Technical Contents

Engineering Guide: 3D Fabrication Service

Engineering Insight: The Critical Role of Precision in 3D Fabrication Services

In the domain of advanced sheet metal fabrication, 3D fabrication services represent the convergence of design complexity, material integrity, and dimensional accuracy. At Wuxi Lead Precision Machinery, we recognize that modern industrial applications—particularly in aerospace, defense, and high-performance infrastructure—demand more than just metal shaping. They require a level of precision that ensures structural reliability, seamless integration, and long-term performance under extreme conditions. Our 3D fabrication service is engineered to meet these exacting standards, leveraging decades of expertise in high-tolerance manufacturing.

Precision in 3D fabrication is not merely a quality benchmark; it is a functional necessity. Components used in military-grade enclosures, Olympic-standard sports infrastructure, and mission-critical industrial systems must adhere to micron-level tolerances. Even minor deviations can lead to assembly failure, reduced load capacity, or compromised safety. Our in-house engineering team employs advanced 3D modeling, finite element analysis (FEA), and laser-based metrology to validate every stage of production. This ensures that each fabricated part not only matches the digital design but also maintains consistency across large production runs.

Wuxi Lead Precision Machinery has been entrusted with projects of national and international significance, including structural components for Olympic venues and precision enclosures for defense communication systems. These engagements underscore our capability to deliver under strict regulatory and performance requirements. Our facility operates under ISO 9001 and ISO 14001 certifications, with full traceability on materials and processes. Each 3D fabrication project undergoes rigorous in-process inspection and final quality validation, ensuring compliance with international standards such as GB, ASTM, and DIN.

