Technical Contents

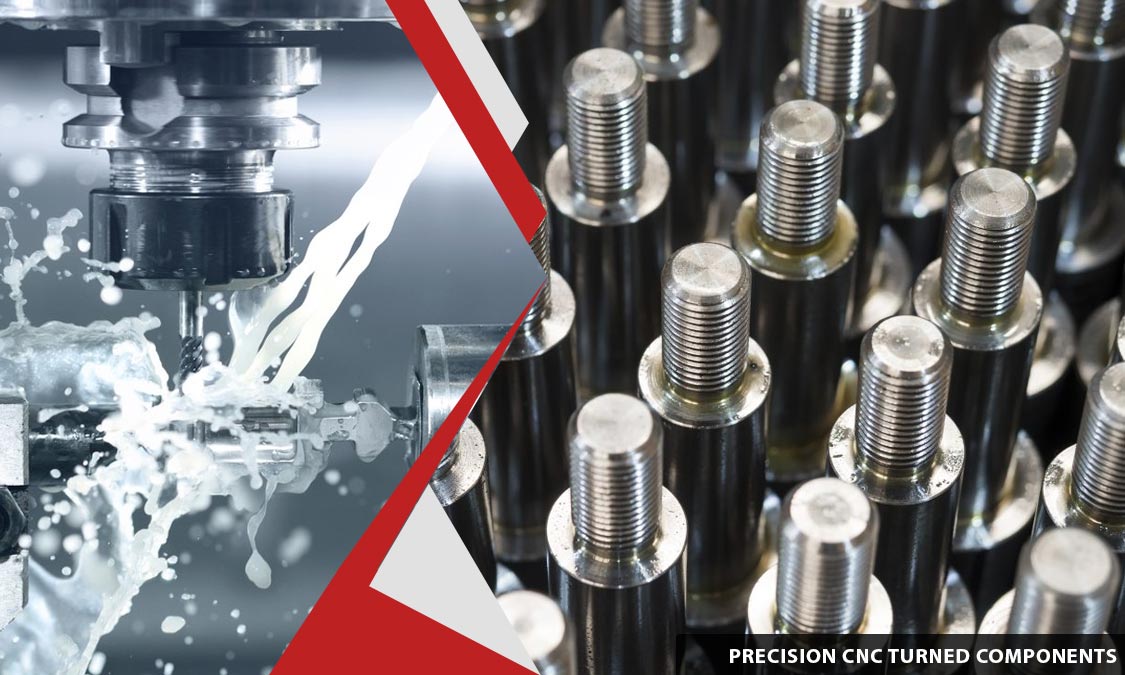

Engineering Guide: Cnc Precision Turning Parts

Engineering Insight: The Critical Role of Precision in CNC Turning Parts

In high-performance industries such as aerospace, defense, medical technology, and advanced automation, the integrity of every mechanical component is paramount. At the heart of these complex systems lie CNC precision turning parts—small in scale, yet monumental in function. These components demand more than mere accuracy; they require micron-level consistency, material integrity, and flawless repeatability. At Wuxi Lead Precision Machinery, we understand that precision is not a feature—it is the foundation.

CNC precision turning involves the controlled removal of material from a rotating workpiece using computer-guided cutting tools. While the process may appear routine, achieving true precision requires mastery of machine dynamics, thermal stability, tooling selection, and real-time process monitoring. Even deviations of a few microns can lead to system failure in mission-critical applications. For example, in aerospace hydraulic systems or military-grade actuators, inconsistent tolerances can compromise safety, efficiency, and compliance with stringent regulatory standards.

Our engineering team at Wuxi Lead has spent over 15 years refining the science of precision turning. This expertise has been validated through our contributions to projects of global significance, including components used in Olympic-standard timing systems and precision subsystems for defense applications. These high-stakes environments demand zero-defect manufacturing, where every part must perform exactly as designed under extreme conditions. Our involvement in such projects underscores our capability to meet and exceed the most rigorous quality benchmarks.

Material selection, tight tolerance control, and surface finish consistency are non-negotiable in our production process. We utilize state-of-the-art CNC lathes equipped with live tooling, multi-axis capabilities, and in-process inspection systems to ensure dimensional accuracy and geometric perfection. Each turning operation is supported by comprehensive quality assurance protocols, including CMM verification, optical measurement, and batch traceability.

