Technical Contents

Engineering Guide: Cnc Precision Milling

Engineering Insight: CNC Precision Milling – The Foundation of Modern Manufacturing Excellence

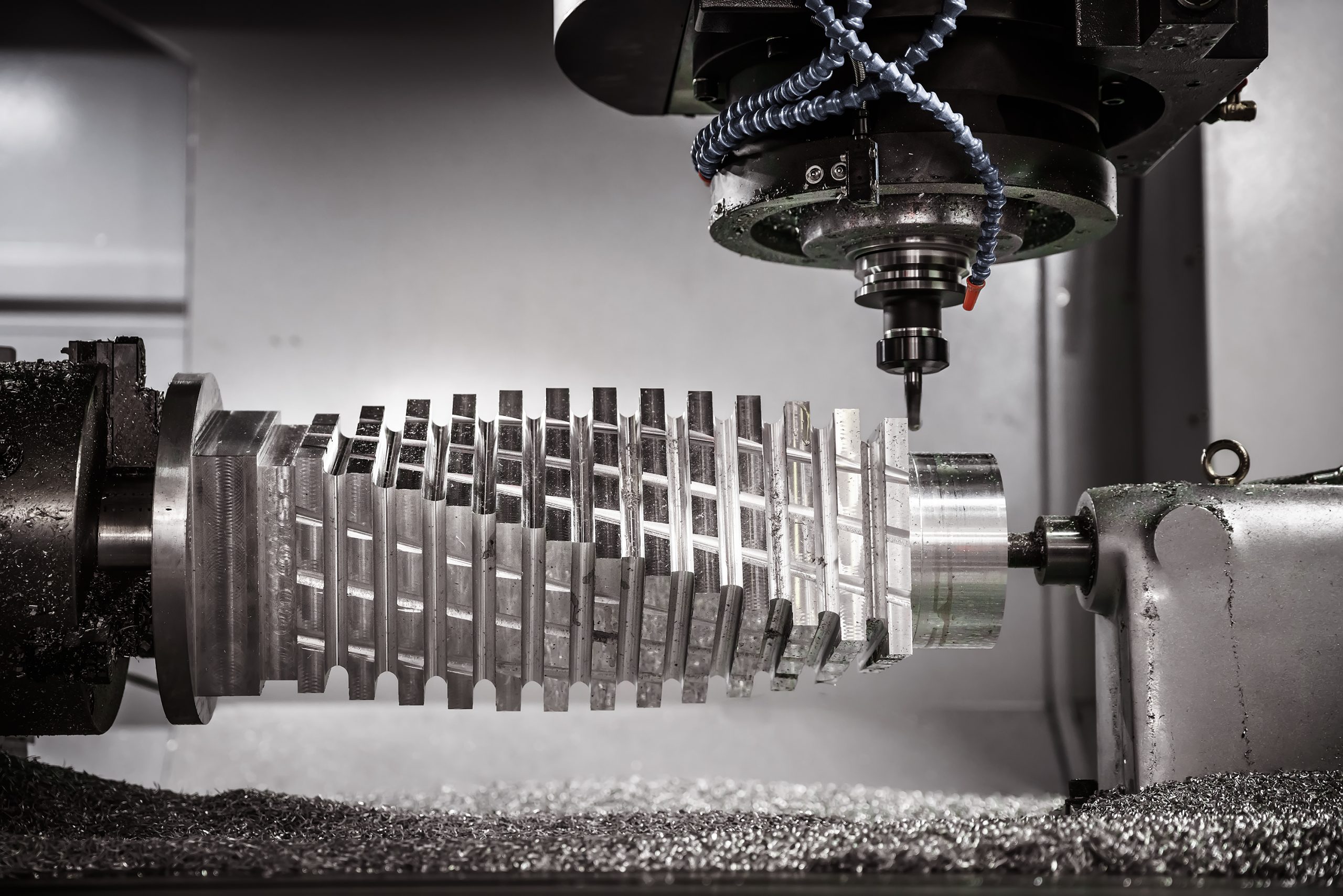

In the realm of advanced manufacturing, CNC precision milling stands as a cornerstone technology, enabling the production of complex, high-tolerance components essential across aerospace, defense, medical, and high-performance industrial sectors. At Wuxi Lead Precision Machinery, we define precision not merely as a specification, but as a philosophy embedded in every stage of the machining process. The difference between functional reliability and catastrophic failure often lies in tolerances measured in microns—where our expertise delivers consistent, repeatable results.