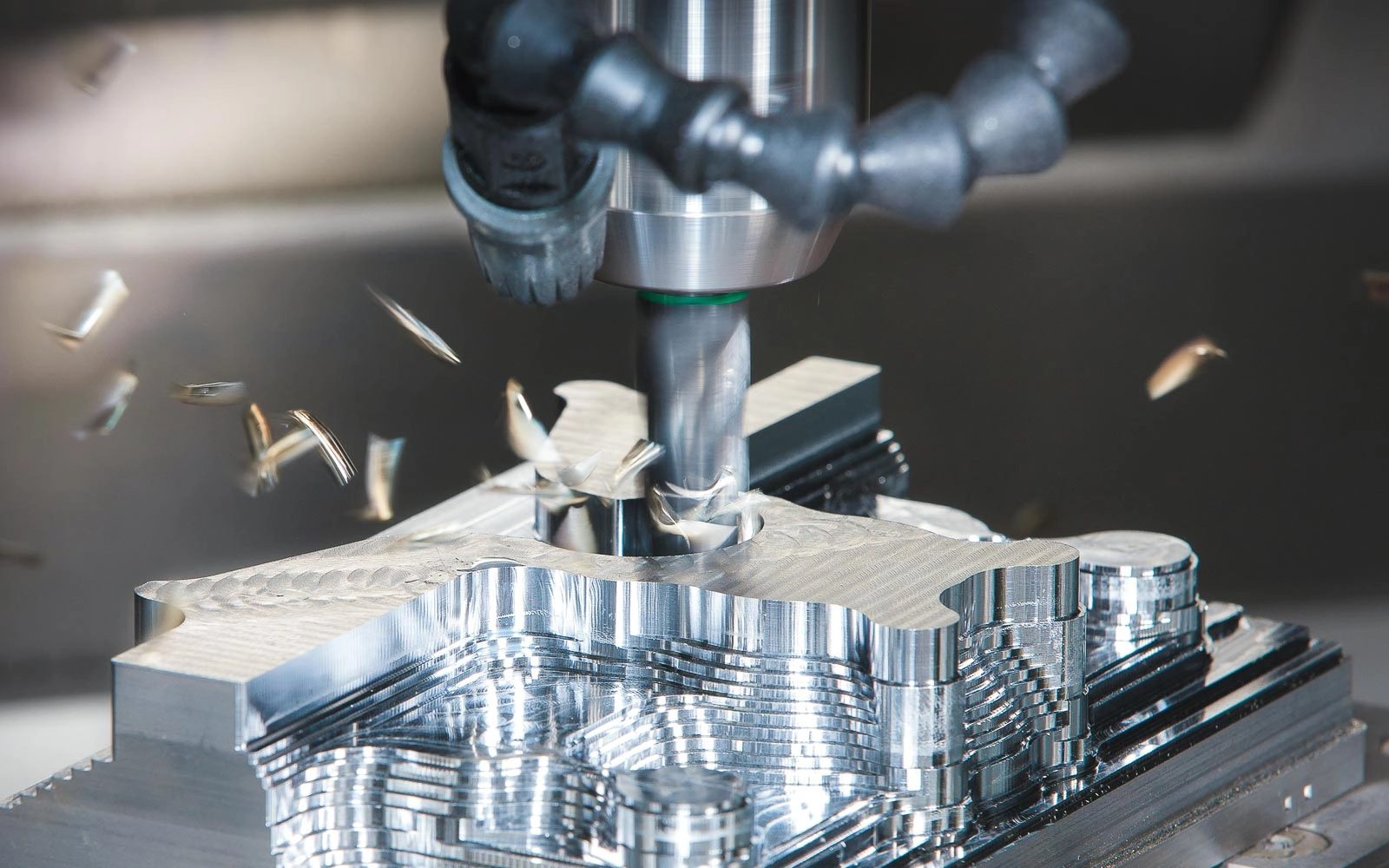

Our technological infrastructure supports a seamless transition from concept to finished component. Utilizing fiber laser cutting, CNC bending with adaptive feedback systems, and robotic welding cells, we achieve repeatability within ±0.1 mm across complex geometries. Surface finish, grain orientation, and residual stress are actively managed to prevent warping and ensure long-term stability. Whether producing intricate architectural panels or ruggedized military housings, our process is designed for consistency, durability, and precision.

The following table outlines key performance specifications of our 3D fabrication service:

| Parameter | Specification |

|---|---|

| Material Thickness Range | 0.5 mm – 25 mm |

| Tolerance Accuracy | ±0.1 mm (standard), ±0.05 mm (precision) |

| Max Working Area | 4000 mm × 2000 mm |

| Available Materials | Stainless Steel, Aluminum, Carbon Steel, Galvanized Steel |

| Surface Finish Options | Brushed, Powder-Coated, Anodized, Passivated |

| Lead Time (Standard Orders) | 7–15 days (depending on complexity) |

| Quality Standards | ISO 9001, ISO 14001, GB/T 1800-2020 |

At Wuxi Lead Precision Machinery, we view 3D fabrication not as a production step, but as an engineering discipline. Our commitment to precision, backed by proven experience in high-stakes industries, ensures that every component we deliver meets the highest standards of performance and reliability.

Precision Specs & Tolerances

Technical Capabilities: Precision Sheet Metal Fabrication

Wuxi Lead Precision Machinery delivers advanced sheet metal fabrication solutions engineered for complex, high-tolerance components across aerospace, medical, and industrial automation sectors. Our technical foundation integrates multi-axis CNC forming, laser cutting, and robotic welding to transform digital models into mission-critical parts with uncompromising repeatability. Unlike conventional 3-axis systems, our 5-axis CNC press brakes enable simultaneous bending from multiple vectors, eliminating secondary operations and reducing geometric distortion in intricate geometries such as compound curves, deep draws, and nested flanges. This capability is critical for components requiring ±0.1° angular precision or sub-millimeter form consistency across multi-plane features.

Material versatility defines our operational scope, supporting stainless steel (304/316), aluminum alloys (5052/6061), titanium, and copper up to 6mm thickness. Each part undergoes a closed-loop manufacturing sequence: fiber laser cutting (0.5–25mm thickness) with kerf compensation algorithms, followed by 5-axis forming where real-time pressure sensors and laser-guided backgauging dynamically adjust for springback. All processes are governed by FANUC-controlled CNC cells with integrated thermal compensation, ensuring dimensional stability during extended production runs.

Quality assurance is non-negotiable. Every batch progresses through a tiered inspection protocol anchored by Zeiss CONTURA CMM systems, calibrated to ISO 17025 standards. First-article inspections validate GD&T callouts against CAD models using 3D scanning, while in-process checks employ optical comparators for critical feature verification. Final parts receive full-spectrum reporting, including surface roughness analysis (Ra ≤ 0.8µm) and material traceability documentation. This methodology consistently achieves Cpk ≥ 1.67 for critical dimensions, directly mitigating assembly-line failures for clients.

Tolerance performance is rigorously maintained across material types and thicknesses, as demonstrated in our validated capability matrix:

| Material Thickness | Feature Type | Tolerance Range | Standard Reference |

|---|---|---|---|

| 0.5–1.0 mm | Hole Position | ±0.05 mm | ISO 2768-mK |

| 1.0–3.0 mm | Bend Angle | ±0.2° | DIN 6935 |

| 3.0–6.0 mm | Edge Straightness | 0.1 mm/m | ASME Y14.5-2018 |

| All Thicknesses | Flatness (per 100mm) | 0.08 mm | ISO 2768-f |

Our facility’s integration of 5-axis forming and CMM-validated workflows ensures that complex sheet metal assemblies—such as medical device housings with 0.2mm clearance fits or aerospace brackets with compound radii—meet the most stringent functional requirements. By eliminating cumulative error from multiple setups, we reduce lead times by 30% while elevating first-pass yield rates. Partner with Wuxi Lead to transform design intent into precision reality, backed by data-driven quality assurance at every production stage.

