Technical Contents

Engineering Guide: Aluminum Electronics Enclosure

Engineering Insight Precision in Aluminum Electronics Enclosures

Achieving optimal performance in aluminum electronics enclosures demands uncompromising precision at every manufacturing stage. Beyond basic structural protection, these critical components must ensure electromagnetic interference (EMI) shielding integrity, precise thermal management pathways, flawless grounding points, and absolute dimensional stability under operational stress. Microscopic deviations in critical interfaces—such as mating surfaces for EMI gaskets, mounting holes for sensitive PCBs, or cooling fin geometries—directly compromise system reliability and functionality. Sub-micron repeatability in CNC machining is not merely desirable; it is the non-negotiable foundation for enclosures destined for aerospace, medical, defense, and high-frequency telecommunications applications where failure is not an option.

At Wuxi Lead Precision Machinery, our engineering philosophy centers on transforming aluminum billet into mission-critical enclosure solutions through rigorously controlled processes. We leverage advanced multi-axis CNC machining centers operating within ISO Class 7 cleanroom environments, coupled with in-process laser metrology systems that verify tolerances in real-time. This capability stems directly from our proven experience delivering enclosures meeting the extreme demands of Olympic broadcast infrastructure and classified military communication systems. For the Olympics, our enclosures ensured uninterrupted 4K/8K signal transmission under intense environmental variables, requiring hermetic sealing and thermal stability within 0.005mm tolerances. Military contracts demanded consistent EMI shielding effectiveness exceeding 100dB across 10MHz-10GHz ranges, achievable only through micron-level control of surface flatness and thread engagement for conductive gaskets.

Material science integration is equally vital. We optimize enclosure performance by precisely matching aluminum alloy selection (typically 6061-T6 or 7075-T6) to the application’s thermal, structural, and corrosion requirements, then applying controlled anodizing processes that maintain critical dimensional tolerances while enhancing surface hardness and dielectric properties. Every chamfer, radius, and counterbore is engineered to eliminate stress concentrations and ensure seamless integration with internal components. This holistic precision engineering approach eliminates costly field failures, reduces assembly time, and extends product lifecycle—delivering tangible ROI through operational reliability.

The following table outlines critical precision parameters we consistently achieve for high-end aluminum enclosures:

| Parameter | Standard Capability | Olympic/Military Grade | Measurement Method |

|---|---|---|---|

| Dimensional Tolerance | ±0.01 mm | ±0.005 mm | CMM (Calibrated to ISO 17025) |

| Surface Flatness | 0.02 mm/m | 0.008 mm/m | Optical Flat Interferometry |

| Hole Positional Accuracy | ±0.015 mm | ±0.008 mm | Laser Tracker |

| Anodizing Thickness | ±5 µm | ±2 µm | Eddy Current Probe |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm | Stylus Profilometer |

| EMI Shielding Effectiveness | 80 dB (100MHz-10GHz) | 100+ dB (10MHz-10GHz) | ASTM D4935 / MIL-STD-285 |

Precision in aluminum enclosure manufacturing is the invisible safeguard for electronic systems operating at the edge of performance. Wuxi Lead’s commitment to this standard, validated by the most demanding global projects, ensures your electronics operate with the reliability your reputation requires. We engineer precision not as a specification, but as a fundamental requirement for mission success.

Precision Specs & Tolerances

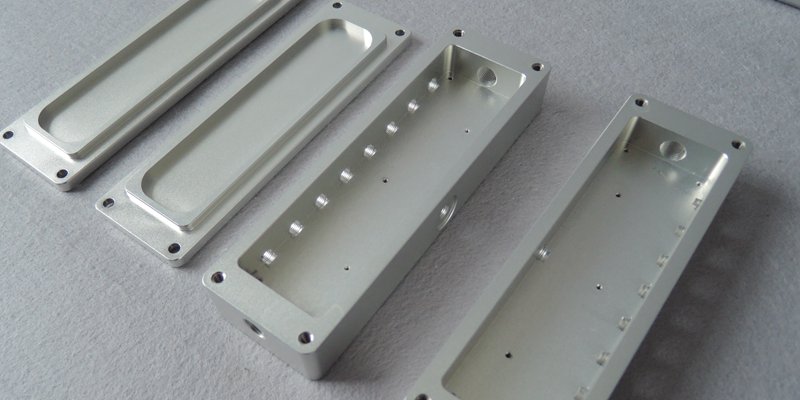

Wuxi Lead Precision Machinery delivers advanced manufacturing solutions for high-performance aluminum electronics enclosures, engineered to meet the stringent demands of industrial, medical, aerospace, and telecommunications applications. Our technical capabilities are built around precision, repeatability, and material optimization, ensuring each enclosure performs reliably in critical environments. At the core of our production workflow is 5-axis CNC machining, which enables complex geometries, tight tolerances, and superior surface finishes—all in a single setup. This reduces cumulative error, improves part consistency, and accelerates lead times for custom designs.

