Technical Contents

Engineering Guide: Metal Cutting Company

Engineering Insight: The Critical Role of Precision in Modern Metal Cutting

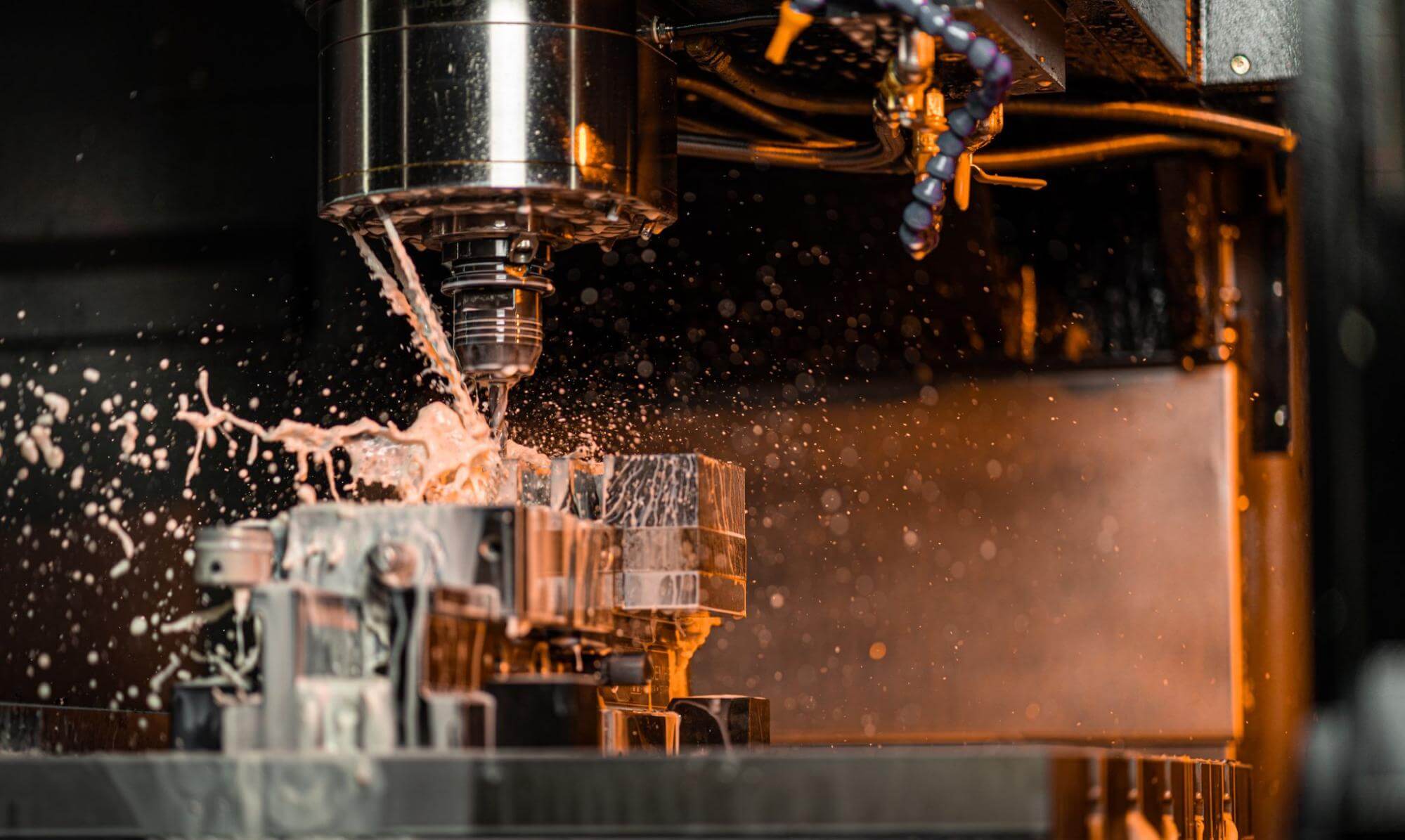

In the realm of custom metal manufacturing, precision is not merely a performance metric—it is the foundation upon which reliability, safety, and innovation are built. For industries ranging from aerospace and defense to high-performance automotive and advanced medical equipment, the margin for error is effectively zero. At Wuxi Lead Precision Machinery, we understand that the integrity of a final product is determined not just by design, but by the exactness with which raw materials are transformed through metal cutting processes.

