Technical Contents

Engineering Guide: Stainless Steel Cutting Service

Engineering Insight: Precision in Stainless Steel Cutting Services

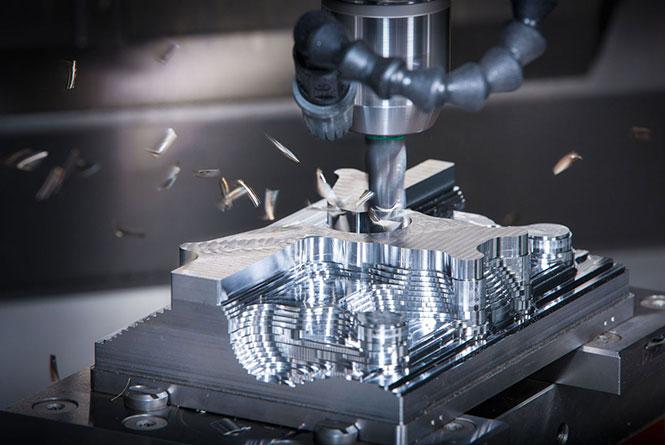

In high-performance industries such as aerospace, defense, and advanced medical equipment, the demand for flawless stainless steel components is non-negotiable. At Wuxi Lead Precision Machinery, we understand that precision in stainless steel cutting is not merely a technical requirement—it is a foundational element of reliability, safety, and operational efficiency. Our decades of experience in custom metal manufacturing have positioned us as a trusted partner for clients requiring the highest standards, including projects associated with Olympic infrastructure and military-grade applications.

Stainless steel, while valued for its corrosion resistance, strength, and durability, presents unique challenges during the cutting process. Its work-hardening characteristics, thermal conductivity, and alloy composition demand a meticulous approach to tooling, speed, feed rates, and cooling strategies. Even minor deviations in cutting parameters can lead to dimensional inaccuracies, surface degradation, or compromised structural integrity—failures that are unacceptable in mission-critical applications.

Our stainless steel cutting service leverages state-of-the-art CNC laser, plasma, and waterjet technologies, each selected and calibrated based on the specific grade of stainless steel and the required tolerance. Whether processing 304, 316, 410, or duplex alloys, our engineering team ensures optimal kerf width, edge squareness, and minimal heat-affected zones. This precision is maintained through real-time monitoring systems and rigorous post-process inspection using coordinate measuring machines (CMM) and optical comparators.

What sets Wuxi Lead apart is not only our advanced equipment but also our deep engineering expertise. Having contributed to high-stakes projects—including structural components for Olympic venues and precision parts for defense systems—we have refined our processes to meet international quality benchmarks such as ISO 9001 and MIL-STD-810. These experiences have ingrained in our team a culture of zero-defect manufacturing, where every micron matters.

Our commitment extends beyond cutting. We offer full material traceability, custom fixturing, and integrated secondary operations such as deburring, welding, and surface finishing—ensuring that every component meets the exact functional and regulatory requirements of the end application.

The following table outlines key specifications and capabilities of our stainless steel cutting service:

| Parameter | Capability |

|---|---|

| Material Thickness Range | 0.5 mm – 50 mm |

| Cutting Methods | Fiber Laser, Plasma, Waterjet, CNC Milling |

| Tolerance (Standard) | ±0.05 mm |

| Edge Quality (Ra) | ≤ 3.2 µm (polished finish available) |

| Max Work Envelope | 4000 mm × 2000 mm × 1500 mm |

| Supported Alloys | 304/L, 316/L, 410, 430, 17-4PH, Duplex 2205 |

| Quality Standards | ISO 9001, MIL-STD-810, ASTM A240 |

| Lead Time (Typical) | 7–15 days (rush options available) |

Precision in stainless steel cutting is not a feature—it is a standard. At Wuxi Lead Precision Machinery, we engineer every cut with the confidence that our components will perform under the most demanding conditions.

