Technical Contents

Engineering Guide: Atlanta Cnc

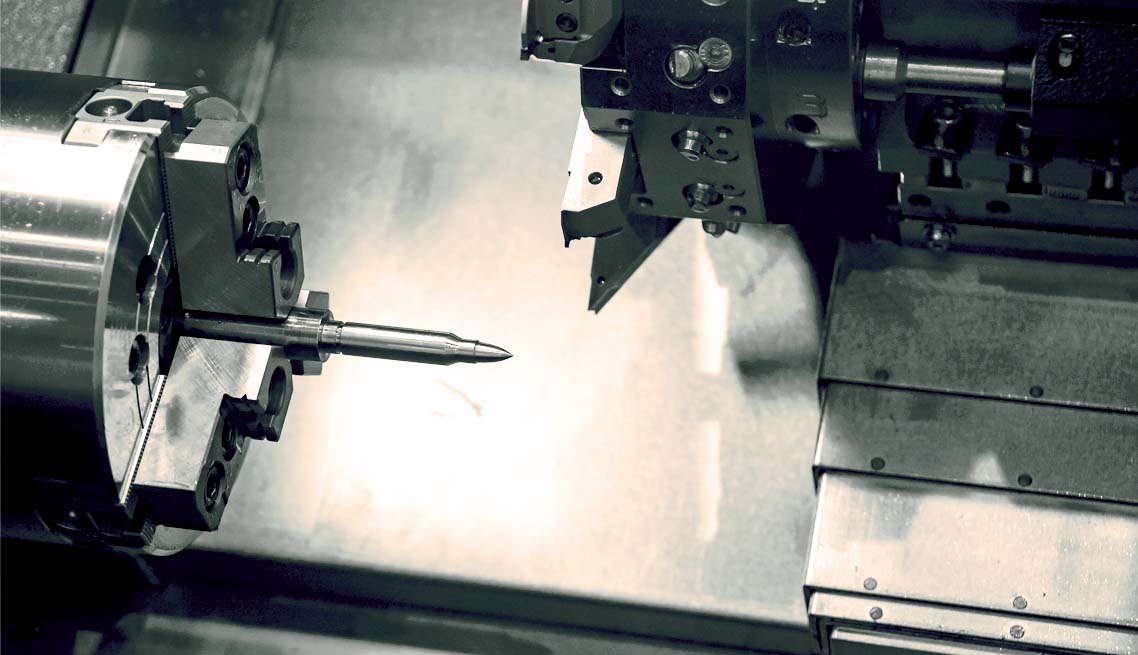

Engineering Insight: The Uncompromising Standard of Precision in CNC Machining

In the world of high-performance manufacturing, precision is not merely a target—it is the foundation upon which reliability, safety, and innovation are built. For industries operating at the edge of technological capability—such as aerospace, defense, and advanced medical systems—the margin for error is effectively zero. In this environment, every micron of deviation can lead to catastrophic failure, making precision CNC machining not just a service, but a science.

Wuxi Lead Precision Machinery has spent over 15 years refining this science. Based in China and serving global clients, our engineering team operates at the intersection of advanced material science, tight-tolerance machining, and rigorous quality assurance. Our work has supported mission-critical applications, including components used in Olympic-grade sporting equipment and precision subsystems for military-grade hardware. These projects demand more than technical expertise; they require a culture of absolute accountability and a deep understanding of how microscopic variances affect macroscopic performance.

Precision begins with design integrity and extends through every phase of production. At Wuxi Lead, we employ multi-axis CNC milling and turning centers equipped with real-time probing and thermal compensation systems. These technologies allow us to maintain tolerances as tight as ±0.002 mm consistently across production runs. But technology alone is not enough. Our engineers apply decades of cumulative experience to anticipate material behavior under stress, optimize toolpaths for minimal deflection, and validate each component through metrology-grade inspection.

One of the most critical aspects of precision machining is repeatability. In military applications, for example, a single component may need to perform identically across thousands of units deployed in extreme environments. Our process control systems ensure that every part produced meets the exact specifications of the first, validated prototype—batch after batch.