Precision metal cutting demands more than advanced machinery; it requires a deep integration of engineering expertise, process control, and quality assurance. Tolerances measured in microns can determine whether a component functions under extreme stress or fails catastrophically. Thermal distortion, tool wear, material anisotropy, and vibration control are all variables that must be anticipated and mitigated at every stage. Our engineering team employs finite element analysis (FEA), real-time monitoring systems, and adaptive machining strategies to ensure that each cut meets the exact specifications required by our clients.

With over 15 years of experience in high-precision manufacturing, Wuxi Lead has delivered mission-critical components for applications where failure is not an option. Our work has supported infrastructure projects for the Olympic Games, where structural integrity and dimensional accuracy were paramount in the construction of advanced support systems. Additionally, we have supplied precision-machined parts to defense contractors, meeting stringent military standards for durability, repeatability, and performance under extreme environmental conditions.

This level of achievement is only possible through a culture of continuous improvement and investment in cutting-edge technology. Our facility in Wuxi, China, operates a fully integrated CNC machining center equipped with 5-axis milling, high-speed turning, and multi-tasking machines capable of handling complex geometries in a wide range of materials—from titanium and Inconel to hardened steels and aluminum alloys.

The table below outlines key capabilities that enable our precision metal cutting services:

| Specification | Detail |

|---|---|

| Positioning Accuracy | ±0.003 mm |

| Repeatability | ±0.002 mm |

| Maximum Work Envelope | 2,500 mm × 1,200 mm × 1,000 mm |

| Material Compatibility | Steel, Stainless Steel, Aluminum, Titanium, Inconel, Brass, Plastics |

| Tolerance Range | ±0.005 mm to ±0.025 mm (depending on geometry and material) |

| Surface Finish | Ra 0.4 μm to Ra 3.2 μm (achievable with post-processing) |

| CNC Systems | Siemens 840D, Fanuc, Heidenhain |

| Quality Standards | ISO 9001:2015, ISO 13485 (medical), MIL-STD-810 (defense) |

Our commitment to precision is validated not only by certifications but by the trust placed in us by global engineering firms and government agencies. At Wuxi Lead Precision Machinery, we do not simply cut metal—we engineer certainty.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Complex Metal Components

Wuxi Lead Precision Machinery delivers uncompromising quality in custom metal manufacturing through advanced technical infrastructure and rigorous process control. Our core strength lies in mastering complex geometries and stringent tolerances demanded by aerospace, medical, and energy sectors. Central to this capability is our integrated suite of state-of-the-art 5-axis CNC machining centers, enabling us to produce highly intricate parts in a single setup. This eliminates cumulative errors from multiple fixtures, significantly reduces lead times, and ensures superior part consistency. Utilizing machines equipped with Fanuc or Siemens controls and high-torque spindles, we achieve simultaneous 5-axis interpolation for contours, undercuts, and organic shapes impossible with conventional 3-axis systems. Our skilled programmers leverage Mastercam and Siemens NX CAM to optimize toolpaths, minimizing cycle times while maximizing surface finish and dimensional accuracy across diverse materials including titanium, Inconel, aluminum alloys, and hardened tool steels.

Precision is non-negotiable in mission-critical applications. Our comprehensive Quality Control system is anchored by multiple Coordinate Measuring Machines (CMMs), including Zeiss and Hexagon models with scanning probes. Every critical feature undergoes 100% inspection against CAD models, with full first-article inspection reports (FAIR) provided per AS9102 or client-specific requirements. The CMM process captures dense point clouds for geometric dimensioning and tolerancing (GD&T) verification, ensuring conformance to complex profile, position, and runout specifications. All measurement equipment undergoes regular calibration traceable to NIST standards, and our certified metrology technicians follow documented procedures aligned with ISO 9001:2015. This systematic approach provides full traceability from raw material to final shipment, guaranteeing zero-defect delivery.

