Technical Contents

Engineering Guide: 3D Printing Metal Parts

Engineering Insight Precision Imperatives in Metal Additive Manufacturing

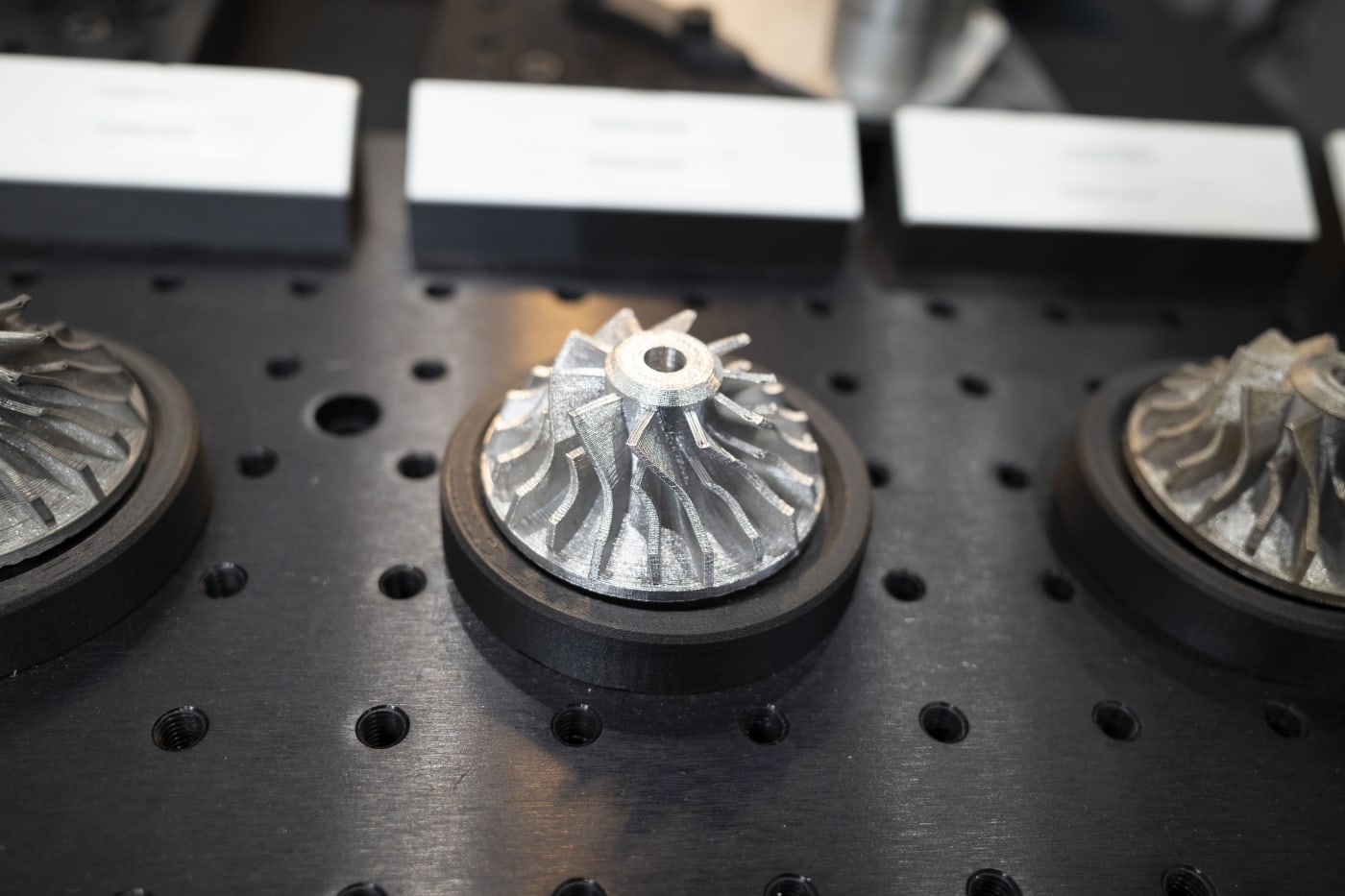

Metal additive manufacturing transcends rapid prototyping to deliver mission-critical end-use components where dimensional fidelity directly dictates functional performance and lifespan. In aerospace turbine blades, medical implants, or defense systems, deviations measured in microns can trigger catastrophic fatigue failure, fluid dynamic inefficiency, or biocompatibility issues. Precision in metal 3D printing is not merely about achieving target dimensions; it encompasses consistent microstructure homogeneity, controlled residual stress, and predictable surface integrity post-processing. Subsurface porosity or anisotropic grain structures—often invisible to standard inspection—compromise mechanical properties far more severely than minor geometric variance. True precision engineering demands holistic control from powder characterization through thermal management during build, to precision machining and non-destructive testing.

