Technical Contents

Engineering Guide: Metal Cnc Services

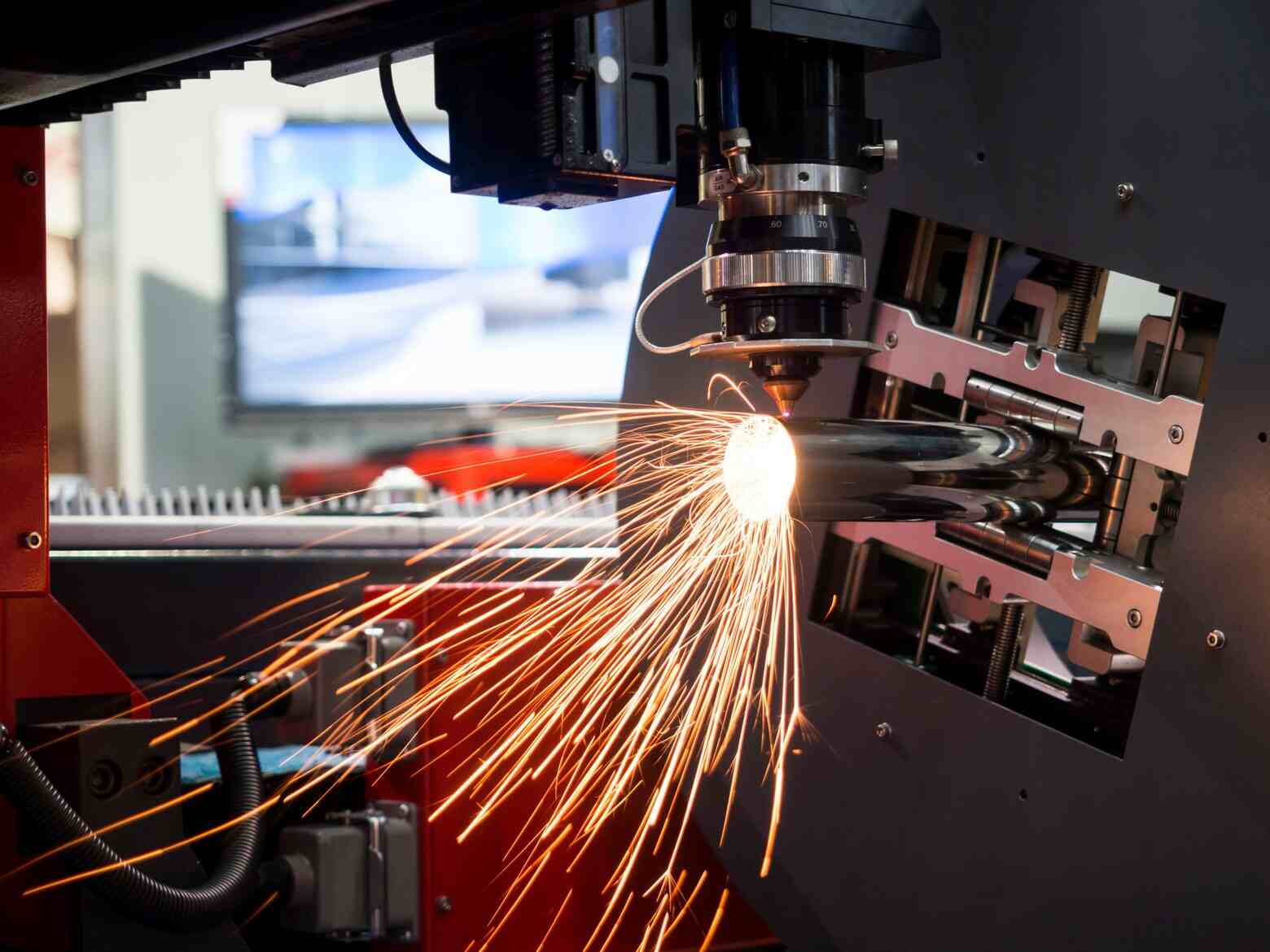

Engineering Insight: The Critical Role of Precision in Metal CNC Services

In high-end manufacturing, precision is not merely a performance metric—it is the foundation of reliability, safety, and operational success. When components are deployed in aerospace, defense, medical, or high-performance industrial systems, even micron-level deviations can lead to catastrophic failure. At Wuxi Lead Precision Machinery, we treat precision as a non-negotiable engineering principle, embedded in every stage of our metal CNC services.

