Technical Contents

Engineering Guide: Parts On Demand

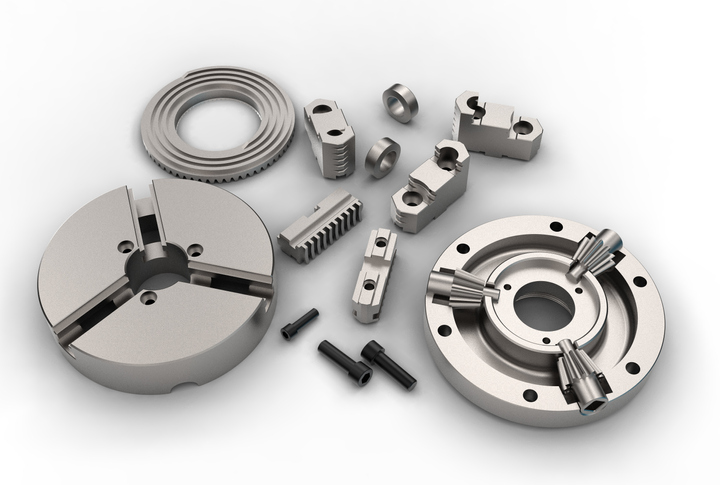

Engineering Insight: Precision as the Non-Negotiable Core of On-Demand Manufacturing

In the high-stakes realm of custom metal manufacturing, particularly for on-demand parts, precision transcends mere specification; it is the fundamental determinant of functional integrity, safety, and ultimate project success. When components are required rapidly to keep critical operations moving – whether for aerospace assembly lines, medical device servicing, or defense logistics – dimensional accuracy and repeatability cannot be compromised. A tolerance stack-up error measured in microns can cascade into catastrophic system failure or costly downtime. True on-demand capability, therefore, is inseparable from the ability to consistently deliver parts meeting the most stringent geometric and surface finish requirements, batch after batch, regardless of complexity or material. This demands more than just advanced machinery; it requires ingrained engineering discipline, rigorous process control, and a culture where quality is engineered in from the first sketch, not inspected in at the end.

Wuxi Lead Precision Machinery operates at this exact intersection of urgency and uncompromising accuracy. Our engineering foundation, forged through decades of supplying mission-critical components, ensures that every on-demand part carries the same pedigree as those destined for the most demanding global stages. We have engineered and delivered precision-machined structural elements and intricate mechanisms for Olympic venue construction, where structural integrity and flawless assembly under tight deadlines were paramount for athlete safety and event success. Similarly, our adherence to military-grade specifications (including MIL-STD and equivalent Chinese national defense standards) for sensitive hardware underscores our capability to meet extreme requirements for durability, consistency, and traceability under pressure. This experience is not a footnote; it is the bedrock of our on-demand service. It means our CNC machining centers, operated by master craftsmen, are calibrated and monitored to achieve micron-level tolerances consistently. It means our quality assurance protocols, including full CMM inspection and material certification, are designed for zero-defect delivery, even on accelerated timelines. Speed without this level of precision is merely fast failure.

The technical capability to deliver such precision on demand is quantifiable. Our core machining processes achieve the following benchmarks across a wide range of alloys and composites:

| Specification | Capability | Application Relevance |

|---|---|---|

| Positional Tolerance | ±0.005 mm (0.0002″) | Critical for multi-part assemblies |

| Surface Roughness (Ra) | As low as 0.4 µm (16 µin) | Essential for sealing, wear, aesthetics |

| Material Range | Aerospace Al, Ti, Stainless, Inconel, Hardened Steels | Supports diverse high-performance needs |

| Max. Machining Volume | 2000 x 1000 x 800 mm | Accommodates large, complex components |

| Lead Time (Typical) | 7-15 days (complex geometries) | Balances speed with uncompromised quality |

