Technical Contents

Engineering Guide: Molding Solutions Inc

Engineering Insight: Precision as the Non-Negotiable Foundation in Custom Metal Manufacturing

In the realm of custom metal manufacturing for demanding applications, precision transcends mere specification; it is the absolute bedrock of performance, reliability, and ultimate success. For partners like Molding Solutions Inc., whose own reputation hinges on delivering flawless end products, the tolerances achieved during component fabrication directly dictate functional integrity, assembly efficiency, and long-term durability. Sub-micron deviations in critical aerospace fittings, hydraulic manifolds, or high-pressure molding cores are not acceptable variances—they are potential points of catastrophic failure. True precision engineering demands an ecosystem of advanced CNC technology, rigorous metrology, environmental control, and, critically, deep experiential knowledge to anticipate and mitigate variables before they impact the final part. It is the difference between a component that merely fits and one that performs flawlessly under extreme operational stress for its entire lifecycle.

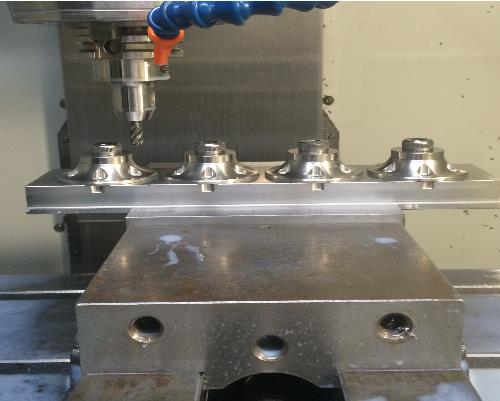

Wuxi Lead Precision Machinery operates at this uncompromising standard daily. Our facility is engineered for micron-level consistency, leveraging state-of-the-art multi-axis CNC machining centers equipped with in-process probing and thermal compensation systems. This technological foundation is guided by engineering teams whose expertise is forged in the most unforgiving environments. We have successfully delivered components meeting the exacting zero-failure requirements for Olympic-grade timing systems, where split-second accuracy is paramount, and critical subsystems for military applications, where reliability under harsh conditions is non-negotiable. This experience instills a fundamental understanding: precision cannot be an afterthought or a target achieved only on paper. It must be engineered into every process step, from material selection and fixture design to cutting strategy and final inspection.

The tangible output of this commitment is measurable in capabilities that directly address the stringent needs of advanced manufacturing partners. Our core machining specifications consistently achieve levels essential for high-integrity applications:

| Critical Specification | Standard Capability | High-Precision Capability |

|---|---|---|

| Dimensional Tolerance | ±0.010 mm (±0.0004″) | ±0.002 mm (±0.00008″) |

| Surface Roughness (Ra) | 0.8 µm (32 µin) | 0.2 µm (8 µin) |

| Geometric Tolerance (GD&T) | ±0.015 mm (±0.0006″) | ±0.003 mm (±0.0001″) |

| Material Range | Aluminum, Steel, Stainless, Titanium, Exotic Alloys | Up to Inconel 718, Waspaloy |

| Max Work Envelope | 1200 x 800 x 600 mm (47 x 31.5 x 23.6″) | Optimized for complex small/medium parts |

For Molding Solutions Inc., partnering with a manufacturer possessing this depth of precision capability and proven high-stakes experience translates to tangible risk reduction. It ensures the cores, cavities, ejector systems, and supporting hardware integral to your molding processes are manufactured to the exacting standards required for consistent part quality, extended tool life, and minimized downtime. Precision machining is not a cost center; it is the essential investment that safeguards your production efficiency, product performance, and brand reputation in the competitive global marketplace. Wuxi Lead Precision Machinery delivers this assurance, built on a foundation of demonstrable achievement where failure is never an option.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions tailored to the rigorous demands of high-performance industries. Our technical capabilities are anchored in state-of-the-art 5-axis CNC machining technology, enabling us to produce complex geometries with exceptional accuracy and surface finish. This multi-axis platform allows simultaneous movement across five planes, significantly enhancing machining efficiency and part precision. By eliminating the need for multiple setups, we reduce cycle times and minimize human error, ensuring repeatability and consistency across production runs. Our 5-axis systems are optimized for a wide range of aerospace, medical, energy, and industrial components where tight tolerances and intricate features are non-negotiable.

Complementing our machining infrastructure is a comprehensive quality control ecosystem centered on Coordinate Measuring Machine (CMM) inspection. Every component undergoes rigorous dimensional verification using calibrated CMM systems, providing traceable, high-resolution data for conformance to engineering specifications. Our inspection protocols follow international standards, including ISO 10360, ensuring measurement certainty and compliance. In addition to CMM, we utilize optical comparators, surface roughness testers, and in-process probing to maintain quality throughout the manufacturing workflow. This end-to-end inspection strategy guarantees that each part meets or exceeds customer-defined tolerances and regulatory requirements.

