Technical Contents

Engineering Guide: Cnc Mil

Engineering Insight: Precision Imperatives in Military CNC Machining

In military-grade CNC machining, precision transcends specification sheets—it becomes a non-negotiable pillar of mission success and personnel safety. The term “cnc mil” inherently demands tolerances measured in microns, not thousandths of an inch, where deviations imperceptible to the naked eye can cascade into catastrophic system failures under extreme operational stress. Modern defense platforms—hypersonic components, satellite guidance systems, and next-generation firearms—operate in environments defined by violent vibration, thermal extremes, and relentless corrosion. Here, dimensional stability under thermal cycling and material integrity at cryogenic temperatures are as critical as the nominal geometry. A tolerance stack-up error of ±0.0005 inches in a missile fin actuator linkage may induce aerodynamic instability at Mach 5; inconsistent surface finish on a firearm bolt carrier group can accelerate wear under sand ingress, jeopardizing soldier safety. This is why military CNC machining requires closed-loop metrology integrated directly within the machining cell, not post-process verification alone. Real-time in-process gauging compensates for tool deflection, thermal growth, and material variance during cutting—transforming theoretical precision into guaranteed part conformity.

Wuxi Lead Precision Machinery operates at this uncompromising threshold daily. Our facility holds AS9100D certification and ITAR registration, but our true validation lies in execution. We engineered titanium alloy housings for China’s BeiDou-3 satellite navigation system, where thermal expansion coefficients demanded tolerances held to ±0.0002 inches across 18-inch spans despite temperature swings from -196°C to +125°C. Similarly, our production of recoil mechanisms for armored vehicle weapon systems required surface finishes of Ra 0.4µm on hardened 4340 steel to prevent galling during sustained fire—a specification where conventional machining would fail within 500 rounds. Our Olympic legacy further proves this capability; we manufactured the precision ball bearings for Beijing 2022 Winter Games bobsled runners, where nanometer-level roundness deviations directly impacted medal-winning speeds on ice tracks. This dual-domain experience—military and elite sports—forged our methodology: treating every part as if human lives depend on its perfection.

Our CNC mil capabilities are quantifiable through stringent process control parameters. The following table outlines critical specifications consistently achieved across defense projects:

| Specification Category | Performance Standard | Verification Method |

|---|---|---|

| Linear Positioning Accuracy | ±0.0001 inches (2.5µm) | Laser interferometer (ISO 230-2) |

| Repeatability | ±0.00004 inches (1.0µm) | Ballbar testing (ISO 230-4) |

| Surface Finish (Machined) | Ra 0.2µm – 1.6µm | Profilometer (ISO 4287) |

| Material Compliance | AMS, MIL-DTL, ASTM | Spectrographic analysis + certs |

| In-Process Metrology Cycle | < 90 seconds per feature | Integrated touch probes + CAM |

This precision ecosystem—combining sub-micron machine tools, physics-based simulation, and military-vetted process validation—ensures zero concessions to reliability. For defense contractors navigating CMMC compliance and performance-critical deliverables, Wuxi Lead delivers not just parts, but provable mission assurance. Every component we produce carries the legacy of systems where precision is measured in lives saved and objectives secured. Partner with an engineering team that treats your mil-spec requirements as the baseline, not the aspiration.

