| Yield Strength | 370 MPa (53.7 ksi) |

| Elongation at Break | 15% (in 2 in) |

| Hardness (Brinell) | 126 HB |

| Density | 7.87 g/cm³ |

| Machinability Rating | 72% (relative to AISI 1112) |

| Weldability | Excellent |

| Formability | Good (in annealed condition) |

These properties make 1018 carbon steel ideal for applications requiring moderate strength, tight tolerances, and high-volume repeatability—especially in automotive, machinery, and industrial equipment sectors.

Partnering with Wuxi Lead Precision Machinery means gaining access to more than advanced equipment and metallurgical expertise. It means working with a team committed to responsiveness, transparency, and long-term collaboration. From prototype development to full-scale production, we align our capabilities with your engineering and supply chain goals.

If your next project demands precision, consistency, and competitive pricing in 1018 carbon steel components, contact us today. Send your drawings, specifications, or inquiries to [email protected]. Our engineering team is ready to provide technical feedback, material recommendations, and a fast-turnaround quotation tailored to your requirements.

Let Wuxi Lead be your strategic manufacturing partner in China—where precision meets performance.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.