At Wuxi Lead Precision Machinery, we treat precision as a non-negotiable engineering parameter, not a marketing claim. Our integrated workflow begins with ISO 21507-certified metal powders, rigorously screened for sphericity and oxygen content. In-house developed thermal simulation software pre-optimizes scan strategies to minimize distortion, while real-time melt pool monitoring via co-axial sensors ensures layer-to-layer consistency. Critical components undergo mandatory hot isostatic pressing (HIP) and precision stress-relief annealing before final CNC contouring, achieving geometric tolerances unattainable through printing alone. This end-to-end discipline is validated through our work on components for Olympic-class competitive equipment requiring sub-10µm surface finishes and military-grade structural assemblies where failure is not an option.

The table below outlines key precision capabilities achievable within our certified production environment:

| Parameter | Capability Range | Industry Standard Reference |

|---|---|---|

| Layer Thickness | 20–60 µm | ASTM F3301/F3318 |

| Build Volume | Ø300 x 400 mm | ISO/ASTM 52900 |

| Dimensional Tolerance | ±0.05 mm (first 50 mm) | ISO 2768-m |

| Surface Roughness (As-Built) | Ra 8–15 µm | ISO 4287 |

| Post-Processed Surface | Ra 0.8–1.6 µm | ISO 1302 |

Our commitment to precision is forged in applications where theoretical specifications meet physical consequences. Components manufactured for national defense programs undergo 100% volumetric CT scanning to verify internal integrity against MIL-STD-883 criteria. Similarly, high-performance sporting goods produced for Olympic athletes demand repeatable mechanical properties within 2% variance across batches—a standard exceeding typical commercial AM outputs. This rigor stems from understanding that in mission-critical metal AM, precision is the convergence of metallurgical science, process control, and uncompromising validation. Wuxi Lead Precision Machinery delivers not just parts, but certified performance where every micron contributes to operational success.

