Technical Contents

Engineering Guide: Plastic Injection Company

Engineering Insight Precision as the Non-Negotiable Foundation for Plastic Injection Success

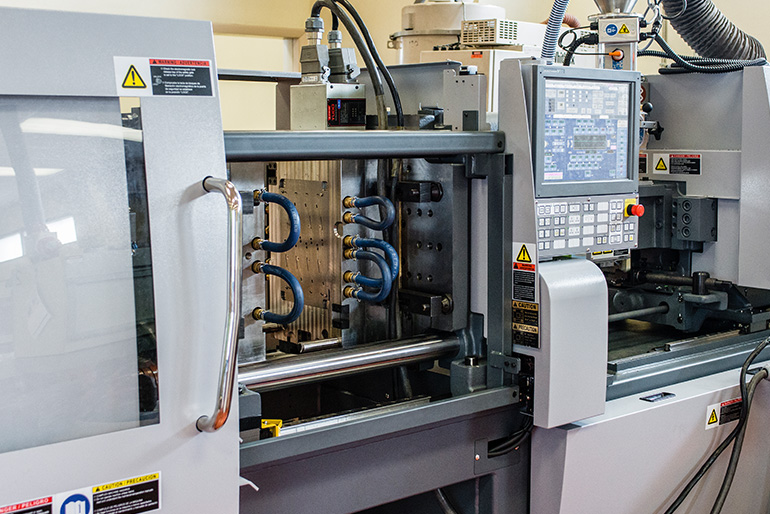

In the competitive landscape of plastic injection molding, the performance and longevity of the mold itself dictate production efficiency, part quality, and ultimately, profitability. Achieving consistent, high-quality output is not merely desirable; it is an absolute requirement driven by precision engineering at every stage of mold fabrication. Sub-micron level deviations in critical mold components—cavities, cores, ejector systems, and cooling channels—translate directly into part defects, increased scrap rates, unplanned downtime, and accelerated wear. The thermal management dynamics within the mold, governed by the exact geometry and placement of cooling circuits machined into the metal, are equally sensitive. Imperfect flow paths or inconsistent channel wall finishes disrupt heat transfer uniformity, causing warpage, sink marks, and extended cycle times. For mold makers and injection molders serving demanding sectors like medical, automotive, or aerospace, where tolerances are measured in thousandths of a millimeters and regulatory scrutiny is intense, precision is not a feature—it is the fundamental prerequisite for viability.

Wuxi Lead Precision Machinery approaches this challenge with the rigor demanded by our core expertise in custom metal manufacturing. Our foundation lies in advanced CNC machining, grinding, and EDM processes, operating within strictly controlled environmental conditions to mitigate thermal drift. We understand that the mold base and critical inserts are not generic metal parts; they are high-stress, high-precision tooling systems requiring metallurgical expertise and exacting process control. This deep-seated precision culture is forged through direct experience delivering components for projects where failure is not an option. Our engineering teams have contributed to infrastructure supporting Olympic-level sporting events and supplied mission-critical metal components for defense applications. These engagements instilled an uncompromising standard: zero-defect tolerance, rigorous material traceability, and processes validated to withstand the most extreme operational demands. This same discipline is applied relentlessly to every plastic injection mold component we manufacture.

The tangible outcome of this commitment is measurable in the performance characteristics of the mold bases and inserts we produce. Below are representative specifications reflecting our standard high-precision capabilities for critical mold elements:

| Feature | Standard Capability | High-Precision Capability | Measurement Standard |

|---|---|---|---|

| Linear Dimension Tolerance | ±0.010 mm | ±0.002 mm | CMM (ISO 10360-2) |

| Geometric Tolerance (Flatness) | 0.010 mm/m | 0.003 mm/m | Laser Interferometer |

| Surface Roughness (Ra) | 0.8 µm | 0.2 µm | Profilometer (ISO 4287) |

| Bore Concentricity | Ø0.015 mm | Ø0.005 mm | CMM (Multi-point Analysis) |

| Thermal Stress Relief | Standard | Vacuum Furnace Certified | Material Cert. + Hardness |

Precision in mold manufacturing is the invisible engine driving injection molding success. It minimizes trial-and-error during mold commissioning, ensures consistent part conformance over millions of cycles, and maximizes the asset life of the mold investment. At Wuxi Lead Precision Machinery, our heritage in delivering metal components for the world’s most exacting applications provides the engineering depth and process discipline necessary to transform precision from an aspiration into the reliable foundation of your plastic injection operations. Partner with a manufacturer whose precision standards are proven where performance is non-negotiable.