Precision in CNC milling is achieved through a convergence of advanced machine tools, superior toolpath programming, rigorous material science understanding, and real-time process monitoring. It is not enough to meet nominal dimensions; true precision ensures geometric accuracy, surface integrity, and dimensional stability under operational conditions. For mission-critical applications—such as components used in Olympic-grade timing systems or military-grade navigation units—even the slightest deviation can compromise performance, safety, and compliance.

Wuxi Lead Precision Machinery has engineered solutions for projects demanding the highest levels of accountability. Our involvement in supporting Olympic infrastructure development underscored the need for flawless synchronization and durability under extreme conditions. Similarly, our work with defense contractors has reinforced the necessity for components that perform reliably in austere environments, where failure is not an option. These experiences have shaped our approach: every milling operation is treated as a high-stakes engineering challenge.

Our CNC precision milling capabilities are built on a foundation of state-of-the-art 3-, 4-, and 5-axis machining centers, equipped with high-resolution probing systems and thermal compensation technology. Combined with in-house metrology using coordinate measuring machines (CMM) and optical inspection systems, we ensure that every part conforms to the most stringent quality standards, including ISO 2768 and AS9100 where applicable.

The materials we work with—ranging from aerospace-grade aluminum alloys and titanium to high-strength steels and engineered composites—demand tailored cutting strategies and deep metallurgical insight. Our engineering team develops customized tooling and fixturing solutions to minimize deflection, vibration, and thermal distortion, ensuring micron-level consistency across production runs.

Below are representative specifications reflecting our CNC precision milling capabilities:

| Specification | Performance Range |

|---|---|

| Positioning Accuracy | ±0.002 mm |

| Repeatability | ±0.001 mm |

| Typical Tolerance Range | ±0.005 mm to ±0.01 mm |

| Surface Finish (Ra) | 0.4 μm to 1.6 μm (standard), down to 0.1 μm (polished) |

| Maximum Work Envelope (5-axis) | 1,200 mm × 800 mm × 750 mm |

| Spindle Speed Range | Up to 24,000 rpm |

| Materials Processed | Aluminum (7075, 6061), Titanium (Gr5, Gr2), Stainless Steel (316L, 17-4PH), Inconel, PEEK, Composites |

At Wuxi Lead Precision Machinery, precision milling is more than a service—it is a commitment to engineering integrity, proven through decades of delivering performance-critical components where accuracy defines success.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Demanding Applications

