Technical Contents

Engineering Guide: Aluminum 6061 Machining Services

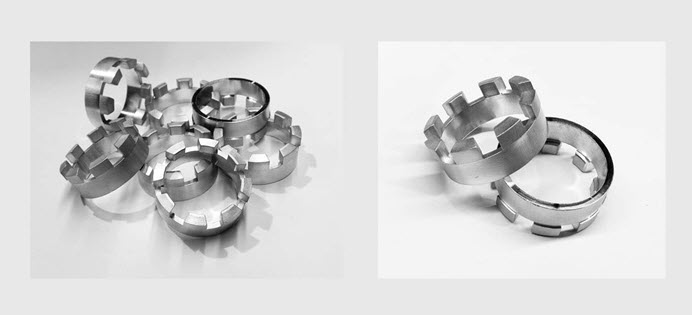

Engineering Insight: Precision Machining of Aluminum 6061 at Wuxi Lead Precision Machinery

Aluminum 6061 is one of the most widely used alloys in high-performance engineering applications due to its excellent strength-to-weight ratio, corrosion resistance, and machinability. However, achieving optimal results with this material demands more than standard CNC capabilities—it requires deep metallurgical understanding, advanced toolpath strategies, and uncompromising attention to dimensional accuracy. At Wuxi Lead Precision Machinery, we specialize in delivering mission-critical components from aluminum 6061, where tolerances are not just targets but commitments.

Precision in machining aluminum 6061 begins with material selection. The alloy’s responsiveness to heat treatment, particularly in the T6 temper condition, directly influences its machinability and final mechanical properties. Our in-house quality control ensures every billet meets stringent aerospace-grade standards before entering production. We utilize high-speed CNC machining centers equipped with thermal compensation systems and real-time tool wear monitoring to maintain tolerances down to ±0.005 mm—critical for clients in aerospace, defense, and high-end automation sectors.

What sets Wuxi Lead apart is our proven track record in projects where failure is not an option. Our machining processes have supported components used in Olympic-grade sporting equipment, where consistency and lightweight performance are paramount. Additionally, we have delivered precision-machined parts for military subcontractors, adhering to strict MIL-STD documentation and traceability requirements. These experiences have refined our approach to process validation, first-article inspection, and batch repeatability.

Our engineers apply adaptive machining techniques to minimize tool deflection and thermal distortion, common challenges when working with aluminum. Through optimized spindle speeds, specialized carbide tooling, and cryogenic cooling when necessary, we achieve superior surface finishes and dimensional stability. Every component undergoes full coordinate measuring machine (CMM) inspection, with detailed reports provided upon request.

Below are key technical specifications for aluminum 6061 machining services at Wuxi Lead Precision Machinery:

| Property | Specification |

|---|---|

| Alloy | 6061-T6 (standard), other tempers on request |

| Tolerance | ±0.005 mm (standard), down to ±0.002 mm (tight-tolerance) |

| Surface Finish | Ra 0.8 µm (standard), down to Ra 0.4 µm (polished/precision) |

| Maximum Part Size | 800 mm × 600 mm × 400 mm |

| Machining Processes | 3-axis, 4-axis, 5-axis CNC milling, CNC turning, drilling, tapping |

| Quality Standards | ISO 9001:2015, full inspection reporting, material traceability |

| Secondary Operations | Deburring, anodizing coordination, bead blasting, laser marking |

At Wuxi Lead Precision Machinery, we treat every aluminum 6061 component as a testament to engineering excellence. Our combination of technical expertise, rigorous quality systems, and real-world experience in elite performance environments ensures that your custom parts meet the highest standards of precision and reliability.

