Technical Contents

Engineering Guide: Metal Fabrication And Machining

Engineering Insight Precision as the Non-Negotiable Foundation of Metal Fabrication and Machining

In high-stakes metal fabrication and machining, precision transcends mere specification; it is the bedrock of functionality, safety, and economic viability. Tolerances measured in microns dictate whether a component integrates seamlessly within a complex aerospace assembly, withstands extreme pressure in deep-sea exploration equipment, or ensures the flawless operation of life-saving medical devices. Compromised precision leads directly to catastrophic field failures, costly rework, extended project timelines, and irreparable damage to brand reputation. The margin for error in critical applications is effectively zero. Achieving this level of accuracy demands far more than advanced machinery; it requires an integrated engineering philosophy encompassing meticulous material science understanding, rigorous process control, continuous environmental monitoring, and an unwavering commitment to statistical process validation. It is the difference between a component that merely exists and one that performs reliably for decades under the most demanding conditions.

Wuxi Lead Precision Machinery operates at this pinnacle of precision manufacturing. Our engineering approach begins with comprehensive material analysis and thermal stability assessment, ensuring raw stock behavior is fully characterized before the first cut. We implement closed-loop feedback systems on all critical CNC machining centers and laser cutting platforms, dynamically compensating for tool wear, thermal drift, and material inconsistencies in real-time. Statistical Process Control (SPC) is not a post-production check but an embedded, continuous process, with Cpk values rigorously maintained above 1.67 for mission-critical features. This systematic control extends through every stage – from laser cutting and precision bending to multi-axis milling and complex welding – guaranteeing dimensional integrity and geometric accuracy are preserved throughout the fabrication sequence. The result is exceptional first-pass yield and components that meet the most stringent global standards without reliance on post-process correction.

Our capability to deliver this level of precision consistently is proven in the world’s most demanding environments. We are a trusted supplier for components integrated into infrastructure supporting the Olympic Games, where structural integrity and perfect fitment under intense public scrutiny are paramount. Furthermore, our processes and quality systems meet the exacting requirements of select military and defense applications, where failure is not an option and traceability is absolute. This experience validates our engineering rigor under conditions where precision directly correlates to operational success and safety.

The following table outlines core precision capabilities achievable within our controlled manufacturing environment:

| Capability | Specification | Relevance for Critical Applications |

|---|---|---|

| Linear Dimensional Tolerance | ±0.005 mm (0.0002″) | Ensures perfect fitment in high-precision assemblies like aerospace actuators or optical mounts |

| Geometric Tolerance (GD&T) | IT6 / IT7 class | Guarantees critical form, position, and runout for rotating machinery and sealing surfaces |

| Surface Roughness (Ra) | Down to 0.4 µm | Critical for fluid dynamics, fatigue resistance, and biocompatibility in medical implants |

| Material Thickness Control | ±0.025 mm (0.001″) | Essential for consistent structural performance in pressure vessels and lightweight frames |

| First-Pass Yield | >98.5% (Cpk ≥ 1.67) | Minimizes scrap, rework costs, and project delays for high-value components |

Precision engineering is not an incremental advantage; it is the fundamental requirement for success in advanced manufacturing. Wuxi Lead Precision Machinery’s proven expertise, honed through Olympic and military-grade projects, delivers the unwavering accuracy and reliability your most critical metal fabrication and machining challenges demand. Partner with engineering certainty.

