Technical Contents

Engineering Guide: Metal Molds For Plastic

Engineering Insight Precision in Metal Molds for Plastic

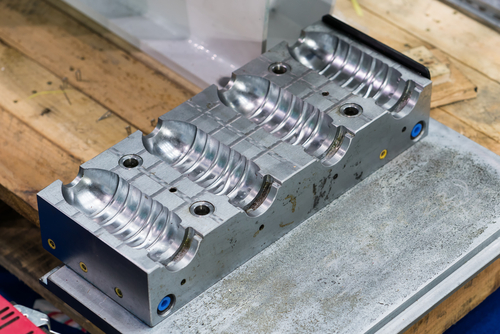

Achieving consistent, high-integrity plastic components demands absolute precision in the foundational metal mold tooling. Variations measured in microns directly translate to part defects, assembly failures, and costly production downtime. At Wuxi Lead Precision Machinery, we recognize that mold precision is not merely a specification; it is the critical determinant of manufacturability, product performance, and total cost of ownership for our clients. The thermal cycling inherent in injection molding subjects molds to extreme stress. Minute deviations in cavity geometry, core alignment, or cooling channel placement induce warpage, sink marks, flash, or dimensional instability in the final plastic part. Surface finish accuracy equally impacts aesthetics, functionality, and secondary processing requirements. This necessitates mold construction where every micron is controlled, from the initial billet to the finished electrode and cavity.

Our mastery stems from integrating advanced multi-axis CNC machining centers with rigorous thermal compensation protocols and metrology-grade validation. We utilize hardened tool steels and specialized alloys processed under tightly controlled environments to minimize internal stress and ensure dimensional stability throughout the mold’s operational life. Precision extends beyond basic cavity dimensions to encompass complex conformal cooling circuits, micro-features, and tight-tolerance ejection systems – all requiring sub-micron repeatability during fabrication. This level of control is non-negotiable for applications demanding zero-defect production, such as medical devices, optical components, or high-performance automotive systems.

The table below outlines key precision parameters where our engineering capabilities deliver measurable advantage:

| Parameter | Industry Standard Capability | Lead Precision Capability | Impact on Plastic Part Quality |

|---|---|---|---|

| Cavity Dimensional Tolerance | ±0.010 mm | ±0.002 mm | Eliminates assembly gaps, ensures sealing integrity |

| Surface Finish (Cavity) | Ra 0.4 µm | Ra 0.05 µm | Critical for optical clarity, paint adhesion, friction reduction |

| Core/Cavity Alignment | 0.020 mm | 0.005 mm | Prevents flash, ensures uniform wall thickness |

| Cooling Channel Position | ±0.10 mm | ±0.02 mm | Optimizes cycle time, minimizes part warpage |

| Thermal Stability | Moderate drift over cycles | < 0.003 mm drift | Guarantees consistent part dimensions in high-volume runs |

This precision is forged through experience on projects where failure is not an option. Wuxi Lead Precision Machinery has successfully engineered and manufactured critical mold tooling for components utilized in Olympic-standard sporting equipment and certified aerospace/military applications. These demanding sectors require adherence to AS9100 and stringent mil-spec standards, validating our ability to deliver under the highest scrutiny. The tolerances and material performance required for a fighter jet canopy mold or a precision athletic component directly inform our approach to every client project, regardless of scale. We translate this elite engineering discipline into reliable, high-yield production for your plastic parts, ensuring your manufacturing process achieves maximum efficiency and part quality from day one. Precision in the mold is the silent guarantee of success in your final product.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in the design and production of metal molds for plastic, serving high-demand industries such as automotive, medical, electronics, and consumer goods. Our expertise lies in precision engineering and repeatable manufacturing processes, ensuring that every mold meets the strictest performance and quality standards. At the core of our operations is a fully integrated 5-axis CNC machining platform, enabling us to produce complex mold geometries with exceptional accuracy and surface finish.

Our 5-axis CNC systems allow simultaneous multi-directional cutting, reducing setup times and minimizing human intervention. This capability is critical when machining intricate cavities, undercuts, and contoured surfaces commonly found in high-performance plastic molds. With full 3D toolpath control, we achieve superior detail replication and reduced cycle times, translating into faster time-to-market for our clients. All machining is supported by advanced CAD/CAM software, ensuring seamless transition from digital design to physical part with optimal tool efficiency and material utilization.

