Technical Contents

Engineering Guide: Precision Machining Parts

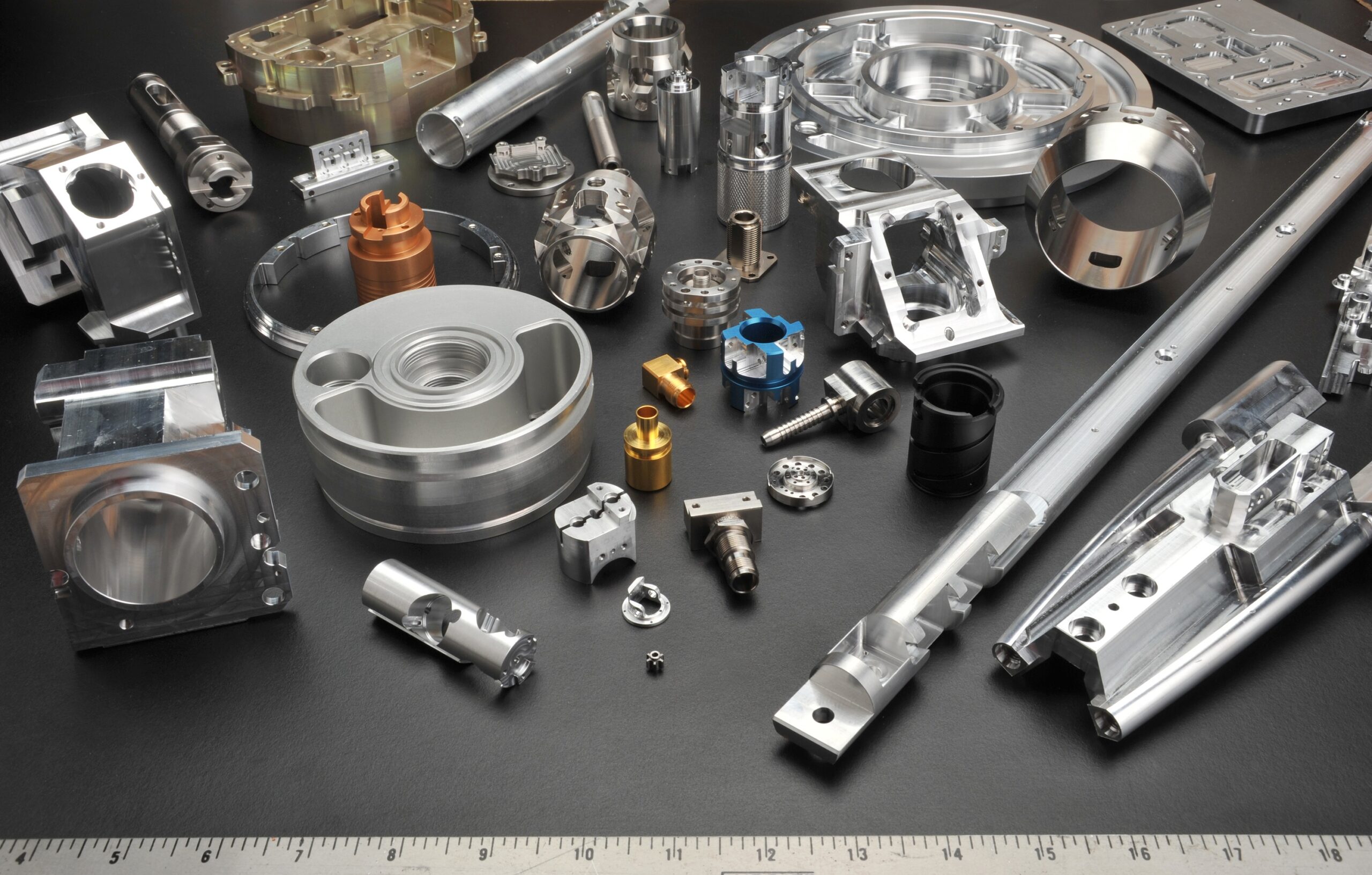

Engineering Insight Precision Machining Parts

Precision machining transcends dimensional accuracy; it defines the operational integrity, safety, and longevity of critical systems across aerospace, defense, medical, and high-performance industrial sectors. At Wuxi Lead Precision Machinery, we recognize that tolerances measured in microns directly impact fatigue resistance, thermal stability, and functional reliability. A deviation of ±0.005 mm in a turbine blade root or hydraulic manifold can cascade into catastrophic system failure under extreme loads. This uncompromising standard is why precision is not merely a specification—it is the foundation of trust between manufacturer and end-user.