Precision Specs & Tolerances

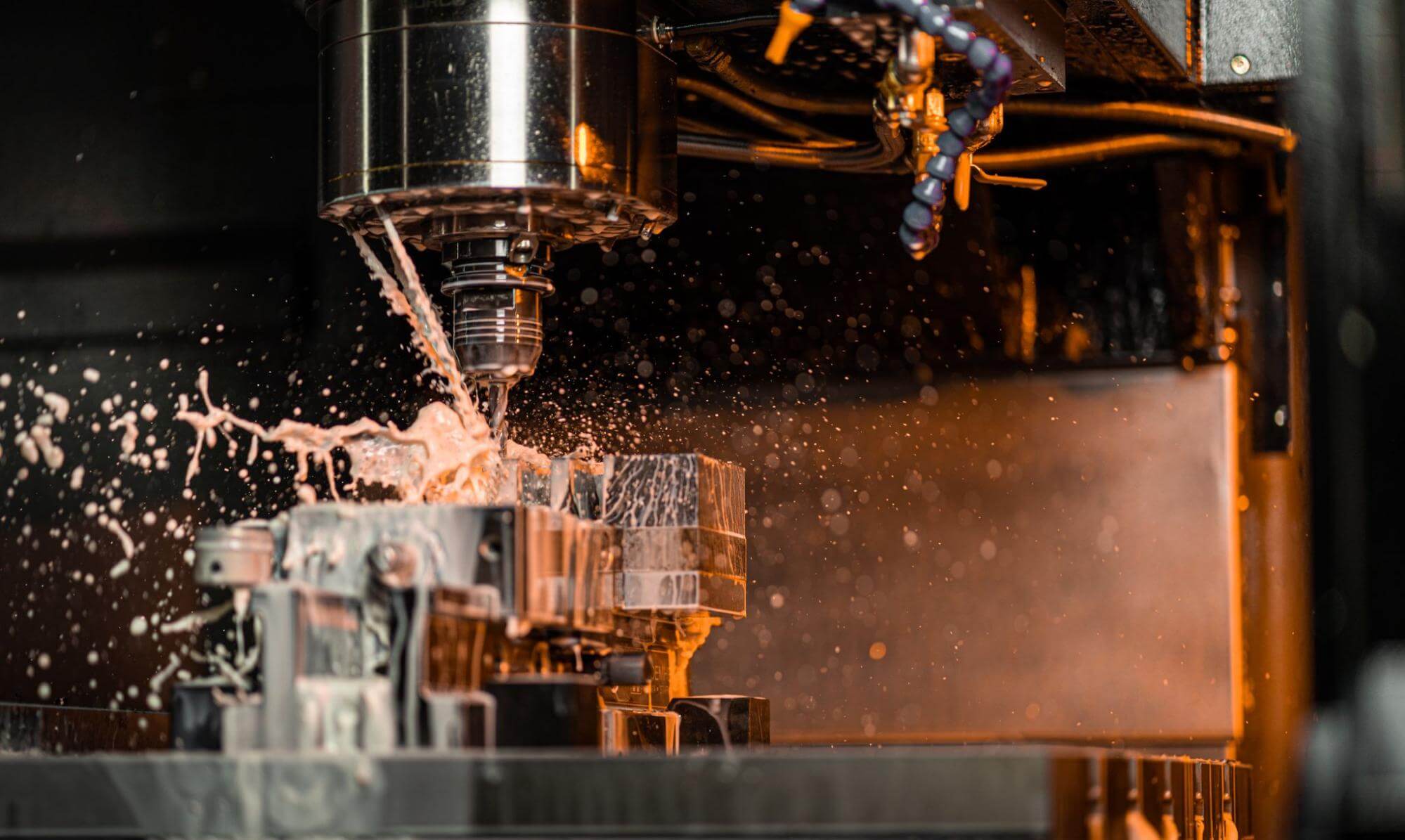

Wuxi Lead Precision Machinery delivers advanced sheet metal fabrication solutions tailored for high-precision industrial applications. Our technical capabilities integrate state-of-the-art machinery, rigorous quality assurance protocols, and engineering expertise to meet the demanding requirements of aerospace, medical, automation, and power transmission sectors. Central to our production workflow is the implementation of 5-axis CNC machining technology, enabling us to execute complex geometries with exceptional accuracy and repeatability. This multi-axis capability allows for simultaneous cutting from five different angles, minimizing setup changes and enhancing dimensional consistency across intricate components.

Our facility is equipped with high-performance 5-axis CNC centers that support a broad range of metals, including stainless steel, aluminum, carbon steel, and specialty alloys. These machines are operated by certified CNC programmers and machinists who utilize advanced CAM software to optimize tool paths, reduce cycle times, and maintain tight tolerances throughout production runs. The integration of 5-axis technology not only improves part accuracy but also reduces lead times and material waste, providing clients with cost-efficient manufacturing without compromising quality.

Quality control is embedded at every stage of our fabrication process. All critical dimensions are verified using a Coordinate Measuring Machine (CMM), ensuring full compliance with ISO 10360 standards. Our CMM inspection system provides traceable, high-resolution measurement data for first-article inspection reports (FAIR) and production batch validation. This metrology-grade verification supports tight tolerance adherence and enables continuous process improvement through real-time feedback loops.

In addition to precision machining and inspection, we maintain strict environmental controls within our metrology lab to eliminate thermal and vibrational interference during measurement. Our quality management system is ISO 9001 certified, reflecting our commitment to operational excellence and customer-specific compliance. Every component undergoes a documented inspection protocol, with digital records archived for full traceability.

The following table outlines the standard tolerances achievable across our sheet metal fabrication and 5-axis machining operations:

| Feature | Standard Tolerance | Precision Capability | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.05 mm | ±0.02 mm | Up to 1,200 mm length |

| Hole Diameter | ±0.03 mm | ±0.01 mm | Reamed and honed options |

| Positional Tolerance | ±0.03 mm | ±0.015 mm | Relative to datum |

| Angular Features | ±0.1° | ±0.05° | Multi-axis alignment |

| Surface Roughness | Ra 3.2 µm | Ra 0.8 µm | Machined surfaces |

| Sheet Metal Bending | ±0.2° | ±0.1° | CNC press brake controlled |

| Feature-to-Feature | ±0.04 mm | ±0.02 mm | Within same setup |

These capabilities are consistently maintained across prototype, bridge, and high-volume production runs. At Wuxi Lead Precision Machinery, we combine technical precision with scalable manufacturing agility to deliver mission-critical components that meet global engineering standards.