For the discerning B2B partner, understanding that precision is the non-negotiable core of viable on-demand manufacturing is critical. Wuxi Lead leverages its proven heritage in Olympic and defense supply chains to ensure that when speed is essential, the integrity of the part never is. We transform urgent requests into reliable, high-performance solutions, engineered to perform exactly as intended, precisely when needed. This is the true value of precision on demand.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions tailored for high-performance industries such as aerospace, medical, energy, and precision automation. At the core of our technical capabilities is a fully integrated 5-axis CNC machining platform, enabling the production of highly complex geometries with superior surface finish and dimensional accuracy. Our machining centers operate with continuous multi-axis synchronization, allowing for the precise execution of intricate contours, deep cavities, and organic forms that are unattainable with conventional 3-axis systems. This level of precision reduces the need for multiple setups, minimizing human intervention and part handling, which in turn enhances repeatability and throughput.

All machining operations are supported by in-house engineering expertise, utilizing advanced CAM software to optimize toolpaths, reduce cycle times, and ensure material integrity. We work with a broad range of metals, including aluminum alloys, stainless steels, titanium, Inconel, and specialty brass and bronze materials, accommodating both prototype development and low-to-mid volume production runs. Our facility maintains strict environmental and operational controls to ensure machine stability, thermal compensation, and vibration damping—critical factors in sustaining micron-level tolerances over extended production cycles.

Quality assurance is embedded into every stage of the manufacturing process. Each component undergoes comprehensive inspection using a Zeiss DuraMax and Contura G2 Coordinate Measuring Machine (CMM), providing full 3D verification against CAD models. Our CMM system supports both tactile and optical probing methods, enabling high-speed data acquisition and GD&T analysis for form, position, and profile tolerances. All inspection reports are documented and archived, providing full traceability for every batch produced. This closed-loop quality process ensures compliance with ISO 9001 standards and customer-specific requirements, including AS9100 for aerospace applications.

The following table outlines the standard tolerance capabilities achievable across our 5-axis CNC and inspection systems under controlled conditions. These values represent our typical production performance; tighter tolerances can be achieved upon engineering review for mission-critical applications.

| Feature Type | Standard Tolerance | Notes |

|---|---|---|

| Linear Dimensions (mm) | ±0.01 mm | Up to 300 mm; ±0.02 mm beyond |

| Angular Dimensions | ±0.1° | Verified via CMM and optical comparator |

| Positional Tolerance | ±0.012 mm | GD&T-compliant; includes concentricity, symmetry |

| Surface Roughness (Ra) | 0.8 µm (typical) | As-machined;可达到 0.4 µm with polishing |

| Profile Tolerance | ±0.01 mm | Complex contours, freeform surfaces |

| Flatness | 0.01 mm per 100 mm | Verified on granite surface plate and CMM |

| Repeatability (Cp/Cpk) | ≥1.67 / ≥1.33 | Statistical process control (SPC) applied on request |

Wuxi Lead Precision Machinery combines cutting-edge 5-axis CNC technology with metrology-grade inspection to deliver parts on demand with uncompromised precision. Our technical capabilities are designed to meet the evolving demands of global OEMs requiring rapid turnaround, full documentation, and zero-defect performance.

Material & Finish Options

Material Selection for Precision On-Demand Manufacturing

Material choice fundamentally dictates the performance, longevity, and cost-efficiency of custom metal components. At Wuxi Lead Precision Machinery, we prioritize aligning material properties with your application’s mechanical, environmental, and regulatory demands. This ensures optimal part functionality while minimizing waste in on-demand production. Below, we detail critical considerations for aluminum, steel, and titanium—three cornerstone alloys in high-precision manufacturing—alongside anodizing as a premier surface enhancement.

Aluminum alloys dominate aerospace, automotive, and electronics due to their exceptional strength-to-weight ratio and thermal conductivity. Grade 6061-T6 offers balanced machinability and weldability for structural brackets, while 7075-T6 delivers superior strength for high-stress components like drone arms. Aluminum’s natural corrosion resistance is adequate for many environments, but anodizing significantly enhances surface hardness and wear resistance. Avoid aluminum in high-temperature or highly abrasive settings exceeding 150°C, where thermal expansion may compromise tolerances.