Our approach begins with advanced 3-, 4-, and 5-axis CNC machining platforms, calibrated to maintain tolerances as tight as ±0.002 mm. This level of accuracy is sustained through rigorous environmental controls, real-time in-process inspection, and the integration of high-resolution probing systems. Material selection, toolpath optimization, and thermal compensation algorithms further ensure that each machined part meets exact design specifications—batch after batch.

Precision in metal CNC services extends beyond dimensional accuracy. Surface finish, geometric consistency, and structural integrity under load are equally critical. For instance, components used in military-grade navigation systems or Olympic-class sporting equipment must perform flawlessly under extreme conditions. Our engineering team collaborates closely with clients to understand not just the blueprint, but the operational environment—enabling us to optimize for fatigue resistance, wear performance, and long-term stability.

Wuxi Lead Precision Machinery brings over 15 years of specialized expertise in mission-critical applications. Our portfolio includes precision-machined components for China’s national defense programs and custom titanium assemblies used in Olympic-level bobsled and track cycling equipment. These projects demand not only technical excellence but also absolute confidentiality and compliance with international quality standards, including ISO 9001 and AS9100.

Our investment in continuous improvement—through staff training, metrology upgrades, and closed-loop quality control—ensures that we consistently exceed client expectations. Whether producing low-volume prototypes or high-volume production runs, our CNC machining processes are designed for repeatability, traceability, and peak performance.

Below are key performance specifications achieved through our precision metal CNC services:

| Parameter | Specification |

|---|---|

| Positional Accuracy | ±0.002 mm |

| Repeatability | ±0.001 mm |

| Surface Roughness (Ra) | As low as 0.4 µm |

| Maximum Work Envelope | 1200 x 800 x 650 mm |

| Materials Supported | Aluminum, Stainless Steel, Titanium, Inconel, Brass, Tool Steels |

| Standard Tolerances | ISO 2768-m (medium) or tighter |

| Quality Certification | ISO 9001:2015, AS9100D (in process) |

At Wuxi Lead Precision Machinery, we understand that every component we produce carries a responsibility. Our commitment to precision ensures that our clients receive not just parts—but engineered solutions built to perform under the most demanding conditions.

Precision Specs & Tolerances

Advanced Technical Capabilities for Mission-Critical Metal Components

Wuxi Lead Precision Machinery delivers uncompromising precision for the most demanding metal CNC services, serving aerospace, medical, energy, and advanced industrial sectors. Our foundation is a rigorously maintained fleet of state-of-the-art 5-axis CNC machining centers, enabling the production of geometrically complex components with exceptional accuracy and reduced setup times. This capability eliminates the need for multiple fixtures, significantly minimizing cumulative error potential inherent in multi-operation processes on lesser equipment. Our Haas, DMG MORI, and Makino platforms feature high-speed spindles, thermal compensation systems, and robust construction to maintain micron-level stability during extended production runs, even with challenging materials like titanium, Inconel, and hardened tool steels. This integrated approach ensures superior part integrity and consistency, directly translating to enhanced performance and longevity in your final assembly.