Material & Finish Options

Strategic Material Selection for Precision Sheet Metal Fabrication

Material selection fundamentally dictates the performance, manufacturability, and lifecycle cost of sheet metal components. At Wuxi Lead Precision Machinery, our engineering team prioritizes matching material properties to your specific application demands, environmental exposure, and production requirements. Choosing incorrectly leads to compromised part integrity, excessive machining time, or premature failure. This guide outlines critical considerations for aluminum, steel, and titanium, alongside essential anodizing finish specifications.

Aluminum alloys, particularly 5052-H32 and 6061-T6, dominate applications requiring an optimal strength-to-weight ratio, excellent corrosion resistance, and good machinability. These grades are ideal for aerospace brackets, electronic enclosures, and transportation components where weight savings are critical. Aluminum’s inherent conductivity also benefits thermal management housings. However, its lower hardness compared to steel necessitates careful handling during fabrication to avoid surface marring. Work hardening characteristics require specific tooling strategies during CNC punching or bending.

Carbon steel, especially grades like SPCC and SUS304 stainless, provides superior strength, durability, and cost-effectiveness for structural frames, machinery guards, and high-wear applications. Mild steel offers excellent weldability and formability but requires protective finishes like powder coating for corrosion-prone environments. Stainless steel variants deliver inherent corrosion and heat resistance, essential for medical devices, food processing equipment, and marine hardware. Be mindful of stainless steel’s higher work hardening rate, demanding precise CNC parameters to maintain dimensional accuracy during milling or shearing.

Titanium alloys, primarily Grade 2 and 5 (Ti-6Al-4V), are reserved for extreme environments demanding exceptional strength-to-weight ratios, unparalleled corrosion resistance (including seawater and chemical exposure), and biocompatibility. Critical aerospace components, medical implants, and high-performance racing parts leverage titanium. Its high cost and challenging machinability—requiring rigid CNC setups, specialized tooling, and controlled feeds/speeds—necessitate expert fabrication partners like Wuxi Lead with vacuum furnaces and deep metallurgical knowledge.

Surface Finishing: Anodizing for Aluminum

Anodizing is the premier electrochemical finish for aluminum, significantly enhancing surface hardness, wear resistance, and corrosion protection while providing an excellent base for dyes. Type II (Sulfuric Acid) anodizing creates a standard decorative and protective layer (5-25 µm). Type III (Hard Anodizing) produces a much thicker, denser, and harder coating (25-125 µm), essential for high-wear applications like hydraulic pistons or military hardware. Critical considerations include dimensional impact—hard anodizing grows the coating both inward and outward, requiring precise pre-machining—and strict control of voltage/temperature to ensure coating integrity and color consistency. Anodizing does not protect cut edges; secondary processes may be needed.

Material properties directly influence fabrication complexity and cost. Partnering with an experienced manufacturer ensures optimal material and finish selection aligned with your functional and economic goals. Consult our engineering team early in the design phase to leverage our CNC expertise and avoid costly revisions.

| Material Property | Aluminum 6061-T6 | Carbon Steel SPCC | Stainless Steel 304 | Titanium Grade 5 (Ti-6Al-4V) |

|---|---|---|---|---|

| Density (g/cm³) | 2.7 | 7.85 | 8.0 | 4.43 |

| Tensile Strength (MPa) | 310 | 270-500 | 505-860 | 900-1000 |

| Common Thickness Range | 0.5mm – 12.7mm | 0.5mm – 10mm | 0.5mm – 6.0mm | 0.8mm – 6.0mm |

| Key Fabrication Note | Low melting point; prone to burring; requires sharp tooling | Excellent bendability; mild steel requires post-fab corrosion protection | High work hardening; requires slower speeds; annealing critical for tight bends | Extremely abrasive; requires low SFM, high coolant flow; prone to galling |

Manufacturing Process & QC

The production process at Wuxi Lead Precision Machinery is engineered for precision, consistency, and zero-defect outcomes across every stage of sheet metal fabrication. Our integrated workflow ensures seamless transition from concept to mass production, maintaining strict adherence to international quality standards.

Design is the foundation of any successful fabrication project. At Wuxi Lead, our engineering team collaborates closely with clients to translate technical requirements into optimized 3D models and 2D drawings using advanced CAD/CAM software. This phase includes detailed material selection, tolerance analysis, and manufacturability assessment to preempt potential production challenges. Finite element analysis (FEA) and design for assembly (DFA) principles are applied to enhance structural integrity and reduce assembly time. All designs undergo internal review and client approval before progression, ensuring alignment with functional and aesthetic goals.

