Technical Contents

Engineering Guide: Action Molding

Engineering Insight: The Critical Role of Precision in Action Molding

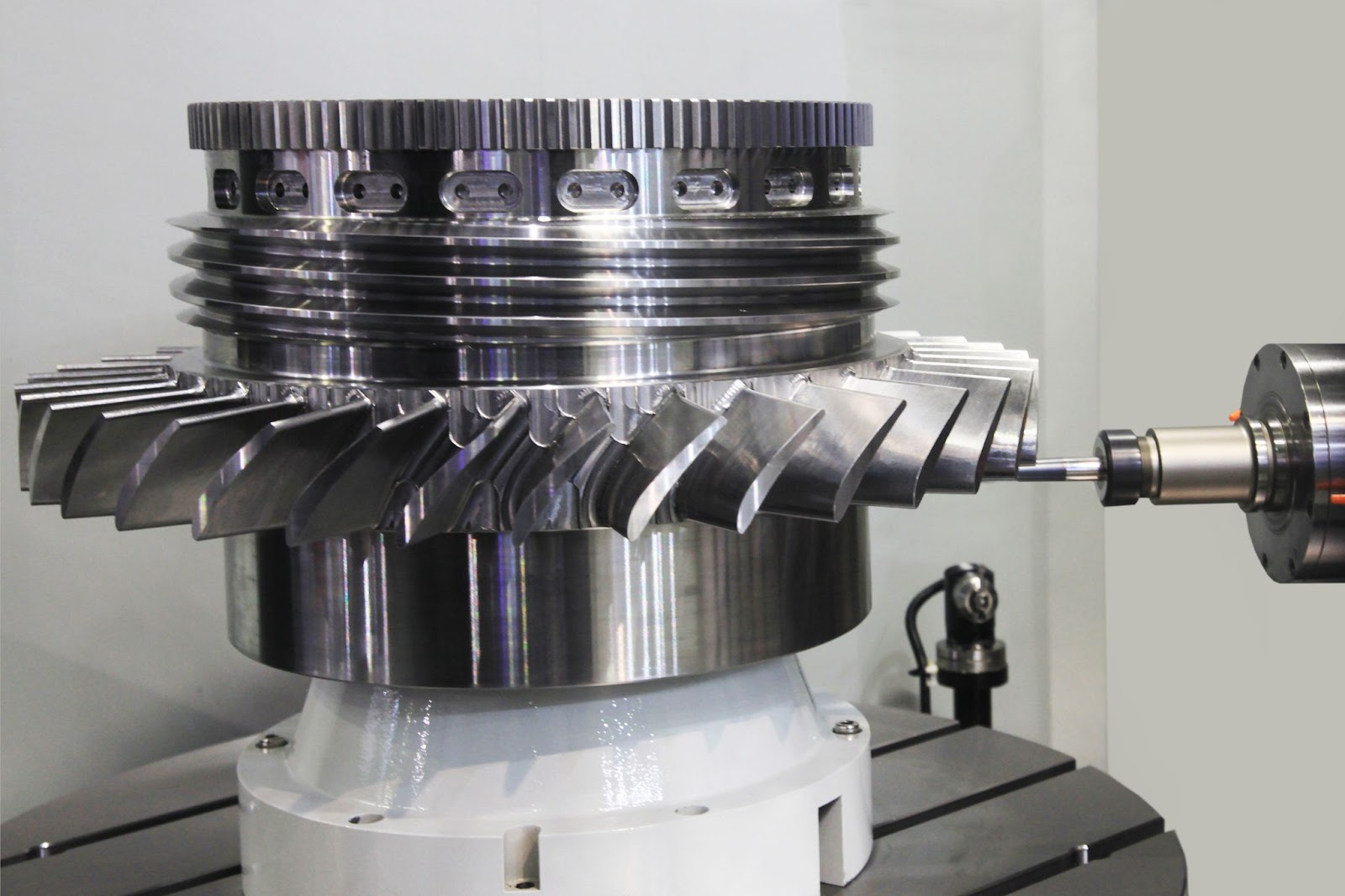

In high-performance manufacturing, the term action molding refers to a specialized process where moving cores or slides are integrated into the mold to produce complex geometries that cannot be achieved through conventional straight-pull molding. This technique is essential in sectors demanding intricate part designs, such as aerospace, defense, and high-end industrial equipment. At Wuxi Lead Precision Machinery, we recognize that the success of action molding hinges on one non-negotiable factor: precision.