Quality assurance is embedded throughout our manufacturing workflow. Each mold undergoes comprehensive inspection using a Coordinate Measuring Machine (CMM), providing metrology-grade verification of dimensional accuracy. The CMM system captures thousands of data points across critical surfaces, comparing actual measurements against the original 3D model to ensure compliance with design intent. This level of inspection is essential for validating tight tolerances and ensuring long-term mold stability under production conditions.

We maintain strict environmental controls in our inspection lab to eliminate thermal distortion, guaranteeing measurement repeatability within microns. In addition to CMM, we employ surface roughness testers, hardness gauges, and optical comparators to validate material properties and finish quality. Every mold is delivered with a full inspection report, traceable to international standards, providing full transparency and audit readiness for regulated industries.

Our technical specifications reflect our commitment to precision and consistency. The following table outlines the standard tolerances we achieve across key parameters:

| Parameter | Standard Tolerance | Capability Range |

|---|---|---|

| Linear Dimensions | ±0.005 mm | Up to ±0.002 mm |

| Positional Tolerance | ±0.01 mm | Down to ±0.005 mm |

| Flatness | 0.01 mm per 100 mm | 0.005 mm per 100 mm |

| Surface Roughness (Ra) | 0.2 µm | As low as 0.05 µm |

| Hole Diameter Tolerance | H7 fit standard | H6 achievable on request |

| Angular Accuracy | ±0.05° | ±0.02° with calibration |

| Mold Cavity Matching | ±0.01 mm (core/cavity) | ±0.005 mm |

These capabilities are backed by rigorous process controls, experienced engineering oversight, and a continuous improvement mindset. Wuxi Lead Precision Machinery is equipped to handle prototyping, low-volume, and high-volume production molds, all manufactured to deliver consistent part quality, extended service life, and minimal maintenance in operational environments.

Material & Finish Options

Material Selection for High-Performance Plastic Injection Molds

Selecting the optimal material for metal molds used in plastic injection molding is a critical engineering decision directly impacting part quality, production efficiency, tool longevity, and overall project economics. At Wuxi Lead Precision Machinery, our decades of precision CNC machining experience for demanding global clients underscore that material choice must align precisely with production volume, part complexity, polymer characteristics, and required surface finish. Aluminum, steel, and titanium each offer distinct advantages and limitations in this high-stakes application.

Aluminum alloys, particularly 7075-T6 and 6061-T6, excel in rapid prototyping and low-to-medium volume production. Their superior thermal conductivity significantly reduces cycle times—often by 30-50% compared to steel—accelerating time-to-market. Aluminum machines faster, lowering initial tooling costs. However, lower hardness limits wear resistance for abrasive polymers or high-cavity-count molds. Steel remains the dominant choice for high-volume production. Pre-hardened steels like P20 offer good machinability and polishability for many applications. For extreme wear resistance and high-temperature stability with engineering plastics, tool steels such as H13 (hot work) or S136 (stainless corrosion-resistant) are essential, providing exceptional longevity despite higher initial cost and machining complexity. Titanium, while possessing outstanding strength-to-weight ratio and corrosion resistance, sees limited mold application due to extremely high cost, challenging machinability, and thermal conductivity often inferior to aluminum. Its use is typically restricted to highly specialized, niche components within a mold assembly rather than the primary mold base.

The following table summarizes key material properties relevant to plastic injection mold performance:

| Material | Typical Alloys | Hardness (HRC) | Thermal Conductivity (W/m·K) | Best Application Context |

|---|---|---|---|---|

| Aluminum | 7075-T6, 6061-T6 | 15-35 HB (≈15-30 HRC equiv) | 130-180 | Prototypes, low/medium volume, fast cycle times, simpler geometries |

| Steel (Pre-hard) | P20, 718 | 28-32 | 25-35 | Medium volume production, good balance of cost, machinability, and durability |

| Steel (Tool) | H13, S136, 420SS | 48-54+ (after heat treat) | 20-30 | High-volume production, abrasive/corrosive polymers, complex parts requiring long tool life |

| Titanium | Ti-6Al-4V | 36-41 (as machined) | 6-7 | Highly specialized inserts/components for extreme corrosion resistance; rarely full molds |

Surface finish, particularly anodizing for aluminum molds, is a vital consideration. Type II (standard) anodizing provides moderate corrosion and wear resistance with good dyeing capability for visual identification. For demanding production environments, Type III (hardcoat) anodizing is strongly recommended. It creates a significantly thicker, harder ceramic layer (60-70 HRC) dramatically improving abrasion resistance, reducing galling with certain polymers, and enhancing release properties—directly extending mold life and maintaining part surface quality over thousands of cycles. Properly specified anodizing transforms aluminum from a prototyping solution into a viable medium-volume production tool.

