Technical Contents

Engineering Guide: Plastic Mould Products

Engineering Insight: The Critical Role of Precision in Plastic Mould Products

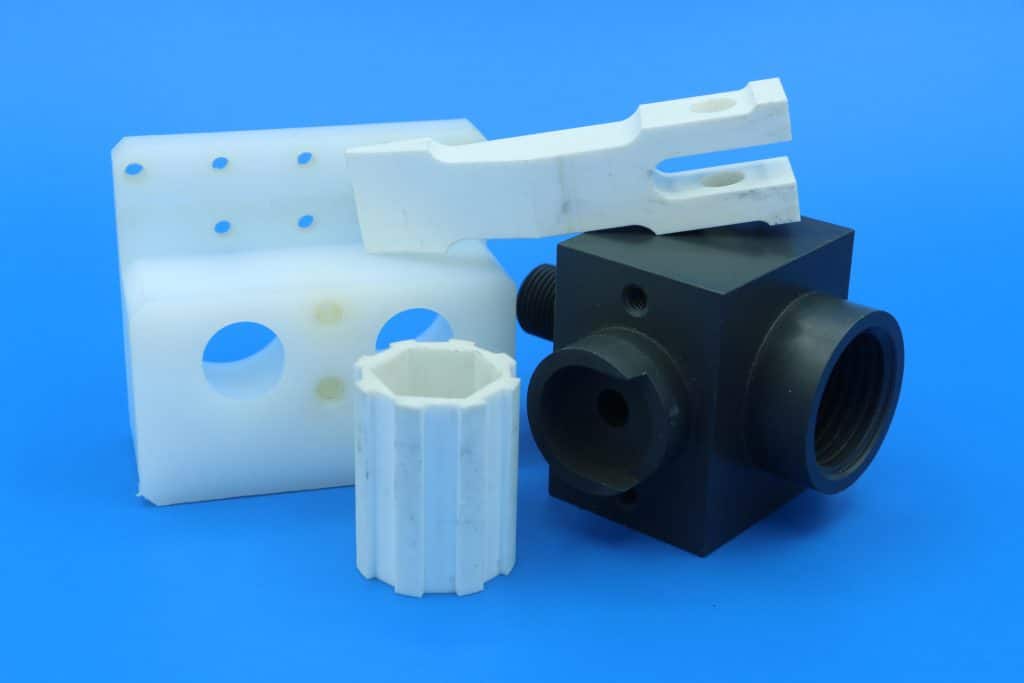

In the realm of custom metal manufacturing, plastic mould products represent a convergence of material science, mechanical engineering, and high-precision tooling. These components are foundational across industries such as automotive, medical devices, consumer electronics, and aerospace, where dimensional accuracy, surface finish, and repeatability are not merely desirable—they are mandatory. At Wuxi Lead Precision Machinery, we understand that the performance of a final plastic component is directly traceable to the precision of the mould that shapes it. Even micron-level deviations in mould geometry can propagate into functional failures, assembly misalignments, or aesthetic defects in end-use parts.

Precision in plastic moulding begins with the design and fabrication of the mould tool, typically machined from high-grade tool steels or aluminum alloys using CNC milling, electrical discharge machining (EDM), and grinding processes. The complexity of cavity and core geometries, combined with stringent requirements for venting, cooling channels, and ejection systems, demands a holistic engineering approach. At Lead Precision, our expertise lies in integrating tight tolerance control—down to ±0.002 mm—into every phase of production, from initial CAD modeling to final inspection. This level of accuracy ensures consistent part replication over high-volume production runs, minimizing flash, warpage, and shrinkage-related defects.

Our experience in delivering mission-critical components for Olympic-standard equipment and military-grade applications has further refined our approach to quality assurance. These projects required adherence to ISO 9001 and MIL-STD specifications, with full traceability, first-article inspection reports (FAIR), and continuous process validation. The same rigor is applied to our plastic mould manufacturing processes, where we leverage coordinate measuring machines (CMM), optical profilometry, and 3D scanning to verify conformity to design intent.

Beyond dimensional accuracy, thermal management within the mould plays a pivotal role in cycle time and part quality. Our engineering team optimizes cooling channel layouts using simulation software to ensure uniform temperature distribution, reducing internal stresses and improving part stability. Surface treatments such as polishing, texturing, and PVD coating are also applied with precision to meet functional and aesthetic requirements.