Precision Specs & Tolerances

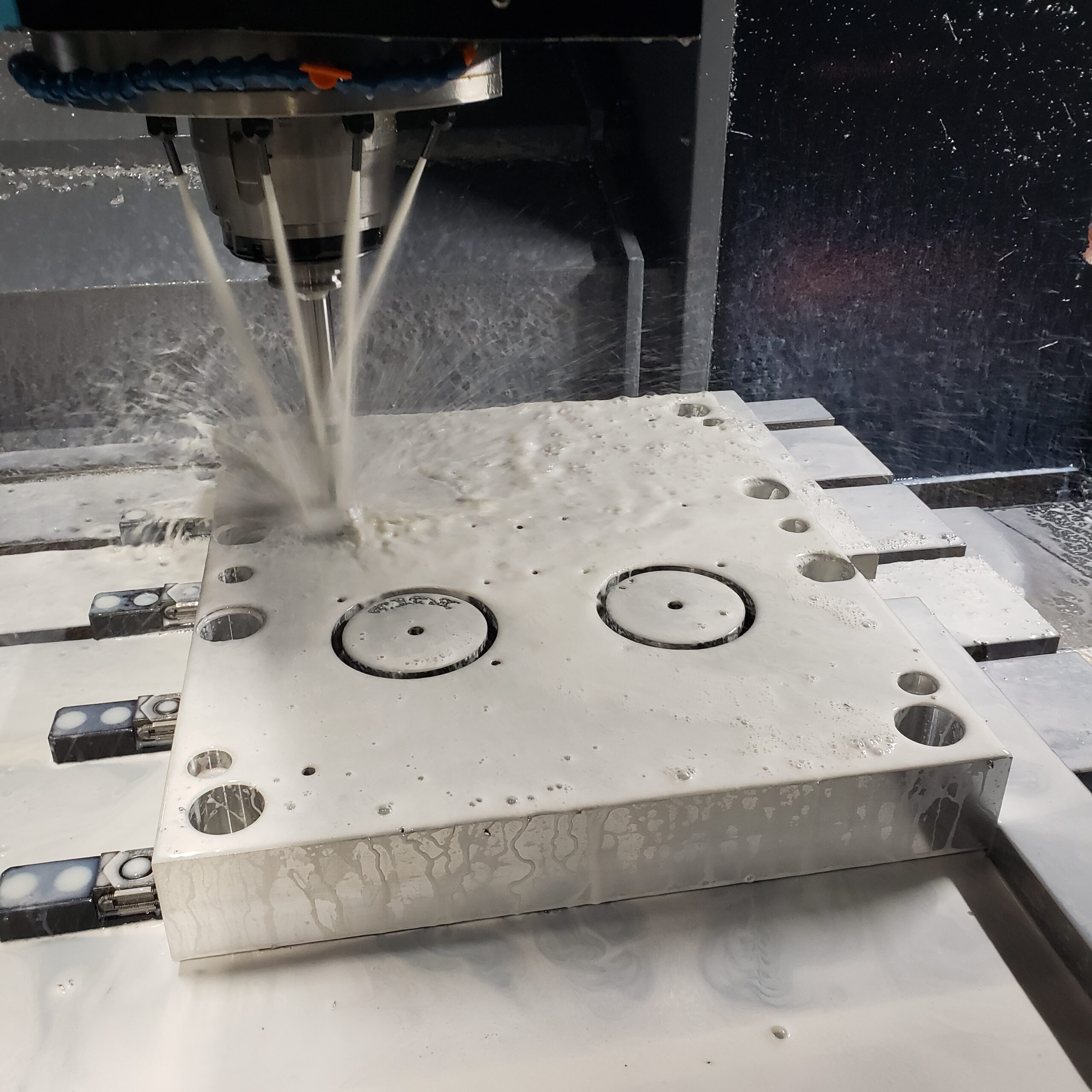

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions tailored for high-performance industries, including automotive, aerospace, medical, and electronics. At the core of our technical capabilities is a fully integrated 5-axis CNC machining platform, enabling the production of complex, high-precision components with superior surface finishes and dimensional accuracy. Our machining centers operate with simultaneous multi-axis movement, allowing for intricate geometries that would be unachievable with conventional 3-axis systems. This level of precision is essential for clients requiring tight-tolerance parts used in mission-critical applications.