The following table outlines the standard precision specifications achievable at Wuxi Lead for CNC turning operations:

| Specification | Capability |

|---|---|

| Tolerance Range | ±0.002 mm to ±0.01 mm |

| Surface Finish (Ra) | 0.4 μm to 3.2 μm |

| Maximum Turning Diameter | 300 mm |

| Minimum Wall Thickness | 0.5 mm |

| Materials Processed | Stainless Steel, Aluminum Alloys, Titanium, Brass, Inconel, PEEK |

| Secondary Operations | Milling, Drilling, Threading, Knurling, Passivation, Anodizing |

| Quality Standards | ISO 9001:2015, ISO 13485 (Medical), RoHS, ITAR-registered facility |

Precision turning is not merely about shaping metal—it is about engineering reliability. At Wuxi Lead Precision Machinery, we combine advanced technology with deep engineering insight to deliver components that perform with absolute certainty. When failure is not an option, our clients trust us to turn precision into performance.

Precision Specs & Tolerances

Advanced Machining Capabilities for Precision CNC Turning Components

Wuxi Lead Precision Machinery delivers exceptional precision and complexity in CNC turning parts through strategic investment in advanced multi-axis technology and rigorous process control. Our core manufacturing capability centers on state-of-the-art 5-axis CNC turning centers, enabling the production of highly intricate geometries in a single setup. This integrated approach eliminates cumulative errors inherent in multi-setup operations, significantly enhancing part accuracy and repeatability while reducing overall production time and handling costs. Our machines feature simultaneous 5-axis interpolation, high-speed spindles, and live tooling capabilities, allowing us to efficiently machine complex features such as off-axis holes, contours, slots, and milled surfaces directly on turned components. This capability is critical for demanding sectors including aerospace actuators, medical implants, and semiconductor fluid handling systems where component integration and micron-level precision are non-negotiable.

Material versatility is fundamental to our service. We routinely machine a comprehensive range of engineering alloys including aerospace-grade aluminum (2024, 7075), stainless steels (303, 304, 316, 17-4PH), titanium (Gr2, Gr5), brass, and specialized plastics like PEEK and Delrin. Each material family undergoes optimized machining protocols developed through extensive process validation to ensure superior surface integrity, dimensional stability, and adherence to specified mechanical properties. Our engineering team collaborates closely with clients during the Design for Manufacturability (DFM) phase to identify potential optimization opportunities, ensuring the final component is not only precise but also cost-effectively produced.

Comprehensive Quality Assurance Protocol

Precision is meaningless without verifiable proof. Wuxi Lead implements a multi-stage quality control system anchored by Zeiss and Hexagon Coordinate Measuring Machines (CMMs). Every critical dimension, geometric tolerance, and surface finish parameter specified on the engineering drawing undergoes systematic verification against international standards (ISO 2768, ASME Y14.5). Our CMM inspection routines are fully programmed and validated, providing traceable, objective data for every batch. This process includes first-article inspection reports (FAIR), in-process checks, and final batch certification. All measurement equipment is maintained under a strict calibration schedule traceable to national standards, ensuring measurement uncertainty is consistently within defined limits. Comprehensive quality documentation, including detailed inspection reports with actual measured values against nominal specifications, is provided with every shipment, offering full transparency and audit readiness for our clients’ quality systems.

Achievable Precision Tolerances

The following table represents typical achievable tolerances for critical features across common materials under standard production conditions. Tighter tolerances are attainable through specialized processes and require specific engineering review.

| Feature Type | Material Group | Typical Tolerance Range | Key Measurement Standard |

|---|---|---|---|

| Linear Dimensions | Aluminum Alloys | ±0.005 mm | ISO 2768-mK |

| Linear Dimensions | Stainless Steel | ±0.008 mm | ISO 2768-mK |

| Linear Dimensions | Titanium Alloys | ±0.010 mm | ISO 2768-mK |

| Concentricity | All Materials | Ø 0.015 mm | ASME Y14.5 (Position) |

| Surface Roughness (Ra) | Machined Surfaces | 0.4 – 0.8 µm | ISO 4287 (Cut-off 0.8mm) |

| Positional Accuracy | Multi-Surface Features | ±0.005 mm | ASME Y14.5 (True Position) |

These capabilities, combined with our stringent quality management system certified to ISO 9001:2015, ensure Wuxi Lead consistently delivers CNC precision turning parts that meet the most exacting performance and reliability requirements of global advanced manufacturing industries.

