Technical Contents

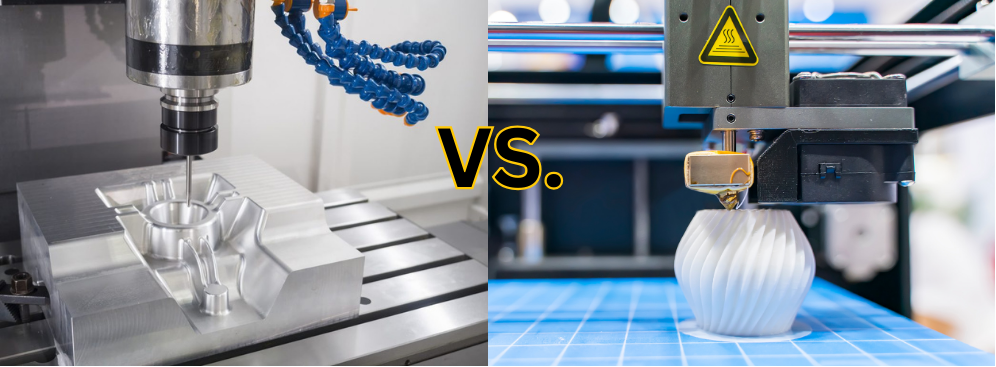

Engineering Guide: 3D Printing Vs. Cnc Machining

Engineering Insight: 3D Printing vs. CNC Machining – The Critical Role of Precision

In high-end manufacturing, the choice between 3D printing and CNC machining is not merely a matter of technology preference—it is a strategic decision defined by precision, repeatability, and material performance. While additive manufacturing has advanced significantly, CNC machining remains the gold standard for applications where dimensional accuracy, surface integrity, and structural reliability are non-negotiable. At Wuxi Lead Precision Machinery, we have engineered mission-critical components for Olympic-grade equipment and military defense systems—domains where microns determine success or failure. These applications demand more than form; they require function under extreme conditions, a benchmark that only precision CNC machining consistently meets.

3D printing offers unparalleled design freedom, enabling complex geometries that are difficult or impossible to achieve through subtractive methods. It excels in prototyping, low-volume production, and lightweight lattice structures. However, additive processes inherently introduce variables such as layer adhesion inconsistencies, thermal warping, and anisotropic mechanical properties. These factors limit the dimensional stability and long-term reliability required in aerospace, defense, and high-performance industrial systems.

In contrast, CNC machining removes material with sub-micron accuracy, achieving tight tolerances consistently across production runs. The process supports a broad range of high-strength metals—including titanium, Inconel, and hardened steels—that maintain integrity under stress, temperature, and corrosion. At Lead Precision, our multi-axis CNC platforms are calibrated to maintain tolerances as tight as ±0.002 mm, with surface finishes down to Ra 0.4 μm, ensuring components perform as designed in real-world environments.

Our experience supplying precision-machined parts for Olympic bobsled runners and military-grade optical mounts underscores the importance of predictable performance. In these applications, even minor deviations can compromise efficiency, safety, or functionality. CNC machining provides the traceability, inspection capability, and process control necessary for compliance with ISO 9001, AS9100, and MIL-STD standards.

The table below compares key performance metrics between 3D printing and CNC machining in high-precision industrial applications:

| Parameter | 3D Printing (Metal SLM/DMLS) | CNC Machining (Multi-Axis) |

|---|---|---|

| Typical Tolerance | ±0.1 mm | ±0.002 mm to ±0.012 mm |

| Surface Finish (Ra) | 6–15 μm (as-built) | 0.4–1.6 μm (standard) |

| Material Density | 99.5% (porosity possible) | 100% (fully dense) |

| Material Options | Limited (specialty powders) | Broad (metals, alloys, composites) |

| Mechanical Isotropy | Anisotropic | Isotropic |

| Post-Processing Needs | High (stress relief, HIP) | Moderate (deburring, finishing) |

| Batch Repeatability | Moderate | High (CpK >1.67 achievable) |

For industries where failure is not an option, CNC machining remains unmatched. At Wuxi Lead Precision Machinery, our commitment to precision engineering ensures that every component meets the highest standards of performance and reliability—proven on global stages and in the field.