The following table details our standard achievable tolerance capabilities under controlled production conditions. Actual tolerances may be refined based on specific part geometry, material, and client collaboration during the design-for-manufacturability (DFM) phase.

| Feature Type | Standard Tolerance Range | Measurement Method |

|---|---|---|

| Position (Holes/Pins) | ±0.005 mm to ±0.015 mm | CMM (Zeiss/Hexagon) |

| Profile (Complex Surfaces) | ±0.010 mm to ±0.025 mm | CMM Scanning |

| Linear Dimensions | ±0.005 mm to ±0.020 mm | CMM / High-Precision Micrometers |

| Surface Roughness (Ra) | 0.4 µm to 1.6 µm | Portable Profilometer |

| True Position (Critical) | ±0.003 mm | CMM (Dedicated Fixturing) |

Beyond machining and inspection, our capabilities include in-house deburring, precision cleaning, and optional non-destructive testing coordination. We partner with clients from prototype through high-volume production, applying deep technical expertise to optimize manufacturability and cost. By integrating 5-axis flexibility with metrology-grade verification, Wuxi Lead ensures your most demanding metal components meet exacting performance criteria, reducing assembly time and enhancing end-product reliability. Contact our engineering team to discuss how our technical foundation solves your specific precision manufacturing challenges.

Material & Finish Options

Material Selection in Custom Metal Manufacturing: Aluminum, Steel, and Titanium

Selecting the appropriate material is a foundational decision in precision metal manufacturing. At Wuxi Lead Precision Machinery, we guide our clients through informed choices based on mechanical performance, environmental exposure, and functional requirements. Among the most widely used materials in high-end industrial applications are aluminum, steel, and titanium—each offering distinct advantages depending on the operational context.

Aluminum is prized for its excellent strength-to-weight ratio, corrosion resistance, and machinability. It is ideal for aerospace, automotive, and consumer electronics components where weight reduction is critical without sacrificing structural integrity. Its natural oxide layer provides inherent protection, but for enhanced durability and aesthetic control, anodizing is frequently applied. Anodizing is an electrochemical process that thickens the oxide layer, improving surface hardness, wear resistance, and allowing for color customization. Type II and Type III (hard coat) anodizing are commonly specified, with the latter offering superior abrasion resistance for high-wear environments.

Steel remains the backbone of industrial manufacturing due to its high tensile strength, durability, and cost-effectiveness. Carbon steel and alloy steel variants are often selected for heavy machinery, tooling, and structural components. While steel is more prone to oxidation than aluminum, proper surface treatments such as plating, painting, or powder coating mitigate corrosion. Stainless steel grades—including 304 and 316—offer inherent corrosion resistance due to chromium content and are widely used in medical devices, food processing, and marine applications. Their machinability is moderate compared to aluminum, requiring optimized toolpaths and cutting parameters to maintain precision.

Titanium stands at the premium end of material selection, offering exceptional strength-to-density ratio and outstanding resistance to extreme temperatures and corrosive environments. It is the material of choice in aerospace, defense, and biomedical implants. However, its high reactivity at elevated temperatures and low thermal conductivity make it more challenging to machine, demanding specialized tooling and slower cutting speeds. Despite higher raw material and processing costs, titanium’s longevity and performance in critical applications justify its use.

Understanding material behavior under load, temperature, and environmental stress ensures optimal component performance and lifecycle. At Wuxi Lead, we combine material science expertise with advanced CNC capabilities to deliver parts that meet exacting specifications.

Comparison of Key Engineering Metals

| Property | Aluminum 6061-T6 | Stainless Steel 304 | Titanium Grade 5 (Ti-6Al-4V) |

|---|---|---|---|

| Tensile Strength (MPa) | 310 | 580 | 900 |

| Yield Strength (MPa) | 275 | 240 | 830 |

| Density (g/cm³) | 2.7 | 8.0 | 4.4 |

| Corrosion Resistance | High (with anodizing) | Very High | Exceptional |

| Machinability Rating | Excellent | Moderate | Poor to Moderate |

| Common Applications | Aerospace, Electronics | Food Processing, Medical | Aerospace, Biomedical |

Material selection directly impacts manufacturability, cost, and performance. Partnering with an experienced precision manufacturer ensures the right balance between engineering requirements and production efficiency.