The success of any plastic mould product hinges on the synergy between design, material selection, and manufacturing fidelity. At Wuxi Lead Precision Machinery, our decades of experience in high-end custom manufacturing enable us to deliver moulds that exceed performance expectations, even under extreme operational conditions.

| Specification | Detail |

|---|---|

| Tolerance Range | ±0.002 mm to ±0.01 mm |

| Standard Materials | P20, 718H, S136, NAK80, Aluminum 7075 |

| Surface Finish | Ra 0.05 µm (mirror) to Ra 3.2 µm (textured) |

| Mould Life | 100,000 to 1,000,000+ cycles |

| Lead Time | 4 to 12 weeks (depending on complexity) |

| Quality Standards | ISO 9001, ISO 13485, MIL-STD-810 compliant |

| Inspection Equipment | CMM, 3D Scanner, Optical Comparator |

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Plastic Mold Excellence

Wuxi Lead Precision Machinery delivers uncompromising precision in custom metal manufacturing, specifically engineered to meet the exacting demands of high-performance plastic mold production. Our core strength lies in advanced multi-axis machining and rigorous quality control, ensuring every mold component meets the stringent tolerances required for flawless plastic part replication and extended mold life. We understand that the dimensional accuracy and surface integrity of mold cavities, cores, and inserts directly dictate the quality, consistency, and cost-efficiency of your final plastic products.

Our foundation is a modern fleet of state-of-the-art 5-axis CNC machining centers. These systems enable simultaneous, complex multi-directional tool movement, critical for producing the intricate geometries, undercuts, and seamless transitions inherent in advanced plastic molds. This capability eliminates the need for multiple setups, significantly reducing cumulative error potential and ensuring superior part-to-part consistency. We expertly machine a wide range of mold-specific materials, including hardened tool steels (P20, 718, H13, S136), aluminum alloys for prototyping, and specialty materials, achieving exceptional surface finishes directly off the machine. This minimizes secondary hand polishing, accelerating time-to-market for your mold projects while guaranteeing the precise surface characteristics necessary for optimal plastic flow and part ejection.

Quality is not a final checkpoint but an integrated process at Wuxi Lead. Every critical dimension undergoes comprehensive verification using industry-standard Coordinate Measuring Machines (CMM). Our Zeiss and Mitutoyo CMMs provide micron-level accuracy in three-dimensional space, generating detailed inspection reports with full traceability. This systematic approach validates conformance to your engineering specifications at every stage, providing absolute confidence in the dimensional integrity of your mold components before assembly. We adhere strictly to international standards, ensuring our processes and outputs are globally recognized for reliability.

The following table details our standard achievable tolerances for machined mold components, reflecting our commitment to precision:

| Feature Type | Standard Tolerance | Capability (Optimized) | Reference Standard |

|---|---|---|---|

| Linear Dimensions | ±0.010 mm | ±0.005 mm | ISO 2768-mK |

| Angular Dimensions | ±0.05° | ±0.02° | ISO 2768-c |

| Positional Tolerance | ±0.015 mm | ±0.008 mm | GD&T Position |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm | ISO 1302 |

| Flatness | 0.015 mm / 100 mm | 0.008 mm / 100 mm | ISO 1101 |

These capabilities are not theoretical benchmarks but proven performance levels consistently achieved across our production floor. By leveraging our 5-axis CNC expertise and rigorous CMM-based quality assurance, Wuxi Lead Precision Machinery provides the dimensional fidelity essential for producing plastic molds that deliver superior part quality, reduced cycle times, and exceptional longevity in your manufacturing operations. Partner with us for mold components where precision is non-negotiable.

Material & Finish Options

Material selection is a foundational step in the production of high-performance plastic mould products, directly influencing durability, precision, and lifecycle cost. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing solutions tailored to the stringent demands of advanced moulding applications. Our expertise spans the selection and processing of aluminum, steel, and titanium—three core materials that serve distinct roles based on operational requirements.

Aluminum alloys are widely favored for prototype and low-to-medium volume production due to their excellent machinability, thermal conductivity, and lightweight properties. They enable faster cycle times in injection moulding and reduce wear on processing equipment. While not as hard as steel or titanium, modern high-strength aluminum grades such as 7075 and 6061 offer sufficient durability for many industrial applications, especially when enhanced with surface treatments like anodizing.

