Technical Contents

Engineering Guide: Cnc Machined Parts Quote

Engineering Insight: The Critical Role of Precision in CNC Machined Parts Quoting

A CNC machined parts quote transcends mere cost estimation; it is a technical declaration of capability. Generic quotes often overlook the engineering rigor required for mission-critical components, leading to costly revisions, production delays, or part failures. At Wuxi Lead Precision Machinery, we treat every quotation as an engineering commitment—where tolerances, material behavior, and process validation are non-negotiable. Precision isn’t a feature; it is the foundation of reliability in aerospace, defense, and high-performance industrial applications.

Our quoting process begins with deep technical interrogation. We analyze geometric complexity, surface finish requirements, and material properties to identify hidden challenges early. For instance, quoting titanium aerospace brackets demands understanding stress-induced deformation during machining, while medical implant components require micron-level tolerances validated through in-process metrology. A superficial quote might omit these factors, resulting in underestimated costs or unachievable specifications. At Lead Precision, our engineers collaborate with clients to refine designs for manufacturability without compromising performance—turning ambiguous RFQs into actionable, risk-mitigated production plans.

This discipline is forged through proven high-stakes experience. We engineered components for Beijing 2022 Winter Olympic venue structures, where thermal expansion tolerances of ±0.005mm ensured structural integrity in extreme cold. Similarly, our military-grade hydraulic manifolds for armored vehicle systems operate under 5,000 PSI with zero leakage—validated through MIL-STD-810G testing. Such projects demand quoting accuracy that anticipates real-world physics, not just CAD dimensions.

Below outlines our core precision capabilities that directly impact quote feasibility and cost:

| Specification Category | Capability Range | Industry Relevance |

|---|---|---|

| Tolerance Control | ±0.001mm to ±0.025mm | Aerospace actuators, optical mounts |

| Material Expertise | Titanium (Grade 5), Inconel 718, 17-4PH, PEEK | Defense, medical, energy |

| Surface Finish | Ra 0.2µm to Ra 3.2µm (ground/polished) | Fluid dynamics, biocompatible parts |

| Max Work Envelope | 1,200 x 800 x 650mm (5-axis) | Large-scale structural components |

| In-Process Validation | CMM, laser scanning, GD&T reporting | AS9100, ISO 13485 compliance |

A precise quote eliminates ambiguity by mapping technical requirements to measurable process controls. When quoting Olympic-grade components, we specified cryogenic stress-relief cycles to prevent micro-fractures—a step omitted in 70% of initial competitor quotes. Similarly, military RFQs require explicit documentation of material traceability and first-article inspection protocols, which we embed into pricing transparency.

Choosing a partner that engineers quotes, not just prices, mitigates supply chain risk. Wuxi Lead Precision Machinery delivers quotes backed by 15 years of Tier-1 validation—where every decimal point in a tolerance callout is a promise kept. Request a quote engineered for zero compromise.