Manufacturing Process & QC

Precision Metal Manufacturing: From Concept to Zero-Defect Production

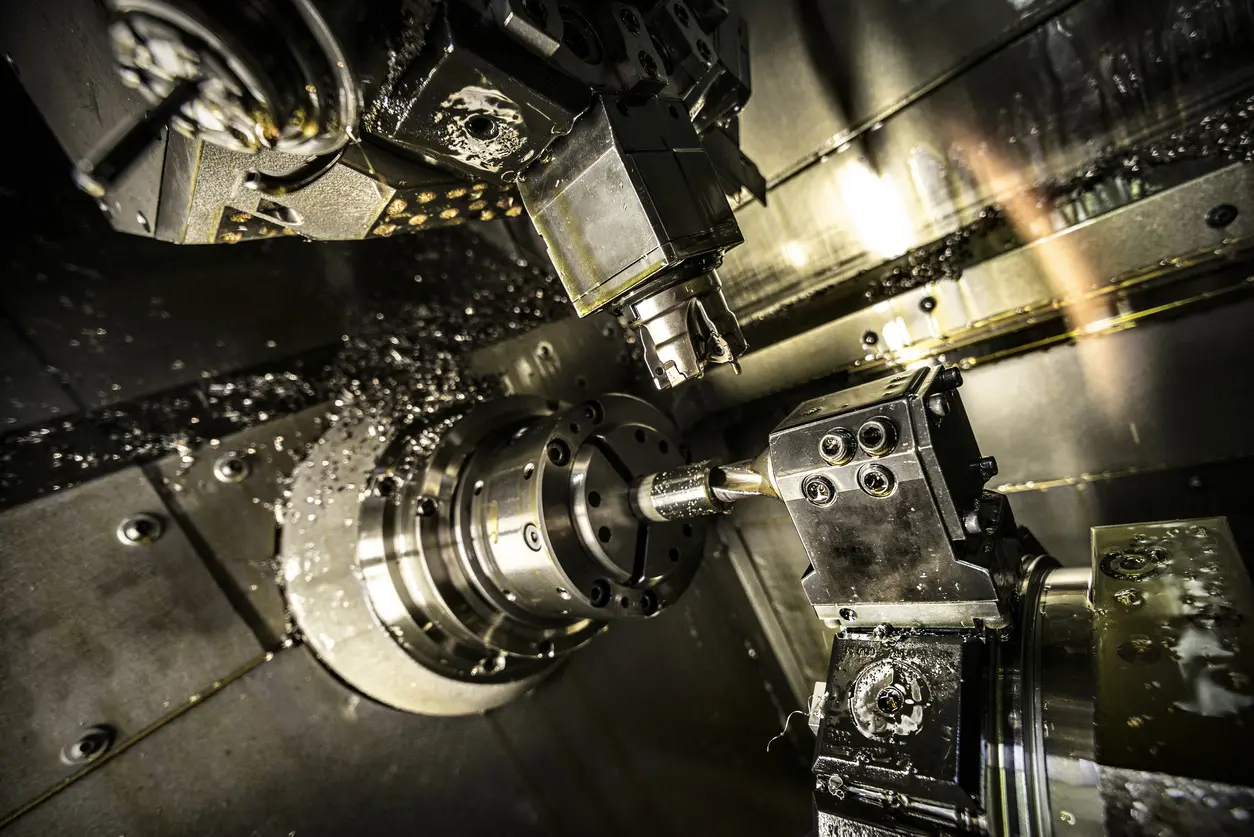

At Wuxi Lead Precision Machinery, our production process is engineered for absolute reliability in high-stakes metal component manufacturing. We integrate rigorous engineering discipline with advanced CNC technology to deliver flawless parts for aerospace, medical, and industrial automation sectors. The journey begins with collaborative Design for Manufacturability (DFM) analysis. Our engineering team reviews client CAD models, identifying potential stress points, material utilization inefficiencies, and geometric complexities early. We apply Geometric Dimensioning and Tolerancing (GD&T) principles to define critical features, ensuring designs align with both functional requirements and our machining capabilities. This phase includes finite element analysis (FEA) for structural validation and material suitability assessment, preventing costly revisions downstream. Client feedback is incorporated iteratively until the digital model meets all performance and producibility criteria.

Prototyping transforms validated designs into physical reality for critical verification. Using our 5-axis CNC milling and turning centers, we produce functional prototypes from the specified alloy—such as titanium, Inconel, or medical-grade stainless steel. Each prototype undergoes comprehensive metrology: Coordinate Measuring Machine (CMM) scans verify dimensional accuracy against the CAD model, surface roughness testers confirm finish requirements, and non-destructive testing (NDT) checks for internal integrity. This stage is not merely a sample run; it is a stress test of the entire manufacturing sequence. Any deviation triggers immediate root-cause analysis and process refinement before mass production commences, eliminating assumptions about scalability.