Precision Specs & Tolerances

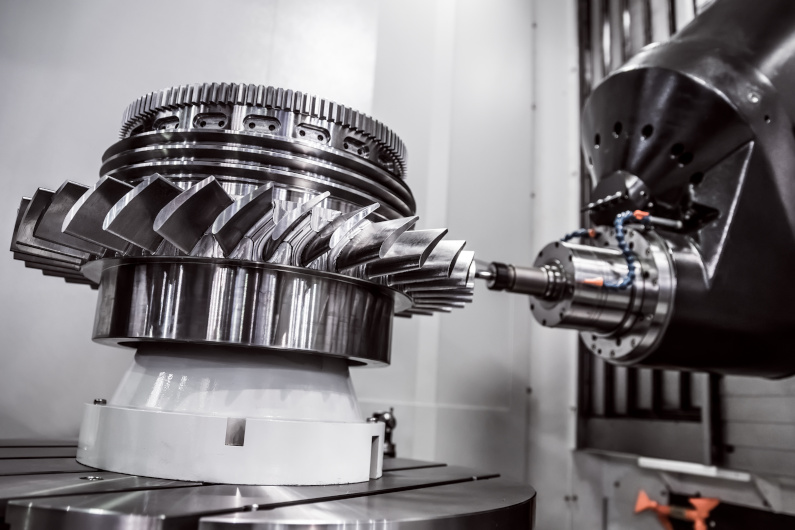

Wuxi Lead Precision Machinery delivers advanced precision CNC machining services tailored to the most demanding industries, including aerospace, medical, energy, and high-performance automotive. At the core of our technical capabilities is a modern fleet of 5-axis CNC machining centers, enabling us to produce highly complex geometries with exceptional accuracy and surface finish. These multi-axis systems allow simultaneous movement across five axes, minimizing setup time and part handling while maximizing dimensional consistency. This capability is critical for components requiring tight tolerances, intricate contours, and superior repeatability across production runs.

Our machining centers are operated by experienced CNC programmers and machinists who utilize industry-leading CAD/CAM software to optimize toolpaths, reduce cycle times, and ensure optimal material removal strategies. Advanced fixturing and high-speed spindle technology further enhance machining efficiency and precision. We work with a broad range of engineering-grade materials, including aluminum alloys, stainless and carbon steels, titanium, Inconel, and engineering plastics, ensuring compatibility with the functional and environmental demands of end-use applications.

Quality assurance is fully integrated into our manufacturing workflow. Every critical dimension is verified through comprehensive inspection protocols, with primary reliance on Coordinate Measuring Machine (CMM) technology. Our CMM systems provide non-contact and tactile measurement with micron-level resolution, ensuring compliance with engineering specifications and international standards such as ISO 2768 and ASME Y14.5. Full inspection reports are generated for batch traceability and customer documentation, supporting compliance with ISO 9001:2015 and industry-specific quality requirements.

In addition to CMM inspection, we employ surface roughness testers, optical comparators, and digital micrometry to validate both macro and micro features. These tools, combined with our disciplined process controls, ensure that every component meets the highest standards of precision and reliability. Our quality management system supports full part traceability, from raw material certification through final inspection and delivery.

The following table outlines typical machining capabilities and achievable tolerances under standard production conditions.

| Feature | Capability |

|---|---|

| Maximum Work Envelope (5-axis) | 1200 x 800 x 600 mm |

| Spindle Speed | Up to 24,000 RPM |

| Positioning Accuracy (X, Y, Z) | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Linear Tolerance (Standard) | ±0.010 mm |

| Linear Tolerance (Precision) | ±0.005 mm |

| Angular Tolerance | ±0.05° |

| Surface Roughness (Ra) | As low as 0.4 μm (typical), down to 0.2 μm (polished) |

| Materials Supported | Aluminum, Steel, Stainless Steel, Titanium, Inconel, Brass, Engineering Plastics |

Our technical infrastructure, combined with rigorous quality control and engineering expertise, positions Wuxi Lead Precision Machinery as a trusted partner for high-complexity, high-reliability CNC machining projects.

Material & Finish Options

Precision Material Selection for Critical CNC Milling Applications

Material choice fundamentally dictates performance, cost, and manufacturability in high-precision CNC milling. At Wuxi Lead Precision Machinery, we prioritize aligning substrate properties with functional requirements to optimize part longevity and production efficiency. Aluminum alloys dominate aerospace and electronics due to their exceptional strength-to-weight ratio and thermal conductivity. Steel variants provide unmatched hardness and wear resistance for tooling and structural components. Titanium excels in extreme environments like medical implants and defense systems where corrosion resistance and biocompatibility are non-negotiable. Each material demands specific machining strategies to achieve micron-level tolerances and surface integrity.