Precision Specs & Tolerances

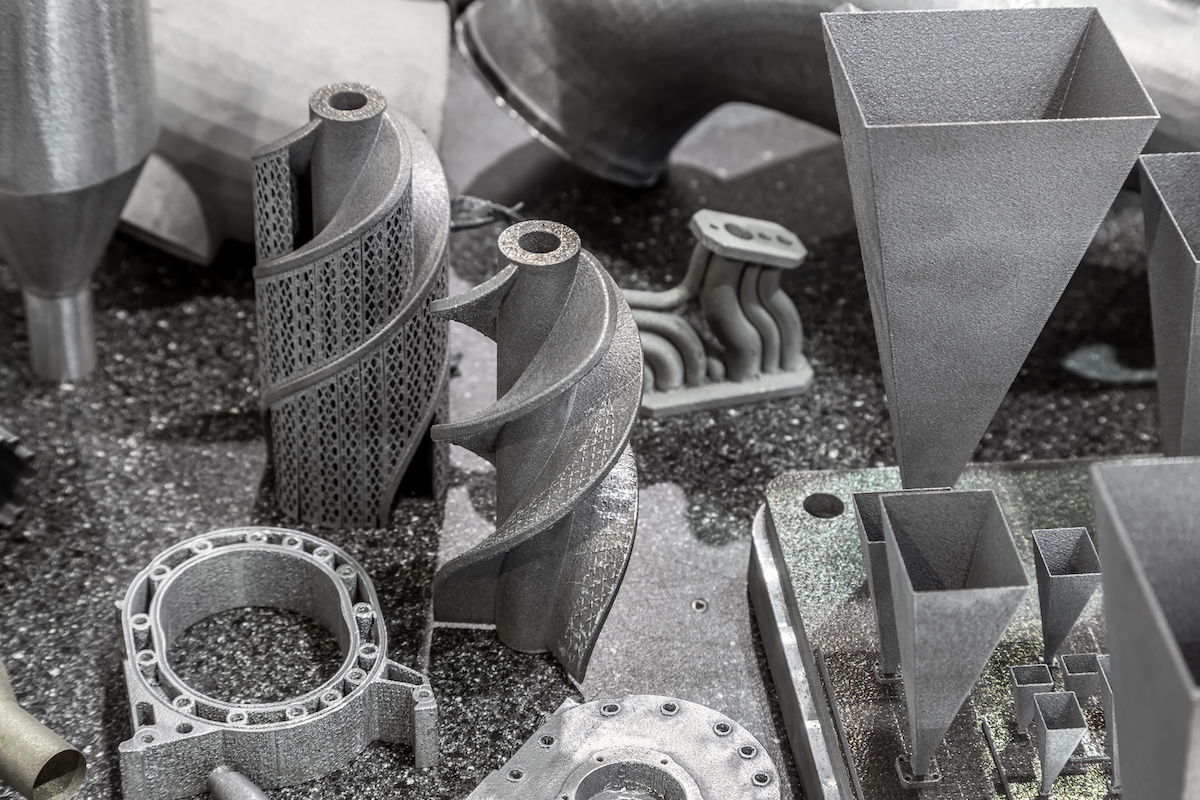

Wuxi Lead Precision Machinery delivers advanced technical capabilities in the production of precision 3D printed metal parts, combining additive manufacturing with high-accuracy post-processing to meet the stringent demands of aerospace, medical, automotive, and industrial clients. Our integrated manufacturing ecosystem ensures that every component not only meets design intent but also achieves the mechanical properties and dimensional accuracy required for mission-critical applications.

At the core of our technical strength is a hybrid production model that pairs metal additive manufacturing with 5-axis CNC machining. While 3D printing enables complex geometries and lightweight structures unachievable through traditional methods, we recognize that surface finish, tight tolerances, and critical feature accuracy often require precision machining. Our 5-axis CNC systems allow for multi-angle access and continuous contouring, enabling the precise finishing of intricate 3D printed components with minimal setup changes. This synergy ensures optimal part integrity, reduced distortion, and superior repeatability across production batches.

All machined and printed components undergo rigorous quality control through our Coordinate Measuring Machine (CMM) inspection process. Our CMM systems provide full 3D geometric dimensioning and tolerancing (GD&T) verification, ensuring compliance with ISO and ASME standards. Each inspection report is traceable and documented, providing customers with full transparency and verification of part conformity. This level of inspection is particularly critical for safety-certified industries where component failure is not an option.

Our facility supports a range of metal 3D printing technologies, including Selective Laser Melting (SLM) and Direct Metal Laser Sintering (DMLS), compatible with materials such as titanium (Ti6Al4V), stainless steel (316L, 17-4 PH), aluminum (AlSi10Mg), and Inconel (718, 625). Post-processing capabilities include stress relieving, hot isostatic pressing (HIP), heat treatment, and surface finishing options such as bead blasting, polishing, and coating, all performed in-house to maintain process control.

The following table outlines the standard technical specifications and achievable tolerances for our 3D printed and CNC-finished metal components:

| Parameter | Standard Capability | Tight Tolerance Option | Notes |

|---|---|---|---|

| Layer Thickness (AM) | 20–50 μm | 20 μm | Depends on material and geometry |

| Build Envelope (AM) | Up to 250 x 250 x 300 mm | Custom builds available | Larger parts via segmentation |

| Dimensional Tolerance (AM) | ±0.1 mm | ±0.05 mm | For features > 50 mm |

| CNC Machining Tolerance | ±0.005 mm | ±0.003 mm | 5-axis precision finishing |

| Surface Roughness (as-printed) | Ra 10–15 μm | Ra 6–8 μm (with machining) | Machining or polishing improves finish |

| Minimum Feature Size | 0.4 mm (walls, pins) | 0.3 mm | Geometry and orientation dependent |

| Positional Accuracy (CMM) | ±0.01 mm | ±0.005 mm | Verified per ASME Y14.5 |

Wuxi Lead Precision Machinery maintains full process traceability from raw material certification to final inspection, ensuring every metal 3D printed part meets the highest standards of quality, consistency, and performance.

Material & Finish Options

Material Selection for Precision Metal 3D Printing

Selecting the optimal material for metal additive manufacturing directly impacts part performance, durability, and cost-efficiency. At Wuxi Lead Precision Machinery, we prioritize material properties aligned with your application’s mechanical, thermal, and environmental demands. Below we detail key considerations for aluminum, steel, and titanium alloys, alongside critical finishing insights.

