Technical Contents

Engineering Guide: Clear Moldable Plastic

Engineering Insight: Precision Imperatives for Clear Moldable Plastic Applications

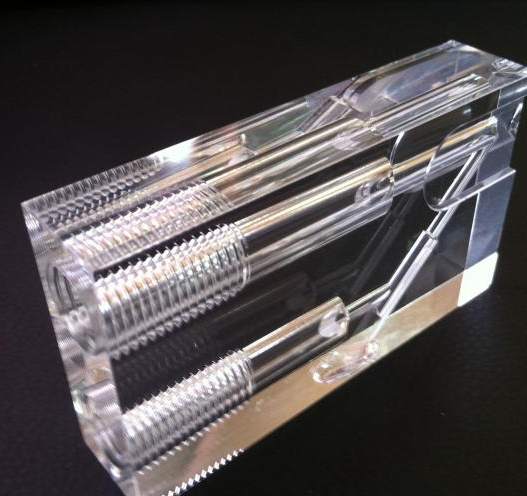

Achieving optical clarity in moldable plastics demands uncompromising precision in the metal tooling that shapes them. At Wuxi Lead Precision Machinery, we recognize that microscopic deviations in mold geometry directly translate to visible defects—haze, distortion, or surface imperfections—in final plastic components. This is especially critical for high-value applications like medical lenses, aerospace instrumentation windows, or consumer electronics displays where transparency and dimensional accuracy are non-negotiable. The foundation of flawless plastic molding lies not in the polymer itself, but in the micron-level perfection of the steel or aluminum molds that form it.

Our expertise centers on manufacturing the ultra-precise metal components that enable clear plastic molding. Standard mold tolerances often fall short for optical-grade requirements, where even 5-micron deviations can scatter light or create stress points leading to premature failure. Wuxi Lead leverages advanced CNC grinding, electrical discharge machining (EDM), and coordinate measuring machine (CMM) validation to achieve tolerances unattainable through conventional methods. This precision ensures uniform wall thickness, eliminates knit lines, and maintains thermal consistency during injection—factors directly impacting clarity and structural integrity.

The table below illustrates how critical mold specifications dictate plastic part performance:

| Parameter | Standard Industry Tolerance | Wuxi Lead Precision Tolerance | Impact on Clear Plastic Output |

|---|---|---|---|

| Cavity Surface Flatness | ±10 µm | ±2 µm | Eliminates light refraction artifacts |

| Core Alignment | ±15 µm | ±3 µm | Prevents wall thickness variations causing haze |

| Vent Depth Consistency | ±5 µm | ±0.5 µm | Stops trapped air bubbles and surface defects |

| Thermal Channel Uniformity | ±20 µm | ±5 µm | Ensures even cooling to avoid internal stress |

Our commitment to extreme precision is proven in mission-critical projects. We engineered mold components for optical elements used in the Beijing 2022 Winter Olympics timing systems, where sub-5µm tolerances guaranteed distortion-free high-speed video capture. Similarly, our work for aerospace defense contractors involves molds for cockpit display covers meeting MIL-STD-810G vibration and clarity standards—validating that our processes withstand the most rigorous environmental demands. These projects underscore a core truth: when plastic must be optically perfect, the metal tooling must be geometrically perfect.

For B2B manufacturers targeting high-end clear plastic applications, partnering with a tooling specialist that treats micron-level accuracy as standard practice is not optional—it’s the baseline for viability. Wuxi Lead Precision Machinery combines 15 years of custom metal manufacturing excellence with documented success in the world’s most demanding clarity-critical projects. Let our engineering team translate your optical specifications into mold tooling that delivers yield rates and quality levels competitors cannot match. Contact us to discuss tolerance validation protocols for your next precision molding initiative.