Material & Finish Options

Material selection is a critical decision in the production of CNC precision turning parts, directly influencing performance, durability, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in machining high-tolerance components using premium-grade aluminum, steel, and titanium—each offering distinct mechanical properties suited to specific industrial applications. Understanding the characteristics of these materials enables engineers and procurement managers to make informed choices that align with functional requirements and environmental conditions.

Aluminum is widely favored in aerospace, automotive, and electronics industries due to its excellent strength-to-weight ratio and inherent corrosion resistance. Grade 6061-T6 is particularly popular for its weldability, machinability, and moderate strength, making it ideal for structural components and housings. For more demanding applications, 7075-T6 offers superior strength, though at a higher cost and reduced corrosion resistance compared to 6061. Aluminum’s lightweight nature also contributes to fuel efficiency and ease of handling in assembly processes.

Steel remains the backbone of heavy-duty applications, especially where high tensile strength and wear resistance are paramount. We commonly machine alloy steels such as 4140 and 4340, which provide excellent hardenability and fatigue resistance, making them suitable for shafts, gears, and tooling components. Stainless steels like 304 and 316 offer enhanced corrosion resistance, critical in medical, food processing, and marine environments. While heavier than aluminum, steel’s robustness ensures long service life under high stress and elevated temperatures.

Titanium, particularly Grade 5 (Ti-6Al-4V), is the material of choice for extreme performance environments. Its exceptional strength-to-density ratio, biocompatibility, and resistance to oxidation at high temperatures make it indispensable in aerospace, defense, and medical implant applications. Though more challenging to machine due to low thermal conductivity and high chemical reactivity, titanium’s longevity in corrosive and high-stress conditions justifies its use where reliability is non-negotiable.

Surface finishing further enhances material performance. Anodizing, primarily applied to aluminum, creates a durable, corrosion-resistant oxide layer that can be dyed for identification or aesthetic purposes. Type II (sulfuric acid) anodizing is standard for general protection, while Type III (hardcoat anodizing) delivers superior wear resistance for industrial components. These finishes do not chip or peel and maintain dimensional stability, crucial for precision-machined parts.

Below is a comparative overview of key material specifications:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Common Grades | Typical Applications | Machinability Rating |

|---|---|---|---|---|---|

| Aluminum | 310 (6061-T6) | 2.7 | 6061, 7075 | Enclosures, brackets | Excellent |

| Steel (Alloy) | 950 (4140) | 7.85 | 4140, 4340 | Shafts, gears | Good |

| Stainless Steel | 580 (304) | 8.0 | 304, 316 | Medical, marine components | Moderate |

| Titanium | 900 (Ti-6Al-4V) | 4.5 | Gr2, Gr5 | Aerospace, implants | Fair |

Selecting the right material and finish requires a balance of mechanical demands, environmental exposure, and production efficiency. Wuxi Lead Precision Machinery supports clients with expert consultation to ensure optimal material pairing for every precision turning project.

Manufacturing Process & QC

Precision CNC Turning Production Process: From Concept to Zero-Defect Delivery

At Wuxi Lead Precision Machinery, our CNC precision turning process is engineered for uncompromising quality and repeatability, adhering strictly to the Zero Defects philosophy. We initiate every project with a rigorous Design for Manufacturability (DFM) review. Our engineering team collaborates closely with clients to optimize part geometry, material selection, and tolerance specifications. This phase leverages advanced CAD/CAM simulation to identify potential machining conflicts, thermal deformation risks, and toolpath inefficiencies before metal is cut. Material certifications and traceability protocols are established here, ensuring compliance with aerospace (AS9100), medical (ISO 13485), and automotive (IATF 16949) standards from inception.

Prototyping transitions design into tangible validation. We utilize high-precision Swiss-type and multi-axis CNC lathes to produce initial samples under full production conditions. Every prototype undergoes comprehensive metrology: CMM inspections verify geometric dimensioning and tolerancing (GD&T) to micron-level accuracy, while surface roughness testers and optical comparators validate critical finish requirements. Dimensional heat maps and first-article inspection reports (FAIR) are shared with the client for approval. This stage is non-negotiable; we iterate until all specifications are met, eliminating latent process flaws that could compromise mass production.