Our 5-axis CNC technology supports a broad range of materials, including aluminum alloys, stainless steels, titanium, brass, and high-performance engineering plastics. This versatility, combined with automated tool changers and high-speed spindles, ensures efficient cycle times and consistent part quality across both prototyping and high-volume production runs. Each machine is operated by certified CNC programmers and machinists who utilize advanced CAM software to optimize toolpaths, minimize material waste, and maintain repeatability.

To ensure every component meets exacting standards, Wuxi Lead implements a rigorous quality control protocol centered on CMM (Coordinate Measuring Machine) inspection. Our Zeiss and Hexagon CMM systems provide full 3D metrology analysis, capturing critical dimensions, geometric tolerances, and surface characteristics with micron-level accuracy. All inspections are documented in comprehensive First Article Inspection (FAI) and Production Part Approval Process (PPAP) reports, traceable to international standards such as ISO 9001 and IATF 16949.

Our quality management system is integrated throughout the manufacturing workflow, from raw material verification to final packaging. In-process inspections are conducted at defined stages to detect and correct deviations in real time, preventing non-conformance and reducing rework. All measurement data is stored digitally for full traceability, supporting audit readiness and long-term quality assurance for our clients.

The following table outlines the standard technical specifications and tolerances achievable through our 5-axis CNC and inspection processes:

| Parameter | Standard Capability | Tight Tolerance Option | Measurement Method |

|---|---|---|---|

| Linear Dimensional Tolerance | ±0.025 mm | ±0.005 mm | CMM, Micrometer, Caliper |

| Geometric Tolerance (GD&T) | ±0.01 mm (Position, Flatness) | ±0.003 mm | CMM, Optical Comparator |

| Surface Roughness (Ra) | 3.2 µm | 0.8 µm (polished finish) | Surface Roughness Tester |

| Maximum Work Envelope | 1200 x 800 x 600 mm | Custom on request | CNC Machine Specifications |

| Repeatability | ±0.008 mm | ±0.002 mm | CMM Statistical Analysis |

| Material Verification | PMI (Positive Material ID) | Spectrometric Analysis | Handheld XRF Analyzer |

Wuxi Lead Precision Machinery combines cutting-edge 5-axis CNC technology with metrology-grade inspection to deliver components that meet the most demanding engineering requirements. Our technical capabilities are backed by a commitment to precision, consistency, and full process transparency.

Material & Finish Options

Material Selection for Injection Molding Tooling: Precision Metal Guidance

Selecting the optimal metal substrate is foundational for injection molding tooling performance, directly impacting cycle time, part quality, tool longevity, and total cost of ownership. At Wuxi Lead Precision Machinery, our engineering team prioritizes material properties aligned with your specific production volume, polymer characteristics, and geometric complexity. Misalignment here leads to premature wear, excessive maintenance, or compromised part finish. We analyze thermal management, hardness, machinability, and corrosion resistance as critical decision drivers.

