Technical Contents

Engineering Guide: Cnc Machinging

Engineering Insight Precision as the Non-Negotiable Foundation of CNC Machining

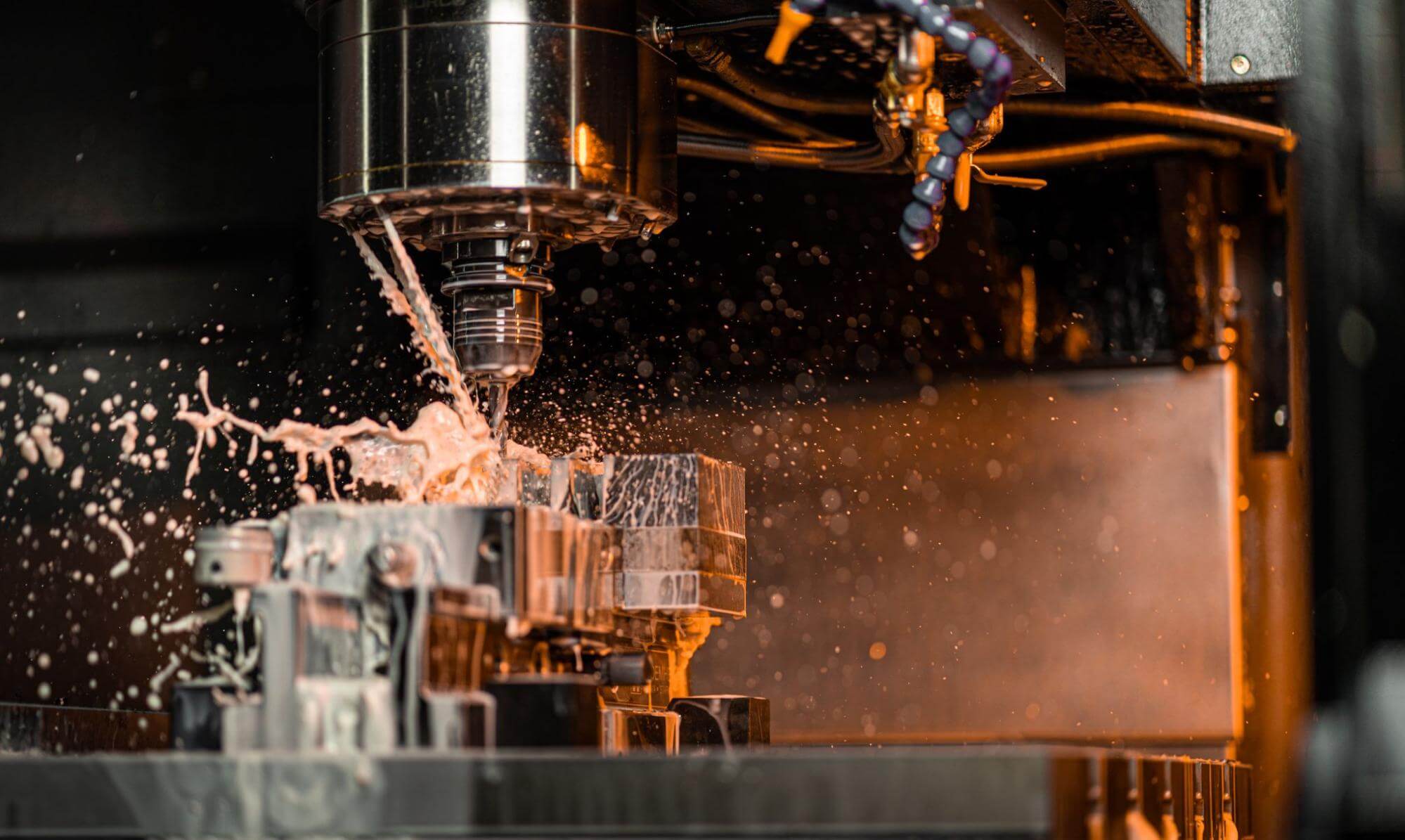

In high-stakes manufacturing, precision transcends mere dimensional tolerance; it is the critical enabler of functionality, reliability, and ultimate product success. Achieving true precision in CNC machining demands far more than advanced machinery alone. It requires a holistic engineering discipline encompassing meticulous material science understanding, sophisticated thermal management strategies, vibration control, cutting tool optimization, and rigorous process validation. Minute deviations, often measured in microns, can cascade into catastrophic field failures for components operating under extreme stress, high speeds, or in critical assemblies. The cost of imprecision extends beyond immediate scrap or rework; it manifests in accelerated wear, compromised safety margins, increased warranty claims, and irreparable damage to a brand’s reputation for quality. For mission-critical applications, precision is not a target – it is the absolute baseline requirement.