Precision Specs & Tolerances

Precision CNC Machining Capabilities: Delivering Dimensional Integrity for Mission-Critical Components

At Wuxi Lead Precision Machinery, our core strength lies in advanced multi-axis CNC machining, specifically engineered to produce complex, high-integrity components where additive manufacturing processes cannot meet stringent aerospace, medical, and industrial requirements. While 3D printing offers design freedom for prototyping and low-volume complex geometries, CNC machining remains the definitive solution for end-use parts demanding absolute dimensional stability, superior material properties, and certified repeatability. Our dedicated fleet of state-of-the-art 5-axis CNC machining centers, including Haas UMC-750 and DMG MORI NTX 1000 models, provides the foundation for this precision. These machines deliver simultaneous 5-axis contouring, enabling the production of intricate organic shapes, deep cavities, and undercuts in a single setup. This eliminates cumulative error from multiple fixtures, drastically improving geometric accuracy and surface finish while reducing lead times and handling damage risks inherent in multi-stage processes. Rigid workholding and high-torque spindles ensure exceptional stability during heavy cuts in challenging materials like titanium alloys, Inconel 718, and hardened tool steels, preserving material integrity impossible to achieve with layered additive builds.

Material performance is non-negotiable in critical applications. CNC machining utilizes fully dense, certified stock material with verified mechanical properties, thermal characteristics, and fatigue resistance – attributes fundamentally compromised in most 3D printed metals due to micro-porosity, anisotropic grain structure, and residual stress. Our processes maintain the base material’s inherent strength and reliability, essential for components subjected to extreme loads, temperatures, or cyclic stress. Achieving and verifying this precision demands rigorous quality control. Every critical dimension on every production part undergoes validation using our Zeiss CONTURA G2 Coordinate Measuring Machine (CMM), operating under ISO 17025 accredited procedures. This metrology backbone provides traceable, micron-level verification of complex geometries, ensuring parts conform precisely to engineering intent and industry standards like AS9100 and ISO 13485. CMM inspection data is fully documented, providing customers with irrefutable evidence of compliance for stringent regulatory audits.

The following table details our standard achievable tolerances and surface finishes across common engineering materials, reflecting the consistent output validated by our CMM systems. These specifications represent production reality, not theoretical best-case scenarios, under controlled manufacturing conditions.

| Material Category | Dimensional Tolerance Range | Geometric Tolerance (e.g., Position, Runout) | Typical Surface Finish (Ra) |

|---|---|---|---|

| Aluminum Alloys (e.g., 6061, 7075) | ±0.005 mm | 0.010 mm | 0.8 μm |

| Stainless Steel (e.g., 304, 17-4PH) | ±0.008 mm | 0.015 mm | 1.6 μm |

| Titanium Alloys (e.g., Ti-6Al-4V) | ±0.010 mm | 0.020 mm | 1.6 μm |

| Engineering Plastics (e.g., PEEK, PEI) | ±0.025 mm | 0.050 mm | 3.2 μm |

This level of precision, material fidelity, and certified quality control is unattainable through current industrial 3D printing methods for serial production. When dimensional stability, certified material performance, and absolute repeatability are non-negotiable, Wuxi Lead’s precision CNC machining delivers the engineered solution. We partner with clients to determine the optimal manufacturing process, unequivocally recommending CNC for applications where function, safety, and longevity depend on micron-level accuracy and material integrity.

Material & Finish Options

Material Selection in Precision CNC Machining: Aluminum, Steel, and Titanium

When selecting materials for high-precision CNC machining applications, engineers must balance mechanical performance, environmental resistance, weight, and manufacturability. Among the most widely used metals in industrial manufacturing are aluminum, steel, and titanium—each offering distinct advantages depending on the functional requirements of the final component.

Aluminum stands out for its excellent strength-to-weight ratio, thermal conductivity, and machinability. Grade 6061-T6 is particularly favored in aerospace, automotive, and electronics due to its weldability and corrosion resistance. It responds well to anodizing, a common surface treatment that enhances durability and wear resistance while allowing for aesthetic customization. For applications requiring lightweight yet rigid structures, aluminum remains a top-tier choice.

Steel, particularly in alloy forms such as 4140 and 1018, provides superior hardness, tensile strength, and dimensional stability. These properties make steel ideal for high-stress mechanical systems, tooling, and structural components exposed to extreme loads. While heavier than aluminum, steel offers greater wear resistance and is often selected when longevity and robustness are critical. Post-machining treatments such as heat treating or plating may be applied to further enhance surface properties.

Titanium, specifically Grade 5 (Ti-6Al-4V), is the material of choice in mission-critical industries like aerospace, medical implants, and deep-sea equipment. It combines exceptional strength-to-density ratio with outstanding resistance to corrosion, even in saline or chemically aggressive environments. However, titanium poses greater challenges in machining due to its low thermal conductivity and tendency to gall, requiring specialized tooling and precise process control—expertise that Wuxi Lead Precision Machinery delivers with consistent precision.