Our 5-axis CNC systems provide full simultaneous motion control across X, Y, Z, A, and B axes, allowing for undercuts, angled mounting features, and integrated heat dissipation channels without the need for secondary operations. This level of flexibility is essential for modern electronics enclosures, where space constraints, electromagnetic shielding, and thermal management require intricate design solutions. We work with high-grade aluminum alloys, including 6061-T6 and 7075-T6, selected for their strength-to-weight ratio, corrosion resistance, and excellent machinability. Material selection is supported by in-house metallurgical verification to ensure batch consistency and compliance with international standards.

Quality assurance is embedded throughout the manufacturing process. Every aluminum enclosure undergoes comprehensive inspection using a Zeiss DuraMax Bridge-type Coordinate Measuring Machine (CMM), enabling micron-level verification of critical dimensions, geometric tolerances, and positional accuracy. Our CMM routines are programmed to match customer CAD models, ensuring full traceability and first-article inspection (FAI) reporting when required. In addition to dimensional accuracy, we perform surface roughness testing, thread verification, and visual inspection under controlled lighting to detect surface anomalies.

All inspection data is documented in detailed quality reports, which are archived for full production traceability. Our quality management system is aligned with ISO 9001 standards, supporting consistent output across prototype, pilot, and full-volume production runs.

The following table outlines the standard technical specifications and achievable tolerances for our 5-axis CNC machined aluminum enclosures:

| Specification | Capability |

|---|---|

| Maximum Work Envelope | 1,200 mm × 800 mm × 600 mm |

| Positional Tolerance | ±0.01 mm |

| Dimensional Tolerance | ±0.02 mm |

| Geometric Tolerance (Flatness, Perpendicularity) | 0.03 mm per 100 mm |

| Surface Roughness (Ra) | As low as 0.8 µm (standard finish: 3.2 µm) |

| Minimum Wall Thickness (Aluminum) | 1.5 mm |

| Thread Sizes Supported | M2 to M16, standard and custom pitches |

| CMM Measurement Accuracy | ±2.5 + L/300 µm (L in mm) |

Wuxi Lead Precision Machinery combines advanced equipment, rigorous quality control, and deep materials expertise to deliver aluminum electronics enclosures that meet the highest standards of performance and reliability.

Material & Finish Options

Material Selection for High-Performance Aluminum Electronics Enclosures

Selecting the optimal material for electronics enclosures is a critical engineering decision impacting thermal management, EMI shielding, structural integrity, weight, and lifecycle cost. At Wuxi Lead Precision Machinery, our decades of CNC machining experience reveal aluminum—specifically 6061-T6 and 7075-T6 alloys—as the dominant choice for high-end applications. Its exceptional strength-to-weight ratio, inherent corrosion resistance, and superior thermal conductivity make it ideal for dissipating heat from sensitive components. Aluminum’s non-magnetic properties further ensure minimal EMI interference, a non-negotiable requirement in precision electronics. While steel offers higher tensile strength and lower material cost, its density increases weight significantly and requires additional coatings like powder coating for corrosion resistance, adding process complexity. Titanium excels in extreme environments demanding maximum strength and corrosion resistance, but its prohibitive cost and challenging machinability limit use to aerospace or defense applications where budget is secondary to performance. For 95% of commercial and industrial electronics enclosures, aluminum delivers the optimal balance of performance, manufacturability, and value.

Critical Role of Anodizing Finishes

Anodizing is not merely cosmetic; it is a functional enhancement essential for aluminum enclosures. This electrochemical process grows a durable, non-conductive oxide layer directly from the base metal, significantly improving surface hardness, wear resistance, and corrosion protection. Type II (sulfuric acid) anodizing provides standard corrosion resistance and dye acceptance for branding, while Type III (hardcoat) anodizing achieves thicknesses of 25–50μm for extreme abrasion resistance in harsh environments. Crucially, anodizing maintains aluminum’s thermal conductivity—unlike painted or powder-coated alternatives—which is vital for heat dissipation. At Wuxi Lead, we precision-control anodizing parameters to meet exacting specifications, ensuring consistent thickness, adhesion, and electrical insulation properties critical for electronics housing.