Wuxi Lead Precision Machinery leverages advanced CNC milling, grinding, and EDM capabilities to machine all these materials to micron-level tolerances. Our engineering team collaborates closely with clients during the design phase to select the optimal material and surface treatment combination, ensuring the mold delivers maximum return on investment through performance, durability, and cost-effectiveness for the specific plastic manufacturing application.

Manufacturing Process & QC

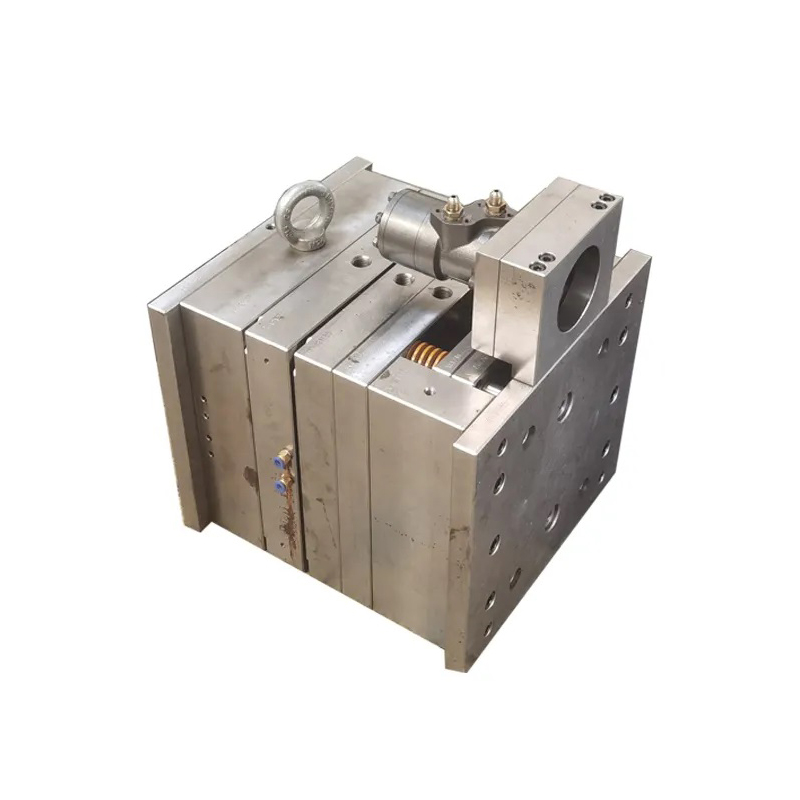

The production of high-precision metal molds for plastic components at Wuxi Lead Precision Machinery follows a rigorously controlled, three-phase process: Design, Prototyping, and Mass Production. Each phase is engineered to ensure dimensional accuracy, material integrity, and zero-defect output, meeting the exacting standards of industries such as automotive, medical, and consumer electronics.

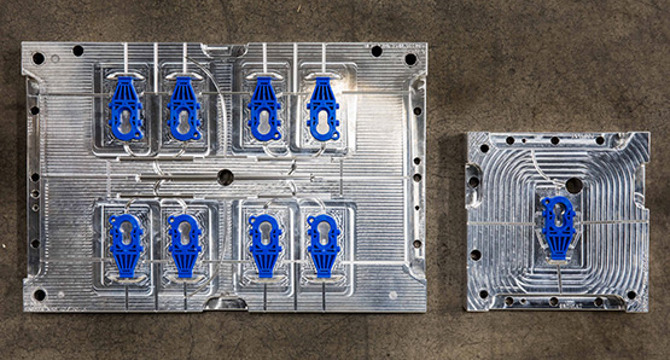

The process begins with Design, where our engineering team collaborates closely with clients to translate conceptual requirements into detailed 3D CAD models. Utilizing advanced simulation software, we analyze mold flow, thermal distribution, and structural stress points to optimize cavity layout, gating systems, and cooling channels. This digital validation phase ensures that the mold will perform consistently under real-world injection conditions, minimizing warpage, shrinkage, and cycle time inefficiencies. All design files are reviewed under our internal Design for Manufacturing (DFM) protocol, guaranteeing manufacturability and long-term durability.