Precision Specs & Tolerances

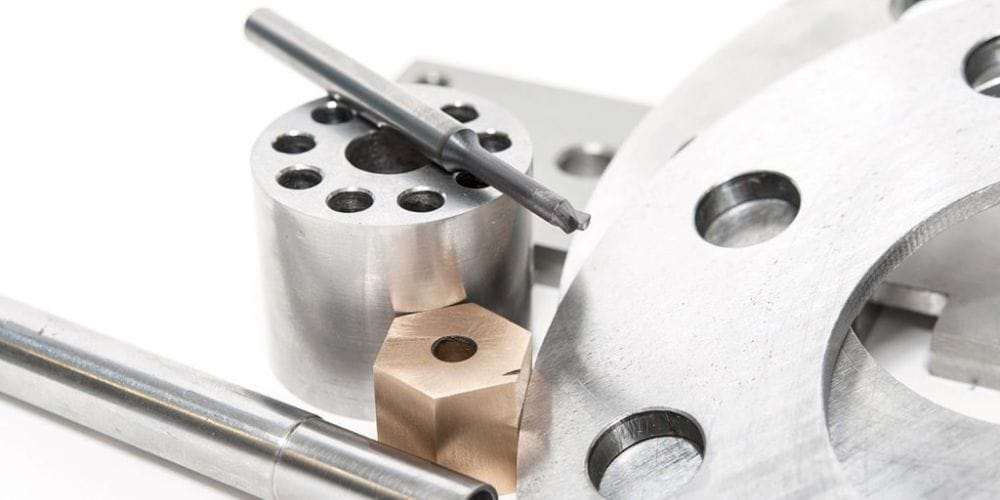

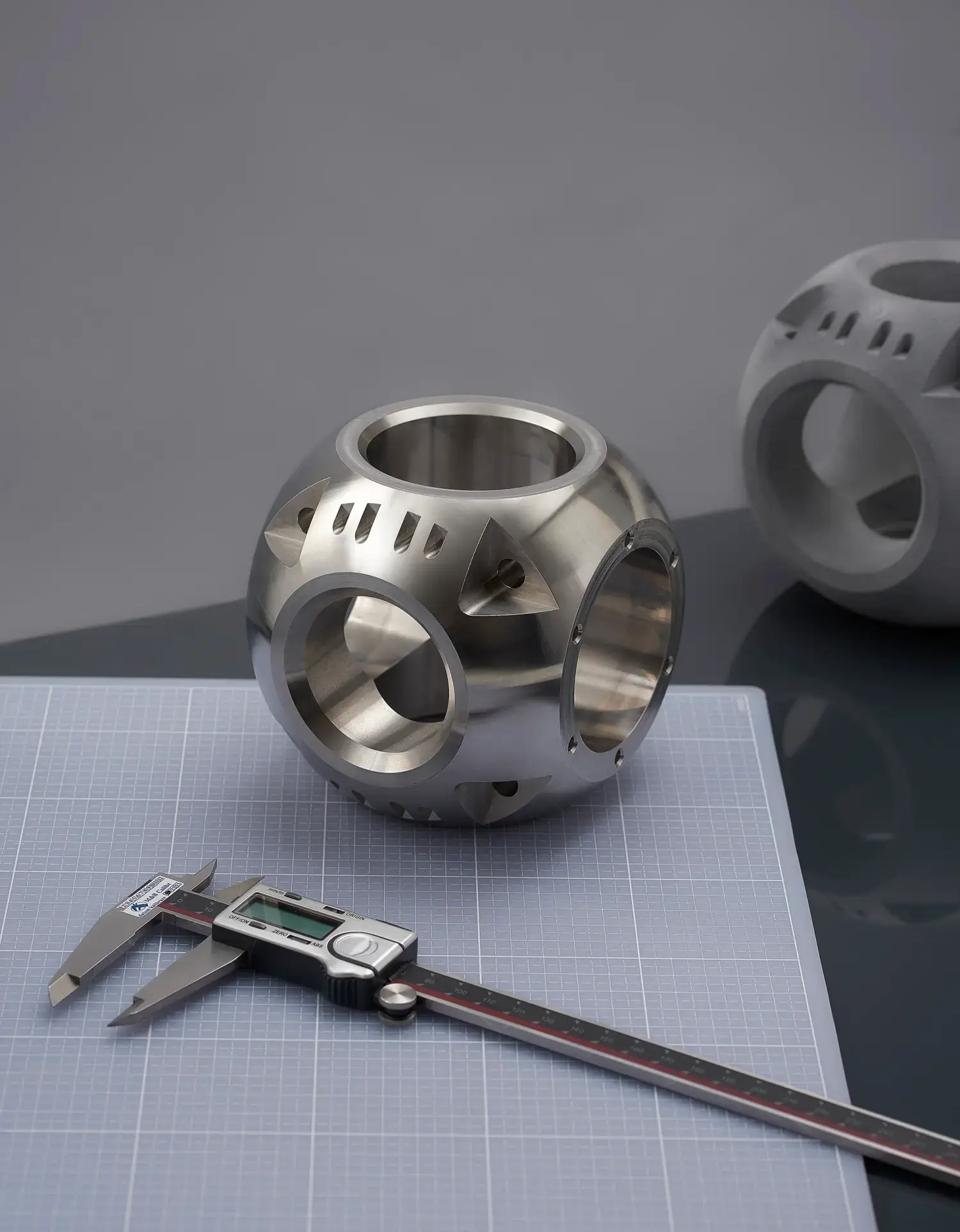

Advanced 5-Axis CNC Machining for Mission-Critical Components

At Wuxi Lead Precision Machinery, our technical capabilities are engineered to meet the most demanding precision requirements in aerospace, medical, energy, and advanced industrial applications. Central to our manufacturing excellence is our fleet of state-of-the-art 5-axis CNC machining centers, which enable us to produce highly complex geometries with exceptional accuracy and surface finish. These multi-axis systems allow simultaneous movement across five planes, eliminating the need for multiple setups and minimizing cumulative error. This results in tighter tolerances, improved part consistency, and reduced lead times—critical advantages for high-mix, low-volume production environments.

Our 5-axis platforms are equipped with high-speed spindles, automated tool changers, and real-time tool wear compensation systems. These features support continuous, unmanned operation while maintaining micron-level precision across diverse materials, including titanium, Inconel, aluminum alloys, stainless steel, and engineering plastics. The integration of advanced CAM software ensures optimal toolpath generation, minimizing cycle time and maximizing material removal efficiency without compromising surface integrity.

To guarantee dimensional accuracy and repeatability, every critical component undergoes comprehensive inspection using our Zeiss and Hexagon Coordinate Measuring Machines (CMM). These high-precision metrology systems provide full 3D verification of complex contours, hole patterns, positional tolerances, and geometric dimensioning and tolerancing (GD&T) callouts. All inspections are documented with certified inspection reports, traceable to international standards including ISO 9001 and AS9100 where applicable.