Precision in action molding is not merely a quality objective—it is a functional necessity. The integration of side actions, lifters, and rotating cores requires micron-level alignment and repeatability to ensure consistent part integrity, dimensional accuracy, and long-term mold reliability. Even minor deviations in core positioning or timing can result in flash, part warpage, or premature mold failure—issues that are unacceptable in mission-critical applications.

Our engineering team at Wuxi Lead has refined action molding processes through decades of hands-on experience in custom metal manufacturing. This includes delivering components for Olympic-grade equipment, where performance under extreme conditions is mandatory, and military-grade systems, where failure is not an option. These high-stakes projects have reinforced our commitment to precision in every phase of design, machining, and assembly.

We utilize advanced CNC machining centers with sub-micron repeatability, coupled with 3D simulation software to model core movements and detect interference before tooling begins. This predictive approach minimizes trial-and-error, reduces lead time, and ensures that every action mold performs flawlessly from the first shot.

Material selection, surface treatment, and thermal management are also optimized to support the dynamic stresses inherent in action molding. Our in-house metallurgical analysis ensures that mold steels are matched not only to the production volume but also to the mechanical demands of the moving components.

The following table outlines key specifications that define our precision standards in action molding:

| Specification | Value/Range | Application Impact |

|---|---|---|

| Positional Accuracy | ±0.002 mm | Ensures exact core alignment |

| Surface Finish (mold cavity) | Ra 0.05 – 0.2 µm | Reduces friction, improves part ejection |

| Tolerance Control | ISO 2768-mK or tighter | Meets aerospace and defense requirements |

| Cycle Life | 1M+ cycles (standard) | Supports high-volume production |

| Core Movement Repeatability | < 0.005 mm per 100,000 cycles | Maintains long-term dimensional stability |

| Material Options | H13, S136, 420SS, Maraging Steel | Tailored for wear resistance and corrosion |

At Wuxi Lead Precision Machinery, we do not treat action molding as a fabrication task—we treat it as an engineering discipline. Our work for Olympic and military programs has instilled a culture of zero compromise. When precision is built into every motion, the result is not just a mold, but a high-performance system engineered to exceed expectations.

Precision Specs & Tolerances

Technical Capabilities: Precision Metal Component Manufacturing

Wuxi Lead Precision Machinery specializes in high-integrity metal component production for mission-critical applications, leveraging advanced CNC machining rather than molding processes. Our expertise lies in transforming complex metal designs—particularly for aerospace, medical, and industrial automation sectors—into finished parts with uncompromising accuracy. The term “action molding” typically applies to plastic injection processes; for metal components requiring dynamic functionality (e.g., hinges, actuators, or linkage systems), precision CNC machining is the industry-standard solution. We excel in producing such components where tight tolerances, material integrity, and geometric complexity are non-negotiable.

Our technical foundation centers on state-of-the-art 5-axis CNC machining centers, including DMG MORI CTX beta 1250 and MAZAK INTEGREX i-200S systems. These platforms enable single-setup machining of intricate geometries, eliminating cumulative error from multiple fixtures. Capabilities include milling, turning, drilling, and contouring across titanium, Inconel, stainless steel, and aluminum alloys. Integrated high-speed spindles (up to 15,000 RPM) and sub-micron linear encoders ensure surface finishes down to Ra 0.4 µm while maintaining thermal stability during extended production runs. Crucially, our 5-axis workflow reduces lead times by 30–50% compared to 3-axis alternatives, as it minimizes secondary operations and manual handling.

Quality assurance is engineered into every phase. All critical dimensions undergo 100% inspection via Zeiss CONTURA G2 Coordinate Measuring Machines (CMM), programmed to ISO 10360-2 standards. Our CMM cells feature temperature-controlled environments (±0.5°C) and automated probe calibration, ensuring measurement uncertainty below 1.5 µm. Digital traceability links each part to its inspection report via our MES system, providing clients with full dimensional analytics and SPC data. This closed-loop process guarantees compliance with AS9100, ISO 13485, and NADCAP requirements.

The table below summarizes achievable tolerances for machined features, validated across 10,000+ production parts annually:

| Feature Type | Standard Tolerance | Tight Tolerance | Ultra-Precision Tolerance |

|---|---|---|---|

| Linear Dimensions (mm) | ±0.025 | ±0.010 | ±0.005 |

| Linear Dimensions (in) | ±0.001 | ±0.0004 | ±0.0002 |

| Geometric (Flatness) | 0.025 mm | 0.010 mm | 0.005 mm |

| Geometric (True Pos.) | ±0.05 mm | ±0.02 mm | ±0.01 mm |

| Surface Finish (Ra) | 1.6 µm | 0.8 µm | 0.4 µm |

These specifications reflect real-world production capability—not theoretical machine limits—ensuring reliability for components governing motion, sealing, or load transfer. By integrating 5-axis flexibility with metrology-grade verification, we deliver parts that require zero post-machining adjustment, directly reducing our clients’ assembly costs and field failure rates. For action-critical metal systems, this precision translates to extended service life and operational safety. Partner with Wuxi Lead to transform demanding designs into field-proven hardware.