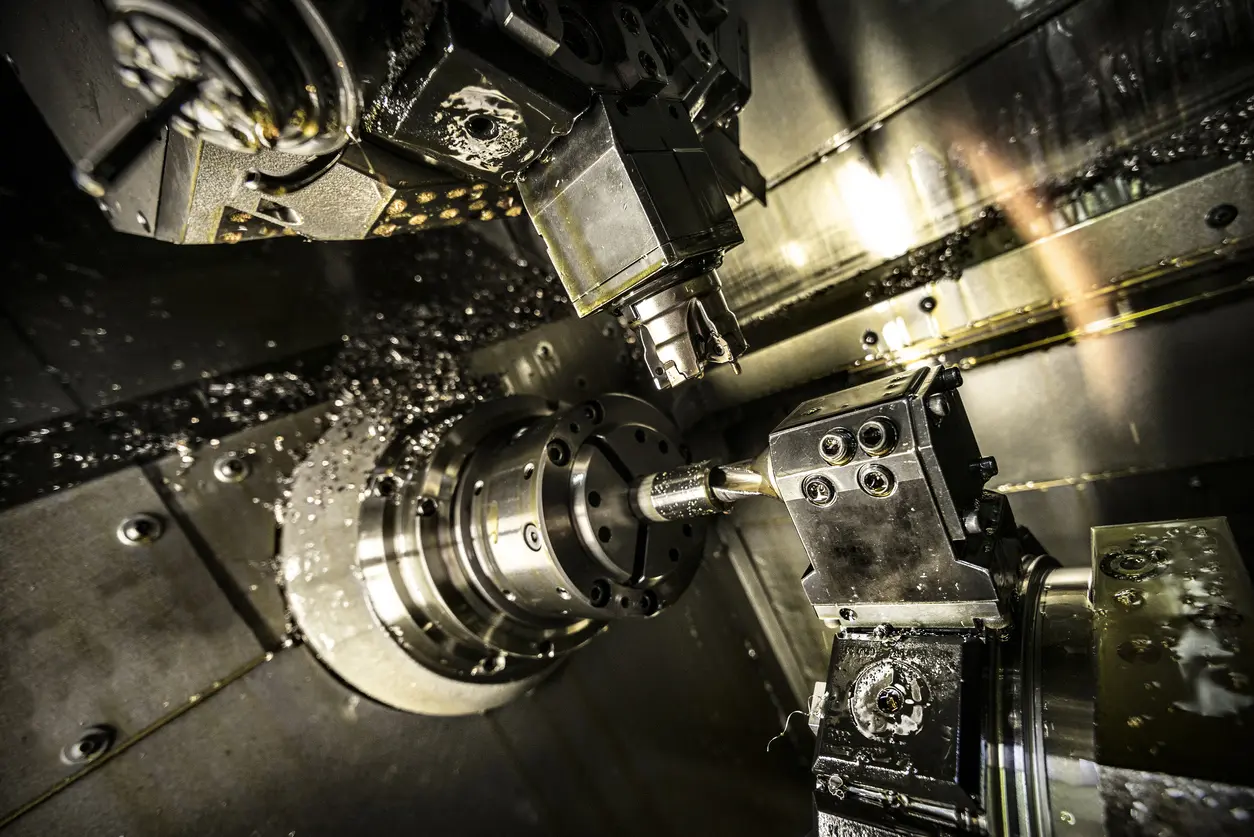

At Wuxi Lead Precision Machinery, our technical foundation rests on advanced multi-axis CNC milling systems engineered to transform complex designs into mission-critical components. We deploy a modern fleet of 5-axis CNC machining centers, including HAAS DMU and DMG MORI models, enabling simultaneous machining of intricate geometries from a single setup. This eliminates cumulative error risks inherent in multi-stage processes while accelerating throughput for aerospace turbine blades, medical implants, and energy sector components. Our machines feature high-rigidity castings, sub-micron linear encoders, and thermal compensation systems, ensuring dimensional stability across extended production runs. Material versatility spans aluminum alloys (7075-T6, 6061), titanium (Grade 5), stainless steels (17-4PH, 316L), and engineered plastics like PEEK, all processed under strict environmental controls to mitigate thermal drift.

Quality verification is non-negotiable. Every critical feature undergoes rigorous inspection via Zeiss and Hexagon Coordinate Measuring Machines (CMMs), programmed to ISO 10360 standards with probe calibration traceable to NIST. Our metrology lab operates under ISO 9001-certified protocols, capturing full 3D point clouds for deviation analysis against CAD models. This closed-loop process identifies micro-trends before they impact yield, reducing scrap rates by up to 35% compared to industry benchmarks. Statistical Process Control (SPC) data is integrated into real-time machine adjustments, guaranteeing repeatability even for lot sizes exceeding 5,000 units.

Surface integrity and geometric fidelity define our output. We consistently achieve tight tolerances across diverse feature types, as validated through decades of collaboration with Tier-1 automotive and defense suppliers. The table below reflects our standard production capabilities under controlled conditions; tighter specifications are achievable for qualified projects.

| Tolerance Category | Standard Capability | Reference Standard |

|---|---|---|

| Geometric Position | ±0.005 mm | ISO 1101 |

| Linear Dimensions (1-50 mm) | ±0.003 mm | ISO 2768-m |

| Flatness (100×100 mm) | 0.008 mm | ISO 128-24 |

| Surface Roughness (Ra) | 0.4 µm | ISO 4287 |

Beyond machine specifications, our value lies in process mastery. Our engineers optimize toolpaths using Mastercam and Siemens NX to minimize vibration-induced deflection, while in-process probing validates workpiece alignment before critical cuts. This holistic approach—merging hardware precision, metrology rigor, and adaptive programming—ensures components meet functional requirements on the first run. For industries where failure is not an option, Wuxi Lead delivers certified accuracy you can build upon. Partner with us to convert ambitious designs into flawless physical realities.