Aluminum Alloys

AlSi10Mg dominates aerospace and automotive applications requiring lightweight structures with thermal conductivity. Its low density (2.68 g/cm³) reduces inertia in moving components, while moderate strength suits non-critical structural parts. Note that aluminum’s lower melting point accelerates build times but necessitates controlled cooling to prevent warpage. Anodizing is essential for surface hardening and corrosion resistance, particularly in humid or chemically exposed environments. Type II or III anodizing (hard coat) adds 25–50 µm thickness, enhancing wear resistance without compromising tight tolerances.

Stainless Steel Alloys

17-4 PH stainless steel delivers exceptional strength (ultimate tensile strength ≥ 1000 MPa) and corrosion resistance for medical instruments, oil/gas tooling, and high-stress molds. Its martensitic structure allows post-build heat treatment to fine-tune hardness up to 44 HRC. Unlike aluminum, steel does not benefit from anodizing; instead, electropolishing or passivation removes surface impurities and maximizes biocompatibility. Avoid steel for weight-sensitive applications due to its higher density (7.8 g/cm³), but leverage its cost-effectiveness for high-volume industrial tooling.

Titanium Alloys

Ti6Al4V (Grade 5) is the benchmark for aerospace and biomedical implants, offering the highest strength-to-weight ratio among common AM metals. Its biocompatibility and corrosion resistance in saline environments make it irreplaceable for surgical components. However, titanium’s reactivity demands inert build chambers (argon atmosphere) to prevent oxygen embrittlement. Anodizing titanium creates colored oxide layers for identification but does not improve wear resistance—mechanical polishing or plasma nitriding is preferred for surface hardening.

Critical Material Properties Comparison

| Property | AlSi10Mg Aluminum | 17-4 PH Stainless Steel | Ti6Al4V Titanium |

|---|---|---|---|

| Density (g/cm³) | 2.68 | 7.8 | 4.43 |

| Ultimate Tensile Strength (MPa) | 400–500 | 1000–1300 | 900–950 |

| Elongation (%) | 8–12 | 10–15 | 10–12 |

| Corrosion Resistance | Moderate (anodized) | Excellent | Exceptional |

| Primary Applications | Heat exchangers, brackets | Surgical tools, molds | Implants, turbine blades |

Finishing Considerations

Anodizing applies exclusively to aluminum, forming a porous oxide layer that seals with dyes or nickel acetate for enhanced corrosion barriers. Incorrect voltage control during anodizing causes microcracking—our ISO 9001-certified process ensures ±2 µm thickness accuracy. For steel and titanium, secondary processes like shot peening or HIP (Hot Isostatic Pressing) eliminate internal porosity, critical for fatigue-prone components. Always specify finish requirements during design to avoid post-processing geometry conflicts.

Material choice is not merely technical—it’s strategic. Wuxi Lead Precision Machinery combines ASTM-certified material testing with application-specific expertise to optimize your metal AM workflow. Contact our engineering team to validate material-finish pairings against your operational lifecycle requirements.

Manufacturing Process & QC

The production process for high-precision 3D printed metal parts at Wuxi Lead Precision Machinery follows a disciplined, end-to-end workflow designed to ensure zero defects and full compliance with industrial quality standards. Our methodology integrates advanced digital engineering with rigorous physical validation, spanning from initial design to full-scale production.

Design begins with a collaborative engineering review, where our team analyzes the client’s CAD models for structural integrity, thermal behavior, and manufacturability. We specialize in topology optimization and support structure simulation using industry-leading software such as ANSYS and Materialise Magics. This phase ensures that every design is not only printable but also optimized for performance, weight reduction, and material efficiency. Critical features such as overhangs, wall thickness, and surface finish are validated against the capabilities of our metal additive systems. All design data is version-controlled and subject to internal DFM (Design for Manufacturing) sign-off before progression.

Prototyping is executed using our in-house metal additive platforms, primarily EOS M290 and SLM Solutions S312 systems, which support a full range of industrial alloys including Inconel 718, Ti6Al4V, 316L stainless steel, and AlSi10Mg. Each prototype is built under controlled atmospheric conditions with real-time layer monitoring via integrated high-resolution cameras and melt pool analysis. Post-build, parts undergo stress relief and hot isostatic pressing (HIP) when required, followed by precision CNC support removal and surface finishing. Dimensional inspection is performed using Zeiss coordinate measuring machines (CMM), with full geometric dimensioning and tolerancing (GD&T) reports provided. This stage confirms functional performance and allows for design refinement with minimal lead time.