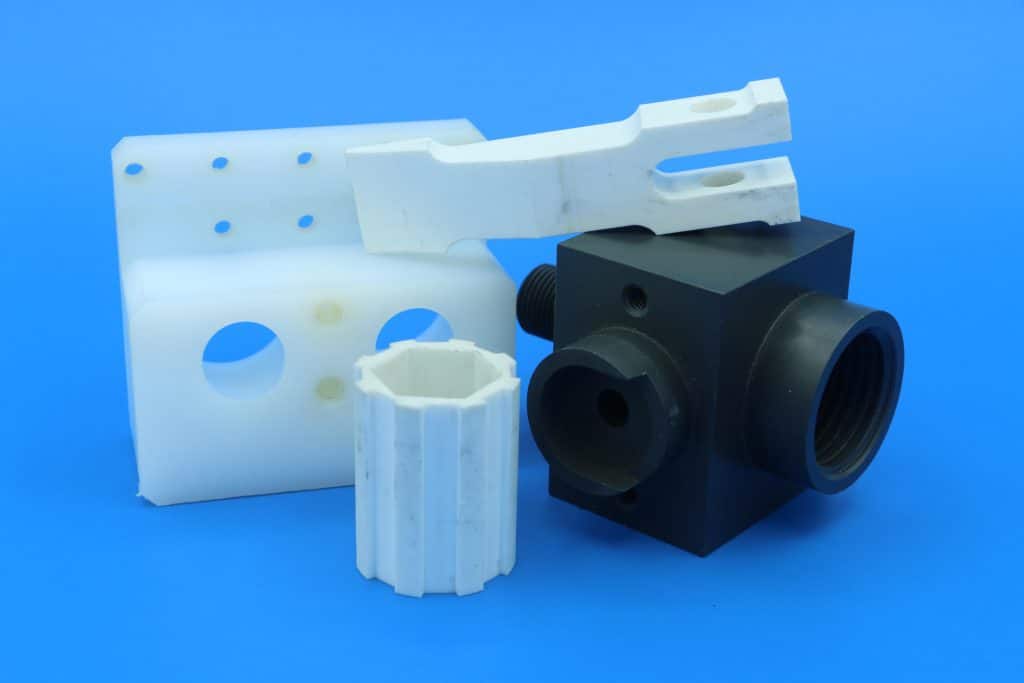

Aluminum alloys, particularly 7075-T6 and 6061-T6, excel in rapid prototyping and low-to-medium volume production. Their superior thermal conductivity significantly reduces cooling cycles compared to steel, accelerating time-to-market. While offering lower hardness than tool steels, modern aluminum grades withstand thousands of cycles for many engineering plastics when properly designed and finished. This makes them cost-effective for initial production runs or complex geometries requiring fast iteration. Steel remains the dominant choice for high-volume manufacturing. Pre-hardened steels like P20 offer a balance of machinability, polishability, and moderate wear resistance for general applications. For demanding polymers (e.g., glass-filled nylons, PVC) or extended production life exceeding 500,000+ cycles, hardened tool steels such as H13 (air-hardening) or S136 (stainless) are essential. These provide exceptional resistance to abrasion, thermal fatigue, and corrosion, ensuring dimensional stability and surface integrity over millions of shots. Titanium alloys see specialized use where extreme corrosion resistance against highly aggressive polymers or ultra-lightweight tooling is paramount, though cost and machining complexity limit widespread adoption.

Surface finishing, particularly anodizing for aluminum tooling, is non-negotiable for performance. Hard anodizing (Type III) creates a dense, wear-resistant ceramic layer significantly enhancing surface hardness (up to 60-70 HRC equivalent) and reducing galling. This is critical for core/cavity surfaces, slides, and lifters interacting directly with molten plastic. It improves release properties, minimizes maintenance frequency, and extends the functional life of aluminum molds, bridging the performance gap closer to steel for specific applications. Always specify the required anodizing thickness and sealing process based on polymer abrasiveness.

Key material properties for common injection molding tooling substrates are summarized below. Consult our applications engineers to match these specs precisely to your project requirements.

| Material | Thermal Conductivity (W/mK) | Hardness (HRC) | Primary Injection Molding Applications |

|---|---|---|---|

| Aluminum 7075-T6 | 120 – 130 | 15 – 20 | Rapid prototyping, low/medium volume, complex cores/cavities |

| P20 Steel | 28 – 36 | 28 – 32 | General purpose production molds, moderate volumes |

| H13 Tool Steel | 26 – 30 | 48 – 52 | High-volume production, abrasive/glass-filled polymers |

| S136 Stainless | 20 – 25 | 48 – 52 | Corrosive polymers (PVC, flame retardants), optical parts |

| Titanium Grade 5 | 7 – 12 | 32 – 36 | Extreme corrosion resistance, specialized lightweight tooling |

Material and finish selection is not generic. Wuxi Lead Precision Machinery leverages decades of CNC machining expertise to translate your production demands into the optimal metal solution, ensuring your tooling delivers maximum ROI through precision, durability, and efficiency. Contact our technical team for a tailored assessment.

Manufacturing Process & QC

At Wuxi Lead Precision Machinery, we specialize in delivering precision-engineered metal components tailored for integration with plastic injection systems. Our end-to-end manufacturing process is engineered for reliability, repeatability, and zero-defect performance. From initial concept to full-scale production, every phase is tightly controlled to meet the exacting standards of high-end industrial clients.

The journey begins with Design, where our engineering team collaborates closely with clients to translate functional requirements into manufacturable metal components. Utilizing advanced CAD/CAM software and finite element analysis (FEA), we optimize part geometry, material selection, and tolerance specifications. This stage includes thermal and stress simulations to ensure compatibility with plastic injection environments, where temperature fluctuations and mechanical loads are critical factors. Design for manufacturability (DFM) reviews are conducted to eliminate potential production risks before any material is cut.