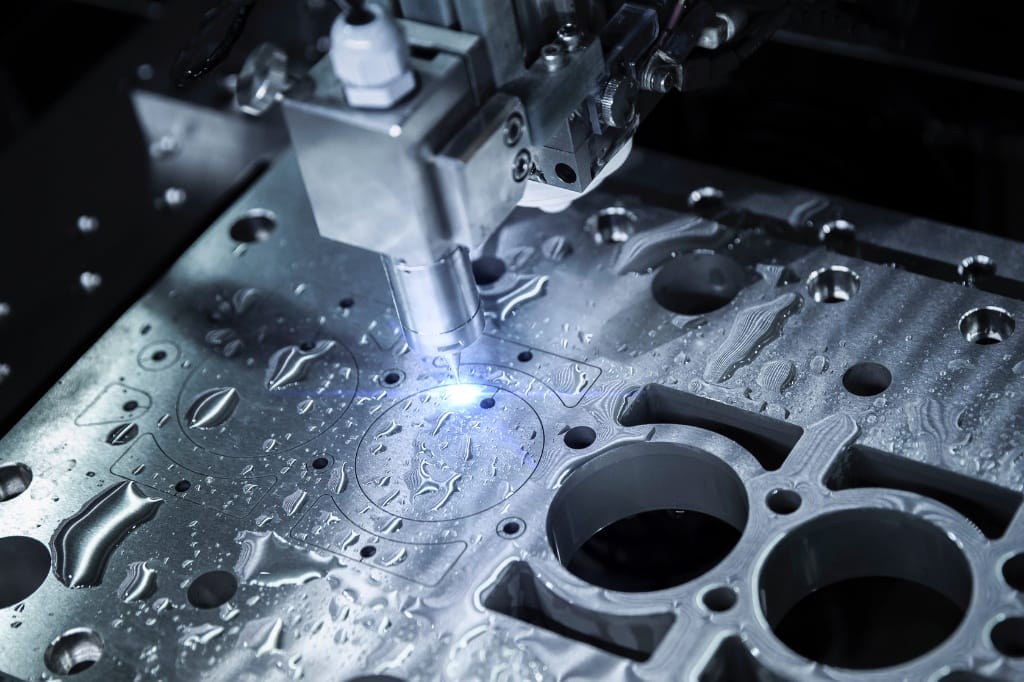

Precision manufacturing demands equally precise verification. Every critical dimension and geometric feature undergoes comprehensive validation through our dedicated Coordinate Measuring Machine (CMM) laboratory. Operating under strict ISO 17025 guidelines, our Zeiss and Hexagon GLOBAL S CMMs perform full 3D dimensional analysis, surface contour verification, and GD&T (Geometric Dimensioning and Tolerancing) assessment. This metrology backbone provides objective, traceable data for every production batch, generating detailed inspection reports that meet AS9100, ISO 13485, and customer-specific quality mandates. Real-time data from the CMM informs our closed-loop process control, allowing immediate corrective action and continuous process refinement, ensuring zero-defect delivery is not aspirational but operational reality.

Our commitment to dimensional excellence is quantifiable. The following table details our standard and achievable tolerance capabilities across common machining processes, reflecting the synergy between our advanced equipment, skilled technicians, and rigorous quality systems. These specifications represent our routine production capability for qualified materials under controlled shop floor conditions.

| Machining Process | Standard Tolerance Range | Tight Tolerance Capability | Typical Surface Finish (Ra) |

|---|---|---|---|

| 5-Axis Milling | ±0.010 mm (±0.0004″) | ±0.005 mm (±0.0002″) | 0.8 – 1.6 μm (32 – 63 μin) |

| Precision Turning | ±0.008 mm (±0.0003″) | ±0.003 mm (±0.0001″) | 0.4 – 0.8 μm (16 – 32 μin) |

| Multi-Task Machining | ±0.007 mm (±0.0003″) | ±0.004 mm (±0.00015″) | 0.8 – 1.6 μm (32 – 63 μin) |

| Complex Geometry (5-Axis) | ±0.015 mm (±0.0006″) | ±0.008 mm (±0.0003″) | 1.6 – 3.2 μm (63 – 125 μin) |

Beyond meeting specifications, Wuxi Lead engineers proactively collaborate during the design for manufacturability (DFM) phase. We identify potential tolerance stack-up issues, material suitability concerns, and process optimizations before cutting metal, preventing costly rework and accelerating time-to-market. Our technical capabilities are not merely about machines and measurements; they represent a holistic system engineered for predictable, high-yield production of components where failure is not an option. Partner with us for metal CNC services where precision is the standard, not the exception.

Material & Finish Options

Material Selection in Precision CNC Machining: Aluminum, Steel, and Titanium

Selecting the appropriate material is a foundational step in precision CNC machining, directly influencing component performance, durability, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in machining high-tolerance parts from three core engineering metals: aluminum, steel, and titanium. Each material offers distinct mechanical and thermal properties, making them suitable for specific industrial applications across aerospace, medical, automotive, and defense sectors.