Mass production deploys fully validated programs across our automated cell. Real-time Statistical Process Control (SPC) monitors key parameters—spindle load, tool wear, and dimensional drift—using in-process gauging. Automated part handling minimizes human intervention, while 100% critical feature inspection via vision systems or touch probes occurs inline. Our Quality Management System mandates continuous Cpk analysis (target ≥1.67), with immediate process correction if trends approach tolerance limits. This closed-loop approach, combined with operator certification and traceable material batches, ensures batch-to-batch consistency. The result is zero escape defects and on-time delivery of mission-critical components.

Wuxi Lead Precision Turning Capabilities

| Specification | Capability Range | Standard Tolerance | Surface Finish (Ra) |

|---|---|---|---|

| Maximum Turning Diameter | 2 – 200 mm | ±0.005 mm | 0.4 – 1.6 μm |

| Minimum Wall Thickness | 0.1 mm | ±0.002 mm | 0.2 – 0.8 μm |

| Geometric Accuracy | Concentricity ≤0.003 mm | Profile ≤0.005 mm | N/A |

| Materials | Stainless Steel, Titanium, Inconel, Brass, PEEK | N/A | N/A |

| Production Volume | Prototypes to 500,000+ units | N/A | N/A |

This integrated workflow—grounded in proactive design, empirical prototyping, and SPC-driven production—eliminates waste and ensures every component meets the exacting demands of high-stakes industries. Partner with Wuxi Lead to transform precision requirements into defect-free reality.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Excellence in CNC Precision Turning Parts

At Wuxi Lead Precision Machinery, we don’t just manufacture CNC precision turning parts—we engineer trust, performance, and long-term value for global industries that demand nothing less than perfection. As a leading provider of high-precision CNC machining solutions based in Wuxi, China, we specialize in delivering complex, tight-tolerance components that meet the rigorous standards of aerospace, medical, automotive, and industrial automation sectors. When you partner with us, you gain more than a supplier—you gain a committed engineering ally.

Our advanced manufacturing ecosystem integrates state-of-the-art CNC turning centers, Swiss-type lathes, and multi-axis machining platforms, all operated by a team of seasoned engineers and technicians. Every component is produced under strict ISO 9001:2015 quality management protocols, ensuring repeatable accuracy, material integrity, and full traceability. From prototype development to high-volume production runs, we are equipped to scale with your project demands while maintaining consistent precision and on-time delivery.

We understand that in high-end manufacturing, tolerances are not just numbers—they are commitments. That’s why our process begins with a collaborative engineering review, where we assess material selection, geometric complexity, surface finish requirements, and functional performance. This proactive approach minimizes risk, reduces lead times, and optimizes cost-efficiency across your supply chain.

Our facility supports a wide range of materials, including stainless steel, aluminum, titanium, brass, and engineering plastics such as PEEK and PTFE. Whether you require micro-turned components for medical devices or robust shafts for industrial gearboxes, our capabilities are built to exceed expectations.

Below are key technical specifications that define our precision turning performance:

| Specification | Capability |

|---|---|

| Maximum Turning Diameter | 32 mm |

| Minimum Achievable Tolerance | ±0.002 mm |

| Surface Roughness (Ra) | As low as 0.2 μm |

| Bar Feed Capacity | Up to 420 mm length |

| Materials Supported | Stainless Steel (303, 304, 316), Aluminum (6061, 7075), Titanium, Brass, PEEK, PTFE, and more |

| Secondary Operations | CNC milling, threading, knurling, drilling, tapping, heat treatment, plating, anodizing |

| Quality Standards | ISO 9001:2015 certified, full inspection reporting (CMM, optical comparators) |

| Lead Time (Typical) | 15–25 days, expedited options available |

At Lead Precision, we measure success not by volume, but by the reliability of the parts we deliver and the strength of the partnerships we build. Our clients return because we combine technical excellence with responsive service, transparent communication, and a relentless focus on solving real-world engineering challenges.

Take the next step toward precision you can count on. Contact us today at [email protected] to discuss your CNC turning requirements. Let our team provide a detailed technical evaluation and competitive quotation tailored to your project. Partner with Wuxi Lead Precision Machinery—where precision turns into performance.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.