Our engineering philosophy integrates metrology into every process phase, from material selection to final inspection. We deploy calibrated CMMs, optical comparators, and in-process probes to validate geometry against first-article requirements, ensuring consistency across production runs. This rigor is validated through our work on projects demanding absolute zero-defect outcomes. For the Beijing 2022 Winter Olympics, we manufactured timing system components where sub-micron repeatability ensured split-second accuracy under sub-zero conditions. Similarly, our military-grade contracts for avionics housings and ordnance subsystems require adherence to AS9100 and MIL-STD-883 standards, with full traceability from raw material to finished part.

Such high-stakes applications demand capabilities beyond standard machining. Below outlines our core technical parameters for precision-critical components:

| Specification Category | Capability Range | Industry Standard Reference |

|---|---|---|

| Dimensional Tolerance | ±0.0001″ (2.5 µm) to ±0.0005″ (12.7 µm) | ISO 2768-mK, ASME Y14.5 |

| Surface Roughness (Ra) | 0.4 µin to 8 µin (0.01 µm to 0.2 µm) | ISO 1302, ASME B46.1 |

| Material Complexity | Titanium (Gr 2,5), Inconel 718, 17-4PH SS, Aluminum 7075-T7351 | AMS, ASTM, MIL specs |

| Geometric Complexity | 5-axis simultaneous milling, Swiss turning with ≤0.0002″ runout | ISO 1101, GD&T controls |

| Production Volume | Prototypes to 10,000+ units with SPC control | PPAP Level 3, APQP |

These metrics reflect our investment in DMG MORI and MAZAK multi-axis platforms, coupled with proprietary fixturing strategies that minimize thermal drift and vibration. Our engineers collaborate with clients during DFM stages to optimize part geometry for manufacturability without sacrificing performance—turning theoretical precision into repeatable reality.

For industries where failure is not an option, precision machining is a strategic partnership. Wuxi Lead’s 15+ years of delivering Olympic and military-certified components prove that exceptional tolerances are achievable at scale. We transform your engineering intent into physically flawless parts, ensuring your systems perform with the reliability your reputation depends on. Contact our engineering team to discuss how our precision capabilities mitigate risk in your next critical application.

Precision Specs & Tolerances

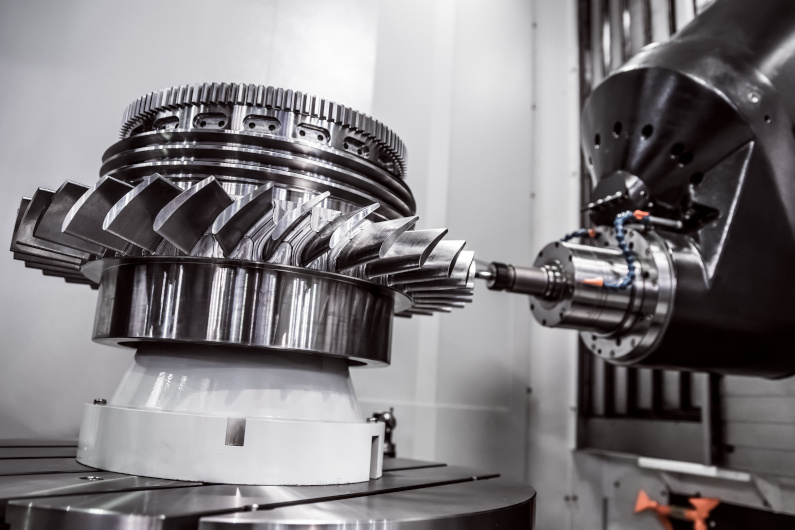

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, specializing in high-precision machining parts for demanding industrial applications. Our expertise is anchored in state-of-the-art 5-axis CNC machining technology, enabling the production of complex geometries with exceptional accuracy and surface finish. This multi-axis capability allows simultaneous movement across five planes, reducing setup times and minimizing cumulative tolerances associated with multiple fixturing operations. As a result, we achieve superior part consistency, tighter tolerances, and enhanced efficiency—critical for industries such as aerospace, medical devices, automotive, and industrial automation.

Our 5-axis CNC machining centers are equipped with high-speed spindles, advanced tool management systems, and real-time monitoring software to ensure optimal performance and process stability. These machines support a wide range of engineering-grade metals, including aluminum alloys, stainless steel, titanium, brass, and specialty alloys such as Inconel and tool steels. Our programming team utilizes industry-leading CAM software to generate optimized toolpaths, ensuring material integrity and dimensional precision while maximizing throughput.

Quality control is integrated at every stage of production. All critical dimensions are verified using Coordinate Measuring Machine (CMM) inspection, providing full traceability and compliance with international quality standards. Our CMM systems offer micron-level measurement accuracy and are calibrated regularly to ISO 17025 standards. This metrology capability ensures that every component meets or exceeds customer specifications, with detailed inspection reports available upon request.

