Technical Contents

Engineering Guide: Plastic Injection Molds For Sale

Engineering Insight: Precision as the Non-Negotiable Foundation of Plastic Injection Molds

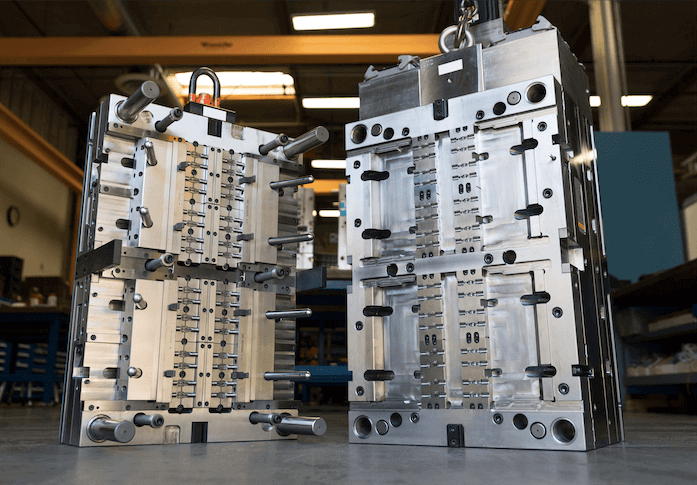

In the high-stakes realm of plastic injection molding, dimensional precision is not merely a desirable attribute; it is the absolute cornerstone of part functionality, assembly integrity, and long-term product success. Microscopic deviations during mold fabrication—measured in microns—translate directly into part warpage, flash, sink marks, or critical fit failures downstream. For components destined for aerospace, medical devices, or precision electronics, tolerances exceeding ±0.01mm can render entire production runs unusable, triggering costly delays and scrap. Achieving true precision demands more than advanced machinery; it requires integrated engineering rigor spanning material science, thermal dynamics, cavity pressure monitoring, and meticulous process validation. At Wuxi Lead Precision Machinery, we treat precision as a systemic engineering discipline, not a final inspection checkpoint. Our CNC machining centers operate under strict environmental controls, while our metrology lab utilizes multi-sensor CMMs and optical comparators calibrated to ISO 17025 standards, ensuring every cavity, core, and runner system adheres to the most stringent specifications before mold assembly even begins.

Our commitment to precision is forged in applications where failure is unacceptable. Wuxi Lead has engineered and manufactured critical injection molds for components used in Olympic timing systems, where split-micron tolerances ensure nanosecond accuracy in world-record validations. Similarly, our molds for specialized military hardware undergo rigorous validation under extreme environmental conditions, meeting MIL-STD-810G requirements for dimensional stability across temperature excursions from -55°C to +125°C. This heritage instills a zero-defect culture across our entire workflow—from initial DFM analysis through hardened steel selection (including proprietary H13 variants for extended wear life) to final mold tryout under simulated production parameters. We understand that a mold “for sale” is not a commodity; it is the physical embodiment of your product’s quality promise.

The table below outlines the precision benchmarks Wuxi Lead consistently achieves, reflecting our engineering capabilities beyond typical industry baselines:

| Specification | Wuxi Lead Standard | Industry Typical Baseline |

|---|---|---|

| Cavity/Coring Tolerance | ±0.002mm to ±0.005mm | ±0.01mm to ±0.025mm |

| Mold Base Flatness | 0.003mm per 100mm | 0.01mm per 100mm |

| Surface Finish (Cavity) | Ra 0.05μm to Ra 0.2μm | Ra 0.4μm to Ra 0.8μm |

| Steel Hardness Consistency | ±1.5 HRC across cavity | ±3.0 HRC across cavity |

| Lead Time (Complex Mold) | 6-8 weeks (validated) | 8-12 weeks |

This precision translates directly into your operational ROI. Tighter mold tolerances minimize part rework, reduce cycle times through optimized cooling channels, and extend mold life by mitigating stress points—factors often overlooked in initial mold procurement but critical to total cost of ownership. When sourcing plastic injection molds, prioritize partners whose engineering depth matches your quality ambition. Wuxi Lead Precision Machinery delivers molds engineered for performance, validated by mission-critical applications, and built to sustain the exacting demands of high-volume, high-precision manufacturing. Your product’s integrity starts with the mold’s micron-level truth.