Precision Specs & Tolerances

Advanced Stainless Steel Cutting Capabilities at Wuxi Lead Precision Machinery

Wuxi Lead Precision Machinery delivers industry-leading stainless steel cutting services engineered for the most demanding aerospace, medical, and energy sector applications. Our core competency lies in precision machining of complex 304, 316/L, 17-4PH, and other high-grade stainless alloys, where material integrity and dimensional accuracy are non-negotiable. We overcome inherent stainless steel challenges—including work hardening, thermal distortion, and stringent surface finish requirements—through integrated 5-axis CNC machining centers and rigorously controlled processes.

Our facility utilizes state-of-the-art DMG MORI and MAZAK 5-axis CNC machining centers, specifically configured for optimal stainless steel performance. These systems feature high-torque spindles, advanced coolant-through-tool delivery, and rigid construction to maintain stability during deep cavity milling and thin-wall profiling. The simultaneous 5-axis capability eliminates secondary operations, ensuring critical feature alignment within a single setup. This is essential for components like surgical instrument housings, valve bodies, and turbine manifolds where angular precision directly impacts functional performance and leak integrity. Our programming leverages Mastercam and Siemens NX CAM to optimize toolpaths, minimizing heat generation and maximizing tool life specific to stainless grades.

Quality assurance is embedded at every stage, not merely a final checkpoint. All critical stainless steel components undergo comprehensive Coordinate Measuring Machine (CMM) inspection using Zeiss CONTURA systems, providing full geometric dimensioning and tolerancing (GD&T) validation against CAD models. This includes verification of complex contours, positional tolerances, and surface profiles to ISO 1101 standards. Material certifications (MTRs) and first-article inspection reports (FAIRs) are standard deliverables, ensuring full traceability from raw bar stock to finished part. Our ISO 9001:2015-certified process includes in-process probing for on-machine verification, reducing scrap and guaranteeing conformance before final CMM validation.

The following table details achievable geometric tolerances for stainless steel components under standard production conditions. Note that specific project requirements may allow for tighter control through optimized fixturing and process parameters.

| Feature Type | Standard Tolerance (Metric) | Standard Tolerance (Imperial) | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.010 mm | ±0.0004 in | CMM / Micrometer |

| Hole Diameter | H7 (0 / +0.015 mm) | H7 (0 / +0.0006 in) | CMM / Air Gage |

| Positional Tolerance | ±0.015 mm | ±0.0006 in | CMM |

| Flatness | 0.010 mm per 100 mm | 0.0004 in per 4 in | CMM / Surface Plate |

| Surface Roughness (Ra) | 0.8 µm (32 µin) | 32 µin | Profilometer |

| Angular Features | ±0.05° | ±0.05° | CMM / Optical Comparator |

We partner with clients from initial design review through volume production, providing DFM feedback specifically for stainless steel machinability. Our technical team ensures your components meet the highest functional and regulatory standards, delivered with the precision engineering Wuxi Lead is recognized for globally. Contact our engineering department to discuss your specific stainless steel cutting requirements and tolerance expectations.

Material & Finish Options

Material Selection for Precision Stainless Steel Cutting Services

When selecting materials for high-precision cutting applications, understanding the mechanical, thermal, and environmental performance of metals is critical. At Wuxi Lead Precision Machinery, we specialize in custom stainless steel cutting services, but our expertise extends across a range of high-performance metals including aluminum, steel, and titanium. Each material offers distinct advantages depending on the application’s requirements for strength, weight, corrosion resistance, and manufacturability.

Stainless steel remains a top choice for industrial components due to its excellent corrosion resistance, high tensile strength, and durability under extreme temperatures. Common grades such as 304 and 316 are widely used in medical devices, food processing equipment, and marine environments. Our advanced CNC laser and plasma cutting systems ensure tight tolerances and clean edges, minimizing post-processing needs. Stainless steel is ideal when long-term reliability in harsh environments is non-negotiable.