Mass production is initiated only after prototype validation and client approval. Our production floor operates under ISO 9001 and IATF 16949 standards, with batch traceability maintained through RFID tagging and digital process logs. Each build undergoes 100% in-process monitoring, and a randomized sample from every batch is subjected to mechanical testing, metallography, and CT scanning for internal porosity. Non-destructive testing (NDT) methods include dye penetrant, ultrasonic, and X-ray inspection as required by application standards.

Throughout the entire process, Wuxi Lead enforces a zero-defect philosophy. Corrective and preventive actions (CAPA) are documented and addressed immediately, ensuring continuous improvement and full transparency. Our closed-loop quality management system guarantees that every metal 3D printed part meets the highest demands of aerospace, medical, and high-performance industrial sectors.

Typical Material Specifications for Metal 3D Printing

| Material | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Build Volume (mm) | Layer Thickness (μm) |

|---|---|---|---|---|---|

| Inconel 718 | ≥1250 | ≥850 | ≥18 | 250 x 250 x 325 | 20 – 60 |

| Ti6Al4V | ≥950 | ≥880 | ≥10 | 250 x 250 x 325 | 30 – 60 |

| 316L Stainless | ≥550 | ≥450 | ≥40 | 250 x 250 x 325 | 20 – 50 |

| AlSi10Mg | ≥480 | ≥400 | ≥8 | 250 x 250 x 325 | 30 – 60 |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Mission-Critical Metal 3D Printing Success

In the demanding realm of high-performance metal additive manufacturing, selecting a partner transcends basic production capability. It demands a strategic alliance grounded in engineering rigor, process mastery, and unwavering commitment to your project’s success. Wuxi Lead Precision Machinery stands as your definitive partner for complex, high-value metal 3D printed components where failure is not an option. We move beyond standard printing services to deliver integrated engineering solutions, transforming your most challenging designs into certified, flight-worthy, or production-ready metal assets.

Our foundation is built upon industrial-scale metal AM systems operating within a certified aerospace and medical manufacturing ecosystem. We leverage decades of precision machining heritage alongside cutting-edge additive expertise, ensuring every part meets exacting dimensional, metallurgical, and functional requirements. This synergy between subtractive and additive mastery guarantees geometric complexity without sacrificing surface integrity, fatigue performance, or long-term reliability. We understand that your application – whether aerospace turbine components, bespoke medical implants, or next-generation energy systems – requires more than just a printed shape; it demands validated performance and seamless integration into your assembly.

Partnering with Lead Precision means engaging a team that speaks your engineering language and operates within your stringent quality frameworks. Our NADCAP-accredited processes, rigorous material traceability, and comprehensive in-house metrology (including CT scanning and mechanical testing) provide the data-driven confidence essential for critical applications. We don’t just print parts; we co-engineer solutions, offering design for additive manufacturing (DfAM) consultation, build optimization, and full post-processing integration to achieve your target specifications and reduce total cost of ownership. Intellectual property protection and secure data handling are non-negotiable pillars of our collaboration.

Lead Precision Metal 3D Printing Core Capabilities

| Parameter | Specification Detail | Industry Relevance |

|---|---|---|

| Build Volume | Up to Ø350 x 400 mm (EOS M 400-4) | Accommodates complex medium-scale parts |

| Materials | Ti-6Al-4V, Inconel 718, 316L, AlSi10Mg, CoCr, Maraging Steel | Aerospace, Medical, Oil & Gas compliance |

| Layer Thickness | 20 – 60 µm | Precision surface finish & detail resolution |

| Dimensional Accuracy | ± 0.05 mm / 100 mm (post-machining) | Meets tight engineering tolerances |

| Key Certifications | ISO 9001, AS9100, NADCAP (pending final audit) | Mandatory for aerospace & critical sectors |

| Post-Processing | Full in-house: HIP, Stress Relief, Precision Machining, Surface Finishing | Ensures final part integrity & performance |

The true value of additive manufacturing is unlocked only through deep technical partnership. Wuxi Lead Precision Machinery provides the engineering depth, quality assurance, and production scalability required to transition your metal AM projects from prototype to certified production. We mitigate risk, accelerate time-to-market, and deliver components that perform under the most extreme conditions. Your vision for advanced metal components demands a partner with proven execution capability and uncompromising standards.

Initiate the engineering dialogue that transforms your metal additive ambitions into reality. Contact our precision engineering team directly at [email protected]. Provide your specific application requirements, target materials, and quality expectations. We will respond within 24 business hours with a detailed technical capability assessment and a clear pathway to your project’s success. Partner with precision. Partner with Lead.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.