Technical Contents

Engineering Guide: Acrylic Nail Molds

Engineering Insight: Precision in Acrylic Nail Molds

In the specialized field of custom metal manufacturing, the production of acrylic nail molds represents a unique convergence of cosmetic application and high-precision engineering. While the end-use may appear delicate—serving the beauty industry—the underlying manufacturing demands are anything but. At Wuxi Lead Precision Machinery, we apply the same rigorous standards to acrylic nail mold tooling as we do to components destined for Olympic-grade equipment and military applications. This level of precision is not merely advantageous—it is essential.

Acrylic nail molds require micron-level accuracy to ensure consistent replication of intricate nail contours, seamless edge definition, and uniform thickness distribution. Even a deviation of ±0.02 mm can result in warping, incomplete curing, or poor fit during application. These molds must withstand repeated thermal cycling and chemical exposure from acrylic resins, necessitating both dimensional stability and material integrity. The mold’s surface finish directly impacts the final product’s gloss, texture, and release performance, making surface treatment and polishing a critical phase in the manufacturing process.

At Lead Precision, our engineering approach begins with advanced 3D modeling and finite element analysis (FEA) to simulate thermal and mechanical behavior under operational conditions. We utilize CNC machining centers with sub-micron positioning accuracy, combined with electrical discharge machining (EDM) for fine detail reproduction. Our quality assurance protocols include laser scanning and coordinate measuring machine (CMM) inspections, ensuring every cavity conforms to the exact design specification.

Our experience extends beyond commercial cosmetics. Having manufactured precision components for high-stakes applications—including structural elements in Olympic training equipment and subsystem housings for military-grade electronics—we bring a discipline of zero-failure tolerance to every project. This heritage informs our methodology: every mold is treated as a mission-critical component, where repeatability, longevity, and performance are non-negotiable.

The result is a mold set engineered for high-cycle durability, optimal thermal conductivity, and flawless part ejection—key factors in maximizing production uptime and minimizing waste. Whether producing molds for mass-market distribution or limited-batch luxury lines, Lead Precision delivers tooling that reflects the same commitment to excellence found in the most demanding industrial sectors.

| Specification | Detail |

|---|---|

| Tolerance Range | ±0.01 mm to ±0.02 mm |

| Surface Finish (Ra) | 0.05 µm to 0.2 µm |

| Material Options | H13, P20, S136 Stainless Steel, 718H |

| Hardness | 48–52 HRC (post-treatment) |

| Machining Process | 5-axis CNC, EDM, CMM Inspection |

| Coating Options | TiN, DLC, Mirror Polishing |

| Production Cycle Life | 100,000+ cycles (typical) |

| Lead Time | 25–35 days (from design approval) |

Precision in acrylic nail mold manufacturing is not a luxury—it is the foundation of performance, consistency, and profitability. At Wuxi Lead Precision Machinery, we engineer every mold with the uncompromising standards of industrial excellence, ensuring our clients receive tooling that performs flawlessly, cycle after cycle.

Precision Specs & Tolerances

Precision Metal Manufacturing for Acrylic Nail Mold Tooling

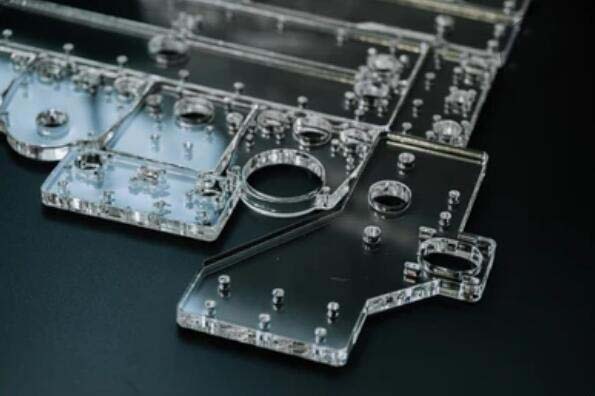

Wuxi Lead Precision Machinery delivers the critical metal components required for high-performance acrylic nail mold production. We specialize in manufacturing the precision steel cavities, cores, and intricate inserts that form the foundation of injection molds used in the cosmetic industry. Our focus is exclusively on the metal tooling elements, ensuring the final acrylic product achieves flawless surface finish, dimensional accuracy, and consistent release properties demanded by premium nail product manufacturers. This requires capabilities far beyond standard machining, addressing complex organic geometries, stringent tolerances, and mirror-finish requirements inherent in modern nail mold design.