Precision Specs & Tolerances

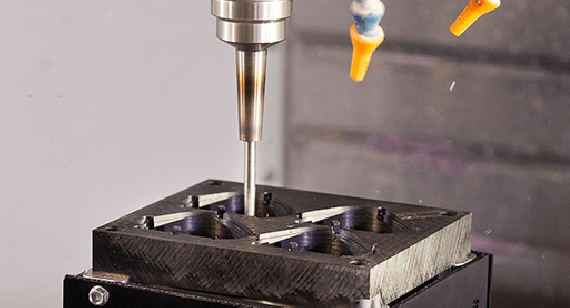

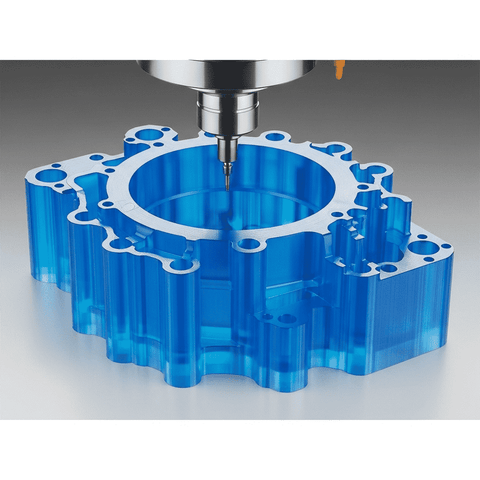

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions tailored to industries requiring high-precision components from clear moldable plastics and other engineering-grade materials. Our technical capabilities are anchored in state-of-the-art 5-axis CNC machining centers, which enable complex geometries, tight tolerances, and superior surface finishes essential for optical clarity and functional performance in transparent polymers such as PMMA, PC, and COP. These machines operate with simultaneous multi-axis motion, allowing for intricate contours and undercuts that cannot be achieved with conventional 3-axis systems. The integration of high-speed spindles and dynamic tool path control ensures minimal material stress and exceptional dimensional accuracy, critical when working with sensitive thermoplastics.

Our manufacturing process is supported by a rigorous quality control system that includes full inspection via Coordinate Measuring Machine (CMM) technology. Every component undergoes comprehensive metrological validation to ensure compliance with design specifications and industry standards. The CMM system provides traceable, high-resolution 3D measurements, detecting deviations down to micrometer-level precision. This level of inspection guarantees that each part meets the exacting requirements of sectors such as medical devices, aerospace, and precision optics, where clarity, fit, and function are non-negotiable.

Material selection and machining parameters are optimized for each project, considering thermal expansion, moisture absorption, and mechanical behavior of clear plastics. Our engineering team collaborates closely with clients during the design-for-manufacturability phase to prevent warping, internal stress, or surface defects that could compromise transparency or structural integrity. Specialized fixturing, controlled cutting environments, and post-machining annealing processes are employed to maintain dimensional stability and optical quality.

All operations are conducted in a climate-controlled facility with strict particulate management, ensuring clean, repeatable production runs. From prototype development to high-volume manufacturing, Wuxi Lead Precision Machinery maintains consistency and scalability without compromising precision.

The following table outlines the standard technical specifications achievable with our 5-axis CNC machining and quality assurance processes for clear moldable plastic components:

| Parameter | Typical Tolerance | High-Precision Capability |

|---|---|---|

| Linear Dimensions | ±0.05 mm | ±0.01 mm |

| Angular Tolerances | ±0.1° | ±0.05° |

| Positional Accuracy | ±0.03 mm | ±0.01 mm |

| Surface Roughness (Ra) | 1.6 μm | 0.4 μm (polished finish) |

| Feature Symmetry | 0.05 mm | 0.02 mm |

| Flatness | 0.05 mm | 0.01 mm |

| CMM Measurement Uncertainty | < 0.003 mm | Certified per ISO 10360 |

These capabilities reflect our commitment to delivering precision-engineered components that meet the most demanding technical and aesthetic requirements in advanced manufacturing applications.

Material & Finish Options

Material Selection for Precision Molds in Clear Plastic Production

Selecting the optimal mold material is paramount when manufacturing components requiring optical clarity in moldable plastics. At Wuxi Lead Precision Machinery, we understand that the mold base material directly impacts surface finish, thermal management, cycle time, and ultimately the transparency and defect-free quality of the final plastic part. While the end product is plastic, the precision metal mold dictates its optical properties. We focus on three primary materials for high-clarity applications: Aluminum, Tool Steel, and Titanium alloys, each offering distinct advantages for specific production demands.