Carbon and stainless steels remain indispensable for industrial machinery, tooling, and load-bearing applications demanding extreme durability. 4140 steel provides excellent toughness for shafts and gears, while 304/316 stainless steels resist corrosion in medical or marine environments. Steel’s higher density increases weight but ensures rigidity under heavy loads. Note that stainless grades like 316 require slower machining speeds to prevent work hardening—a process our CNC centers optimize through adaptive toolpath strategies.

Titanium alloys, particularly Grade 5 (Ti-6Al-4V), excel in aerospace, medical implants, and defense where strength, biocompatibility, and corrosion resistance are non-negotiable. With 45% the density of steel yet comparable strength, titanium withstands extreme temperatures and saltwater exposure. However, its low thermal conductivity challenges machining, necessitating specialized tooling and coolants to avoid galling. Reserve titanium for mission-critical applications where lifecycle costs justify the premium material investment.

Anodizing transforms aluminum surfaces through electrolytic passivation. Type II (sulfuric acid) anodizing offers decorative color options and moderate wear resistance, ideal for consumer hardware. For engineering applications, Type III (hardcoat) anodizing creates a 50–100 µm ceramic layer with 60–70 HRC hardness—critical for hydraulic pistons or firearm components exposed to abrasion. Unlike paint, anodizing penetrates the substrate, ensuring uniform protection without dimensional compromise.

Key Material Properties Comparison

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Primary Applications |

|---|---|---|---|---|

| Aluminum 6061-T6 | 2.7 | 310 | Moderate | Brackets, heat sinks, enclosures |

| Steel 4140 | 7.85 | 655 | Low (uncoated) | Shafts, gears, tooling |

| Stainless 316 | 8.0 | 570 | Excellent | Marine hardware, medical devices |

| Titanium Grade 5 | 4.43 | 900 | Exceptional | Aircraft fittings, surgical implants |

Selecting the right material and finish requires balancing performance needs with manufacturability. Wuxi Lead’s engineering team collaborates early in your design phase to recommend alloys and processes that maximize yield in on-demand production—reducing lead times without sacrificing precision. Contact us to validate your material strategy against real-world CNC machining constraints and application-specific requirements.

Manufacturing Process & QC

From Design to Delivery: The Precision Path at Wuxi Lead Precision Machinery

At Wuxi Lead Precision Machinery, we engineer certainty into every custom metal component we produce. Our end-to-end manufacturing process is built on a foundation of precision, traceability, and zero-defect execution. From initial design to full-scale production, we ensure that every part meets exacting standards—on time, every time.

The journey begins with collaborative design engineering. Our technical team works directly with clients to analyze 3D CAD models, assess material suitability, and optimize geometries for manufacturability. This stage includes comprehensive Design for Manufacturing (DFM) reviews, where we identify potential challenges in tolerancing, surface finish, and assembly integration. By resolving these issues upfront, we eliminate costly revisions and reduce time-to-market.

Once the design is validated, we move into precision prototyping. Utilizing advanced CNC machining centers and coordinate measuring machines (CMM), we produce functional prototypes that mirror final production quality. These prototypes undergo rigorous dimensional inspection, material verification, and, when required, performance testing under simulated operational conditions. Client feedback is incorporated at this stage to ensure alignment with functional and aesthetic requirements before scaling to mass production.

Mass production is executed on our high-efficiency CNC lathes, milling machines, and multi-axis machining centers, all maintained to OEM specifications and monitored in real time. Our production floor operates under strict ISO 9001-certified quality protocols, with every process step documented and traceable. In-process inspections occur at critical control points, ensuring deviations are detected and corrected immediately. Final inspection includes full dimensional reporting, surface roughness analysis, and material certification.

Our zero-defect philosophy is enforced through a combination of advanced technology, disciplined process control, and a culture of continuous improvement. Every operator is trained in precision techniques, and every machine is calibrated regularly. Statistical process control (SPC) data is analyzed daily to maintain process capability and predict potential variances before they occur.