Below is a comparative specification overview for common high-performance alloys processed in our ISO 9001-certified facility

| Material Grade | Density (g/cm³) | Tensile Strength (MPa) | Machinability Rating | Primary Applications |

|---|---|---|---|---|

| Aluminum 6061-T6 | 2.70 | 310 | Excellent (65) | Enclosures, brackets, heat sinks |

| Aluminum 7075-T6 | 2.81 | 572 | Moderate (40) | Aerospace fittings, high-stress components |

| Steel 4140 | 7.85 | 655 | Good (60) | Shafts, gears, tooling fixtures |

| Stainless 304 | 8.00 | 515 | Fair (45) | Food processing, chemical equipment |

| Titanium Gr5 (Ti-6Al-4V) | 4.43 | 900 | Poor (20) | Medical implants, jet engine parts |

Anodizing transforms aluminum surfaces into hardened, corrosion-resistant layers critical for mission-critical components. Type II (sulfuric acid) anodizing delivers standard wear protection with dye compatibility for identification, achieving 10–25 μm thickness. For extreme durability, Type III (hardcoat) anodizing produces 25–100 μm dense oxide layers with Rockwell hardness exceeding 60 HRC. This process is indispensable for hydraulic manifolds and military hardware exposed to abrasive or saline environments. Our integrated finishing cell ensures precise thickness control and adhesion verification per ASTM B580 and MIL-A-8625 standards.

Material selection must balance mechanical demands with production realities. While titanium offers superior performance, its low thermal conductivity and high reactivity necessitate reduced cutting speeds and specialized tooling—increasing cycle times by 30–50% versus aluminum. Similarly, 7075 aluminum’s strength comes with higher tool wear rates than 6061, requiring optimized feed rates. Wuxi Lead engineers collaborate with clients during DFM analysis to identify cost-performance sweet spots, such as substituting 304 stainless with coated 4140 steel where corrosion exposure is limited. Always specify finish requirements early; anodizing tolerances directly impact final dimensions, particularly on tight-tolerance bores.

Our 15-year expertise in exotic material machining ensures your selected alloy achieves target geometries without compromising structural integrity. Partner with us to convert material science into manufacturing advantage.

Manufacturing Process & QC

From Concept to Consistency: The Precision CNC Manufacturing Process at Wuxi Lead Precision Machinery

At Wuxi Lead Precision Machinery, we engineer excellence at every stage of production. Our end-to-end manufacturing process is designed for one objective: zero-defect delivery of high-precision CNC machined components. Rooted in advanced engineering and rigorous quality control, our workflow seamlessly transitions from design through prototyping to full-scale mass production, ensuring unmatched consistency and performance for global industrial clients.

The journey begins with precision engineering and collaborative design. Our engineering team works closely with clients to analyze CAD/CAM data, assess material suitability, and optimize geometries for manufacturability. Using state-of-the-art simulation software, we validate toolpaths, anticipate thermal deformation, and ensure dimensional stability before any material is cut. This digital-first approach minimizes risk and accelerates time to prototype.

Prototyping is not a formality—it is a critical validation phase. We produce functional prototypes using the same 5-axis CNC machining centers and quality protocols intended for mass production. This ensures that every prototype reflects real-world performance under operational tolerances. Each prototype undergoes comprehensive inspection using coordinate measuring machines (CMM), optical comparators, and surface roughness testers. Clients receive full dimensional reports and material certification, enabling informed design approvals and rapid iteration if required.

Once design validation is complete, we transition to high-efficiency mass production. Our facility integrates automated pallet systems, robotic part handling, and real-time process monitoring to maintain throughput without compromising precision. Every production run is governed by documented work instructions, first-article inspections, and statistical process control (SPC) methodologies. In-process gauging and post-machining inspections ensure that tolerances are held consistently across batches.