Wuxi Lead Precision Machinery operates at this uncompromising standard. Our engineering philosophy is forged through direct experience delivering components where failure is not an option. We have engineered and manufactured precision parts for infrastructure supporting the Olympic Games, demanding flawless performance under intense global scrutiny and immense structural loads. Furthermore, we hold and consistently meet stringent specifications for defense and aerospace sectors, where adherence to military-grade tolerances (often exceeding ISO 2768-mK or customer-specific MIL-STD requirements) is mandated for operational safety and national security. This experience instills a unique operational rigor, embedding precision into every stage from initial design consultation through final inspection and traceability.

Our capability to consistently deliver this level of precision is underpinned by significant investment in advanced technology and stringent process control. The following specifications represent the core performance envelope achievable across our primary machining platforms for critical features:

| Specification Parameter | Typical Performance Level | Measurement Standard |

|---|---|---|

| Positioning Accuracy (X, Y, Z) | ±0.002 mm | ISO 230-2 (2014) |

| Repeatability (X, Y, Z) | ±0.001 mm | ISO 230-2 (2014) |

| Spindle Runout (TIR) | ≤ 0.0015 mm | At spindle nose, 150mm |

| Thermal Compensation System | Active, Multi-point | Real-time spindle/axis |

| Standard Inspection Equipment | CMM (0.5 + L/500) µm | ASME B89.4.1024 |

This technical capability, validated daily on projects demanding Olympic and military-grade reliability, translates directly to tangible client value. Precision machining minimizes assembly difficulties, reduces field failures, extends product lifecycle, and ultimately lowers the total cost of ownership. At Wuxi Lead Precision Machinery, we understand that your component’s performance is our legacy. We engineer precision not as a specification to meet, but as the fundamental guarantee of your product’s success in the most demanding global markets. Partnering with us ensures your most critical components are manufactured to the exacting standards where performance and reliability are non-negotiable.