This seamless integration of design, prototyping, and production ensures that our clients receive parts that are not only dimensionally accurate but also consistent across batches—critical for industries such as aerospace, medical devices, and high-performance automation.

Typical Production Specifications at Wuxi Lead Precision Machinery

| Parameter | Capability |

|---|---|

| Materials | Aluminum, Stainless Steel, Titanium, Brass, Alloy Steel, Plastics |

| Tolerances | ±0.005 mm (standard), down to ±0.001 mm (tight-tolerance) |

| Surface Finish | Ra 0.8 µm (standard), down to Ra 0.2 µm (polished) |

| Max Part Size | 800 x 600 x 500 mm |

| Minimum Feature Size | 0.5 mm (milled), 1.0 mm (drilled) |

| Production Volume | 1 – 100,000+ units |

| Lead Time (Prototype) | 7–14 days |

| Lead Time (Production) | 15–30 days (depending on volume) |

| Quality Standards | ISO 9001:2015, Full First Article Inspection (FAI), PPAP Level 3 available |

At Wuxi Lead Precision Machinery, we don’t just manufacture parts on demand—we deliver precision on promise.

Why Choose Wuxi Lead Precision

Elevate Your Supply Chain with Precision Engineering Partnership

In high-stakes manufacturing, component failure is not an option. Delays, dimensional inaccuracies, or material inconsistencies erode profitability and damage client trust. Wuxi Lead Precision Machinery eliminates these risks through an engineered partnership model designed for mission-critical applications. We do not merely fulfill orders; we integrate as your technical extension, ensuring every component meets exacting aerospace, medical, and industrial standards from prototype to volume production. Stop compromising between speed, precision, and reliability. Partner with a manufacturer certified to ISO 9001 and AS9100D, where 99.8% of deliveries arrive on schedule and 100% of parts pass first-article inspection.

Our technical capabilities are engineered for complexity. The table below details core specifications for rapid assessment:

| Capability | Specification Detail | Material Range | Lead Time (Typical) |

|---|---|---|---|

| CNC Machining | 5-axis milling, turning, grinding | Aluminum, Titanium, Inconel, Stainless Steel, Brass | Prototype: 10 days Production: 25 days |

| Tolerances | ±0.005 mm (±0.0002″) | Certified aerospace alloys | Customizable |

| Max Work Envelope | 1,200 x 800 x 600 mm (47″ x 31″ x 24″) | Exotic metals, hardened steels | Scalable to 50k units |

| Surface Finishes | Anodizing, passivation, bead blasting | Medical-grade compliant | Integrated quoting |

| Quality Assurance | CMM, optical comparators, metallurgical testing | Full traceability | Real-time reporting |

What distinguishes Lead Precision is our proactive engineering engagement. From initial RFQ review to post-delivery support, dedicated project engineers collaborate with your team to resolve design-for-manufacturability challenges, optimize material utilization, and preempt production bottlenecks. We deploy digital twin verification for complex geometries and maintain redundant capacity to absorb urgent demand spikes—without sacrificing quality. Our factory in Wuxi operates under Western-style project management protocols, with English-speaking technical staff available during your business hours. This eliminates communication barriers common in offshore manufacturing while leveraging China’s cost efficiency.

Global OEMs partner with us because we treat your deadlines as our commitments. When your project requires zero-defect components for life-support systems or satellite assemblies, our closed-loop quality system ensures compliance with NADCAP, ITAR, and FDA 21 CFR Part 820. We invest in your success through rigorous process validation and transparent production dashboards accessible via secure client portals.

Do not let supply chain vulnerabilities jeopardize your next project. Submit your technical drawings and requirements to [email protected]. Our engineering team will respond within 4 business hours with a detailed manufacturability analysis, competitive quotation, and actionable timeline. Experience precision manufacturing where capability meets accountability—partner with Wuxi Lead Precision Machinery for components that perform, delivered when you need them. Your innovation deserves an engineering partner, not just a supplier.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.