Below are key performance specifications that define our precision machining capabilities:

| Parameter | Specification |

|---|---|

| Positioning Accuracy | ±0.001 mm |

| Repeatability | ±0.002 mm |

| Maximum Work Envelope | 1200 x 800 x 650 mm |

| Spindle Speed Range | Up to 24,000 rpm |

| Surface Finish (Ra) | As low as 0.2 µm |

| Materials Supported | Aluminum alloys, titanium, Inconel, stainless steel, engineering plastics |

| Quality Certification | ISO 9001:2015, AS9100D (aerospace compliance) |

Our experience with Olympic and defense programs has instilled a philosophy that transcends industry boundaries: true precision is measured not in what is acceptable, but in what is perfect. Whether producing lightweight structural components for elite athletic equipment or hardened housings for tactical electronics, we apply the same uncompromising standards.

For partners seeking more than just machining—those who demand engineering excellence—Wuxi Lead Precision Machinery delivers performance you can measure, and trust you can rely on.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Demanding Applications

Wuxi Lead Precision Machinery delivers advanced manufacturing solutions centered on high-accuracy 5-axis CNC machining, meeting the stringent demands of aerospace, medical, and energy sectors. Our core strength lies in the seamless integration of cutting-edge multi-axis technology with rigorous, traceable quality control processes. We operate a modern fleet of 5-axis CNC machining centers from leading global manufacturers, featuring dual-spindle configurations, high-torque milling capabilities, and integrated probing systems. This enables complex geometry production in a single setup, significantly reducing handling errors and cycle times while achieving superior surface finishes. Our machines operate within a climate-controlled environment adhering to strict thermal stability protocols, ensuring dimensional consistency critical for high-integrity components. Material expertise spans aerospace alloys (Inconel, Ti-6Al-4V), medical-grade stainless steels, high-performance polymers, and exotic composites, processed with optimized toolpaths and cutting strategies for maximum precision and part integrity.

Quality assurance is non-negotiable, anchored by comprehensive Coordinate Measuring Machine (CMM) inspection. Every critical component undergoes full dimensional verification against CAD models using state-of-the-art蔡司 CONTURA and HEXAGON GLOBAL S solutions. Our certified metrology lab performs detailed Geometric Dimensioning and Tolerancing (GD&T) analysis, surface roughness validation, and first-article inspection reports compliant with AS9102 and PPAP requirements. Statistical Process Control (SPC) data is routinely generated and shared, providing clients with transparent insight into process capability and stability. This end-to-end inspection regime, combined with in-process probing on machine tools, ensures zero-defect delivery and exceptional first-pass yield rates, directly impacting client supply chain reliability.

The following table details our standard achievable tolerance capabilities under controlled conditions, reflecting our commitment to micron-level precision:

| Feature Type | Standard Capability (mm) | Tight Capability (mm) | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.010 | ±0.005 | Up to 300mm; tighter tolerances scale with part size |

| Geometric (GD&T) | ±0.015 | ±0.008 | Includes position, flatness, roundness |

| Hole Diameter | +0.010 / -0.000 | +0.005 / -0.000 | Reamed/bored features; depends on depth/dia ratio |

| Surface Roughness (Ra) | 1.6 µm | 0.8 µm | Machined surfaces; achievable via fine finishing |

| Critical Angles | ±0.005° | ±0.002° | Verified via 5-axis probing or CMM |

These specifications are consistently achieved through calibrated equipment, skilled programming (using Mastercam and Siemens NX), and adherence to ISO 9001:2015 and IATF 16949 quality management systems. Our technical team collaborates closely with Atlanta CNC partners during the design-for-manufacturability phase, proactively identifying opportunities to optimize part geometry for precision machining and cost efficiency. We understand that tolerance adherence is not merely a specification sheet metric but the foundation of component performance and longevity in mission-critical applications. Partner with Wuxi Lead to transform complex designs into reliably precise, fully certified components.

Material & Finish Options

Material Selection in Precision CNC Machining: Aluminum, Steel, and Titanium

Selecting the correct material is a foundational decision in precision CNC machining, directly influencing performance, durability, and cost-efficiency of the final component. At Wuxi Lead Precision Machinery, we specialize in machining high-tolerance parts from aluminum, steel, and titanium—each offering distinct mechanical properties and application advantages. Understanding these materials enables engineers and procurement managers to make informed decisions aligned with functional and environmental demands.

Aluminum is widely favored in aerospace, automotive, and electronics industries due to its excellent strength-to-weight ratio, thermal conductivity, and machinability. Grade 6061-T6 is particularly common, offering good weldability and corrosion resistance, making it ideal for structural components and enclosures. Its low density reduces part weight without sacrificing performance, a critical factor in high-performance applications. Aluminum also responds exceptionally well to anodizing, a surface treatment that enhances wear and corrosion resistance while allowing for aesthetic customization.