Steel remains the standard for high-volume production moulds where wear resistance and dimensional stability are paramount. Tool steels such as P20, H13, and S136 provide excellent hardness and can withstand repeated thermal cycling without deformation. These materials are ideal for complex mould geometries requiring tight tolerances and long service life. Through proper heat treatment and finishing, steel moulds deliver consistent performance across millions of cycles.

Titanium, while less common due to cost and machining complexity, offers an exceptional strength-to-density ratio and outstanding corrosion resistance. It is typically reserved for specialized applications where weight reduction and environmental resistance are critical, such as in aerospace or medical device moulding. Titanium’s low thermal conductivity requires careful process planning but contributes to reduced heat transfer in sensitive mould zones.

Surface finishing, particularly anodizing, plays a crucial role in enhancing material performance. Anodizing aluminum creates a durable, corrosion-resistant oxide layer that improves wear resistance and allows for color coding or aesthetic customization. Hard anodizing (Type III) can increase surface hardness to near that of tool steel, significantly extending mould life in abrasive environments.

Below is a comparative overview of key material properties relevant to plastic mould manufacturing.

| Material | Tensile Strength (MPa) | Hardness (HB) | Thermal Conductivity (W/m·K) | Typical Applications | Anodizing Compatible |

|---|---|---|---|---|---|

| Aluminum 6061 | 310 | 95 | 167 | Prototypes, low-volume moulds | Yes |

| Aluminum 7075 | 572 | 150 | 130 | High-stress mould components | Yes (Hard Anodize) |

| P20 Steel | 900–1100 | 280–320 | 30 | High-volume injection moulds | No |

| H13 Steel | 1600 | 450 | 27 | Hot work, high-temp moulds | No |

| Titanium Grade 5 | 900 | 330 | 7 | Aerospace, medical moulds | Limited |

Selecting the right material requires a balance of mechanical performance, thermal behavior, and cost efficiency. At Wuxi Lead Precision Machinery, we support clients in making informed decisions based on application-specific demands, ensuring optimal mould performance and return on investment.

Manufacturing Process & QC

Production Process: From Precision Design to Zero-Defect Mass Production

At Wuxi Lead Precision Machinery, our commitment to flawless plastic mould products begins with a rigorously defined production process. This integrated workflow—spanning Design, Prototyping, and Mass Production—ensures every component meets exacting aerospace, medical, and automotive standards. We eliminate defects at the source through engineering discipline and closed-loop validation.

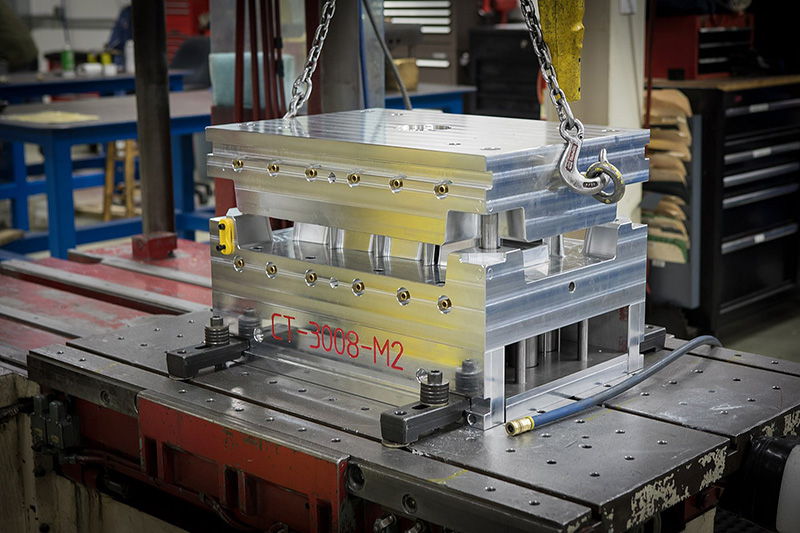

The Design phase leverages advanced CAD/CAM and mold flow simulation to preempt manufacturing challenges. Our engineers meticulously analyze part geometry, material behavior, and cooling dynamics, optimizing gate locations and runner systems before any metal is cut. Material selection is validated against thermal stability and chemical resistance requirements, ensuring compatibility with both the polymer and end-use environment. This virtual validation reduces physical iterations by up to 70%, accelerating time-to-market while securing structural integrity.