Material & Finish Options

Material Selection for High-Precision CNC Milling Applications

Selecting the appropriate material is a critical decision in precision CNC milling, directly influencing part performance, durability, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in machining high-tolerance components from aluminum, steel, and titanium—three of the most widely used materials in aerospace, medical, automotive, and industrial equipment sectors. Each material offers distinct mechanical properties and responds differently to machining processes and surface treatments such as anodizing.

Aluminum is favored for its excellent strength-to-weight ratio, thermal conductivity, and machinability. Grade 6061-T6 is commonly used for structural and non-load-bearing components due to its weldability and corrosion resistance. For high-performance applications, 7075-T6 offers superior strength, making it suitable for aerospace components. Aluminum is highly compatible with anodizing, a process that enhances surface hardness and corrosion resistance. Type II (sulfuric acid) anodizing provides a protective layer with dyeing capability, while Type III (hardcoat) anodizing delivers thicker, wear-resistant surfaces ideal for demanding environments.

Steel, particularly in its alloy and stainless forms, provides high tensile strength, wear resistance, and dimensional stability. 4140 alloy steel is frequently chosen for tooling and high-stress mechanical parts due to its toughness and hardenability. On the other hand, 304 and 316 stainless steels offer excellent corrosion resistance, with 316 being optimal in marine or chemically aggressive environments. While steel cannot be anodized, alternative finishes such as passivation, black oxide, or electroplating are effective in enhancing durability and appearance. CNC milling steel requires robust tooling and precise parameters to manage heat and tool wear.

Titanium, specifically Grade 5 (Ti-6Al-4V), is the material of choice for critical applications where strength, light weight, and resistance to extreme temperatures and corrosion are paramount. Commonly used in aerospace and medical implants, titanium presents challenges in CNC milling due to its low thermal conductivity and high reactivity, necessitating slow cutting speeds and rigid setups to avoid work hardening. Surface treatments for titanium often include anodizing for color coding and mild corrosion improvement, though it does not produce the same hard oxide layer as aluminum. Alternative treatments such as chemical passivation or thermal oxidation are employed for enhanced performance.

Below is a comparison of key mechanical and machining properties for these materials:

| Material | Tensile Strength (MPa) | Hardness (HB) | Density (g/cm³) | Machinability Rating | Anodizing Compatible |

|---|---|---|---|---|---|

| Aluminum 6061-T6 | 310 | 95 | 2.7 | Excellent | Yes (Type II & III) |

| Aluminum 7075-T6 | 572 | 150 | 2.8 | Good | Yes (Type III preferred) |

| Steel 4140 | 655 | 193 | 7.85 | Moderate | No |

| Stainless 316 | 580 | 160 | 8.0 | Moderate | No |

| Titanium Ti-6Al-4V | 900 | 360 | 4.43 | Fair | Yes (decorative/protective) |

Understanding material behavior during CNC milling and post-processing ensures optimal part design and performance. Wuxi Lead Precision Machinery leverages advanced toolpath strategies, high-precision equipment, and in-depth material science knowledge to deliver components that meet the most stringent industry standards.