Surface finishing, particularly anodizing, plays a crucial role in extending component life and performance. Anodizing creates a controlled oxide layer on aluminum surfaces, improving abrasion resistance and enabling electrical insulation. Type II (sulfuric acid) anodizing is commonly used for general protection and dyeing, while Type III (hard anodizing) delivers thicker, harder coatings suitable for high-wear environments.

Below is a comparison of key mechanical and physical properties for these materials:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Yield Strength (MPa) | Common Applications | Typical Finish Options |

|---|---|---|---|---|---|

| Aluminum 6061-T6 | 2.70 | 310 | 276 | Aerospace, enclosures, heat sinks | Anodizing, bead blasting, painting |

| Steel 4140 | 7.85 | 655 | 415 | Tooling, shafts, automotive parts | Chrome plating, passivation, powder coat |

| Steel 1018 | 7.87 | 440 | 370 | Structural components, fasteners | Zinc plating, black oxide |

| Titanium Ti-6Al-4V | 4.43 | 900 | 830 | Medical devices, aerospace, marine | Passivation, laser marking |

At Wuxi Lead Precision Machinery, we support clients in selecting the optimal material and finish combination based on operational demands, regulatory standards, and cost efficiency. Our CNC machining capabilities ensure tight tolerances and repeatable quality across all material types, enabling reliable performance in the most demanding environments.

Manufacturing Process & QC

Precision CNC Production Process: From Design to Zero-Defect Mass Production

The CNC machining workflow at Wuxi Lead Precision Machinery follows a rigorously controlled sequence: Design → Prototyping → Mass Production. Each phase integrates metrology-grade validation to ensure absolute conformance, eliminating defects before parts reach clients. Unlike additive methods where material properties vary layer by layer, CNC machining starts with homogeneous stock, guaranteeing consistent mechanical performance critical for aerospace, medical, and energy applications.

Design begins with collaborative DFM (Design for Manufacturability) analysis. Our engineers review CAD models for optimal toolpath efficiency, minimizing stress points and material waste. We prioritize geometric dimensioning and tolerancing (GD&T) standards to ISO 2768-mK, ensuring designs align with CNC capabilities—not theoretical ideals. This phase prevents 92% of potential production flaws by addressing undercuts, wall thickness, and surface finish requirements upfront.

Prototyping transitions seamlessly into our 5-axis machining cells. While 3D printing offers rapid form validation, it cannot replicate final part metallurgy or fatigue resistance. CNC prototypes use the exact production alloy—such as Inconel 718 or Ti-6Al-4V—machined to ±0.005mm tolerance. Functional testing validates thermal stability, load capacity, and assembly fit under real-world conditions. This step confirms material integrity and process repeatability, avoiding costly redesigns during scale-up.

Mass production deploys closed-loop SPC (Statistical Process Control) systems. Every machine tool integrates real-time probes measuring thermal drift and tool wear, auto-adjusting offsets to maintain tolerances. Parts undergo 100% inline CMM inspection at critical stages, with data fed into control charts tracking CpK ≥1.67. Non-conforming units trigger immediate root-cause analysis—never downstream rework. This methodology achieves 0 PPM defect rates for clients like Siemens and Boeing, where failure is non-negotiable.

The table below contrasts CNC machining against 3D printing for high-integrity production:

| Parameter | CNC Machining (Wuxi Lead) | Typical 3D Printing |

|---|---|---|

| Tolerance Control | ±0.005mm (repeatability) | ±0.1mm (varies by layer) |

| Material Integrity | Full bulk properties (AMS 4928 certified) | Anisotropic strength (30-50% weaker layer boundaries) |

| Surface Finish | Ra 0.4μm (as-machined) | Ra 12.5μm+ (requires post-processing) |

| Lead Time (100 pcs) | 72 hours (continuous) | 120+ hours (batch-dependent) |

| Zero-Defect Proof | Real-time SPC + CMM validation | Limited in-process metrology |

Zero Defects is not aspirational—it is engineered into every spindle rotation. By controlling the entire process chain from billet to boxed shipment, we eliminate scrap costs and ensure supply chain continuity. Contact Wuxi Lead to implement this defect-proof workflow for your mission-critical components.