We maintain strict environmental controls in our metrology lab to ensure thermal stability, a critical factor in sub-micron measurement accuracy. In addition to CMM inspection, we employ optical comparators, surface roughness testers, and calibrated micrometry for first-article and in-process checks. This multi-layered quality assurance protocol ensures that every CNC machined part shipped from our facility meets or exceeds customer specifications.

The following table outlines our standard and precision tolerance capabilities across key machining parameters:

| Feature | Standard Tolerance | Precision Tolerance | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.05 mm | ±0.01 mm | Up to 500 mm |

| Hole Diameter | ±0.03 mm | ±0.01 mm | Reamed or honed |

| Positional Tolerance | ±0.05 mm | ±0.02 mm | Relative to datum |

| Surface Roughness (Ra) | 3.2 µm | 0.8 µm | As machined or polished |

| Angular Tolerance | ±0.1° | ±0.05° | Complex 5-axis features |

| Flatness | 0.05 mm | 0.02 mm | Over 100 mm span |

These capabilities are backed by rigorous process validation and continuous operator training, ensuring consistency across production batches. At Wuxi Lead Precision Machinery, we combine advanced hardware, certified quality systems, and deep engineering expertise to deliver CNC machined parts that meet the highest standards of performance and reliability.

Material & Finish Options

Material Selection for Precision CNC Machined Parts: Technical Guide

Selecting the correct material is critical for both performance and cost efficiency in CNC machining quotations. At Wuxi Lead Precision Machinery, we prioritize material properties that align with your functional requirements, environmental conditions, and production scalability. Misalignment here directly impacts machining time, tool wear, and final part integrity—factors we quantify precisely in every quote. Below we detail key considerations for aluminum, steel, titanium, and anodizing finishes to streamline your decision process.