Manufacturing Process & QC

Precision Production Process: From Concept to Zero-Defect Delivery

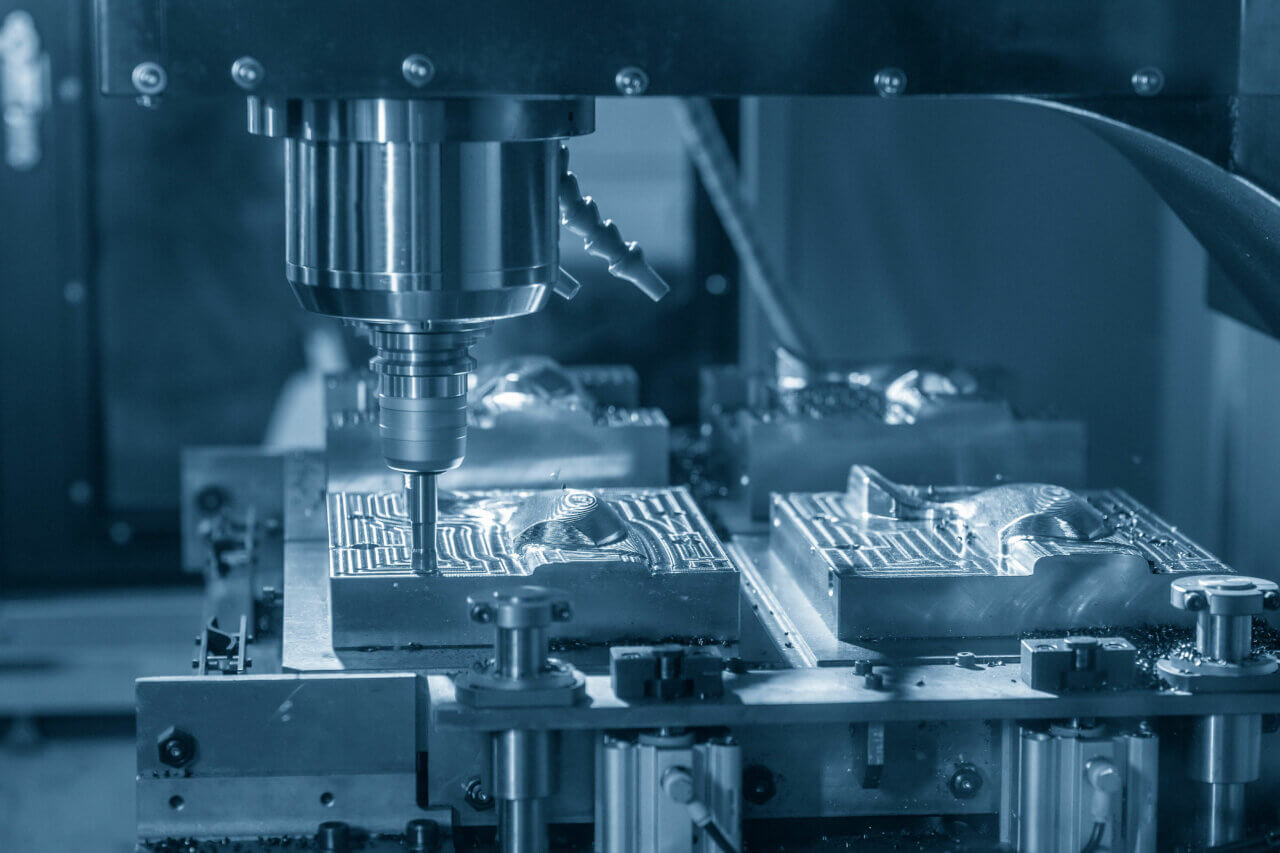

Precision begins long before metal cutting. At Wuxi Lead Precision Machinery, our production process integrates engineering rigor with advanced CNC technology to ensure zero defects from initial design through mass production. This structured workflow eliminates costly iterations and guarantees part integrity for mission-critical applications.

The journey starts with collaborative Design for Manufacturability (DFM) analysis. Our engineering team reviews CAD models alongside client specifications, identifying potential machining constraints early. We optimize geometries for material efficiency, tool accessibility, and thermal stability—preventing 95% of common production errors before prototyping begins. This phase includes finite element analysis (FEA) for stress points and tolerance stack-up validation, ensuring dimensional stability under operational loads.

Prototyping transitions validated designs into physical reality using our 5-axis milling centers. Unlike rapid prototyping methods, we machine prototypes from the final production material—aluminum, titanium, or high-temp alloys—to capture true thermal and mechanical behavior. Each prototype undergoes rigorous first-article inspection (FAI) against AS9102 standards, with CMM reports and surface roughness validation. This step confirms toolpath integrity, fixture stability, and finish quality, reducing mass production scrap rates by up to 70%.