Our technical foundation is built upon advanced 5-axis CNC machining centers, including Haas UMC and DMG MORI models. These systems enable the simultaneous, coordinated movement of the cutting tool across five axes, eliminating the need for multiple setups and fixture errors. This is non-negotiable for producing the complex undercuts, compound curves, and micro-features characteristic of contemporary nail molds. We machine directly from 3D CAD models, utilizing high-rigidity spindles and sub-micron linear encoders to achieve exceptional geometric accuracy and surface integrity on hardened tool steels like S136H and NAK80. The elimination of manual repositioning guarantees part-to-part consistency and significantly reduces lead times for complex mold components.

Quality control is integrated at every stage, with Coordinate Measuring Machine (CMM) inspection serving as the cornerstone of our verification process. Every critical feature undergoes rigorous measurement using Zeiss CONTURA CMMs, programmed directly from the customer’s CAD data. We perform comprehensive dimensional analysis, including geometric dimensioning and tolerancing (GD&T) checks for flatness, profile, and position, ensuring absolute conformity to the design intent. Full inspection reports, including deviation maps and statistical process control (SPC) data, are provided with first-article submissions and batch certifications. This level of metrological rigor guarantees that the mold tooling will perform reliably in high-volume production, minimizing scrap and downtime for our clients.

The following table details our standard and tight-tolerance capabilities for critical mold tooling features:

| Parameter | Standard Capability | Tight Capability | Units |

|---|---|---|---|

| Linear Dimension | ±0.010 | ±0.005 | mm |

| Geometric Profile | 0.020 | 0.010 | mm |

| Flatness | 0.010 | 0.005 | mm |

| Angular Tolerance | ±0.05 | ±0.02 | deg |

| Surface Roughness | Ra 0.4 | Ra 0.1 | µm |

Wuxi Lead Precision Machinery provides the engineering expertise and manufacturing precision necessary to transform demanding acrylic nail mold concepts into production-ready metal tooling. Our integrated 5-axis CNC capabilities and uncompromising CMM-based quality assurance deliver the repeatability, accuracy, and surface quality essential for manufacturers seeking a competitive edge in the high-end cosmetic market. We partner with clients to solve complex geometries and stringent tolerance challenges inherent in this specialized application.

Material & Finish Options

Material Selection for High-Precision Acrylic Nail Molds

When manufacturing high-performance acrylic nail molds, material selection is critical to ensuring dimensional accuracy, surface finish quality, and production longevity. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing for precision tooling, and our expertise guides clients toward optimal material and finish combinations tailored to their production volume, mold complexity, and performance demands.

Aluminum is often the preferred choice for prototyping and low-to-medium volume production. Its excellent machinability allows for faster turnaround and intricate cavity designs, essential for the fine geometries found in nail molds. Additionally, aluminum’s superior thermal conductivity promotes even cooling, reducing cycle times and minimizing warpage in the final acrylic product. However, aluminum’s lower hardness makes it less suitable for extended production runs unless enhanced with surface treatments.

For high-volume manufacturing, tool steel—particularly pre-hardened or hardened P20 or H13 grades—offers exceptional wear resistance and durability. Steel molds maintain dimensional stability over hundreds of thousands of cycles, making them ideal for industrial-scale operations. While steel is more challenging to machine and slower to cool than aluminum, its longevity and resistance to deformation under repeated thermal cycling justify the initial investment for large production batches.