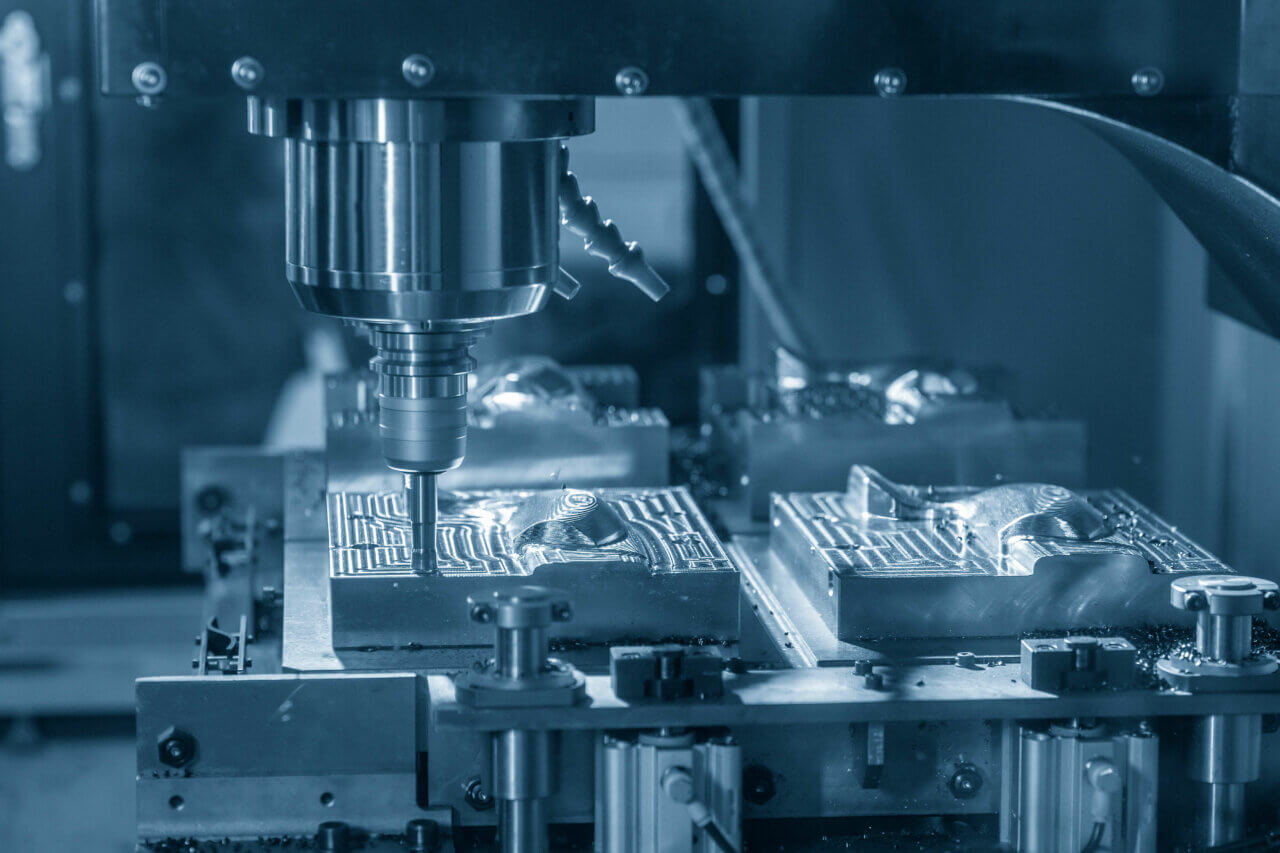

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in precision CNC machining, engineered to meet the stringent demands of high-performance industries such as aerospace, medical, automotive, and industrial automation. At the core of our manufacturing excellence is a modern fleet of 5-axis CNC machining centers, enabling us to produce complex geometries with superior accuracy and reduced setup times. These multi-axis systems allow simultaneous movement across five planes, facilitating the machining of intricate contours, deep cavities, and organic forms that are unattainable with conventional 3-axis equipment. This capability ensures minimal part handling, improved repeatability, and enhanced surface finishes—critical for mission-critical components.

Our 5-axis machining platforms are operated by certified CNC programmers and machinists who utilize industry-leading CAM software to optimize toolpaths, reduce cycle times, and maintain tight tolerances throughout production. We support a broad range of engineering-grade materials, including aluminum alloys, stainless steels, titanium, Inconel, and high-performance plastics such as PEEK and ULTEM. Each machining process is meticulously planned to preserve material integrity, minimize thermal distortion, and achieve the desired mechanical properties.

Quality control is integrated at every stage of production. All critical components undergo comprehensive inspection using a Zeiss DuraMax and Contura G2 Coordinate Measuring Machine (CMM), ensuring dimensional compliance with design specifications. Our CMM system provides micron-level measurement accuracy and generates full inspection reports, including GD&T analysis, for full traceability. In addition to CMM, we employ optical comparators, surface roughness testers, and calibrated hand tools to validate part conformance across all critical features.

The following table outlines the standard precision tolerances achievable across common machining operations at Wuxi Lead Precision Machinery:

| Feature | Standard Tolerance | Precision Capability | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.005 mm | Depending on part size and geometry |

| Hole Diameter | ±0.01 mm | ±0.005 mm | Reamed or honed features |

| Positional Tolerance | ±0.02 mm | ±0.01 mm | Per GD&T standards |

| Flatness | 0.02 mm per 100 mm | 0.005 mm per 100 mm | Verified on granite surface plate |

| Surface Roughness (Ra) | 3.2 µm | 0.4 µm | Achieved via fine finishing passes |

| Angular Features | ±0.05° | ±0.02° | On 5-axis indexed or simultaneous machining |

These tolerances reflect our commitment to precision and consistency, with the ability to exceed standard industry benchmarks when required. Our technical team collaborates closely with clients during the design-for-manufacturability (DFM) phase to optimize part geometry, material selection, and tolerance allocation—ensuring cost-effective production without compromising performance. With integrated 5-axis CNC machining and rigorous CMM-based quality assurance, Wuxi Lead Precision Machinery provides a reliable, scalable solution for high-complexity precision components in low to mid-volume production runs.

Material & Finish Options

Strategic Material Selection for Precision CNC Machining

Material selection fundamentally impacts part performance, manufacturability, and total cost in precision CNC machining. At Wuxi Lead Precision Machinery, we guide clients through this critical decision, focusing on application requirements, environmental factors, and production economics. Aluminum, steel, and titanium represent core material families for high-performance components, each offering distinct advantages and machining considerations. Choosing correctly ensures optimal function, longevity, and value.

Aluminum alloys, particularly 6061-T6 and 7075-T6, dominate aerospace, electronics, and consumer goods due to their exceptional strength-to-weight ratio, inherent corrosion resistance, and excellent machinability. These alloys cut cleanly at high speeds, minimizing tool wear and enabling complex geometries. Aluminum’s thermal conductivity also benefits heat-sensitive applications. While strong, aluminum lacks the ultimate strength and wear resistance of hardened steels, making it less suitable for high-stress wear surfaces without secondary treatments.