Precision Specs & Tolerances

Technical Capabilities for Aluminum 6061 Machining

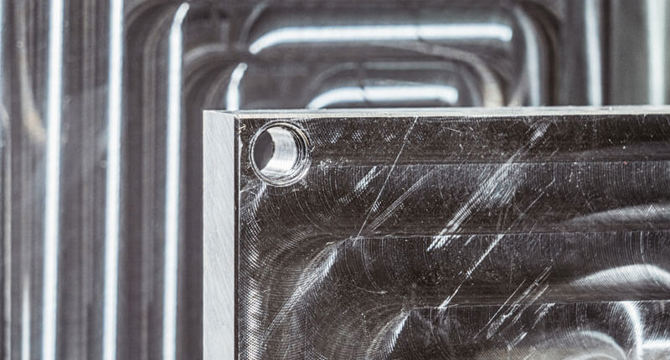

Wuxi Lead Precision Machinery delivers exceptional precision and repeatability for aluminum 6061 components, leveraging advanced 5-axis CNC milling centers and rigorous quality control protocols. Aluminum 6061-T6 presents unique machining characteristics—excellent machinability coupled with susceptibility to thermal distortion and chatter during high-speed operations. Our engineering team optimizes toolpaths, cutting parameters, and fixturing specifically for this alloy, ensuring dimensional stability and surface integrity critical for aerospace, medical, and automation applications.

Our HAAS UMC-750 and DMG MORI CTX beta 1250 5-axis machining centers eliminate multiple setups, reducing cumulative error and lead times for complex geometries. Simultaneous 5-axis interpolation enables undercuts, deep cavities, and organic contours in a single operation, maintaining tight tolerances across all features. High-speed spindles (up to 24,000 RPM) paired with through-tool coolant minimize heat generation and chip recutting, preserving the material’s mechanical properties and achieving superior surface finishes down to Ra 0.4 µm. Dedicated aluminum tooling libraries and non-stick coatings prevent built-up edge, ensuring consistent edge quality and burr-free results.

Quality assurance is non-negotiable. Every 6061 component undergoes comprehensive inspection using Zeiss CONTURA G2 Coordinate Measuring Machines (CMM) with SP25 scanning probes. First-article inspections validate geometric dimensioning and tolerancing (GD&T) per ASME Y14.5, while in-process checks monitor critical features during production. Statistical process control (SPC) data is documented for full traceability, providing clients with certified dimensional reports for every batch. Our ISO 9001-certified workflow ensures compliance with stringent industry standards, including Nadcap for aerospace suppliers.

The following table details achievable tolerances for aluminum 6061 machining under controlled conditions. Note that precision ranges require thermal stabilization protocols and are validated via CMM.

| Feature | Standard Tolerance | Precision Tolerance |

|---|---|---|

| Linear Dimensions (mm) | ±0.05 mm | ±0.0125 mm |

| Angular Features | ±0.1° | ±0.05° |

| Positional Tolerance | ±0.05 mm | ±0.025 mm |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm |

Precision tolerances assume controlled ambient temperature (20±1°C), stress-relieved material, and features within 300 mm cube volume. Thermal compensation routines are applied for critical dimensions exceeding 500 mm. Surface finish values are achievable on non-critical faces; cosmetic surfaces may require additional polishing.

We partner with clients during design for manufacturability (DFM) reviews to optimize part geometry for 6061’s properties, minimizing cost drivers while meeting functional requirements. Contact our engineering team to discuss your specific tolerance stack-up challenges or material certification needs. Wuxi Lead transforms complex aluminum 6061 designs into high-integrity components with unwavering precision.

Material & Finish Options

When selecting materials for precision machining in high-performance industries such as aerospace, automotive, and medical devices, understanding the mechanical properties, machinability, and finishing compatibility of aluminum 6061, steel, and titanium is essential. Each material offers distinct advantages depending on the application’s requirements for strength, weight, corrosion resistance, and thermal performance.

Aluminum 6061 stands out as one of the most versatile and widely used alloys in custom metal manufacturing. Known for its excellent strength-to-weight ratio, good corrosion resistance, and superior machinability, 6061 is ideal for structural components, enclosures, and parts requiring post-machining treatments such as anodizing. Its primary alloying elements—magnesium and silicon—contribute to its weldability and heat-treatable characteristics, making it suitable for complex assemblies. In environments where weight reduction is critical without sacrificing durability, aluminum 6061 is often the preferred choice.