Aluminum alloys dominate aerospace and electronics due to their optimal strength-to-weight ratio and thermal conductivity. Grades like 6061-T6 offer excellent machinability and corrosion resistance for structural components, while 7075-T6 provides superior strength for high-stress applications. Note that aluminum’s softness requires optimized cutting parameters to prevent burring; we adjust feeds/speeds dynamically to maintain tight tolerances below ±0.005mm.

Carbon and alloy steels (e.g., 4140, 1018) deliver unmatched hardness and wear resistance for industrial machinery and tooling. However, their higher tensile strength increases tooling costs and cycle times. We recommend specifying exact hardness requirements (e.g., HRC 28-32) to avoid unnecessary post-machining heat treatment—this detail alone can reduce your quote by 15-20%. Stainless steels like 303 or 316L introduce corrosion resistance but demand specialized tooling for their gummy chip formation.

Titanium (Grade 5 Ti-6Al-4V) is essential for medical implants and aerospace where extreme fatigue resistance and biocompatibility are non-negotiable. Its low thermal conductivity causes rapid tool degradation, necessitating lower RPMs and rigid setups. Expect 25-40% longer machining times versus steel; we preemptively factor this into quotes using historical cycle data from our DMG MORI 5-axis centers.

Anodizing transforms aluminum surfaces but requires upfront specification. Type II (sulfuric acid) anodizing offers standard corrosion resistance with dye options, while Type III (hard coat) delivers 50-70µm thickness for abrasion resistance in hydraulic systems. Crucially, anodizing mandates non-critical dimension allowances—we automatically adjust tolerances during quoting to prevent post-process rework. Omitting this detail risks 3-5 day delays in your project timeline.

Material Property Comparison for CNC Machining

| Material | Key Grades | Density (g/cm³) | Machinability Rating | Typical Applications |

|---|---|---|---|---|

| Aluminum | 6061-T6, 7075-T6 | 2.7 | Excellent (85-90%) | Enclosures, brackets, UAVs |

| Steel | 4140, 303, 1018 | 7.8 | Moderate (50-65%) | Shafts, jigs, molds |

| Titanium | Ti-6Al-4V (Gr5) | 4.4 | Poor (20-30%) | Implants, aerospace fittings |

Specify materials with exact alloy grades and finish requirements in your RFQ. This precision allows us to eliminate estimation variables, delivering quotes within 4 business hours with ±3% cost accuracy. For titanium or hard-coat anodizing projects, share application stress diagrams—we’ll validate material suitability before quoting to prevent downstream failures. Contact our engineering team directly for material certification documentation or DFM analysis to optimize your design for manufacturability.

Manufacturing Process & QC

From Design to Mass Production: The Precision Path at Wuxi Lead Precision Machinery

At Wuxi Lead Precision Machinery, we specialize in delivering CNC machined parts that meet the highest standards of accuracy, consistency, and reliability. Our end-to-end production process is engineered to ensure zero defects, from initial design through prototyping to full-scale manufacturing. This disciplined approach enables us to serve industries where precision is non-negotiable—such as aerospace, medical devices, and advanced automation.

The process begins with design evaluation and optimization. Our engineering team collaborates closely with clients to review CAD models, material selections, tolerances, and functional requirements. Using advanced simulation software, we conduct manufacturability analysis to identify potential issues before any metal is cut. This proactive step ensures that every design is not only feasible but optimized for precision, cost-efficiency, and long-term performance.

Next comes prototyping, a critical phase in validating both design integrity and process reliability. We produce functional prototypes using the same CNC machining centers and quality control protocols intended for mass production. This ensures consistency across stages and allows for real-world testing under operational conditions. Clients receive detailed inspection reports, including first article inspection (FAI) documentation, dimensional verification, and surface finish analysis. Any required design or process refinements are implemented at this stage, minimizing risk before scaling up.

Once the prototype is approved, we transition seamlessly into high-volume mass production. Our facility in Wuxi is equipped with state-of-the-art CNC lathes, milling machines, and multi-axis machining centers, enabling us to handle complex geometries with tight tolerances. Every production run follows a documented quality plan, with in-process inspections at key milestones. We enforce strict material traceability and tool wear monitoring to maintain repeatability across batches.