In addition to CMM inspection, we employ a comprehensive quality management system that includes first-article inspection, in-process checks, and final validation. Our quality engineers work closely with clients during the design-for-manufacturability (DFM) phase to identify potential challenges and recommend optimizations that improve performance and reduce production costs.

The table below outlines the standard tolerance capabilities achievable across common machining operations. These values reflect our baseline performance; tighter tolerances can be achieved upon request based on material, geometry, and functional requirements.

| Feature | Standard Tolerance | Typical Range | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.005 mm | 0.1 mm – 500 mm | Depending on part size and geometry |

| Hole Diameter | +0.010 / -0.000 mm | Ø1 mm – Ø50 mm | Precision reaming and boring |

| Positional Tolerance | ±0.01 mm | All features | Verified via CMM |

| Surface Roughness (Ra) | 0.8 μm | 0.4 – 3.2 μm | Adjustable based on finish requirements |

| Angular Features | ±0.05° | All 5-axis features | High-accuracy rotary positioning |

| Flatness | 0.01 mm per 100 mm | Up to 300 mm span | Measured with CMM and optical flats |

Wuxi Lead Precision Machinery combines advanced equipment, rigorous quality assurance, and engineering expertise to deliver precision machining parts that meet the highest standards of performance and reliability. Our technical capabilities are designed to support complex, low-to-medium volume production runs with consistent repeatability and fast turnaround times.

Material & Finish Options

Precision Material Selection for Critical Machined Components

Material selection directly impacts part performance, manufacturability, and lifecycle cost in precision machining. At Wuxi Lead Precision Machinery, we prioritize engineering alignment between material properties and application demands. Aluminum alloys offer exceptional strength-to-weight ratios and thermal conductivity, making them ideal for aerospace brackets, heat sinks, and automotive components. Grade 6061-T6 provides balanced machinability and weldability, while 7075-T6 delivers superior strength for high-stress structural elements. Steel remains indispensable for wear resistance and structural integrity. Alloy 4140 excels in shafts and tooling due to its hardenability, whereas 17-4PH stainless steel combines corrosion resistance with high strength for medical and marine applications. Titanium Grade 5 (Ti-6Al-4V) dominates aerospace and biomedical sectors where extreme strength-to-weight ratios and biocompatibility are non-negotiable, though its low thermal conductivity necessitates specialized toolpaths and slower feeds to prevent work hardening.

Surface finishing, particularly anodizing, enhances functional performance beyond aesthetics. Type II (sulfuric acid) anodizing provides moderate corrosion resistance and dye receptivity for consumer and industrial housings. For mission-critical wear surfaces, Type III (hardcoat) anodizing creates a dense, abrasion-resistant layer up to 100µm thick on aluminum, significantly extending service life in hydraulic systems or military equipment. Crucially, anodizing dimensional effects must be accounted for in tight-tolerance features, requiring precise pre-plate machining allowances.

Material selection requires holistic analysis of mechanical loads, environmental exposure, regulatory constraints, and cost targets. Below are key comparative specifications:

| Material | Key Grades | Tensile Strength Range (MPa) | Machinability Rating | Optimal Applications |

|---|---|---|---|---|

| Aluminum | 6061-T6, 7075-T6 | 310–570 | Excellent (A) | Aerospace frames, heat exchangers |

| Alloy Steel | 4140, 4340 | 655–1035 | Good (B) | Gears, landing gear components |

| Stainless | 17-4PH, 316L | 795–1310 | Moderate (C) | Surgical instruments, marine fittings |

| Titanium | Ti-6Al-4V (Gr5) | 900–1100 | Poor (D) | Aircraft engine parts, implants |

Wuxi Lead Precision Machinery leverages decades of metallurgical expertise to optimize material-finish combinations. We conduct rigorous DFMA (Design for Manufacturability Analysis) to prevent costly rework, ensuring your selected material achieves target tolerances ±0.005mm while meeting fatigue and corrosion requirements. Partner with us to transform material science into precision-engineered reality—where every micron and modulus is engineered for performance.

Manufacturing Process & QC

From Concept to Perfection: The Precision Machining Workflow at Wuxi Lead Precision Machinery

At Wuxi Lead Precision Machinery, we engineer excellence at every phase of custom metal manufacturing. Our end-to-end production process is designed to deliver zero-defect precision machining parts for industries where performance, reliability, and consistency are non-negotiable. From initial design to full-scale production, every step is tightly controlled, validated, and optimized to ensure flawless outcomes.

The journey begins with engineering collaboration. Our technical team works closely with clients to analyze design specifications, material requirements, tolerance levels, and functional demands. Utilizing advanced CAD/CAM software, we conduct design for manufacturability (DFM) reviews to identify potential challenges early, optimize tool paths, and ensure that every component can be produced with maximum precision and minimal waste. This phase is critical to preventing downstream issues and laying the foundation for defect-free production.