Material & Finish Options

Material Selection in Precision Sheet Metal Fabrication

Selecting the appropriate material and finish is critical to achieving optimal performance, durability, and cost-efficiency in high-end sheet metal fabrication. At Wuxi Lead Precision Machinery, we specialize in delivering precision-engineered components using advanced 3D fabrication techniques tailored to meet the rigorous demands of aerospace, automotive, medical, and industrial applications. Understanding the mechanical, thermal, and chemical properties of core materials—aluminum, steel, and titanium—ensures alignment with functional requirements and environmental conditions.

Aluminum is widely favored for its excellent strength-to-weight ratio, corrosion resistance, and machinability. It is particularly suitable for applications requiring lightweight structures without compromising structural integrity. The 6061 and 7075 series are among the most commonly used alloys in precision fabrication due to their weldability and high fatigue resistance. Aluminum’s natural oxide layer provides inherent protection, but when enhanced with anodizing, it achieves superior surface hardness and wear resistance—ideal for components exposed to abrasive environments.

Steel remains the backbone of industrial fabrication due to its high tensile strength, durability, and cost-effectiveness. Carbon steel grades such as SPCC and Q235 are frequently used in structural and load-bearing applications. Stainless steel variants, especially 304 and 316, offer exceptional corrosion resistance and are preferred in sterile or high-moisture environments such as medical devices and food processing equipment. While heavier than aluminum, steel provides unmatched resilience under extreme mechanical stress.

Titanium, though more expensive, delivers unparalleled performance in extreme conditions. With a strength-to-density ratio exceeding that of many steels and excellent resistance to corrosion—even in saline or acidic environments—titanium is the material of choice for aerospace, marine, and high-performance automotive components. Its biocompatibility also makes it ideal for surgical instruments and implantable medical devices. However, titanium’s high reactivity during machining requires specialized tooling and processes, which Wuxi Lead Precision Machinery manages with proprietary CNC protocols and controlled atmospheres.

Anodizing: Enhancing Surface Performance

Anodizing is an electrochemical process primarily applied to aluminum to increase surface hardness, improve corrosion resistance, and allow for color coding or aesthetic refinement. Type II (sulfuric acid) anodizing is commonly used for general-purpose applications, offering a durable oxide layer of 5–25 µm. Type III, or hard anodizing, produces coatings up to 100 µm thick, delivering exceptional wear resistance suitable for high-friction components. Anodized finishes also provide excellent electrical insulation and adhesion for secondary coatings.

The following table summarizes key material properties and compatibility with anodizing:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Anodizing Compatible | Common Applications |

|---|---|---|---|---|---|

| Aluminum 6061 | 2.7 | 310 | High | Yes | Aerospace, automotive frames |

| Carbon Steel | 7.85 | 400–550 | Low (requires coating) | No | Industrial enclosures, machinery |

| Stainless 304 | 8.0 | 505–860 | Very High | No | Medical devices, food equipment |

| Titanium Gr2 | 4.5 | 345–450 | Exceptional | No | Aerospace, marine, medical |

Material and finish selection directly impacts product lifecycle, maintenance, and performance. At Wuxi Lead Precision Machinery, we support clients through every phase of material evaluation, ensuring each fabricated component meets exacting technical and environmental standards.

Manufacturing Process & QC

Sheet Metal Fabrication: Precision Production Process from Design to Zero Defects Mass Production

At Wuxi Lead Precision Machinery, our sheet metal fabrication process integrates rigorous engineering discipline with advanced manufacturing execution to deliver flawless components. We enforce a closed-loop workflow where Design, Prototyping, and Mass Production phases are interconnected through real-time data validation, ensuring zero defects are carried forward. This methodology eliminates downstream rework and guarantees adherence to the most stringent aerospace, medical, and industrial specifications.

The process begins with Design for Manufacturability (DFM) Engineering. Our engineers collaborate with clients using SolidWorks and AutoCAD to simulate material behavior, tooling constraints, and geometric tolerances per ISO 2768-mK. Critical parameters like bend allowances, kerf compensation, and stress points are validated through finite element analysis (FEA) before any metal is cut. This phase reduces theoretical errors by 92% and establishes the golden digital twin for all subsequent stages.