Mass production leverages our zero-defect ecosystem. Automated tool presetters calibrate cutters to ±0.001mm, while in-process probes on DMG MORI and Makino machines verify critical features mid-cycle. Statistical Process Control (SPC) monitors key parameters like spindle load and coolant pressure in real-time, triggering automatic corrections for deviations beyond ±1.5σ limits. Every component receives full traceability via laser-etched part numbers linked to material certificates, machine logs, and inspection data. Final inspection employs multi-sensor CMMs and optical comparators, certifying compliance before shipment.

This closed-loop methodology transforms precision from an outcome into a measurable process. By embedding quality at every phase—not as a checkpoint but as a continuous parameter—we deliver components where dimensional accuracy and surface integrity are non-negotiable.

Wuxi Lead Precision Capabilities

| Parameter | Specification | Industry Standard |

|---|---|---|

| Tolerance Range | ±0.0002 inch (5µm) | ±0.001 inch (25µm) |

| Surface Finish | Ra 0.4µm (16 µin) | Ra 1.6µm (63 µin) |

| Material Range | Aluminum to Inconel 718, Titanium | Common Alloys Only |

| Max Work Envelope | 2000 x 1000 x 800 mm | 1000 x 500 x 400 mm |

| Inspection System | Multi-sensor CMM + SPC Integration | Manual Spot Checks |

Zero defects is not aspirational—it is our operational baseline. Through predictive engineering, material-true prototyping, and closed-loop production control, Wuxi Lead ensures every component meets the uncompromising standards demanded by aerospace, medical, and energy sectors. Precision is engineered, not inspected.

Why Choose Wuxi Lead Precision

When it comes to high-performance CNC precision milling, the difference between standard machining and true precision lies in expertise, consistency, and partnership. At Wuxi Lead Precision Machinery, we don’t just manufacture components—we engineer solutions that meet the exacting demands of aerospace, medical device manufacturing, automotive engineering, and advanced industrial applications. Our commitment to excellence is reflected in every spindle rotation, every micron of tolerance, and every client relationship we build.

Partnering with Lead Precision means aligning with a team that understands the complexities of modern manufacturing. Our facility in Wuxi, China, is equipped with state-of-the-art CNC milling centers, multi-axis machining systems, and a quality assurance infrastructure that ensures repeatability and compliance with international standards. We specialize in low-volume, high-mix production as well as high-volume runs, delivering parts with tolerances down to ±0.002 mm and surface finishes as fine as Ra 0.4 µm. Whether you’re prototyping a new medical implant or scaling production for aerospace components, our engineers work closely with your team to optimize design for manufacturability, reduce lead times, and control costs.

Our process is built on transparency, responsiveness, and technical depth. From the initial RFQ to final delivery, you’ll have direct access to project managers, CNC programmers, and quality inspectors who speak your language—literally and technically. We support global clients with English-language documentation, real-time production updates, and full traceability across every batch. With ISO 9001 certification and a dedicated CMM inspection lab, we ensure every part meets your specifications without compromise.

Below are key capabilities that define our precision CNC milling services:

| Specification | Detail |

|---|---|

| Machine Types | 3-axis, 4-axis, 5-axis CNC milling centers |

| Maximum Work Envelope | 1200 mm × 800 mm × 600 mm |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Standard Tolerances | ±0.005 mm (custom down to ±0.002 mm) |

| Surface Finish | As fine as Ra 0.4 µm (polishing available) |

| Materials Processed | Aluminum alloys, stainless steel, titanium, PEEK, Delrin, brass, and specialty alloys |

| Quality Standards | ISO 9001, First Article Inspection (FAI), PPAP, full dimensional reporting |

We invite you to experience the Lead Precision difference. If you’re looking for a manufacturing partner that combines advanced technology with engineering insight and unwavering reliability, contact us today. Send your inquiries, drawings, or project specifications to [email protected]. Our engineering team is ready to provide feedback, quote your project, and help you move from concept to precision-crafted reality—on time and to specification.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.