Our commitment to zero defects is reinforced through a closed-loop quality management system. Non-conformances are immediately flagged, analyzed, and corrected using root cause analysis and corrective action (RCCA) procedures. All equipment is calibrated monthly, and operators are certified to ISO 9001 standards, ensuring full traceability and compliance.

Wuxi Lead Precision Machinery combines engineering rigor with industrial scalability. Whether producing a single prototype or managing annual volumes exceeding 500,000 units, our process guarantees precision, repeatability, and zero-defect outcomes.

| Specification | Capability |

|---|---|

| Machining Tolerances | ±0.002 mm |

| Surface Roughness | Ra 0.2 – Ra 1.6 µm |

| Maximum Work Envelope | 1200 x 800 x 600 mm |

| Materials Processed | Aluminum, Stainless Steel, Titanium, Inconel, Brass, Engineering Plastics |

| CNC Equipment | 3-axis, 4-axis, 5-axis Vertical Machining Centers |

| Quality Standards | ISO 9001:2015, IATF 16949, Full PPAP Support |

| Production Capacity | Up to 500,000 units/year per product line |

Why Choose Wuxi Lead Precision

Elevate Your Manufacturing Partnership with Lead Precision

In the demanding landscape of precision CNC machining, your choice of manufacturing partner directly impacts product integrity, time-to-market, and operational resilience. Wuxi Lead Precision Machinery transcends conventional supplier relationships by integrating deep engineering expertise with scalable production excellence. We specialize in transforming complex design challenges into zero-defect deliverables for aerospace, medical, and defense sectors where tolerances are non-negotiable and failure is not an option. Our facility operates under ISO 9001:2015 and AS9100D certifications, ensuring every component meets stringent global compliance standards while optimizing your total cost of ownership.

Our technical infrastructure combines 27 state-of-the-art CNC systems with advanced metrology suites, enabling uncompromising precision across diverse material families. The table below summarizes our core production capabilities:

| Capability | Specification | Application Impact |

|---|---|---|

| Max Work Envelope | 2000 x 1200 x 1000 mm | Large-scale structural components |

| Positional Accuracy | ±0.0002 inches (5 microns) | Critical sealing surfaces, optics |

| Material Range | Titanium, Inconel, PEEK, 7075-T7351 | Extreme-environment performance |

| Surface Finish | Ra 0.4 µm to 3.2 µm (as machined) | Biocompatible & high-wear interfaces |

| Lead Time (Prototype) | 10–15 business days | Accelerated validation cycles |

Beyond equipment, our value lies in proactive engineering collaboration. Our team engages during your design phase to identify manufacturability improvements, reducing material waste by up to 22% and eliminating downstream assembly bottlenecks. Real-time SPC monitoring across all production lines ensures 100% traceability, while our dedicated quality cell performs in-process GD&T validation using Zeiss CONTURA CMM systems. This methodology delivers consistent first-pass yield rates exceeding 99.4%—a critical advantage when production delays cascade through global supply chains.

Partnering with Lead Precision means securing a strategic extension of your engineering department. We absorb volatile market pressures through long-term material contracts and dynamic capacity allocation, guaranteeing on-time delivery even during peak demand cycles. Our clients achieve 30% faster time-to-revenue by leveraging our turnkey solutions—from rapid prototyping to serialized production—without compromising audit readiness for ITAR or FDA requirements.

Your next production bottleneck ends here. Contact our engineering team directly to initiate a capability assessment tailored to your project’s technical and logistical constraints. Email [email protected] with your component drawings and volume requirements. We will respond within 4 business hours with a detailed production plan, including DFM feedback and timeline validation. Trust Lead Precision to manufacture not just parts, but competitive advantage.

Wuxi Lead Precision Machinery: Where Precision Engineering Meets Uncompromised Delivery.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.