Once the design is finalized, we move into prototyping. Our high-accuracy CNC machining centers produce functional prototypes using the same processes and materials intended for mass production. This allows us to validate form, fit, and function under real-world conditions. Every prototype undergoes rigorous inspection using coordinate measuring machines (CMM), optical comparators, and surface roughness testers. Feedback from this stage is used to refine the design or process before scaling up—ensuring that only validated, high-integrity parts progress further.

With the prototype approved, we transition seamlessly into mass production. Our state-of-the-art facility in Wuxi operates over 120 CNC machines, including multi-axis milling, turning, and grinding systems, all maintained to ISO 9001 standards. Production runs are monitored in real time using statistical process control (SPC) methodologies. In-process inspections occur at predefined intervals to verify dimensional accuracy and surface quality. Any deviation triggers immediate corrective action, maintaining strict adherence to specifications.

Our zero-defect philosophy is enforced through a comprehensive quality management system. Every batch is traceable, with full documentation of materials, machine parameters, inspection reports, and operator logs. Final inspection includes 100% critical dimension checks and random sampling for non-critical features, all aligned with customer-specific acceptance criteria.

The result is a seamless, transparent, and highly reliable manufacturing process that delivers precision parts on time, every time.

Key Production Specifications

| Parameter | Capability |

|---|---|

| Tolerance Control | As tight as ±0.001 mm |

| Surface Roughness (Ra) | Down to 0.1 µm |

| Materials Supported | Aluminum, Stainless Steel, Titanium, Brass, Inconel, Tool Steels |

| Max Part Size | 800 mm × 600 mm × 500 mm |

| CNC Equipment | 3-axis, 4-axis, 5-axis machining centers |

| Quality Standards | ISO 9001:2015, Full CMM Inspection Reports |

| Lead Time (Prototype) | 7–12 days |

| Lead Time (Mass Production) | 15–25 days (volume-dependent) |

Why Choose Wuxi Lead Precision

Partner with Lead Precision: Your Engineered Path to Manufacturing Excellence

At Wuxi Lead Precision Machinery, we transcend conventional custom metal manufacturing. For global enterprises demanding uncompromising precision in aerospace, medical, and advanced industrial applications, we deliver engineered solutions where tolerances are measured in microns and reliability is non-negotiable. Our ISO 9001:2015 and IATF 16949 certified facility in Wuxi integrates cutting-edge 5-axis CNC milling, Swiss turning, and multi-tasking centers with a zero-defect culture. This is not merely component production—it is the strategic elevation of your supply chain’s capability.

Our engineering team collaborates directly with your design and production specialists from initial concept through volume delivery. We de-risk complex projects through rigorous DFMA analysis, material science expertise, and real-time process validation. Whether prototyping a titanium orthopedic implant or scaling production of Inconel turbine components, we ensure dimensional stability, surface integrity, and full traceability. This partnership model eliminates costly iterations and accelerates time-to-market without sacrificing quality.

Critical Specifications We Routinely Achieve

| Parameter | Capability Range | Industry Standard Compliance |

|---|---|---|

| Tolerance | ±0.001 mm (±0.00004″) | ISO 2768-mK, ASME Y14.5 |

| Surface Finish | Ra 0.4 µm (16 µin) to mirror polish | ISO 1302, ASTM B912 |

| Materials | Titanium Gr5, Inconel 718, 17-4PH SS, Aluminum 7075, PEEK | AMS, ASTM, EN, ISO |

| Max Work Envelope | 1200 x 800 x 600 mm (47 x 31 x 24″) | Customizable for large assemblies |

| Inspection | CMM, OGP SmartScope, Roughness testers, Metallurgical analysis | PPAP Level 3, FAI reports |

Choosing Lead Precision means aligning with a partner who treats your specifications as our mandate. Our facility operates under strict environmental controls to maintain thermal stability for micron-level accuracy, while our ERP system provides full digital traceability from raw material lot to finished part. We understand that in high-stakes industries, a single micron deviation can cascade into operational failure—this awareness drives our relentless process discipline.

Initiate your precision manufacturing partnership today. Contact our engineering team directly at [email protected] to discuss your most demanding project requirements. Include your target tolerances, material specifications, and volume needs for a tailored capability assessment within 24 business hours. Our CNC engineers will provide actionable insights on optimizing your design for manufacturability, cost efficiency, and accelerated delivery.

Do not settle for suppliers who view machining as a transaction. Partner with an engineering-led manufacturer where precision is engineered into every process, not merely inspected at the end. Let Lead Precision become the invisible advantage in your product’s performance legacy. Your next breakthrough component begins with a single email—act now to secure your manufacturing edge.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.