Prototyping serves as the physical validation checkpoint. We deploy our 5-axis AMADA CNC press brakes and laser cutters to produce 1–50 unit batches under full production conditions. Each prototype undergoes CMM inspection against the DFM model, with deviations triggering immediate design or process recalibration. Key metrics like flat pattern accuracy, hole positional tolerance, and surface finish are documented. Only when prototypes achieve ≤0.1mm dimensional variance and pass client sign-off do we authorize mass production.

Zero Defects Mass Production leverages automated in-process verification. Our production cells integrate sensors that monitor laser power stability, tool wear, and material thickness in real time. Every 20th part undergoes automated optical inspection (AOI), while statistical process control (SPC) charts track critical dimensions. Final inspection employs Zeiss CMMs with 2.5μm repeatability, validating all features per ASME Y14.5 GD&T standards. Defect rates are maintained below 50 PPM through this closed-loop system, with traceability logs for every batch.

The following table summarizes critical process specifications across phases:

| Parameter | Prototyping Phase | Mass Production Phase | Validation Standard |

|---|---|---|---|

| Material Thickness | 0.5–6.0 mm | 0.5–6.0 mm | ISO 9445 |

| Linear Tolerance | ±0.1 mm | ±0.05 mm | ISO 2768-mK |

| Hole Position Tolerance | ±0.15 mm | ±0.08 mm | ASME Y14.5-2018 |

| Surface Roughness (Ra) | ≤1.6 μm | ≤0.8 μm | ISO 1302 |

| Throughput | 5–20 parts/hour | 50–120 parts/hour | OEE ≥85% |

| Defect Rate Target | ≤0.5% | ≤0.05% | PPAP Level 3 |

This integrated approach transforms theoretical designs into field-ready components with uncompromised precision. By anchoring each phase to quantifiable metrics and automated verification, Wuxi Lead ensures your sheet metal parts perform reliably in the most demanding applications—without hidden costs from defects or delays. Contact our engineering team to initiate a DFM audit for your next project.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery for Unmatched 3D Fabrication Excellence

In the rapidly evolving landscape of industrial manufacturing, precision, scalability, and reliability are no longer optional—they are essential. At Wuxi Lead Precision Machinery, we specialize in high-end 3D fabrication services tailored to meet the exacting demands of global OEMs, engineering firms, and advanced technology integrators. As a trusted partner in sheet metal fabrication, we combine cutting-edge technology with decades of engineering expertise to deliver components and assemblies that exceed performance expectations.

Our facility in Wuxi, China, is equipped with state-of-the-art CNC punching, laser cutting, bending, and welding systems, enabling us to handle complex 3D fabrication projects from prototype to full-scale production. Whether you require intricate enclosures, structural frames, or custom chassis with tight tolerances, our end-to-end manufacturing capabilities ensure consistency, repeatability, and superior quality across every batch.

What sets us apart is our commitment to engineering collaboration. We don’t just manufacture parts—we partner with your team to optimize designs for manufacturability, reduce material waste, and accelerate time to market. Our engineers work closely with your specifications, offering DFM feedback and rapid prototyping to ensure every component performs as intended in real-world applications.

We serve industries where precision matters most—industrial automation, renewable energy, telecommunications, and advanced machinery—delivering parts that meet international standards for dimensional accuracy, surface finish, and structural integrity. With ISO 9001-certified processes and rigorous in-house quality control, including CMM inspection and first-article reporting, we ensure every product shipped is fully traceable and compliant.

Our 3D fabrication service integrates seamlessly with secondary operations such as powder coating, anodizing, silk screening, and hardware insertion, allowing us to deliver fully finished components ready for assembly. This turnkey approach minimizes supply chain complexity and reduces your total production costs.

For high-mix, low-volume projects or high-volume production runs, our scalable infrastructure and lean manufacturing principles ensure agility without sacrificing quality. We maintain strict data security and IP protection protocols, making us a secure offshore partner for innovation-driven enterprises.

Technical Capabilities Overview

| Parameter | Specification |

|---|---|

| Material Thickness Range | 0.5 mm – 25 mm (steel, stainless, aluminum, copper) |

| Laser Cutting Accuracy | ±0.1 mm |

| CNC Bending Tolerance | ±0.2°, ±0.1 mm |

| Maximum Part Size | 4000 mm × 2000 mm (laser), 3000 mm × 1500 mm (punch) |

| Welding Processes | MIG, TIG, Spot, Robotic Welding |

| Surface Treatments | Powder Coating, Anodizing, Passivation, Plating |

| Quality Standards | ISO 9001:2015, First Article Inspection, CMM |

Partner with Wuxi Lead Precision Machinery and experience the difference of a manufacturing ally dedicated to precision, performance, and partnership. To discuss your next 3D fabrication project, contact us at [email protected]. Let’s build the future—accurately, efficiently, together.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.