Precision Specs & Tolerances

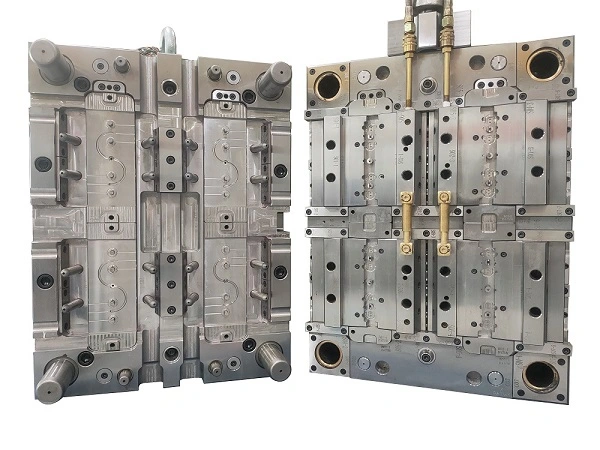

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, specializing in high-precision plastic injection molds for global industrial clients. Our engineering expertise is built on state-of-the-art infrastructure, enabling consistent production of complex mold systems that meet the most stringent performance and quality standards. At the core of our manufacturing process is 5-axis CNC machining, which allows for simultaneous multi-directional cutting with exceptional accuracy and surface finish. This technology enables us to produce intricate mold cavities, cores, and inserts with reduced setup times and superior geometric control, ensuring tight integration and long-term durability in demanding injection molding applications.

Our machining centers are operated by certified CNC programmers and toolmakers who utilize industry-leading CAD/CAM software to translate client designs into precision-machined components. The 5-axis platform supports continuous tool engagement and optimal toolpath strategies, minimizing thermal deformation and tool wear while maximizing material removal efficiency. This results in molds that exhibit exceptional dimensional stability, fine detail reproduction, and extended service life under high-volume production cycles. Materials are carefully selected based on application requirements, including hardened tool steels, pre-hardened alloys, stainless steels, and aluminum for prototype tooling, all processed under controlled environmental conditions to ensure consistency.

Quality assurance is integral to every stage of production. Each mold component undergoes rigorous inspection using a coordinate measuring machine (CMM) with probe technology capable of micron-level accuracy. The CMM system verifies critical dimensions, form tolerances, and positional relationships in full 3D space, generating comprehensive inspection reports traceable to international standards (ISO 9001). These reports are provided with every mold delivery, offering full transparency and documentation for customer validation and regulatory compliance.

The following table outlines our standard technical tolerances, reflecting our commitment to precision and repeatability in mold manufacturing:

| Feature | Standard Tolerance | High-Precision Capability |

|---|---|---|

| Linear Dimensions (mm) | ±0.01 mm | ±0.005 mm |

| Hole Diameter | ±0.01 mm | ±0.007 mm |

| Positional Tolerance | ±0.01 mm | ±0.005 mm |

| Flatness | 0.01 mm per 100 mm | 0.005 mm per 100 mm |

| Surface Finish (Ra) | 0.8 µm | 0.4 µm |

| Angular Tolerance | ±0.05° | ±0.02° |

| Profile Tolerance | ±0.01 mm | ±0.005 mm |

These capabilities are supported by a structured quality management system, in-process inspections, and final assembly validation under real-world simulation conditions. Wuxi Lead Precision Machinery ensures that every plastic injection mold shipped meets exacting technical specifications, delivering reliability, repeatability, and performance for high-end manufacturing environments.

Material & Finish Options

Material Selection: Optimizing Plastic Injection Molds for Performance and ROI

Material selection is the foundational decision determining your plastic injection mold’s lifespan, part quality, and overall return on investment. At Wuxi Lead Precision Machinery, we engineer molds using Aluminum, Steel, and Titanium, each serving distinct production demands. Choosing incorrectly risks premature wear, dimensional instability, and costly downtime. Understanding the precise application requirements is non-negotiable for optimal manufacturing economics.

Aluminum alloys, particularly 7075-T6 and 6061-T6, offer exceptional thermal conductivity and machinability. This makes them ideal for rapid prototyping, low-volume production (typically under 10,000 cycles), and molds requiring quick heat cycling. Aluminum significantly reduces lead times and initial tooling costs. However, its lower hardness necessitates protective surface treatments. Anodizing is essential for aluminum molds, creating a hard, wear-resistant, and corrosion-inhibiting oxide layer. Standard hard anodizing to 25-50µm thickness is common, while specialized processes can reach 75µm for abrasive materials. Without this finish, aluminum molds suffer accelerated wear in production environments.