Steel variants, including 4140, 4340, and 17-4 PH stainless, provide superior strength, hardness, and wear resistance essential for tooling, automotive drivetrains, and structural components. Carbon and alloy steels offer excellent weldability and fatigue resistance. Stainless grades like 304 and 316 add critical corrosion resistance for medical and marine environments. Machining steel generally requires more robust tooling, lower speeds, and higher torque compared to aluminum, impacting cycle times and cost. Heat treatment is often necessary post-machining to achieve final mechanical properties.

Titanium Grade 5 (Ti-6Al-4V) is the aerospace and medical implant material of choice, offering an unparalleled strength-to-weight ratio combined with outstanding corrosion resistance and biocompatibility. However, its low thermal conductivity and high chemical reactivity present significant machining challenges. Titanium generates intense heat at the cutting edge, demanding specialized tool geometries, rigid setups, precise coolant application, and controlled feed rates to prevent work hardening and tool failure. This complexity inherently increases production costs.

The following table summarizes key comparative specifications for common grades:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Machinability Rating | Primary Applications |

|---|---|---|---|---|

| Aluminum 6061-T6 | 2.7 | 310 | Excellent (Machining Index 100) | Enclosures, brackets, heat sinks |

| Steel 4140 | 7.85 | 655 | Good (Machining Index 65) | Shafts, gears, structural parts |

| Titanium Ti-6Al-4V | 4.43 | 900 | Fair (Machining Index 30) | Aircraft components, medical implants |

Surface finishing significantly enhances performance and aesthetics. Anodizing is the premier finish for aluminum, creating a durable, corrosion-resistant oxide layer that can be dyed for identification. Type II (sulfuric acid) anodizing offers good wear resistance for general use, while Type III (hardcoat) anodizing provides exceptional hardness and abrasion resistance for demanding applications. Proper masking and process control are essential for critical dimensions and sealing requirements.

Selecting the optimal material and finish requires balancing technical demands with production realities. Wuxi Lead Precision Machinery leverages deep metallurgical expertise and advanced multi-axis CNC systems to machine these challenging materials to stringent tolerances. We partner with clients from the design phase to ensure material choices align with functional needs and manufacturability, delivering components that meet the highest standards of precision and reliability. Contact our engineering team to determine the ideal solution for your specific application.

Manufacturing Process & QC

From Concept to Consistency: The CNC Machining Production Process at Wuxi Lead Precision Machinery

At Wuxi Lead Precision Machinery, our production process is engineered for precision, repeatability, and zero defects. We follow a disciplined progression from design through prototyping to full-scale mass production, ensuring every component meets the highest standards of quality and performance. This structured approach enables us to deliver complex, high-tolerance parts for industries such as aerospace, medical devices, and advanced automation.

The process begins with design integration. Our engineering team collaborates closely with clients to review CAD models, perform Design for Manufacturability (DFM) analysis, and optimize geometries for CNC machining. Material selection, tolerances, surface finishes, and critical features are evaluated at this stage to eliminate potential production issues before metal is cut. Using advanced simulation software, we validate toolpaths and detect collisions or stress points virtually, reducing risk and accelerating time-to-market.

Next comes prototyping, a critical phase for verification. We produce a small batch of functional prototypes using the same CNC equipment and materials intended for mass production. This ensures consistency across stages and allows for real-world testing of fit, form, and function. Our prototyping cycle includes rigorous in-process inspections using coordinate measuring machines (CMM), optical comparators, and surface roughness testers. Feedback from this phase is used to fine-tune programs and fixturing, guaranteeing that the final design is not only manufacturable but also reliable under operational conditions.