Material & Finish Options

Material Selection for High-Precision Action Molding Components

In the realm of custom metal manufacturing for action molding applications, material selection plays a pivotal role in determining performance, durability, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in precision-engineered components that meet the exacting demands of high-cycle, high-stress environments. The choice between aluminum, steel, and titanium depends on mechanical requirements, environmental exposure, and functional lifespan. Each material offers distinct advantages, and pairing the right alloy with an appropriate finish—such as anodizing—ensures optimal performance.

Aluminum is a preferred choice for action molding components where weight reduction and thermal conductivity are critical. Its high strength-to-weight ratio, coupled with excellent machinability, makes it ideal for dynamic parts such as mold inserts, ejector plates, and support housings. The most commonly used grades, such as 6061-T6 and 7075-T6, offer robust mechanical properties while remaining cost-effective for medium to high-volume production. When exposed to corrosive environments or abrasive wear, aluminum benefits significantly from anodizing—a controlled electrochemical process that enhances surface hardness and corrosion resistance. Type II (sulfuric acid) and Type III (hardcoat) anodizing are routinely applied at Wuxi Lead, with hard anodizing achieving surface hardness up to 60 HRC, dramatically improving wear resistance.

Steel, particularly tool steels like H13, P20, and S7, is selected when maximum durability and resistance to deformation under high pressure are required. These alloys are standard in core and cavity blocks, sliders, and other load-bearing mold components. Their superior hardness and thermal stability ensure long service life in aggressive molding cycles. While steel does not anodize, alternative surface treatments such as nitriding, chrome plating, or PVD coatings are often employed. However, for hybrid systems where aluminum and steel components interface, maintaining material compatibility is essential to prevent galvanic corrosion.

Titanium, though less common due to higher cost and machining complexity, is unmatched in applications demanding extreme strength, lightweight construction, and corrosion resistance. Grade 5 (Ti-6Al-4V) is frequently used in aerospace and medical molding systems where reliability under stress and exposure to harsh chemicals is non-negotiable. While titanium cannot be anodized in the traditional sense, it undergoes a similar anodic oxidation process that enhances surface protection and allows for decorative or identification coloring.

Below is a comparative overview of key material properties relevant to action molding applications.

| Material | Typical Grade | Tensile Strength (MPa) | Hardness (HB) | Density (g/cm³) | Key Applications | Suitable for Anodizing |

|---|---|---|---|---|---|---|

| Aluminum | 6061-T6 / 7075-T6 | 310 / 570 | 95 / 150 | 2.7 | Mold frames, inserts, cooling plates | Yes (Type II & III) |

| Steel | H13 / P20 | 1,300 / 1,000 | 250 / 280 | 7.8 | Cavities, cores, sliders | No |

| Titanium | Ti-6Al-4V | 900 | 340 | 4.4 | Aerospace, medical molds | Yes (anodic oxidation) |

Selecting the right material and finish requires a deep understanding of operational parameters and lifecycle expectations. At Wuxi Lead Precision Machinery, our engineering team collaborates closely with clients to ensure every component is optimized for performance, longevity, and manufacturability.

Manufacturing Process & QC

Precision Metal Manufacturing Process: From Concept to Zero-Defect Production

At Wuxi Lead Precision Machinery, we recognize that true manufacturing excellence in custom metal components begins long before the first chip is cut. Our rigorously defined process—spanning Design, Prototyping, and Mass Production—is engineered specifically to achieve the ultimate goal: Zero Defects. This systematic approach eliminates costly errors downstream and ensures absolute reliability for your high-stakes applications. We address a critical industry point upfront: the term “action molding” is not standard within precision metal manufacturing. For metals, processes like precision die casting, CNC machining, and sheet metal fabrication are the appropriate methodologies. Our expertise lies in these proven metal forming and subtractive techniques, delivering the dimensional accuracy and structural integrity demanding applications require.

The Design Phase is the bedrock of Zero Defects. Our engineering team collaborates intensely with your specifications, utilizing advanced 3D CAD/CAM software and finite element analysis (FEA). This isn’t merely drafting; it’s virtual manufacturing. We simulate material flow, thermal dynamics, stress points, and potential failure modes under real-world operating conditions. Critical tolerances, surface finishes, and material properties are meticulously defined and validated against your functional requirements. This proactive simulation identifies and resolves potential flaws in the digital realm, preventing physical failures later. Only when the virtual component meets all performance criteria does the design lock for prototyping.