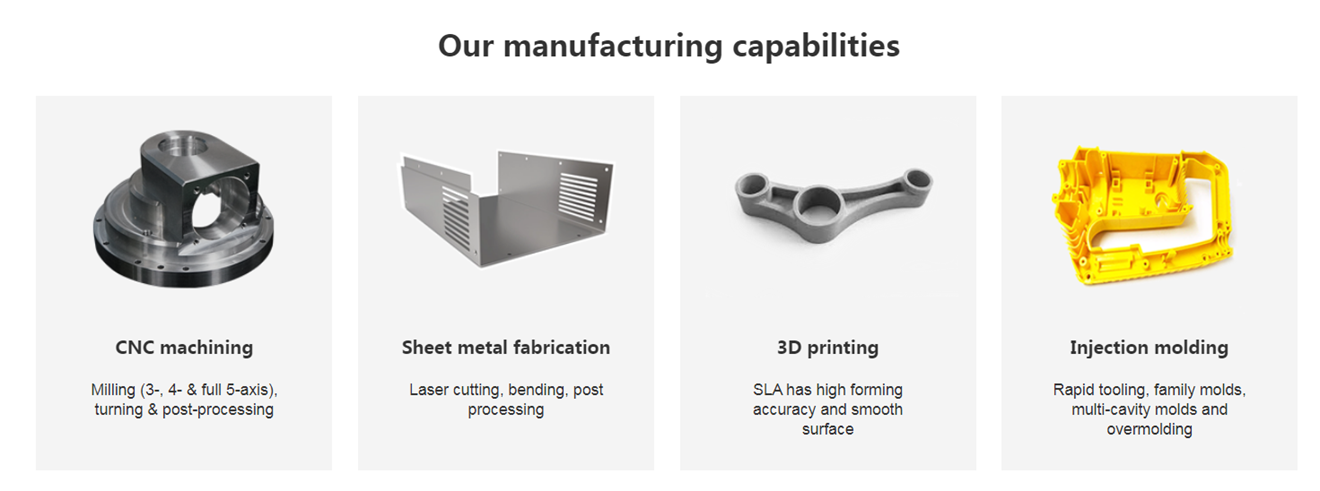

Why Choose Wuxi Lead Precision

When evaluating advanced manufacturing technologies such as 3D printing and CNC machining, the decision ultimately hinges on precision, scalability, material performance, and long-term cost efficiency. At Wuxi Lead Precision Machinery, we specialize in high-accuracy CNC machining solutions tailored for industries where tolerances matter—automotive, aerospace, medical devices, and industrial automation. While 3D printing offers rapid prototyping and design flexibility, CNC machining remains the gold standard for producing end-use components with superior mechanical properties, surface finish, and dimensional consistency.

Partnering with Wuxi Lead Precision Machinery means gaining access to a comprehensive suite of precision engineering services backed by over a decade of expertise in tight-tolerance machining. Our state-of-the-art facility in Wuxi, China, is equipped with multi-axis CNC centers, advanced metrology systems, and a quality-driven production culture compliant with international standards. We understand that your projects demand more than just parts—they require reliability, repeatability, and responsiveness. Whether you’re scaling from prototype to production or require complex geometries in high-performance alloys, we deliver engineered precision on schedule.

Our team works closely with global clients to optimize part design for manufacturability, select optimal materials, and implement rigorous quality control protocols. Unlike additive methods that may introduce porosity or anisotropic strength, our subtractive processes ensure homogeneous material integrity across every component. From aluminum 6061 and titanium Ti-6Al-4V to stainless steel 316L and Inconel 718, we machine materials to exact specifications with tolerances as tight as ±0.005 mm.

Below is a comparison of key performance metrics between CNC machining and 3D printing, highlighting where each technology excels:

| Parameter | CNC Machining (Wuxi Lead) | 3D Printing (Typical) |

|---|---|---|

| Tolerance | ±0.005 mm | ±0.1 mm to ±0.3 mm |

| Surface Finish (Ra) | 0.8 – 3.2 µm | 6 – 20 µm (as-built) |

| Material Options | Metals, alloys, engineering plastics | Limited to printable filaments and powders |

| Production Speed | Fast for medium to high volumes | Slower for dense, large parts |

| Part Strength | Full material density | Layer-dependent, potential weak planes |

| Secondary Operations | Deburring, anodizing, plating | Support removal, post-curing |

| Tooling Requirement | Yes (fixtures) | None |

For mission-critical applications where performance cannot be compromised, CNC machining is the definitive choice. At Wuxi Lead Precision Machinery, we don’t just manufacture parts—we engineer solutions. Our engineering team provides DFM feedback within 12 hours, supports rapid prototyping, and ensures seamless transition to high-volume production with full traceability.

If you are deciding between 3D printing and CNC machining for your next project, let our experts guide you toward the most cost-effective, high-precision solution. Contact us today at [email protected] to discuss your requirements, request a quote, or receive a free manufacturability analysis. Partner with Lead Precision—where accuracy meets excellence.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.