Steel, particularly grades such as 304 stainless steel and 4140 alloy steel, offers higher tensile strength and wear resistance compared to aluminum. It is best suited for applications exposed to high stress, elevated temperatures, or aggressive environments. However, steel is significantly heavier and more challenging to machine, requiring more robust tooling and longer cycle times. While it can be anodized in limited cases, steel typically relies on plating, passivation, or painting for surface protection.

Titanium, especially Grade 5 (Ti-6Al-4V), delivers exceptional strength-to-density performance and outstanding resistance to corrosion, even in marine and high-temperature environments. It is commonly used in aerospace and medical implant applications. However, titanium is more expensive and difficult to machine due to its low thermal conductivity and tendency to gall. Specialized cutting strategies and tooling are required, increasing production costs.

For all three materials, surface finishing plays a critical role in performance and longevity. Anodizing is most effective on aluminum 6061, creating a durable, corrosion-resistant oxide layer that can also be dyed for identification or aesthetic purposes. Hard anodizing (Type III) further enhances surface hardness and wear resistance, making it suitable for high-wear components. Steel and titanium require alternative surface treatments, such as electroplating or thermal spray coatings, as they are not compatible with standard anodizing processes.

Below is a comparative overview of key mechanical and machining properties:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Machinability Rating | Anodizing Compatible | Common Applications |

|---|---|---|---|---|---|

| Aluminum 6061 | 310 | 2.70 | Excellent | Yes | Enclosures, brackets, aerospace parts |

| 304 Stainless Steel | 515 | 8.00 | Fair | No | Medical devices, food processing |

| 4140 Steel | 655 | 7.85 | Moderate | No | Shafts, tooling, high-stress parts |

| Titanium (Ti-6Al-4V) | 900 | 4.43 | Poor | No | Aerospace, implants, marine components |

At Wuxi Lead Precision Machinery, we support clients in selecting the optimal material and finish based on functional requirements, environmental exposure, and cost targets. Our expertise in machining aluminum 6061, along with advanced finishing capabilities such as hard anodizing, ensures high repeatability and precision for mission-critical components.

Manufacturing Process & QC

Integrated Production Process for Aluminum 6061 Machining Excellence

At Wuxi Lead Precision Machinery, our aluminum 6061 machining services deliver uncompromising quality through a rigorously controlled, closed-loop production sequence. We eliminate defects at the source by integrating Design for Manufacturability (DFM) analysis directly with our manufacturing capabilities from the project inception. Our engineering team collaborates with your design data, identifying potential machining challenges in complex geometries or tight tolerance zones specific to 6061-T6 material behavior. This proactive DFM review prevents costly revisions later, optimizing tool paths, fixture strategies, and material utilization while ensuring the design fully leverages 6061’s excellent machinability and structural properties. This foundational step is critical for achieving true Zero Defects outcomes in subsequent phases.

Prototyping transitions seamlessly from validated designs using the exact production-grade CNC equipment and processes intended for volume work. We machine functional prototypes under full production parameters, enabling precise validation of form, fit, function, and critical dimensions. Comprehensive metrology, including CMM inspection against your CAD model and first-article inspection reports per AS9102, verifies conformance before mass production launch. This stage is not merely a sample check; it is a full process capability study, confirming that our machining parameters, tooling, and fixturing consistently produce parts within specification under real production conditions. Any micro-adjustments identified here are implemented immediately, ensuring the production run starts with a proven, stable process.

Mass production executes the perfected process with unwavering adherence to Zero Defects principles. We implement statistical process control (SPC) monitoring on critical dimensions in real-time across all production shifts. Automated in-process gauging and 100% critical feature inspection at defined intervals prevent drift. Our dedicated quality cells perform rigorous final inspections using calibrated CMMs, optical comparators, and surface roughness testers against the agreed quality plan. Every batch is traceable to material certs and process records. This systematic approach, combined with our skilled technicians and maintenance protocols for Haas and DMG MORI machining centers, guarantees consistent output meeting the most stringent aerospace, medical, and industrial requirements. Defects are not corrected downstream; they are engineered out of the process flow entirely.