Tool steels dominate high-volume manufacturing. P20 (1.2311) provides a balanced solution for medium runs (50,000 – 100,000+ cycles), offering good polishability and moderate wear resistance at a reasonable cost. For demanding applications exceeding 500,000 cycles – especially with glass-filled or abrasive polymers – H13 (1.2344) or S136 stainless steel are critical. H13 excels in thermal fatigue resistance for complex cores, while S136 delivers superior corrosion resistance for medical or optical clarity parts. Nitriding or PVD coatings further enhance surface hardness and lifespan for these premium steels.

Titanium alloys represent a specialized solution for extreme conditions. Their exceptional strength-to-weight ratio, corrosion resistance, and non-magnetic properties suit highly corrosive environments (e.g., specific medical or chemical applications) or where weight reduction is paramount. While significantly more expensive and challenging to machine, titanium molds offer unparalleled longevity in niche scenarios where steel would rapidly degrade.

The following table summarizes key comparative specifications for common mold materials:

| Material | Typical Hardness (HRC) | Max Estimated Cycles | Relative Cost Index | Primary Applications |

|---|---|---|---|---|

| Aluminum 7075-T6 | 150 HB (Anodized) | 5,000 – 10,000 | 1.0 | Prototyping, Very Low Volume, Jigs |

| P20 Steel | 28-32 | 50,000 – 100,000+ | 1.8 | Medium Volume, General Purpose |

| H13 Steel | 48-52 (After Heat Treat) | 500,000 – 1,000,000+ | 3.0 | High Volume, Hot Runner Systems, Cores |

| S136 Stainless | 48-52 | 500,000 – 1,000,000+ | 3.5 | Corrosive Resins, Medical, Optical Parts |

| Titanium Grade 5 | 36-40 (Surface Treated) | 1,000,000+ | 8.0+ | Extreme Corrosion, Weight Critical, Niche |

Selecting the right material requires analyzing your polymer, part complexity, expected volume, surface finish requirements, and total cost of ownership. Wuxi Lead Precision Machinery leverages decades of metallurgical expertise and advanced finishing capabilities to match your specific production goals with the optimal mold solution. We do not sell generic tools; we engineer precision assets designed for your profitability. Contact our engineering team to define the precise material strategy for your next mold project.

Manufacturing Process & QC

Precision-Driven Manufacturing: From Design to Zero-Defect Mass Production

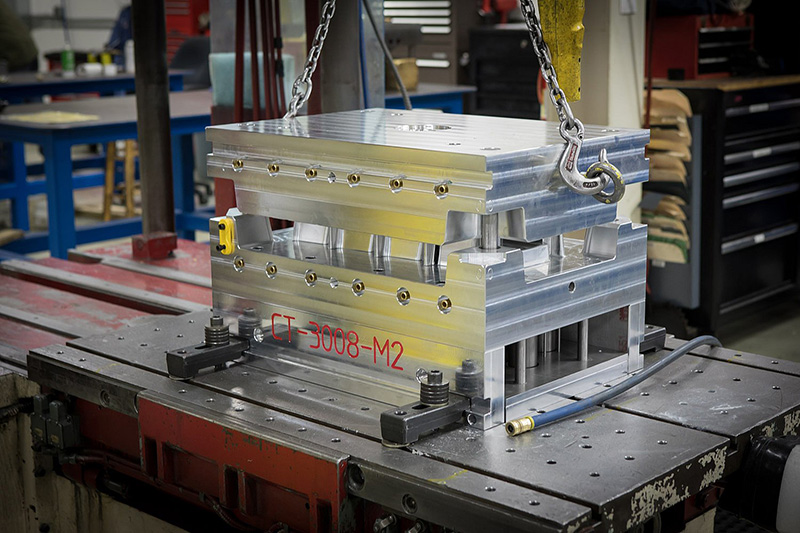

At Wuxi Lead Precision Machinery, we engineer plastic injection molds to meet the exacting standards of global industries, including automotive, medical, and consumer electronics. Our production process is a disciplined, phase-gated system designed to ensure precision, repeatability, and zero defects at scale. Every mold we deliver is the result of a tightly controlled workflow that begins with engineering insight and culminates in flawless mass production.

The process starts with Design Engineering, where our team collaborates with clients to translate product concepts into manufacturable mold designs. Using advanced CAD/CAM software such as Siemens NX, SolidWorks, and Autodesk Moldflow, we conduct detailed 3D modeling and mold flow analysis. This stage evaluates gate placement, cooling efficiency, and potential warpage, ensuring optimal filling and ejection. All design iterations are reviewed and approved digitally, minimizing misinterpretation and accelerating time-to-prototype.