Prototyping transitions validated designs into tangible validation. Utilizing high-speed CNC machining and EDM, we produce functional molds for initial runs of 1–50 parts. Each prototype undergoes comprehensive dimensional inspection via CMM and optical comparators, alongside rigorous material and performance testing. Critical tolerances are verified against GD&T callouts, and any deviations trigger immediate design refinements. This stage confirms manufacturability and identifies micro-defect risks—such as weld lines or sink marks—before committing to full production tooling.

Mass Production activates only after prototype approval, deploying hardened steel molds built for 500,000+ cycles. Our automated production cells integrate real-time process monitoring: cavity pressure sensors, temperature controllers, and robotic part handling feed data into a centralized SPC system. Every cycle is tracked against predefined parameters, with automatic machine lockout on deviation. In-process metrology stations conduct hourly first-article inspections, while 100% automated vision systems scan for surface defects. This multi-layered quality gate ensures consistent conformance, with traceability from raw material lot to finished part.

The transition from prototyping to volume production is defined by controlled scalability and unwavering quality focus. Key specifications governing this shift include:

| Parameter | Prototyping Stage | Mass Production Stage |

|---|---|---|

| Typical Volume | 1–50 parts | 10,000+ parts |

| Cycle Time Focus | Validation stability | Optimized repeatability |

| QC Frequency | 100% inspection per run | Hourly SPC + 100% vision |

| Defect Rate Target | < 0.5% | < 0.05% (Zero Defects) |

Zero Defects is not aspirational—it is engineered. By embedding precision at every phase and leveraging data-driven corrections, Wuxi Lead delivers plastic mould products where reliability is non-negotiable. This process guarantees that your supply chain receives only components meeting the highest global quality benchmarks, batch after batch.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Custom Metal Manufacturing for Plastic Mould Products

At Wuxi Lead Precision Machinery, we understand that precision, reliability, and consistency are non-negotiable in the production of plastic mould products. As a leading provider of custom metal manufacturing solutions based in China, we specialize in delivering high-performance components and systems engineered to meet the exacting demands of modern injection moulding and plastic processing industries. Our advanced CNC machining capabilities, rigorous quality control protocols, and deep engineering expertise enable us to support global manufacturers in achieving superior product performance and operational efficiency.

When you partner with Lead Precision, you gain more than a supplier—you gain a strategic collaborator committed to your success. From initial design consultation to final delivery, our team works closely with clients to ensure every component meets tight tolerances, material specifications, and functional requirements. Whether you require mould bases, inserts, cores, cavities, or complete mould assemblies, our facility is equipped with state-of-the-art machinery and staffed by experienced engineers who understand the complexities of plastic mould tooling.

Our manufacturing process integrates precision CNC milling, wire EDM, grinding, and surface finishing technologies, all supported by comprehensive metrology and inspection systems. We serve industries ranging from automotive and consumer electronics to medical devices and industrial equipment, where quality and repeatability are paramount.

We pride ourselves on delivering not only exceptional parts but also responsive service, on-time delivery, and scalable production capacity. Our commitment to continuous improvement ensures that we remain at the forefront of innovation in custom metal manufacturing.

Below are key technical specifications that define our capabilities:

| Specification | Detail |

|---|---|

| Machining Tolerances | ±0.002 mm |

| Maximum Workpiece Size | 1200 mm × 800 mm × 600 mm |

| Materials Processed | P20, 718, H13, S136, Stainless Steel, Aluminum, Brass, Tool Steels |

| CNC Milling Capacity | 3-axis, 4-axis, 5-axis machining |

| Surface Finish | Ra 0.1 – 0.8 μm (custom finishes available) |

| Quality Standards | ISO 9001:2015 certified, Full inspection reports provided |

| Lead Times | Prototype: 7–14 days; Production: 15–25 days (varies by complexity) |

Partnering with Wuxi Lead Precision Machinery means choosing a manufacturer that combines technical excellence with customer-centric service. We are equipped to handle low-volume prototyping and high-volume production runs with equal precision and dedication.

For engineering support, quotations, or technical collaboration, contact us today at [email protected]. Let us help you elevate the performance and reliability of your plastic mould products through precision manufacturing you can trust.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.