Prototyping transforms the validated digital model into physical reality for exhaustive verification. Utilizing our high-precision CNC machining centers and metrology labs, we produce functional prototypes with the same rigor applied to final production. Every dimension, feature, and material property undergoes stringent inspection against the approved design. This phase is iterative; minor adjustments based on physical testing and fit-checks are expected and efficiently managed. Crucially, the prototype validates not only the part geometry but also the feasibility and stability of the intended production process itself. Successful prototype sign-off confirms the process is inherently capable of Zero Defects.

Mass Production executes the proven process at scale, governed by closed-loop quality control systems. Our state-of-the-art CNC machining cells operate under strict environmental controls. Real-time in-process monitoring tracks critical parameters like tool wear, cutting forces, and dimensional drift. Every component undergoes 100% automated optical inspection (AOI) or coordinate measuring machine (CMM) verification at key stages, with data fed back instantly to adjust machining parameters. Statistical process control (SPC) charts continuously monitor capability indices (Cp/Cpk), ensuring the process remains centered and stable. This relentless focus on process control, not just final inspection, is how Zero Defects becomes an operational reality, not just a target.

The following table outlines key specifications and verification methods integral to our Zero Defects process:

| Process Parameter | Specification | Verification Method |

|---|---|---|

| Dimensional Tolerance | Down to ±0.001mm | CMM, Optical Comparator, Laser Scanning |

| Surface Roughness (Ra) | As low as 0.1 µm | Profilometer |

| Material Certification | Full traceability, Mill Certs | Documentation Review, Spectro Analysis |

| In-Process Defect Rate | Target: 0 PPM | SPC Monitoring, 100% AOI |

| Final Inspection Pass | 100% conformance required | Multi-Stage CMM & Visual Audit |

This seamless integration of predictive design, validated prototyping, and tightly controlled mass production delivers consistent, defect-free metal components. Partner with Wuxi Lead to transform your precision requirements into flawless physical reality, minimizing risk and maximizing the performance and longevity of your end products.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Action Molding and Custom Metal Manufacturing

At Wuxi Lead Precision Machinery, we specialize in high-precision custom metal manufacturing with a focused mastery in action molding—a dynamic process that combines injection molding with integrated metal components to deliver robust, high-performance parts for demanding industrial applications. Our engineering-driven approach ensures that every component meets exacting standards for durability, precision, and repeatability. Whether you are developing mission-critical components for automotive systems, industrial automation, or advanced consumer electronics, partnering with Lead Precision means aligning with a manufacturer that values innovation, quality, and long-term collaboration.

Our facility in Wuxi, China, is equipped with state-of-the-art CNC machining centers, multi-axis grinding systems, and advanced molding technologies, enabling us to produce complex metal and hybrid components at scale. We work closely with design engineers and product developers to optimize part geometry, material selection, and manufacturability—reducing lead times and minimizing total production costs. Our team’s deep understanding of action molding allows us to seamlessly integrate metal inserts into polymer matrices, ensuring superior mechanical performance and thermal stability in the final product.

Quality is not an afterthought—it is engineered into every stage of our process. We adhere to ISO 9001 standards and perform rigorous in-process inspections using coordinate measuring machines (CMM), optical comparators, and 3D scanning technology. From prototype development to full-scale production, we maintain tight tolerances and full traceability, providing documentation packages that meet the requirements of regulated industries.

When you choose to partner with Wuxi Lead Precision Machinery, you gain more than a supplier—you gain a strategic manufacturing ally committed to your success. Our responsive engineering support, transparent communication, and flexible production scheduling ensure that your projects stay on track and exceed performance expectations.

Below are key technical capabilities that define our action molding and custom metal manufacturing services:

| Specification | Detail |

|---|---|

| Material Options | Stainless steel, aluminum alloys, brass, tool steel, PEEK, PPS, nylon with metal inserts |

| Tolerance Range | ±0.005 mm (precision machining), ±0.02 mm (molded components) |

| Maximum Part Size | 600 mm × 400 mm × 300 mm |

| Molding Press Capacity | Up to 1,200 tons |

| Secondary Operations | CNC turning, milling, threading, polishing, anodizing, plating |

| Quality Standards | ISO 9001:2015, RoHS compliant, full PPAP and FAI support |

Take the next step toward superior manufacturing outcomes. Contact us today at [email protected] to discuss your action molding requirements or request a detailed engineering consultation. Let Wuxi Lead Precision Machinery bring your most challenging designs to life—with precision, reliability, and unmatched technical expertise.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.