Titanium, though less common due to cost and machining complexity, provides a unique combination of high strength-to-density ratio and corrosion resistance. It is typically reserved for specialized applications where weight reduction or extreme environmental resistance is required. In standard acrylic nail mold production, titanium is rarely necessary but may be considered for niche, high-end tooling systems operating under aggressive conditions.

Surface finish plays a pivotal role in part release and aesthetic quality. Anodizing is the most effective post-processing treatment for aluminum molds. Hard anodizing, in particular, increases surface hardness, improves wear resistance, and enhances non-stick properties—critical for clean demolding of acrylic resins without residue or surface defects. The anodized layer also resists chemical degradation from repeated exposure to acrylic monomers and cleaning agents.

For steel molds, alternatives such as chrome plating or nitriding are more common, but anodizing is not applicable due to steel’s composition. Titanium can be anodized, offering both protective and decorative benefits, though this is seldom utilized in nail mold applications.

Below is a comparative overview of key material properties relevant to acrylic nail mold manufacturing.

| Material | Hardness (HRC) | Thermal Conductivity (W/m·K) | Typical Mold Life (cycles) | Suitable for Anodizing | Machinability Rating |

|---|---|---|---|---|---|

| Aluminum 6061 | 30–35 (after hard anodizing) | 167 | 10,000–50,000 | Yes | Excellent |

| P20 Tool Steel | 28–32 | 36 | 100,000–1,000,000 | No | Good |

| H13 Steel | 48–52 | 34 | 500,000–1,000,000+ | No | Moderate |

| Titanium Grade 5 | 36–41 | 7.2 | 50,000–200,000 | Yes | Poor |

Selecting the right material and finish requires balancing performance, cost, and production goals. Wuxi Lead Precision Machinery supports clients in making data-driven decisions, ensuring every mold meets the exacting standards of the beauty and personal care manufacturing industry.

Manufacturing Process & QC

Precision Engineering Pathway for Acrylic Nail Molds

At Wuxi Lead Precision Machinery, we execute a rigorously controlled production sequence for custom acrylic nail mold tooling, engineered to achieve absolute dimensional fidelity and zero-defect output. This process is fundamental to ensuring consistent, high-quality nail enhancements for our beauty industry partners. Our methodology integrates advanced CNC technology with stringent quality protocols across three critical phases.

The Design Phase begins with collaborative specification refinement. Utilizing industry-standard CAD/CAM software, our engineering team translates client requirements into precise 3D models, incorporating critical factors like resin flow dynamics, ejection mechanics, and thermal management. Material selection focuses on high-grade 420 stainless steel for its optimal balance of polishability, corrosion resistance against acrylic monomers, and dimensional stability. Finite Element Analysis (FEA) validates structural integrity under production cycling, while mold flow simulation optimizes gate placement and cooling channel design to prevent warpage or sink marks. This digital foundation ensures manufacturability and performance from inception.

Prototyping leverages our high-precision 5-axis CNC machining centers and wire EDM capabilities to produce a single, fully functional mold cavity and core set. This physical iteration undergoes metrology-grade verification against the CAD model using calibrated CMM equipment, checking critical features like cavity depth, sidewall angles, and venting micro-channels to micron-level accuracy. We actively engage the client in functional trials using their specific acrylic formulations, analyzing fill behavior, cure consistency, and part release. Any deviations trigger immediate design adjustments within our PLM system, followed by rapid re-machining. This closed-loop validation confirms the mold design meets all performance and cosmetic requirements before committing to full production.

Mass Production deploys the final, approved design across our dedicated mold manufacturing cells. Each mold set undergoes sequential, fully documented machining operations on hardened tool steel blanks, monitored by in-process gauging. Critical surfaces achieve a mirror finish (Ra ≤ 0.05 µm) via precision grinding and diamond polishing to ensure flawless nail surface replication and easy release. Our zero-defect mandate is enforced through automated optical inspection of all critical geometries post-machining and 100% functional testing of every mold set under simulated production conditions. Statistical Process Control (SPC) charts track key parameters in real-time, enabling immediate process correction. Final approval requires passing stringent client-specific criteria, including dimensional reports and sample part validation, guaranteeing every mold shipped delivers consistent, defect-free production.