Our commitment to precision is reflected in the dimensional control we achieve across diverse materials, including aluminum alloys, stainless steels, titanium, and high-temperature superalloys. Whether producing low-volume prototypes or high-volume production runs, Wuxi Lead maintains uniform quality and performance. The integration of advanced CNC programming, tooling optimization, and real-time monitoring systems ensures minimal variation and maximum process stability. We also employ first-article inspection (FAI) and production part approval process (PPAP) documentation upon request, supporting seamless integration into our clients’ quality frameworks.

The following table outlines the standard capabilities and tolerances achievable through our 5-axis CNC and inspection systems:

| Parameter | Standard Capability | Tight Tolerance Option | Notes |

|---|---|---|---|

| Positional Tolerance | ±0.025 mm | ±0.010 mm | Verified via CMM |

| Linear Dimensional Tolerance | ±0.05 mm | ±0.012 mm | Per ISO 2768-m |

| Surface Roughness (Ra) | 3.2 µm | 0.8 µm | Achieved with fine finishing passes |

| Geometric Tolerance (GD&T) | ±0.02 mm | ±0.005 mm | Full ASME Y14.5 compliance |

| Feature Repeatability | ±0.015 mm | ±0.008 mm | Across production batches |

| Maximum Work Envelope | 1200 x 800 x 600 mm | Custom configurations | Based on machine model |

| Material Compatibility | Aluminum, Steel, Stainless, Titanium, Inconel, Brass | Up to 65 HRC hardness | Verified for machinability and stability |

Wuxi Lead Precision Machinery combines engineering expertise with advanced technology to deliver custom metal components that meet the highest standards of precision and reliability. Our technical capabilities are designed to support innovation and performance in mission-critical applications worldwide.

Material & Finish Options

Material Selection for Precision Metal Components: Engineering Excellence Through Informed Choices

Selecting the optimal material is foundational to achieving performance, longevity, and cost efficiency in custom metal manufacturing. At Wuxi Lead Precision Machinery, our decades of CNC machining expertise reveal that misaligned material choices often lead to premature failure or inflated lifecycle costs. This guide clarifies critical considerations for aluminum, steel, and titanium—three pillars of high-performance industrial applications—alongside the strategic value of anodizing finishes.

Aluminum alloys, particularly 6061-T6, dominate aerospace and automotive sectors due to their exceptional strength-to-weight ratio and thermal conductivity. They machine efficiently at high speeds, reducing production time and tool wear. However, standard aluminum lacks corrosion resistance in harsh environments, necessitating protective finishes. Steel variants like 4140 offer superior hardness and wear resistance for tooling, structural frames, and high-stress mechanical parts. Its machinability requires slower feeds and rigid setups but delivers unmatched durability under load. For extreme conditions—such as marine, chemical, or high-temperature aerospace systems—titanium Grade 5 (Ti-6Al-4V) is indispensable. Its biocompatibility and near-impervious corrosion resistance justify higher costs in mission-critical applications, though its low thermal conductivity demands specialized toolpaths to prevent work hardening.

Key mechanical properties must align with operational demands. The table below summarizes comparative specifications for common grades:

| Material | Yield Strength (MPa) | Corrosion Resistance | Machinability Rating | Typical Applications |

|---|---|---|---|---|

| Aluminum 6061-T6 | 276 | Moderate (requires finish) | Excellent (9/10) | Enclosures, brackets, heat sinks |

| Steel 4140 | 655 | Low (prone to rust) | Good (7/10) | Shafts, gears, tooling fixtures |

| Titanium Grade 5 | 880 | Exceptional | Fair (5/10) | Aircraft components, medical implants |

Anodizing transforms aluminum’s surface into a durable, corrosion-resistant oxide layer while enabling color coding for part identification. Type II (sulfuric acid) anodizing suits general industrial use with moderate wear resistance, while Type III (hardcoat) anodizing achieves 50–100 µm thickness for extreme abrasion resistance in hydraulic systems or military hardware. Crucially, anodizing thickness must be specified early in design; it adds dimensional tolerance that affects press fits or sealing surfaces. Our CNC processes integrate finish requirements into machining programs, ensuring precise anodizing allowances without post-process rework.

Material selection transcends basic specs—it requires anticipating thermal cycling, chemical exposure, and lifecycle stresses. At Wuxi Lead, we collaborate with clients during the design phase to model material behavior under real-world conditions, preventing costly revisions. Request our full material compatibility matrix or schedule a technical consultation to optimize your next project’s material strategy. Precision begins with the right foundation.

Manufacturing Process & QC

At Wuxi Lead Precision Machinery, our custom metal manufacturing process is engineered to deliver precision, consistency, and zero-defect performance for global partners like Molding Solutions Inc. We integrate advanced CNC technology, rigorous quality control, and decades of industrial expertise into a seamless workflow that spans from initial design to full-scale production.