Aluminum is widely favored for its excellent strength-to-weight ratio, corrosion resistance, and machinability. Grade 6061-T6 is particularly common in structural and enclosure applications due to its weldability and post-machining stability. While not as strong as steel or titanium, aluminum’s low density makes it ideal for weight-sensitive designs. It also responds exceptionally well to anodizing, enhancing surface hardness and wear resistance. Type II (sulfuric acid) and Type III (hardcoat) anodizing are standard finishes we provide, with the latter offering superior durability for high-wear environments.

Steel, particularly alloy and stainless variants such as 4140, 17-4 PH, and 304/316 stainless, delivers high tensile strength, thermal stability, and resistance to deformation under load. These properties make steel the material of choice for high-stress mechanical components, tooling, and parts exposed to elevated temperatures or corrosive environments. Stainless steels further offer inherent corrosion resistance, critical in medical and food-grade applications. While heavier than aluminum, steel’s versatility and predictable behavior during machining ensure consistent, repeatable results in high-volume production runs.

Titanium, specifically Grade 5 (Ti-6Al-4V), stands out for its exceptional strength-to-density ratio and outstanding performance in extreme environments. It maintains structural integrity at elevated temperatures and exhibits superior resistance to fatigue and corrosion, especially in saltwater or chemical exposure. These characteristics make titanium indispensable in aerospace, marine, and biomedical implants. However, its low thermal conductivity and high chemical reactivity require specialized tooling and slower machining parameters, demanding expertise and precision—capabilities we maintain at Wuxi Lead through optimized CNC protocols and experienced engineering oversight.

The choice of surface finish further enhances material performance. Anodizing aluminum not only improves wear resistance but also allows for color coding and aesthetic refinement. Our in-house finishing capabilities ensure tight control over coating thickness, adhesion, and uniformity, meeting stringent industry standards.

Below is a comparative overview of key properties for common materials used in our CNC machining services.

| Material | Tensile Strength (MPa) | Density (g/cm³) | Common Grades | Typical Applications | Key Finish Options |

|---|---|---|---|---|---|

| Aluminum | 310 | 2.7 | 6061-T6, 7075-T6 | Enclosures, aerospace frames | Anodizing (Type II/III) |

| Steel | 655–1000 | 7.8 | 4140, 17-4 PH, 304 | Tooling, shafts, medical devices | Passivation, plating |

| Titanium | 900 | 4.5 | Ti-6Al-4V (Gr 5) | Aerospace, implants, marine parts | As-machined, bead blasting |

Material selection must balance performance requirements, environmental exposure, and cost. At Wuxi Lead Precision Machinery, we support clients in making informed decisions backed by material science and decades of machining expertise.

Manufacturing Process & QC

Precision Metal CNC Services: The Zero-Defect Production Process

At Wuxi Lead Precision Machinery, our core commitment is delivering flawless metal components through a rigorously controlled production process. We understand that in high-stakes industries like aerospace, medical, and semiconductor manufacturing, a single defect is unacceptable. Our integrated workflow—spanning Design, Prototyping, and Mass Production—is engineered for zero defects, ensuring your parts meet exacting specifications consistently and reliably.

The Design Phase is foundational. Our engineering team collaborates closely with your specifications, utilizing advanced CAD/CAM software to create optimized toolpaths and manufacturing plans. Critical attention is paid to Geometric Dimensioning and Tolerancing (GD&T), material behavior analysis, and manufacturability. This phase includes comprehensive Design for Manufacturing (DFM) reviews to identify and resolve potential issues before metal is cut, preventing costly errors downstream and establishing the blueprint for perfection.

Prototyping transforms the digital design into physical reality for validation. Using the same high-precision CNC machines and materials destined for production, we manufacture initial units under strict process control. Each prototype undergoes meticulous inspection using calibrated Coordinate Measuring Machines (CMMs), optical comparators, and surface roughness testers against the original CAD model and GD&T requirements. This phase is not merely a form check; it validates the entire process capability, confirms material suitability, and provides tangible evidence that the design is production-ready with zero deviations. Only after full dimensional and functional validation do we proceed.