Next, we move to Prototyping, a critical validation phase. Using CNC milling, turning, and wire EDM technologies, we produce functional prototypes within 7–14 days, depending on complexity. These prototypes are subjected to rigorous dimensional inspection using coordinate measuring machines (CMM) and surface roughness testing. We also conduct fit, form, and function trials with actual injection molds to verify alignment, sealing integrity, and thermal performance. Feedback from this stage is incorporated into final design adjustments, ensuring that the transition to mass production is seamless and defect-free.

Mass Production is executed on automated, high-precision CNC platforms equipped with in-process probing and real-time tool monitoring. Our production cells operate under strict ISO 9001-certified quality protocols, with statistical process control (SPC) applied to key dimensions. Each component undergoes 100% visual inspection and batch sampling for metallurgical verification. We maintain full traceability through serialized part tracking and digital quality dossiers, enabling rapid root-cause analysis if required. Production throughput is scalable from hundreds to hundreds of thousands of units annually, with consistent adherence to ±0.005 mm tolerance standards.

Our zero-defect philosophy is enforced through preventive controls, not just final inspection. By integrating quality into every process node, we eliminate waste, reduce rework, and ensure that every metal component performs reliably in demanding plastic injection applications.

| Specification | Detail |

|---|---|

| Material Options | Stainless Steel (304, 316), Tool Steel (H13, S136), Aluminum (6061, 7075), Brass, Titanium |

| Tolerance | ±0.005 mm (standard), up to ±0.002 mm (tight-tolerance) |

| Surface Finish | Ra 0.2–1.6 µm (polished, bead-blasted, or coated options) |

| Max Part Size | 800 mm × 600 mm × 500 mm |

| Production Capacity | 50,000–200,000 units/year (automated lines) |

| Quality Standards | ISO 9001:2015, PPAP, FAIR, SPC, 100% inspection reporting |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising Metal Solutions in Injection Molding

In high-volume plastic injection manufacturing, the performance and longevity of your molds and tooling directly dictate production efficiency, part quality, and ultimately, your bottom line. Substandard metal components lead to costly downtime, inconsistent outputs, and accelerated wear. Wuxi Lead Precision Machinery exists to eliminate these critical pain points. We specialize in delivering mission-critical custom metal components engineered to the exacting tolerances and material specifications demanded by advanced injection molding operations. Our focus isn’t merely on fabrication; it’s on providing engineered solutions that enhance your mold performance, extend service life, and ensure repeatable precision cycle after cycle.

As your strategic manufacturing partner, we integrate deep expertise in CNC machining, advanced metallurgy, and mold engineering dynamics. We understand that a tolerance deviation of microns or an incorrect surface finish on a core pin, cavity insert, or ejection system component can cascade into significant production failures. Our engineering team collaborates closely with your design and production staff from the initial concept phase, ensuring manufacturability and optimizing component geometry for maximum durability and performance within your specific molding process parameters. We utilize state-of-the-art multi-axis CNC centers, rigorous in-process metrology, and stringent material traceability protocols to guarantee every part meets or exceeds your most demanding requirements.

Our commitment to precision and reliability is quantifiable. The table below outlines core technical capabilities directly relevant to injection molding tooling excellence.

| Capability Category | Specification Detail | Relevance to Injection Molding |

|---|---|---|

| Dimensional Tolerance | ±0.002 mm (0.00008″) standard | Ensures perfect mold alignment, zero flash |

| Surface Finish | Ra 0.05 µm (2 µin) achievable | Critical for part release, cosmetic quality |

| Material Expertise | Hardened Tool Steels (H13, S7), Stainless, Aluminum Alloys | Optimized for wear resistance, thermal stability |

| Max Part Size (Milling) | 2000 x 1000 x 800 mm | Supports large mold bases, complex cavities |

| Lead Time (Prototype) | As low as 15 working days | Accelerates mold validation and production ramp |

When your next mold project demands components that withstand high clamping forces, thermal cycling, and abrasive materials without compromise, partnering with Lead Precision is the strategic decision. We move beyond simple component supply to become an extension of your engineering team, focused on solving your toughest manufacturing challenges. Our goal is to be the reason your molds run longer, produce higher yields, and deliver parts that consistently meet the most stringent quality standards.

Do not let subpar metal components undermine your injection molding success. Contact our engineering and sales team today to discuss how our precision manufacturing capabilities can be integrated into your next project. Submit your inquiry or CAD files to [email protected]. Our specialists will respond within one business day to initiate a technical consultation focused squarely on achieving your production objectives. Elevate your mold performance – partner with precision.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.