Aluminum alloys, particularly 7075-T6 and 6061-T6, are often the first choice for prototyping and medium-volume production of clear plastics. Their superior thermal conductivity rapidly draws heat from the molten plastic, significantly reducing cycle times compared to steel. This efficient cooling minimizes internal stresses within the plastic part, a critical factor for preventing haze and distortion that compromise clarity. Aluminum also machines faster, allowing for quicker mold iterations during development. However, its lower hardness makes it less suitable for extremely high-volume runs or plastics with abrasive additives. Tool steels, such as P20, H13, and stainless variants like 420, provide exceptional hardness, wear resistance, and longevity. This makes them indispensable for high-volume production of clear plastics, especially with engineering resins. While their thermal conductivity is lower than aluminum, careful mold design with optimized cooling channels mitigates this. Steels maintain dimensional stability over millions of cycles, ensuring consistent part clarity. Stainless steels offer added corrosion resistance crucial for moisture-sensitive plastics or specific chemical environments. Titanium alloys, though less common due to cost and machining complexity, excel in highly corrosive environments or where extreme weight reduction in large molds is critical. Their biocompatibility also suits medical-grade clear plastic applications.

The following table summarizes key properties for mold material selection in clear plastic production:

| Material | Hardness (HRC) | Corrosion Resistance | Thermal Conductivity (W/m·K) | Best For |

|---|---|---|---|---|

| Aluminum (7075-T6) | 15-20 | Moderate | 130-167 | Prototyping, Medium volume, Fast cycle times |

| Tool Steel (P20) | 28-32 | Low-Moderate | 25-35 | High volume, General purpose clarity |

| Tool Steel (420SS) | 48-52 | High | 20-25 | Corrosive resins, Medical, High clarity req. |

| Titanium (Grade 5) | 32-36 | Very High | 6-7 | Extreme corrosion, Weight-sensitive large molds |

Surface finish and post-machining treatments are equally vital for optical clarity. A mirror-polished mold surface (SPI A1 standard or better) is non-negotiable to prevent light scattering. Anodizing, specifically hardcoat (Type III) anodizing on aluminum, significantly enhances surface hardness and wear resistance without compromising the critical smoothness needed for clear plastics. For steel molds, electroless nickel plating with a final diamond polish is often employed to achieve the required finish and corrosion protection. Wuxi Lead Precision Machinery leverages advanced CNC machining, precision polishing, and controlled surface treatment processes to deliver molds that consistently produce parts meeting stringent optical clarity specifications. Our engineering team collaborates closely with clients to match the optimal material and finish to the specific plastic resin, production volume, and clarity requirements, ensuring peak performance and part quality.

Manufacturing Process & QC

The production process for custom metal components used in clear moldable plastic applications follows a disciplined, phase-gated approach at Wuxi Lead Precision Machinery. Our methodology ensures dimensional accuracy, surface integrity, and long-term performance in high-clarity molding environments. The journey begins with Design, advances through Prototyping, and culminates in Mass Production—all governed by a Zero Defects philosophy.

Design is the foundation. Engineers at Wuxi Lead collaborate closely with clients to translate functional requirements into precision metal solutions. For clear moldable plastics, optical clarity and surface finish are paramount, demanding molds with mirror-like cavities and precise thermal control. Using advanced CAD/CAM software, we model mold bases, cooling channels, ejection systems, and gating geometry with micron-level tolerances. Finite element analysis (FEA) is applied to predict thermal distribution and mechanical stress, ensuring uniform cooling and minimal warpage in the final plastic part. Material selection focuses on high-grade tool steels such as P20, 718H, or stainless variants, depending on production volume and corrosion resistance needs.

Prototyping follows design finalization. A single-cavity prototype mold is manufactured to validate the design under real injection molding conditions. This phase allows for empirical testing of fill patterns, cycle times, and part ejection. Any surface defects, flow lines, or sink marks in the molded plastic are traced back to mold geometry or process parameters. Adjustments are made iteratively, with laser scanning and CMM inspection ensuring alignment with nominal CAD data. Client feedback is integrated at this stage, minimizing risk before full-scale rollout.