Following design approval, we proceed to Prototyping. A single-cavity prototype mold is fabricated using high-grade tool steels such as P20, H13, or S136, depending on application demands. Machining is performed on state-of-the-art 5-axis CNC centers with micron-level precision, followed by fine surface treatments including mirror polishing or texturing as required. The prototype mold undergoes a trial run using the client’s specified polymer resin, producing a limited batch of parts for functional and dimensional evaluation. These sample components are subjected to full metrological inspection using CMM (Coordinate Measuring Machines) and optical profilometers, ensuring conformity to GD&T specifications. Any deviations are traced back to the mold geometry or process parameters and corrected before advancing.

Only after successful prototype validation do we initiate Mass Production. Full-scale molds—ranging from multi-cavity to family configurations—are manufactured under the same stringent quality controls. Each mold is assembled, tested, and certified for continuous operation. We implement real-time monitoring systems during production runs to track injection pressure, temperature stability, and ejection timing, ensuring batch-to-batch consistency. Our quality assurance framework is built on ISO 9001 standards, with 100% in-process inspection of critical features and zero acceptance of non-conforming parts.

Throughout all stages, traceability is maintained via digital work orders and material certifications. This closed-loop process—anchored in precision engineering and proactive defect prevention—enables Wuxi Lead Precision Machinery to deliver metal molds that achieve zero-defect performance in high-volume plastic manufacturing environments.

| Specification | Detail |

|---|---|

| Material Options | P20, 718H, H13, S136, 2344, NAK80 |

| Tolerance | ±0.005 mm |

| Surface Finish | Ra 0.05 µm (mirror) to Ra 3.2 µm (textured) |

| Mold Life | 500,000 to 1,000,000 cycles |

| Lead Time (Prototype) | 15–25 days |

| Lead Time (Production Mold) | 30–50 days |

| Quality Standard | ISO 9001:2015, ISO 13485 (medical) |

| Testing Equipment | CMM, Mold Flow Analyzer, Hardness Tester |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising Metal Mold Excellence

At Wuxi Lead Precision Machinery, we transform complex plastic molding challenges into seamless production realities. With over 15 years of specialized expertise in custom metal mold manufacturing, we serve global leaders in automotive, medical, and consumer electronics industries where precision directly impacts product integrity and profitability. Our ISO 9001:2015-certified facility in Wuxi integrates advanced CNC machining, EDM, and surface engineering under one roof—eliminating supply chain fragmentation and ensuring absolute control over every micron of your mold’s geometry. Unlike generic manufacturers, we engineer solutions for zero-defect production, leveraging 5-axis milling centers with sub-micron repeatability and proprietary thermal stabilization processes to combat warpage in high-cavitation molds.

Our commitment begins with deep technical collaboration. When you engage Lead Precision, our engineering team conducts a rigorous Design for Manufacturability (DFM) review, identifying potential ejection, cooling, or stress points before metal is cut. This proactive approach reduces time-to-market by up to 30% while extending mold life beyond 1 million cycles. We specialize in hardened tool steels (H13, S136), aluminum rapid prototypes, and exotic alloys for corrosive environments—each processed through our in-house heat treatment and polishing stations to achieve mirror finishes or textured surfaces meeting ASTM D2240 standards. Material traceability and first-article inspection reports are non-negotiable components of every delivery.

Critical performance specifications define our capability:

| Parameter | Specification Range | Industry Benchmark |

|---|---|---|

| Material Options | P20, 718, H13, S136, NAK80, Aluminum 7075 | Broadest alloy selection in Eastern China |

| Tolerance Range | ±0.002 mm (core/cavity) | Exceeds ISO 2768-mK |

| Surface Finish | Ra 0.025 µm (polished) to MT-11000VDI (textured) | 40% finer than standard EDM |

| Lead Time | 25-45 days (complex molds) | 20% faster than regional competitors |

This technical rigor translates to tangible ROI: reduced scrap rates, lower maintenance costs, and accelerated cycle times for your injection molding operations. We do not merely supply molds—we deliver production certainty. Our clients consistently achieve >99.5% first-pass yield rates, even for micro-molded components under 0.1g.

The cost of mold failure extends far beyond tooling expenses—it halts assembly lines, damages brand reputation, and triggers costly rework. Partner with an engineering ally that guarantees dimensional stability across 500,000+ cycles. Contact our technical sales team today to request a confidential DFM analysis. Email [email protected] with your part drawings and production requirements. Let Lead Precision’s metallurgical expertise and CNC mastery become your competitive advantage—where precision isn’t promised, it’s proven. Your next high-yield production run starts with a single email.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.