The following table details the critical specifications achievable through this process:

| Specification Parameter | Target Value | Verification Method |

|---|---|---|

| Dimensional Tolerance | ±0.005 mm | CMM (Calibrated to ISO 17025) |

| Cavity Surface Roughness (Ra) | ≤ 0.05 µm | Profilometer Measurement |

| Core/Cavity Hardness | 52-54 HRC | Rockwell Hardness Tester |

| Parallelism (Parting Line) | ≤ 0.01 mm over 100 mm | Optical Comparator / CMM |

| Venting Micro-Channel Depth | 0.01 – 0.02 mm (controlled) | Optical Microscopy / CMM |

| Zero Defect Rate (Shipment) | 100% | 100% Functional Test + SPC Review |

This integrated Design-Prototype-Production workflow, underpinned by Wuxi Lead’s engineering discipline and advanced manufacturing infrastructure, delivers acrylic nail molds that consistently exceed industry standards for precision, longevity, and flawless output.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Excellence in Acrylic Nail Mold Manufacturing

At Wuxi Lead Precision Machinery, we understand that success in the beauty tool industry begins with precision, consistency, and innovation. As a leading provider of custom metal manufacturing solutions based in China, we specialize in delivering high-performance acrylic nail molds that meet the exacting standards of global OEMs and beauty device brands. Our engineering expertise, advanced CNC capabilities, and deep understanding of mold dynamics position us as the ideal manufacturing partner for businesses seeking reliability, scalability, and superior product quality.

Acrylic nail molds are more than just functional components — they are critical to achieving flawless nail shaping, durability, and user comfort. Whether you are developing professional-grade nail tools or expanding into automated nail care systems, our team collaborates closely with your design and R&D departments to deliver molds that are optimized for performance, longevity, and cost-efficiency. From initial concept and material selection to final production and quality assurance, we manage every phase with precision and accountability.

Our facility is equipped with state-of-the-art 5-axis CNC machines, EDM systems, and automated inspection technologies, ensuring micron-level accuracy and repeatability. We utilize high-grade tool steels and advanced surface treatments to enhance wear resistance and reduce maintenance cycles. Every mold undergoes rigorous testing for dimensional stability, thermal performance, and release efficiency, guaranteeing consistent output across thousands of production cycles.

We pride ourselves on being more than a supplier — we are a strategic partner. Our engineering team provides DFM (Design for Manufacturability) feedback early in the development process, helping you avoid costly revisions and accelerate time-to-market. With full in-house capabilities, including rapid prototyping and low-to-high volume production, we offer flexible solutions tailored to your business needs.

Below are the key technical specifications we support for custom acrylic nail mold manufacturing:

| Specification | Details |

|---|---|

| Material Options | P20, 718H, S136, H13 Tool Steels; Stainless Steel; Aluminum Alloys |

| Tolerance | ±0.005 mm |

| Surface Finish | Mirror polish up to Ra 0.05 µm; textured finishes available |

| Mold Life | 100,000+ cycles (depending on material and usage) |

| Cooling System | Optimized conformal cooling channels |

| Production Lead Time | 15–25 days for prototype; 30–45 days for mass production |

| Quality Control | 100% CMM inspection, 3D scanning, hardness testing |

| Certifications | ISO 9001:2015, RoHS compliant |

Partnering with Wuxi Lead Precision Machinery means gaining access to a vertically integrated manufacturing ecosystem backed by over 15 years of industrial expertise. We serve clients across North America, Europe, and Asia, consistently delivering molds that exceed expectations in performance and reliability.

For your next generation of acrylic nail molds, trust a partner who combines engineering rigor with manufacturing excellence. Contact us today at [email protected] to discuss your project requirements, request a quote, or schedule a technical consultation. Let us help you turn precision into profit.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.