Mass Production leverages the validated process for sustained excellence. Our state-of-the-art facility employs automated CNC machining centers with real-time tool monitoring and in-process gauging. Statistical Process Control (SPC) is implemented at critical stages, continuously analyzing data to detect and correct microscopic process drifts before they affect part quality. 100% of critical dimensions are verified via automated CMM routines, while final inspection includes comprehensive material certification review and surface finish validation. This closed-loop system, combined with our certified ISO 9001:2015 quality management system, guarantees zero-defect output across any production volume.

Wuxi Lead Precision Mass Production Capabilities

| Parameter | Specification |

|---|---|

| Dimensional Tolerance | Down to ±0.001 mm (±0.00004″) |

| Surface Finish (Ra) | As low as 0.4 μm (16 μin) |

| Materials | Aluminum, Steel, Stainless, Titanium, Brass, Exotic Alloys |

| Max Work Envelope | 1200 x 800 x 750 mm (47 x 31.5 x 29.5″) |

| Key Equipment | DMG MORI, Haas, Makino 3-5 Axis Centers |

| Quality Standards | ISO 9001:2015, Full Traceability, CMM Reports |

This disciplined progression from design intent through physical validation to high-volume execution eliminates guesswork and rework. By embedding quality at every stage, Wuxi Lead Precision Machinery ensures your metal CNC components arrive on time, within specification, and ready for immediate integration—delivering true zero-defect performance that protects your reputation and your bottom line.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched CNC Manufacturing Excellence

At Wuxi Lead Precision Machinery, we don’t just deliver parts—we deliver precision, reliability, and long-term value. As a trusted leader in high-end CNC machining services, we specialize in producing complex, tight-tolerance components for industries where failure is not an option. From aerospace and medical devices to industrial automation and energy systems, our engineering-driven approach ensures every component meets the highest global standards.

Choosing the right manufacturing partner is critical. Lead Precision combines advanced CNC technology with decades of in-house expertise to offer scalable, responsive, and technically superior solutions. Whether you require rapid prototyping, low-volume specialty runs, or high-volume production, our facility in Wuxi, China is equipped with state-of-the-art 3-, 4-, and 5-axis machining centers, multi-axis turning, and automated inspection systems. We maintain full process control—from material sourcing and CAM programming to final quality validation—ensuring consistency and traceability across every order.

Our commitment to precision is reflected in every dimension we machine. We work with a wide range of materials including aluminum alloys, stainless and carbon steels, titanium, brass, and engineering plastics such as PEEK and Delrin. All parts are inspected using calibrated CMMs, optical comparators, and surface finish testers, with full inspection reports available upon request. ISO 9001:2015 certified, we adhere to strict quality protocols while maintaining competitive lead times and transparent communication throughout the production cycle.

When you partner with Lead Precision, you gain more than a supplier—you gain a collaborator. Our engineering team actively engages with clients during the design-for-manufacturability (DFM) phase to optimize part geometry, reduce costs, and accelerate time to market. We support both CAD and STEP file formats and provide detailed feedback to ensure manufacturability without compromise.

Below are key capabilities that define our service offering:

| Specification | Detail |

|---|---|

| Machining Types | 3-axis, 4-axis, 5-axis CNC milling, CNC turning, mill-turn |

| Tolerances | As tight as ±0.005 mm (±0.0002″) |

| Materials | Aluminum, Stainless Steel, Titanium, Brass, PEEK, Delrin, Carbon Steel, and more |

| Max Work Envelope | 1200 x 600 x 500 mm (47″ x 23.6″ x 19.7″) |

| Surface Finishes | As-machined, anodizing, powder coating, passivation, plating, polishing |

| Quality Standards | ISO 9001:2015, First Article Inspection, PPAP, FAI reports |

| Lead Times | Prototypes: 5–7 days; Production: 10–20 days (varies by complexity) |

Your next breakthrough component starts with the right partner. Contact us today at [email protected] to discuss your project, request a quote, or receive a DFM analysis. At Wuxi Lead Precision Machinery, we’re ready to turn your designs into precision-engineered reality—on time, every time.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.