The process begins with collaborative design engineering. Our technical team works directly with client specifications to develop optimized 3D models and engineering drawings. Using CAD/CAM software and finite element analysis (FEA), we ensure structural integrity, dimensional accuracy, and manufacturability before any material is cut. This phase includes material selection, tolerance analysis, and design for manufacturability (DFM) reviews to preemptively resolve potential production challenges.

Once the design is validated, we proceed to prototyping. Functional prototypes are produced using high-precision CNC milling, turning, and multi-axis machining centers. These prototypes are subjected to comprehensive metrological inspection using coordinate measuring machines (CMM), optical comparators, and surface finish testers. The prototype stage allows Molding Solutions Inc. to verify form, fit, and function under real-world conditions. Any necessary design refinements are implemented digitally and re-validated before release to mass production.

Mass production is executed on automated, high-efficiency machining lines with strict adherence to lean manufacturing principles. Our facility operates over 80 CNC machines, including 5-axis machining centers and robotic workcells, enabling continuous, lights-out production when required. Every component is traceable through our ERP system, with real-time monitoring of machine parameters, tool wear, and environmental conditions to maintain process stability.

Quality assurance is embedded at every stage. We follow ISO 9001-certified procedures and utilize Statistical Process Control (SPC) to detect and correct deviations before defects occur. Final inspection includes 100% critical dimension checks and batch sampling for material certification, hardness testing, and geometric tolerances.

Our zero-defect philosophy is not a target—it is a standard achieved through precision engineering, automation, and relentless process control. From concept to delivery, Wuxi Lead ensures every component meets the exacting demands of advanced industrial applications.

Production Specifications

| Parameter | Specification |

|---|---|

| Material Compatibility | Aluminum Alloys, Stainless Steel, Carbon Steel, Brass, Titanium |

| Tolerance Range | ±0.005 mm to ±0.025 mm |

| Surface Finish | Ra 0.4 µm to Ra 3.2 µm (custom finishes available) |

| Max Workpiece Size | 1200 mm × 800 mm × 600 mm |

| Production Capacity | Up to 50,000 units/month (scalable) |

| Quality Standards | ISO 9001:2015, SPC, PPAP, FAI |

| Lead Time (Prototype) | 7–14 days (depending on complexity) |

| Lead Time (Mass Production) | 20–35 days after approval |

Why Choose Wuxi Lead Precision

Partner with Lead Precision: Your Engineering Advantage in Critical Metal Manufacturing

Wuxi Lead Precision Machinery delivers more than custom metal components—we engineer certainty for mission-critical applications. For decades, global leaders in aerospace, medical technology, and advanced industrial systems have relied on our precision CNC machining and metal forming expertise to solve their most demanding manufacturing challenges. When tolerances are measured in microns and material integrity is non-negotiable, our integrated engineering and production ecosystem ensures zero compromise on quality, repeatability, or delivery integrity. We operate at the intersection of advanced metallurgy and cutting-edge process control, transforming complex designs into certified, production-ready solutions that withstand the harshest operational environments.

Commodity suppliers cannot replicate our commitment to embedded engineering collaboration. From initial design review through final inspection, our team becomes an extension of your R&D and production staff. We proactively identify manufacturability risks, optimize material utilization, and validate processes against your exact performance criteria—eliminating costly iterations and accelerating time-to-market. Our facility in Wuxi, China, is not merely a factory but a certified engineering hub, featuring climate-controlled metrology labs, real-time SPC monitoring, and full material traceability from mill certificate to finished part. This systematic rigor is why we consistently achieve first-pass yield rates exceeding 99.2% for clients where failure is not an option.

Our technical capabilities are engineered for the extreme. The table below reflects the precision envelope we maintain across all production runs:

| Specification Category | Performance Standard |

|---|---|

| Dimensional Tolerance | ±0.002 mm (0.00008 inches) |

| Surface Roughness (Ra) | As low as 0.1 µm |

| Material Compatibility | Titanium, Inconel, Hastelloy, Tool Steels, Aluminum Alloys |

| Maximum Part Size | 1,200 x 800 x 600 mm |

| Certifications | ISO 9001:2015, AS9100D, NADCAP |

This level of control is sustained through continuous investment in 5-axis milling, Swiss-type turning, and high-pressure die casting technologies—all operated by engineers with minimum 10-year industry experience. Every process parameter is documented and auditable, providing the transparency required for regulated industries.

Your next critical component demands a partner who treats your specifications as inviolable commitments, not mere suggestions. Contact us to initiate a technical review of your most challenging project. Email [email protected] with your design files or requirements. Within 24 business hours, our lead manufacturing engineer will provide a detailed capability assessment, including feasibility analysis, risk mitigation strategies, and a validated production timeline. Do not compromise on the foundation of your product’s performance. Partner with the precision engineering authority trusted by Tier-1 aerospace integrators and Class III medical device innovators worldwide. Let Lead Precision become your definitive solution for metal manufacturing excellence.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.