Aluminum is favored in aerospace, automotive, and electronics industries where lightweight design and good thermal conductivity are essential. While not as strong as steel, aluminum offers an outstanding strength-to-weight ratio and is highly machinable. It naturally forms a protective oxide layer, providing inherent corrosion resistance. However, for enhanced surface protection and aesthetic finish, aluminum components are often post-processed with anodizing. This electrochemical process thickens the natural oxide layer, improving wear resistance and allowing for color customization—critical in consumer-facing applications.

Titanium stands at the premium end of the material spectrum, offering exceptional strength-to-density ratio and outstanding resistance to corrosion, especially in saline or acidic environments. It is commonly specified in aerospace, medical implants, and high-performance automotive systems. While more challenging to cut due to its low thermal conductivity and tendency to work-harden, our precision cutting technologies are optimized to handle titanium with minimal tool wear and dimensional deviation.

For applications requiring enhanced surface properties, anodizing is a recommended finish—particularly for aluminum. This process not only improves durability but also allows for precise color matching, which is valuable in branding or identification systems. Our in-house finishing capabilities ensure seamless integration from cutting to surface treatment, maintaining consistency across production batches.

Below is a comparative overview of key material properties to guide selection:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Typical Applications | Common Finishes |

|---|---|---|---|---|---|

| Stainless Steel | 7.9–8.0 | 500–900 | Excellent | Medical, Marine, Food Processing | Passivation, Brushed, Polished |

| Aluminum | 2.7 | 100–350 | Good | Aerospace, Electronics, Automotive | Anodizing, Powder Coating |

| Titanium | 4.5 | 900–1,200 | Exceptional | Aviation, Medical Implants, Racing | Bead Blasting, Anodizing |

Selecting the right material is a balance of performance, cost, and manufacturability. At Wuxi Lead Precision Machinery, we support engineers and procurement teams with material consultation, ensuring optimal outcomes from design through delivery.

Manufacturing Process & QC

Precision Stainless Steel Cutting: The Zero Defect Production Pathway

Achieving flawless stainless steel components demands a rigorously controlled production sequence, not merely sequential steps. At Wuxi Lead Precision Machinery, our Zero Defects philosophy is embedded from the initial design review through to final mass production shipment. This integrated approach eliminates costly rework and ensures absolute compliance with the most stringent aerospace, medical, and semiconductor industry standards.

The process begins with comprehensive Design for Manufacturability (DFM) analysis. Our engineering team collaborates closely with your designers, scrutinizing CAD models for optimal material utilization, geometric feasibility, and inherent manufacturability within stainless steel’s unique properties. We identify potential stress points, warpage risks, and tolerance stack-ups before metal is cut, leveraging decades of experience with grades like 304, 316/L, and 17-4PH. Critical material certification (mill test reports) and specific grade suitability are verified at this stage, preventing downstream material-related failures. This proactive engineering gate ensures the design is not just possible, but optimized for zero-defect production.

Prototyping is non-negotiable for complex or mission-critical parts. Using the exact production-grade CNC laser, waterjet, or plasma cutting equipment intended for volume runs, we fabricate functional prototypes. This phase validates the DFM recommendations, confirms dimensional accuracy against your CAD model using CMM inspection, and assesses critical surface finish requirements. Material behavior under actual cutting parameters is observed, allowing fine-tuning of kerf compensation, heat input management, and fixturing strategies. Client sign-off on the prototype is mandatory, providing tangible proof of process capability and eliminating assumptions before committing to full production.

Mass production executes under our certified Quality Management System (ISO 9001:2015). Every stage incorporates real-time monitoring and statistical process control (SPC). Cutting parameters are locked based on prototyping data. In-process inspections at defined intervals verify critical dimensions, edge quality, and absence of heat-affected zone (HAZ) issues. Final 100% inspection against your drawing, including material traceability verification, is standard. Our focus on first-time-right execution, driven by the前期 DFM and prototyping rigor, consistently achieves first-pass yield rates exceeding 99.8%. Zero Defects is the outcome of systematic prevention, not last-minute detection.