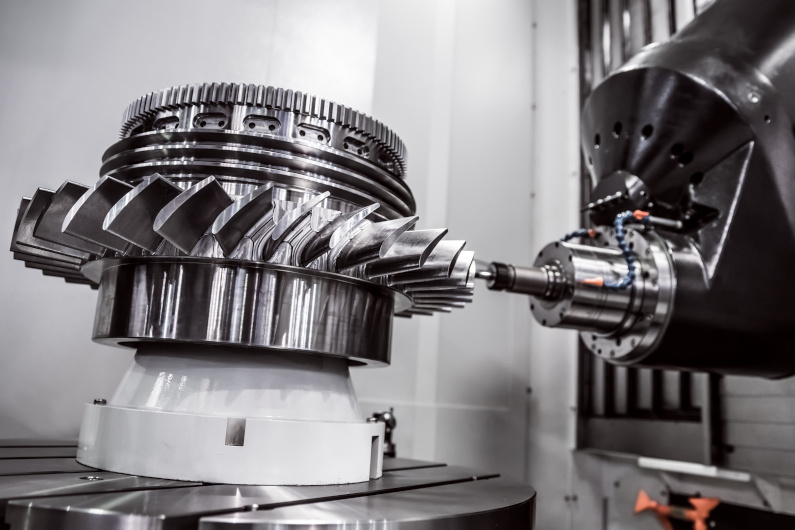

Once approved, the project transitions into high-volume CNC machining. Our facility in Wuxi operates a fleet of multi-axis CNC mills, turning centers, and Swiss-style machines, all maintained to strict calibration standards. Production runs are supported by automated tool management systems, real-time process monitoring, and Statistical Process Control (SPC) to detect deviations instantly. Every part undergoes 100% dimensional inspection on critical features, with batch sampling for full certification. Our quality management system is ISO 9001 certified, and we maintain full traceability from raw material to final shipment.

To support consistent output, we define key process parameters clearly. The following table outlines typical capabilities and tolerances achieved across our production lines:

| Parameter | Typical Capability |

|---|---|

| Machining Tolerances | ±0.005 mm |

| Surface Roughness (Ra) | 0.4 – 3.2 μm |

| Maximum Work Envelope | 1200 x 800 x 600 mm |

| Materials Supported | Aluminum, Stainless Steel, Titanium, Brass, Engineering Plastics |

| Spindle Speed Range | Up to 24,000 rpm |

| Positioning Accuracy | ±0.002 mm |

| Production Volume Range | 1 – 100,000+ units |

Our zero-defect philosophy is not aspirational—it is operational. By integrating precision engineering, continuous monitoring, and closed-loop feedback across all stages, Wuxi Lead Precision Machinery ensures that every component shipped performs exactly as designed, every time.

Why Choose Wuxi Lead Precision

Elevate Your Manufacturing Partnership with Lead Precision

Precision manufacturing partnerships succeed or fail at the specification handoff. At Wuxi Lead Precision Machinery, we engineer collaboration into every process—transforming complex designs into mission-critical components with zero compromise. For global OEMs in aerospace, medical, and energy sectors, tolerances below ±0.001mm and material integrity are non-negotiable. Our facility in Wuxi operates as your seamless extension, merging German-engineered machinery with China’s most rigorous quality protocols. We eliminate the guesswork in high-stakes production, ensuring your components meet AS9100 and ISO 13485 standards without schedule disruption.

Our technical infrastructure delivers what generic shops cannot. Below are core capabilities defining our partnership value:

| Capability | Specification | Relevance for Critical Applications |

|---|---|---|

| Max Work Envelope | 1,200 x 800 x 650 mm | Large-scale structural components |

| Positioning Accuracy | ±0.001 mm | Aerospace hydraulic manifolds |

| Surface Finish | Ra 0.2 µm | Medical implant interfaces |

| Material Range | Titanium, Inconel, PEEK | Extreme-environment performance |

| Quality Certification | ISO 9001:2015, ITAR | Defense and regulated industry compliance |

| Lead Time Reduction | 30% vs. industry avg. | Accelerated time-to-market |

This precision is sustained through closed-loop metrology systems and real-time SPC analytics—no batch surprises. Our engineers proactively identify manufacturability risks during your design phase, reducing scrap rates by up to 22%. Unlike offshore vendors reliant on manual oversight, Lead Precision integrates your PLM data directly into our Siemens NX workflow, ensuring digital continuity from CAD model to certified part.

Partnering with us means accessing a strategic manufacturing hub where geopolitical complexity becomes your advantage. We manage export controls, customs documentation, and DDP shipping terms—so your supply chain remains insulated from regional volatility. Our facility’s 24/7 production cells, staffed by certified Haas and DMG MORI technicians, guarantee on-time delivery even for 500+ part runs.

The next component you outsource must perform flawlessly. Contact our engineering team directly at [email protected] to initiate a capability assessment. Include your project specifications and target timeline—we respond within 4 business hours with a feasibility analysis and process flowchart. Do not settle for vendors who treat precision as a commodity. Lead Precision engineers trust through execution. Your blueprint, our discipline, zero deviations.

Wuxi Lead Precision Machinery: Where Global Standards Meet Asian Efficiency.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.