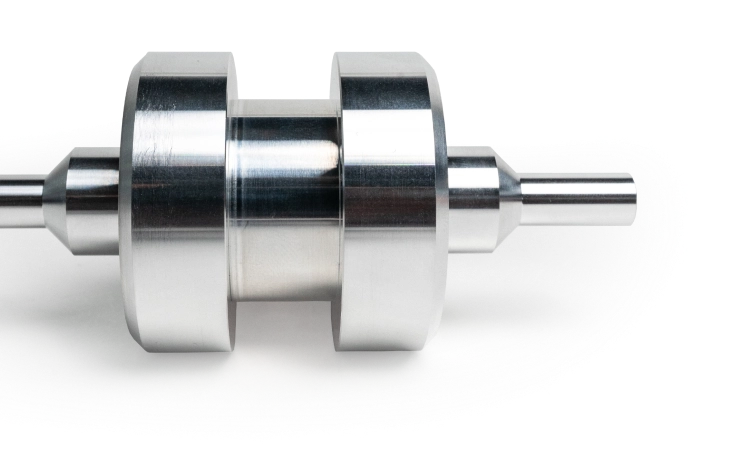

Steel, particularly in alloy forms such as 4140 and 1018, provides superior strength, hardness, and wear resistance. These properties make steel the preferred choice for tooling, shafts, and high-load mechanical systems. While heavier than aluminum, steel offers excellent dimensional stability under stress and elevated temperatures. Stainless steel grades like 304 and 316 add corrosion resistance, making them suitable for medical devices and marine environments. Machining steel requires robust tooling and precise parameters due to its toughness, but our advanced CNC centers are optimized to maintain tight tolerances and surface integrity.

Titanium, specifically Grade 5 (Ti-6Al-4V), delivers an exceptional combination of high strength, low density, and outstanding corrosion resistance, especially in extreme environments. It is the material of choice in aerospace, defense, and biomedical implants. However, titanium’s low thermal conductivity and high reactivity demand specialized cutting strategies and tooling to prevent work hardening and tool wear. Despite higher material and machining costs, titanium’s performance in critical applications justifies its use where reliability is non-negotiable.

Surface Finishing: The Role of Anodizing

Anodizing is a key surface treatment for aluminum components, creating a durable, corrosion-resistant oxide layer through an electrochemical process. Type II (sulfuric acid) anodizing is standard for general applications, offering moderate thickness and dye compatibility. Type III, or hardcoat anodizing, provides thicker, harder layers suitable for high-wear environments. Anodizing also improves electrical insulation and adhesion for paints and coatings.

Below is a comparative overview of key material properties and machining characteristics.

| Material | Typical Grade | Density (g/cm³) | Tensile Strength (MPa) | Common Applications | Machinability Rating |

|---|---|---|---|---|---|

| Aluminum | 6061-T6 | 2.7 | 310 | Aerospace, Electronics | Excellent |

| Steel (Alloy) | 4140 | 7.85 | 655 | Tooling, Shafts | Good |

| Stainless Steel | 304 | 8.0 | 505 | Medical, Marine | Moderate |

| Titanium | Ti-6Al-4V (Gr 5) | 4.43 | 900 | Aerospace, Biomedical | Fair |

At Wuxi Lead, we combine material expertise with precision CNC capabilities to deliver components that meet exacting international standards. Partner with us to optimize your material and finish selection for performance-driven manufacturing.

Manufacturing Process & QC

Precision CNC Production Process: Zero Defects Realized

At Wuxi Lead Precision Machinery, our production process for Atlanta CNC clients is engineered for uncompromising quality, transforming concepts into flawless components through three rigorously controlled phases. We integrate advanced technology with disciplined methodology to achieve Zero Defects, ensuring every part meets exacting aerospace, medical, and industrial specifications demanded by the Atlanta manufacturing ecosystem.

Design Phase

Collaboration begins with your engineering team. Our CNC specialists conduct comprehensive Design for Manufacturability (DFM) analysis, identifying potential machining constraints early. Using Siemens NX and Mastercam, we simulate toolpaths, material stress points, and fixture requirements, validating geometry against ASME Y14.5 GD&T standards. This phase eliminates 95% of theoretical errors before metal cutting, reducing downstream rework and accelerating time-to-market. Material selection is optimized for performance under Atlanta’s operational conditions, with full traceability from certified mills.