Next is Prototyping and Validation. We fabricate initial mold samples using high-precision CNC machining, wire EDM, and surface grinding, ensuring tolerances as tight as ±0.002 mm. These prototype molds are used to produce first-article parts, which undergo comprehensive inspection via CMM (Coordinate Measuring Machine), optical comparators, and automated vision systems. Material compatibility, dimensional accuracy, and surface finish are rigorously tested. Any deviations trigger immediate design or process adjustments—long before full-scale production begins.

Only when prototype validation confirms full compliance do we transition to Mass Production. Our automated production lines integrate real-time monitoring systems that track temperature, pressure, cycle time, and part weight. Each mold is built from premium-grade tool steels such as P20, 718H, or NAK80, selected based on wear resistance, polishability, and production volume. Hardened cores, precision-guided ejector systems, and conformal cooling channels are standard features that enhance durability and part consistency.

Throughout production, we enforce a zero-defect philosophy through Statistical Process Control (SPC) and First Article Inspection Reports (FAIR). Every mold is subjected to a 48-hour continuous run test under simulated factory conditions, verifying stability and output quality. Final acceptance includes a full mold performance report, maintenance guidelines, and spare parts documentation.

Our clients rely on Wuxi Lead not just for molds—but for guaranteed manufacturability. By integrating design intelligence, empirical validation, and industrial-grade execution, we deliver injection molds that perform flawlessly from the first shot to the millionth cycle.

Typical Mold Specifications and Capabilities

| Parameter | Specification |

|---|---|

| Maximum Mold Size | 1200 × 800 × 900 mm |

| Weight Capacity | Up to 8,000 kg |

| Tolerance | ±0.002 mm |

| Surface Finish | SPI A1, A2, B1, B2, VDI 3400 up to #1200 grit |

| Tool Steel Options | P20, 718H, S136, NAK80, H13, SKD61 |

| Lead Time (Prototype) | 15–25 days |

| Lead Time (Production Mold) | 30–50 days |

| Production Run Validation | 48-hour continuous test, 100% part inspection |

| Quality Standards | ISO 9001:2015, IATF 16949 (automotive) |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising Injection Mold Excellence

Securing a manufacturing partner capable of delivering precision-engineered plastic injection molds on time and within specification is critical for your product’s success. At Wuxi Lead Precision Machinery, we transform complex design challenges into high-performance tooling solutions through rigorous engineering discipline and advanced manufacturing capabilities. Our ISO 9001-certified facility in Wuxi, China, operates under stringent quality protocols to ensure every mold meets global automotive, medical, and consumer electronics standards. We specialize in custom molds for high-cavitation production, micro-molding applications, and corrosion-resistant tooling requiring micron-level tolerances. Partnering with us means gaining a single-source solution from initial CAD analysis through steel selection, CNC machining, EDM, polishing, and validation testing—all under one roof with full traceability.

Our technical capabilities are engineered for reliability in demanding production environments. The table below outlines core specifications for our standard and high-precision mold offerings:

| Specification | Standard Precision Molds | High-Precision Molds |

|---|---|---|

| Steel Grades | P20, 718H, NAK80 | S136, H13, 2738HH |

| Maximum Mold Size | 1200 x 800 x 800 mm | 1500 x 1000 x 1000 mm |

| Tolerance Range | ±0.01 mm | ±0.003 mm |

| Surface Finish (Cavity) | SPI-A2 (Ra 0.1 µm) | SPI-A1 (Ra 0.025 µm) |

| Lead Time (Complex Mold) | 35-45 days | 45-60 days |

| Validation Testing | 50k cycles | 100k+ cycles |

What distinguishes Lead Precision is our proactive engineering collaboration. We engage early in your design phase to identify potential manufacturability issues, optimize gate locations, and recommend material-specific cooling strategies—reducing time-to-market by up to 30%. Our technical team utilizes Moldflow simulation and 3D metrology to validate performance before steel cutting, eliminating costly revisions. Every project benefits from dedicated project management with real-time progress tracking and transparent communication in English or Mandarin. With over 15 years of experience serving Tier-1 suppliers across Europe, North America, and Asia, we consistently achieve first-article approval rates exceeding 98%.

Your next-generation product demands tooling that delivers zero-defect production at scale. Do not compromise on precision when your brand reputation and production efficiency are at stake. Contact our engineering team today to discuss your specific requirements and receive a detailed capability assessment. Email Contact [email protected] with your part drawings or project scope for a tailored technical consultation within 24 business hours. Let Lead Precision become your strategic partner in achieving manufacturing excellence—where precision engineering meets unwavering reliability.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.