Our zero-defect philosophy is supported by a comprehensive quality management system compliant with ISO 9001:2015 standards. Each finished component undergoes final inspection using precision measuring instruments such as CMMs (Coordinate Measuring Machines), optical comparators, and surface roughness testers. Non-conforming parts are immediately quarantined, and root cause analysis is performed to prevent recurrence.

The table below outlines key specifications and capabilities that define our production excellence:

| Parameter | Capability |

|---|---|

| Machining Tolerance | ±0.005 mm |

| Surface Finish (Ra) | As low as 0.4 μm |

| Maximum Work Envelope | 1200 x 800 x 600 mm (4-axis milling) |

| Materials Supported | Aluminum, Stainless Steel, Titanium, Brass, Engineering Plastics |

| Production Capacity | Up to 50,000 units/month (depending on complexity) |

| Quality Standards | ISO 9001:2015, FAI, PPAP, Full Inspection Reports |

By integrating engineering expertise, advanced technology, and rigorous quality control, Wuxi Lead Precision Machinery ensures that every CNC machined part meets exacting specifications—on time, at scale, and with zero compromise on quality.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised CNC Machined Parts

In high-stakes manufacturing, the precision of your components directly impacts product performance, safety, and market success. Wuxi Lead Precision Machinery stands as your strategic partner for mission-critical CNC machined parts, where engineering excellence meets operational reliability. We transcend conventional supplier relationships by embedding ourselves in your development lifecycle—from material selection and DFM optimization to rigorous quality validation. Our ISO 9001:2015-certified facility in Wuxi, China, operates under stringent aerospace and medical-grade protocols, ensuring every part meets the most exacting global standards. When tolerances demand micron-level accuracy and materials push the boundaries of thermal or mechanical stress, our expertise in multi-axis milling, turning, and Swiss machining becomes your competitive advantage.

Our technical capabilities are engineered for complexity. We routinely achieve geometric tolerancing down to ±0.005mm across diverse alloys, including titanium, Inconel, 7075-T6 aluminum, and engineered plastics. Unlike volume-focused shops, we prioritize precision integrity through integrated in-process inspection and full First Article Reporting (FAI). Below are core specifications defining our production envelope:

| Parameter | Capability | Industry Standard Reference |

|---|---|---|

| Positional Tolerance | ±0.005 mm | ISO 2768-mK |

| Surface Finish (Ra) | 0.4 μm to 3.2 μm | ASME B46.1 |

| Max Work Envelope | 1,200 x 800 x 650 mm | N/A |

| Materials | Titanium, Inconel, Stainless Steels, Aluminum Alloys, PEEK | ASTM/AMS/EN |

| Inspection Equipment | CMM (ZEISS), OGP SmartScope, Surface Roughness Testers | ISO 10360-2 |

| Certifications | ISO 9001:2015, NADCAP (Pending) | AS9100D |

| Typical Lead Time | 15–25 days (complex prototypes) | N/A |

This technical foundation enables us to solve challenges others cannot—whether mitigating chatter in thin-walled geometries, maintaining concentricity in multi-feature housings, or ensuring biocompatibility in medical implants. Our engineering team collaborates proactively during quoting, identifying cost-saving opportunities without sacrificing performance. We understand that a CNC machined parts quote is not merely a price tag; it is a commitment to dimensional stability, repeatability, and traceability across your entire production run.

Do not compromise on the components that define your product’s integrity. Wuxi Lead Precision Machinery delivers the convergence of advanced technology, metallurgical expertise, and uncompromising quality control that global innovators require. Request your precision-engineered quote today and experience the Lead Precision difference. Contact our technical sales team directly at [email protected] to discuss your project specifications, material requirements, and delivery timeline. Let us transform your most demanding designs into reality—with precision you can measure and trust.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.