Aluminum 6061-T6 Machining Specifications at Wuxi Lead

| Parameter | Standard Capability | Tight Tolerance Option | Key Process Control |

|---|---|---|---|

| Dimensional Tolerance | ±0.025 mm (±0.001″) | ±0.005 mm (±0.0002″) | SPC charts, CMM first/last/every 50th |

| Surface Roughness | Ra 0.8 µm (32 µin) | Ra 0.4 µm (16 µin) | In-process profilometer checks |

| Feature Location | ±0.012 mm (±0.0005″) | ±0.003 mm (±0.0001″) | Fixture validation, CMM full FAI |

| Material Traceability | Mill Cert 3.1B per EN 10204 | Full heat lot traceability | Integrated ERP batch tracking |

| Inspection Standard | ISO 2768-mK / ASME Y14.5 | Customer-specific CMM reports | Automated reporting, PPAP Level 3 support |

This disciplined progression from intelligent design through validated prototyping to statistically controlled mass production forms the bedrock of our Zero Defects commitment. Wuxi Lead ensures your aluminum 6061 components meet exacting performance demands, delivered with the precision you can measure.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Aluminum 6061 Machining Expertise

When your project demands precision, consistency, and performance, partnering with Wuxi Lead Precision Machinery ensures that your aluminum 6061 components meet the highest standards of quality and reliability. As a leading provider of custom metal manufacturing in China, we specialize in high-accuracy CNC machining services tailored to industries such as aerospace, automotive, medical devices, and industrial automation. Our expertise in machining aluminum 6061—renowned for its excellent strength-to-weight ratio, corrosion resistance, and machinability—positions us as the ideal partner for mission-critical applications.

At Lead Precision, we understand that precision isn’t just about tight tolerances; it’s about consistency across production runs, material integrity, and adherence to your exact specifications. Our state-of-the-art CNC milling, turning, and multi-axis machining centers are operated by experienced engineers who combine technical mastery with rigorous quality control. Every component undergoes comprehensive inspection using coordinate measuring machines (CMM) and optical comparators, ensuring compliance with ISO 9001 standards and your unique requirements.

We offer full-service manufacturing from prototyping to high-volume production, with rapid turnaround times and seamless communication throughout the process. Whether you require simple brackets or complex geometries with tight tolerances, our team is equipped to deliver. Our facility supports secondary operations including anodizing, deburring, heat treating, and precision tapping, providing a single-source solution for complete part readiness.

Our commitment to excellence is reflected in the technical capabilities we bring to every project. The following table outlines our core machining specifications for aluminum 6061 components:

| Specification | Capability |

|---|---|

| Material | Aluminum 6061-T6, 6061-T651 (bar, plate, billet) |

| Tolerance | ±0.005 mm (standard), down to ±0.001 mm (tight-tolerance) |

| Maximum Work Envelope | 800 mm × 500 mm × 400 mm (3-axis), 600 mm diameter × 300 mm height (4/5-axis) |

| Surface Finish | As-machined (Ra 3.2 µm), up to Ra 0.8 µm with polishing |

| CNC Equipment | 3-axis, 4-axis, 5-axis machining centers; CNC turning centers |

| Secondary Operations | Deburring, anodizing (Type II & III), passivation, precision tapping, heat treatment |

| Quality Standards | ISO 9001:2015, First Article Inspection (FAI), PPAP documentation available |

| Lead Times | Prototype: 5–7 days; Production: 10–15 days (varies by complexity and volume) |

Partnering with Wuxi Lead Precision Machinery means gaining a reliable, technically advanced manufacturing ally dedicated to your success. We bridge the gap between design intent and physical performance, delivering components that perform under real-world conditions.

For immediate assistance with your aluminum 6061 machining needs, contact us at [email protected]. Our engineering team is ready to review your drawings, provide DFM feedback, and deliver a competitive quote tailored to your project’s scope and timeline. Let Lead Precision be your trusted partner in precision manufacturing.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.