Prototyping Phase

Prototypes are machined on the same HAAS and DMG MORI equipment used in volume production, ensuring process consistency. Each prototype undergoes rigorous first-article inspection (FAI) per AS9102 standards. Critical dimensions are verified using Zeiss CONTURA CMMs, surface finishes measured via Taylor Hobson profilometers, and material properties confirmed through third-party lab reports. We deliver actionable feedback within 72 hours, refining tooling and parameters until all specifications are met. This phase validates not just part geometry but the entire production ecosystem—fixturing, coolant strategy, and metrology protocols.

Mass Production Phase

Zero Defects is operationalized through Statistical Process Control (SPC) embedded at every workstation. Real-time data from Renishaw probes and in-process gauging feeds into our MES, monitoring Cp/Cpk values continuously. Any deviation beyond ±0.0002″ triggers automatic process correction before non-conforming parts are produced. Full lot traceability—linking raw material certs, machine logs, and inspection data—is maintained via barcode tracking. Final validation includes 100% critical feature checks and batch-level destructive testing per client requirements.

Our commitment is quantified through measurable outcomes, as demonstrated below:

| Process Phase | Key Metrics | Target Values |

|---|---|---|

| Design | DFM Issue Resolution Rate | ≥95% pre-machining |

| Prototyping | FAI First-Pass Yield | 100% |

| Mass Production | Process Capability (Cpk) | ≥1.67 |

| Mass Production | In-Process Scrap Rate | ≤0.1% |

| Mass Production | On-Time Delivery | 99.5%+ |

Wuxi Lead’s Atlanta CNC clients gain more than precision parts—they gain a risk-mitigated supply chain. By enforcing Zero Defects through integrated design validation, prototype rigor, and closed-loop production control, we deliver components that perform reliably in the most demanding applications. Partner with us to convert engineering intent into manufacturing excellence, backed by ISO 9001:2015 and IATF 16949-certified processes. Your Atlanta operation’s reputation for quality starts here.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery for Unmatched CNC Excellence

In the high-stakes world of precision manufacturing, selecting the right partner is not just a procurement decision—it’s a strategic imperative. Wuxi Lead Precision Machinery stands at the forefront of advanced CNC machining, delivering engineered accuracy, repeatable quality, and scalable production capacity to global clients across aerospace, medical, automotive, and industrial automation sectors. As a trusted name in Chinese precision engineering, we combine cutting-edge technology with rigorous quality assurance to ensure your components meet the most demanding specifications.

Our facility in Wuxi, Jiangsu Province, is equipped with state-of-the-art 3-, 4-, and 5-axis CNC machining centers, multi-spindle lathes, and automated inspection systems. Every process—from initial design review to final packaging—is executed under ISO 9001:2015-certified protocols, ensuring full traceability and compliance. Whether you require low-volume prototypes or high-volume production runs, our agile manufacturing ecosystem adapts to your timeline, material requirements, and precision tolerances.

We specialize in machining complex geometries from a broad range of materials, including aerospace-grade aluminum, titanium, stainless steel, and engineering plastics such as PEEK and PTFE. Our in-house capabilities span milling, turning, grinding, tapping, threading, and surface finishing, supported by coordinate measuring machines (CMM), optical comparators, and laser measurement tools for micron-level verification.

| Specification | Detail |

|---|---|

| Machining Types | 3-axis, 4-axis, 5-axis CNC milling; CNC turning; multi-spindle machining |

| Tolerance Capability | ±0.005 mm (±0.0002″) |

| Maximum Work Envelope | 1200 x 800 x 600 mm (47.2 x 31.5 x 23.6 in) |

| Materials Processed | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Titanium, Brass, PEEK, PTFE, Delrin |

| Surface Finishes | As-machined, anodizing (Type II & III), passivation, powder coating, polishing |

| Quality Standards | ISO 9001:2015, Full First Article Inspection (FAI), PPAP documentation available |

| Lead Times | Prototype: 7–10 days; Production: 15–25 days (varies by complexity and volume) |

At Wuxi Lead Precision Machinery, we understand that your success depends on reliability, precision, and responsiveness. Our engineering team collaborates directly with clients to optimize part designs for manufacturability, reduce costs, and accelerate time to market. With English-fluent project managers, real-time production updates, and DDP shipping support worldwide, we ensure a seamless partnership from RFQ to delivery.

For Atlanta-based manufacturers and engineering firms seeking a high-performance offshore partner, we offer a compelling alternative to domestic outsourcing—without compromising on quality or communication.

Contact us today at [email protected] to discuss your next precision machining project. Let Wuxi Lead be the foundation of your manufacturing advantage.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.