Comparative Material Specifications for Electronics Enclosures

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Machinability Rating | Relative Cost |

|---|---|---|---|---|---|

| Aluminum 6061-T6 | 2.7 | 310 | ★★★☆☆ | ★★★★☆ | 1.0x |

| Stainless Steel 304 | 8.0 | 505 | ★★★★☆ | ★★☆☆☆ | 1.8x |

| Titanium Grade 5 | 4.4 | 900 | ★★★★★ | ★★☆☆☆ | 5.0x+ |

Strategic Recommendation

Prioritize aluminum 6061-T6 for most applications, leveraging Type III anodizing where mechanical durability or extended outdoor exposure is required. Reserve steel for cost-sensitive, non-portable units where weight is irrelevant, and titanium only for mission-critical scenarios justifying its cost. Remember: improper finish selection can compromise thermal performance—always specify anodizing thickness and sealing method. Wuxi Lead’s engineering team collaborates with clients to validate material and finish choices against your specific environmental, electrical, and lifecycle requirements, ensuring globally competitive production without sacrificing precision. Consult our technical specialists to optimize your enclosure’s material strategy.

Manufacturing Process & QC

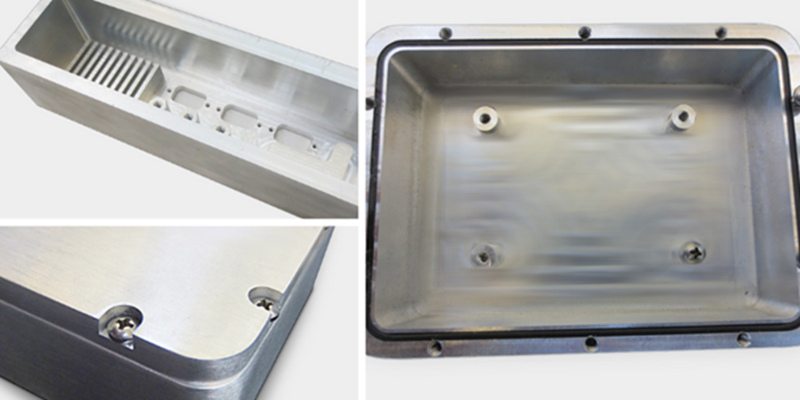

Design: Precision Engineering at the Foundation

The production of aluminum electronics enclosures begins with a rigorous design phase, where engineering precision meets functional necessity. At Wuxi Lead Precision Machinery, every enclosure is developed using advanced CAD/CAM software, ensuring dimensional accuracy and seamless integration with electronic components. Our engineering team collaborates closely with clients to analyze thermal management, electromagnetic shielding, structural integrity, and mounting requirements. Finite element analysis (FEA) is applied to simulate stress points and environmental durability, particularly for enclosures deployed in industrial or outdoor settings. Design for manufacturability (DFM) reviews are conducted to eliminate potential production flaws before any material is cut. This proactive approach ensures that the final design supports both performance and efficient manufacturing.

Prototyping: Validating Form, Fit, and Function

Once the design is finalized, we proceed to prototype development using high-precision CNC machining. Prototypes are produced from actual production-grade aluminum alloys—typically 6061-T6 or 7075-T6—ensuring that mechanical properties and surface finishes reflect the final product. Each prototype undergoes comprehensive inspection using coordinate measuring machines (CMM) and 3D scanning to verify tolerances within ±0.025 mm. Functional testing includes fit checks with PCBs, connectors, and thermal components, along with environmental exposure where required. Feedback from the prototype phase is systematically integrated into the design, minimizing risk during mass production. This iterative validation is critical to achieving zero defects in high-volume runs.

Mass Production: Consistency Through Automation and Control

With client-approved prototypes, we transition to mass production using automated CNC machining cells, stamping lines, and robotic deburring systems. Our facility in Wuxi operates under ISO 9001-certified quality management protocols, with real-time process monitoring to maintain consistency. Each enclosure is tracked through a digital manufacturing execution system (MES), enabling full traceability of materials, tooling, and inspection data. In-process inspections occur at critical stages, including post-machining, surface finishing (anodizing, powder coating, or brushing), and final assembly. All finished units are subjected to 100% visual inspection and batch sampling for dimensional compliance.