Wuxi Lead Stainless Steel Cutting Capabilities

| Parameter | Specification Range | Critical Impact |

|---|---|---|

| Material Grades | 304, 304L, 316, 316L, 17-4PH, 430 | Corrosion resistance, strength, weldability |

| Thickness Range | 0.5mm – 25mm (Laser); Up to 150mm (Waterjet) | Process selection, edge quality control |

| Tolerance (Typical) | ±0.02mm – ±0.1mm (depends on process) | Fit, function, assembly integrity |

| Surface Finish (Ra) | 0.8µm – 6.3µm (as-cut); Polishing options | Corrosion performance, aesthetics, sealing |

| Industry Applications | Aerospace hydraulic fittings, Medical implants, Semiconductor chambers, Food processing equipment | Demands absolute dimensional stability & purity |

This disciplined progression—where design validation informs prototyping, and prototyping certifies the mass production process—is the cornerstone of our Zero Defects commitment. It transforms stainless steel cutting from a basic operation into a guaranteed precision engineering outcome.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Stainless Steel Cutting Excellence

When precision, durability, and repeatability define your manufacturing requirements, partnering with Wuxi Lead Precision Machinery ensures your stainless steel components meet the highest global standards. As a trusted leader in custom metal manufacturing, we specialize in advanced stainless steel cutting services tailored to the exacting needs of aerospace, medical, automotive, and industrial sectors. Our integrated approach combines cutting-edge CNC technology, expert engineering, and rigorous quality control to deliver components that perform under the most demanding conditions.

At Lead Precision, we understand that each project presents unique challenges—whether it’s maintaining tight tolerances on complex geometries or ensuring material integrity across high-volume runs. Our facility in Wuxi, China, is equipped with state-of-the-art fiber laser cutting systems, high-speed CNC machining centers, and plasma cutting solutions, enabling us to process a full range of stainless steel grades including 304, 316, 410, and 17-4PH. Every operation is monitored in real time to ensure dimensional accuracy down to ±0.02 mm and superior edge quality with minimal burr formation.

Our engineering team collaborates closely with clients from design through delivery, offering DFM (Design for Manufacturability) analysis to optimize part geometry, reduce waste, and accelerate time-to-market. With full material traceability, ISO 9001-certified processes, and in-house metrology using CMM and optical inspection systems, we guarantee consistency across every batch—no matter the complexity or volume.

Below are key specifications for our stainless steel cutting services:

| Specification | Capability |

|---|---|

| Material Types | 304/L, 316/L, 410, 420, 17-4PH, 904L, Duplex (2205), and custom alloys |

| Cutting Methods | Fiber Laser, CNC Plasma, Waterjet, and Precision Shearing |

| Thickness Range | 0.5 mm – 25 mm (laser), up to 50 mm (plasma/waterjet) |

| Tolerance | ±0.02 mm to ±0.1 mm (depending on process and thickness) |

| Max Work Envelope | 4000 mm × 2000 mm (laser), 6000 mm × 3000 mm (plasma/waterjet) |

| Surface Finish | As-cut (Ra ≤ 3.2 µm), optional deburring, passivation, or polishing |

| Certifications | ISO 9001:2015, Material Test Reports (MTR), First Article Inspection (FAI) |

| Lead Time | 7–15 days (standard), expedited options available |

Choosing the right manufacturing partner is critical to your product’s success. At Wuxi Lead Precision Machinery, we don’t just cut metal—we engineer solutions. Our commitment to innovation, quality, and responsive service makes us the preferred choice for global OEMs and Tier-1 suppliers.

Take the next step toward precision manufacturing excellence. Contact us today at [email protected] to discuss your stainless steel cutting requirements, request a quote, or schedule a virtual tour of our facility. Let Lead Precision be your trusted partner in turning high-performance designs into reality.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.