Prototyping follows design finalization, serving as a critical validation step. We produce functional prototypes using precision laser cutting, CNC bending, and welding techniques that mirror the final production process. This ensures that the prototype accurately reflects the performance and fit of the end product. Prototypes are subjected to rigorous inspection using coordinate measuring machines (CMM), optical comparators, and first article inspection (FAI) reports. Feedback from testing is incorporated into final design adjustments, minimizing risk during scale-up.

Mass production leverages our automated manufacturing lines, where CNC-controlled punch presses, laser cutters, press brakes, and robotic welding cells operate under real-time monitoring. Each workstation follows standardized work instructions and visual aids to eliminate variability. In-process inspections occur at key control points, supported by statistical process control (SPC) data tracking. Our production environment is ISO 9001:2015 certified, with full traceability from raw material to finished component.

To ensure zero defects, Wuxi Lead implements a multi-layered quality assurance system. This includes incoming material inspection, first piece approval, in-line dimensional checks, and final 100% functional and visual inspection. Non-conforming parts are quarantined immediately, with root cause analysis conducted using 8D methodology. Continuous improvement is driven by real-time data analytics and customer feedback loops.

The table below outlines key capabilities and specifications across our production process:

| Parameter | Specification |

|---|---|

| Material Thickness Range | 0.5 mm – 25 mm |

| Tolerance (Standard) | ±0.1 mm (tighter upon request) |

| Laser Cutting Accuracy | ±0.05 mm |

| Max Part Size | 4000 mm × 2000 mm |

| Bending Tolerance | ±0.2° |

| Welding Processes | MIG, TIG, Spot, Robotic |

| Surface Finishes | Anodizing, Powder Coating, Passivation, Plating |

| Quality Standards | ISO 9001:2015, ISO 14001, RoHS Compliant |

Through disciplined execution and technological integration, Wuxi Lead Precision Machinery delivers defect-free sheet metal components at scale, ensuring reliability, repeatability, and client satisfaction.

Why Choose Wuxi Lead Precision

Partner with LEAD PRECISION for Uncompromising Sheet Metal Excellence

At Wuxi Lead Precision Machinery, we engineer solutions where precision meets scalability. For global OEMs and tier-one suppliers demanding zero-defect sheet metal components, our integrated facility in Wuxi, China, delivers certified quality from prototype to high-volume production. We specialize in complex geometries, tight-tolerance assemblies, and mission-critical parts for aerospace, medical, and industrial automation sectors—where dimensional accuracy below ±0.05mm is non-negotiable. Our ISO 9001:2015 and IATF 16949-certified processes eliminate supply chain volatility through in-house laser cutting, CNC punching, bending, welding, and finishing. No subcontracting. No quality compromises.

Our technical capabilities are engineered for your most demanding specifications. The table below details core production parameters:

| Capability | Specification Range | Tolerance Control | Supported Materials |

|---|---|---|---|

| Laser Cutting | 0.5–25mm thickness | ±0.03mm | Stainless Steel, Aluminum, Carbon Steel |

| CNC Punching | 0.8–6.0mm thickness | ±0.05mm | Galvanized, Pre-painted Steel |

| Press Brake Forming | 0.5–12mm thickness; 4m length | ±0.1° angular | All standard alloys |

| Robotic Welding | TIG/MIG; thin-wall to structural | ISO 13920 Class B | Aerospace-grade alloys |

| Surface Finishing | Anodizing, Powder Coating, Passivation | ASTM D3359 adhesion | Medical-grade compliant options |

Beyond machinery, our value lies in proactive engineering collaboration. Our bilingual technical team engages during your design phase to optimize manufacturability—reducing material waste by up to 22% and accelerating time-to-market. We implement real-time SPC monitoring on critical features, with full traceability via serialized part documentation. For urgent projects, our 72-hour rapid prototyping service delivers functional samples with production-intent tooling, not 3D-printed approximations.

Choosing LEAD PRECISION means partnering with a manufacturer invested in your long-term success. We maintain strategic inventory buffers for critical components, ensuring 99.6% on-time delivery even during global logistics disruptions. Our client portal provides live production tracking, quality reports, and engineering change management—transparency you control. When your reputation hinges on flawless metalwork, trust a partner with 14 years of audited performance for Fortune 500 innovators.

Initiate your precision manufacturing partnership today. Contact our engineering team at [email protected] to discuss technical requirements, request a DFM analysis, or schedule a virtual facility audit. We respond to all inquiries within 4 business hours with actionable solutions—not generic sales pitches. Let’s build what matters, together.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.