To ensure zero defects, we employ statistical process control (SPC) and root cause analysis for any deviation. Our lean manufacturing model minimizes waste while maximizing throughput, supporting scalable production from hundreds to hundreds of thousands of units annually.

Typical Material and Tolerance Specifications

| Parameter | Specification |

|---|---|

| Material Options | Aluminum 6061-T6, 7075-T6, 5052-H32 |

| Standard Tolerance | ±0.025 mm (machined), ±0.1 mm (stamped) |

| Surface Roughness (Ra) | 0.8–3.2 µm (machined), 0.4 µm (polished) |

| Anodizing Thickness | 10–25 µm (Type II or Type III as required) |

| Coating Adhesion | Passes ASTM D3359 cross-hatch test |

| Dimensional Inspection | CMM, optical comparator, laser scanning |

| Environmental Compliance | RoHS, REACH compliant; ISO 14001 certified |

Through integrated design, validated prototyping, and tightly controlled mass production, Wuxi Lead ensures every aluminum electronics enclosure meets the highest standards of performance and reliability.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised Aluminum Electronics Enclosure Solutions

In the demanding realm of high-performance electronics, the enclosure is far more than a protective shell; it is a critical engineering component governing thermal management, EMI/RFI shielding, structural integrity, and product longevity. Selecting a manufacturing partner capable of translating complex design requirements into flawless, high-tolerance aluminum housings demands proven expertise and unwavering commitment to precision. At Wuxi Lead Precision Machinery, we specialize exclusively in the intricate challenges of custom aluminum electronics enclosures, serving global leaders in telecommunications, medical devices, industrial automation, and defense systems. Our decades of focused experience in CNC milling, turning, and finishing ensure your enclosure meets the exacting standards your application requires, from initial prototype through high-volume production.

We understand the nuanced requirements inherent in electronics packaging. Achieving optimal thermal dissipation pathways, maintaining strict electromagnetic compatibility (EMC), ensuring seamless gasket integration for environmental sealing, and hitting micron-level tolerances on critical mounting features are non-negotiable. Our engineering team collaborates closely with your design staff from the outset, conducting thorough Design for Manufacturability (DFM) reviews to optimize part geometry, material selection, and process flow. This proactive partnership prevents costly iterations, accelerates time-to-market, and guarantees the final component performs flawlessly within your integrated system. Our ISO 9001-certified processes, utilizing state-of-the-art Haas and DMG MORI CNC centers, provide the repeatability and traceability essential for mission-critical applications.

Our core strength lies in delivering complex, high-value enclosures with exceptional consistency, regardless of order size. We eliminate the barriers often associated with offshore manufacturing through transparent communication, rigorous quality control, and a deep understanding of international engineering standards. Below represents our standard capability envelope for aluminum electronics enclosures; we routinely exceed these parameters for specialized projects.

| Specification Category | Capability Range |

|---|---|

| Material Grades | 6061-T6, 6063-T5, 7075-T6, Custom Alloys |

| Dimensional Range | 50mm x 50mm x 20mm up to 800mm x 600mm x 400mm |

| Standard Tolerance | ±0.025mm (Machined Features) |

| Precision Tolerance | ±0.005mm (Critical Features, Controlled Environment) |

| Surface Finish (Machined) | Ra 0.8µm standard; Ra 0.4µm achievable |

| Anodizing | Type II (Clear/Black), Type III (Hard Coat) up to 50µm thickness |

| Environmental Rating | IP65, IP67 achievable with proper design & sealing |

| Secondary Operations | Precision Tapping, Hardware Insertion, Laser Marking, EMI Gasket Grooves |

Partnering with Wuxi Lead Precision means gaining a true engineering extension of your team. We solve the toughest manufacturing challenges in aluminum enclosure production, providing not just parts, but validated solutions that enhance your product’s performance and reliability. Our commitment to quality, technical agility, and responsive service ensures your project succeeds on schedule and to the highest global standards. Do not compromise on the foundation of your electronic system. Contact our engineering sales team today to discuss your specific enclosure requirements and discover how our precision manufacturing capabilities can elevate your next project. Initiate an engineer-to-engineer consultation by emailing [email protected]. Let us demonstrate why global innovators trust Lead Precision for their most demanding aluminum enclosure needs.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.