Mass production leverages the perfected workflow under our Zero Defects framework. Every component is machined using optimized CNC programs with real-time tool wear monitoring and in-process gauging. Statistical Process Control (SPC) charts track critical dimensions continuously, with automatic machine adjustments if trends approach tolerance limits. Full material traceability—from heat number to final inspection—is maintained via our digital MES system. Final inspection includes 100% verification of critical features using calibrated CMMs and optical comparators, alongside batch-level material certification. This closed-loop system ensures conformance to ISO 2768-mK or tighter customer-specific standards, with defect rates consistently below 50 PPM.

Our validated production capabilities deliver uncompromising quality at scale:

| Specification | Capability | Industry Standard Exceeded |

|---|---|---|

| Material Range | Titanium, Inconel, Stainless Steel, Aluminum Alloys | AMS, ASTM, ISO |

| Dimensional Tolerance | ±0.001 mm (±0.00004″) | ISO 2768-mK (Typ. ±0.05mm) |

| Surface Finish (Ra) | 0.4 μm (16 μin) achievable | Aerospace Grade N5 |

| Max Part Size | Ø600 x 800 mm turning; 1000 x 800 x 600 mm milling | Custom fixturing available |

| Certifications | ISO 9001:2015, IATF 16949, NADCAP (pending) | AS9100 compliance pathway |

This disciplined progression—from intelligent design through validated prototyping to rigorously controlled mass production—ensures your components perform flawlessly in mission-critical applications. Wuxi Lead’s Zero Defects commitment is not aspirational; it is embedded in every process parameter, measurement, and decision, directly translating to reduced scrap costs, accelerated time-to-market, and unwavering supply chain confidence for our global clients.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising Quality in Custom Metal Manufacturing

At Wuxi Lead Precision Machinery, we understand that precision, consistency, and reliability are non-negotiable in high-performance industries such as aerospace, medical devices, automotive, and industrial automation. As a leading custom metal cutting company based in China, we specialize in delivering complex, high-tolerance components with unmatched repeatability and speed. When you partner with us, you’re not just outsourcing production—you’re gaining a strategic manufacturing ally committed to your success.

Our advanced CNC machining capabilities, combined with rigorous quality control protocols, ensure every part meets exacting specifications. From prototype development to full-scale production runs, we provide end-to-end solutions tailored to your unique engineering requirements. Whether you’re working with aluminum, stainless steel, titanium, or exotic alloys, our state-of-the-art equipment and experienced engineering team deliver precision down to ±0.005 mm.

We pride ourselves on transparency, responsiveness, and technical expertise. Our engineers collaborate closely with your design and R&D teams to optimize manufacturability, reduce lead times, and lower total production costs—without sacrificing quality. With ISO 9001 certification and a fully integrated quality management system, including in-process inspections and final QA documentation, we guarantee every shipment meets international standards.

Our manufacturing capabilities are built for scalability and precision. Below are key technical specifications that define our production excellence:

| Capability | Specification |

|---|---|

| CNC Machining Types | 3-axis, 4-axis, 5-axis milling, turning, multi-tasking |

| Maximum Work Envelope | 1,200 mm × 800 mm × 600 mm (XYZ) |

| Tolerance | ±0.005 mm standard, tighter upon request |

| Surface Finish | As low as Ra 0.4 µm (16 µin), customizable |

| Materials | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Titanium (Gr2, Gr5), Brass, Inconel, Tool Steels |

| Secondary Processes | Deburring, anodizing, passivation, plating, laser marking |

| Quality Assurance | CMM inspection, GD&T reporting, First Article Inspection (FAI), PPAP documentation |

We serve global clients who demand more than just parts—they demand precision, partnership, and peace of mind. Our logistics network ensures on-time delivery to North America, Europe, and Asia, with flexible production scheduling to support just-in-time inventory models.

If you’re looking for a trusted metal cutting company that combines advanced technology with engineering insight, it’s time to elevate your supply chain. Contact us today at [email protected] to discuss your next project. Let Wuxi Lead Precision Machinery become your preferred partner in precision manufacturing—where engineering excellence meets operational reliability.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.