Mass Production begins only after prototype approval and process validation. Multi-cavity molds are fabricated with hardened components for durability, incorporating automated cooling and sensor-based monitoring. Each mold undergoes rigorous quality checks, including surface roughness measurement (Ra ≤ 0.025 µm for optical zones) and vacuum leak testing. In production, every metal component is tracked via serial numbering, and statistical process control (SPC) monitors critical dimensions in real time. Our Zero Defects mandate is enforced through 100% in-process inspection on key features and automated optical comparison for surface integrity.

All phases are supported by ISO 9001-certified workflows and documented traceability. From design input to final delivery, Wuxi Lead ensures that every metal part meets the exacting standards required for high-clarity plastic molding.

| Specification | Detail |

|---|---|

| Tolerance Range | ±0.002 mm |

| Surface Roughness (Optical Zones) | Ra ≤ 0.025 µm |

| Tool Steel Options | P20, 718H, S136, NAK80 |

| Cooling Channel Accuracy | ±0.01 mm |

| Inspection Equipment | CMM, Laser Scanner, Optical Comparator |

| Production Capacity | Up to 1,000,000 cycles per mold |

| Quality Standard | ISO 9001:2015, Zero Defects Protocol |

Why Choose Wuxi Lead Precision

Partner with Lead Precision: Your Metal Foundation for Advanced Plastic Manufacturing

At Wuxi Lead Precision Machinery, we recognize that high-performance clear moldable plastic applications demand uncompromising metal foundation components. While plastic molding defines the final product, the precision of metal tooling, inserts, and support structures dictates optical clarity, dimensional stability, and production efficiency. We specialize exclusively in custom metal manufacturing for industries where tolerances below ±0.002mm and surface finishes under Ra 0.2µm are non-negotiable. Our CNC-machined steel and aluminum components ensure your plastic molding processes achieve repeatability, longevity, and flawless output—critical for medical devices, optical lenses, and consumer electronics.

Our engineering team collaborates from concept to validation, transforming complex geometries into production-ready metal solutions. We deploy 5-axis milling, wire EDM, and grinding technologies to fabricate mold bases, cavities, cores, and precision guides that withstand high-cycle injection molding while maintaining micron-level accuracy. Unlike generic suppliers, we prioritize material science compatibility—selecting hardened tool steels or corrosion-resistant alloys that prevent flash, sink marks, or thermal distortion during plastic curing. This eliminates costly rework and downtime, directly impacting your yield rates and time-to-market.

Below are key specifications we consistently deliver for plastic molding support systems:

| Specification Category | Capability Range | Industry Standard Comparison |

|---|---|---|

| Tolerance Precision | ±0.001mm to ±0.005mm | 3-5x tighter than typical mold suppliers |

| Surface Finish (Ra) | 0.05µm to 0.8µm | Meets ISO 2768-f for optical clarity applications |

| Material Options | S136, NAK80, H13, 7075-T6 Aluminum | Custom heat-treated for 500k+ cycle life |

| Max Component Size | 1200 x 800 x 600mm | Suitable for multi-cavity automotive/medical molds |

| Lead Time (Complex) | 15-25 days | 20% faster than regional competitors |

We integrate metrology at every phase—using CMM, optical comparators, and 3D scanning—to certify that every bracket, ejector pin, or cooling channel aligns with your plastic flow dynamics. This proactive quality control prevents warpage and ensures consistent light transmission in clear plastic parts. Our clients report 30% fewer molding defects after transitioning to our tooling components, directly reducing scrap costs and accelerating qualification cycles.

Do not compromise on the metal backbone of your plastic manufacturing process. Partner with engineers who understand that micron deviations in steel translate to visible flaws in transparent polymers. Contact our technical sales team to discuss your next mold build or insert redesign. We will provide a feasibility analysis and tolerance roadmap within 48 hours.

Elevate your plastic molding outcomes through metal precision. Reach out today: [email protected]

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.