Technical Contents

Engineering Guide: 3D Printing Service Providers

Engineering Insight: Precision as the Non-Negotiable Foundation for Metal 3D Printing Service Providers

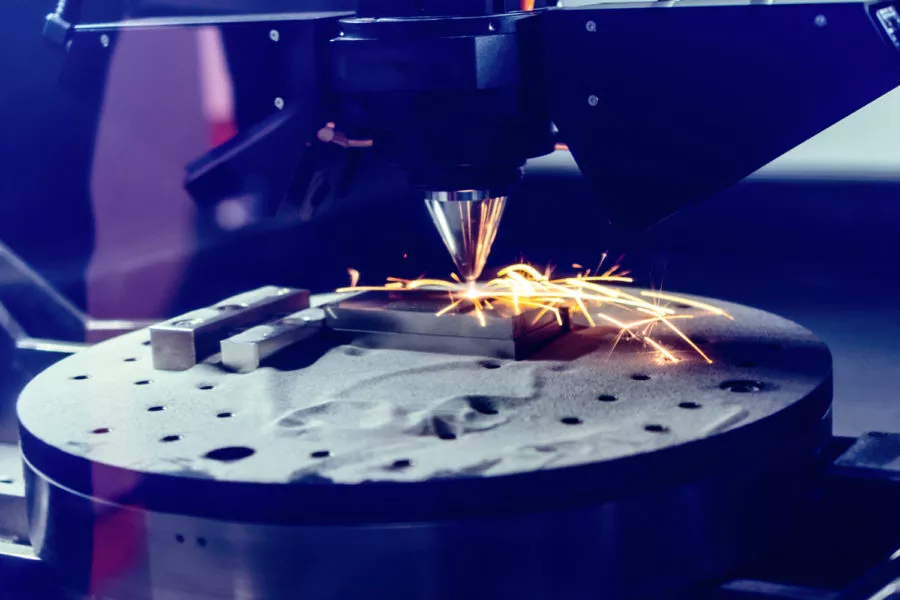

In the rapidly evolving landscape of metal additive manufacturing, service providers face a critical challenge that directly impacts client success and operational viability: achieving true, repeatable precision. While 3D printing unlocks unprecedented design freedom for complex metal components, the raw output often falls short of the stringent tolerances demanded by high-performance industries like aerospace, medical, and defense. Merely producing a near-net-shape part is insufficient; the transition from printed artifact to mission-critical component hinges on mastering dimensional accuracy, surface integrity, and material consistency. Ignoring this precision gap leads to unacceptable scrap rates, costly rework, delayed time-to-market, and ultimately, eroded client trust. The true value proposition for discerning 3D printing service providers lies not just in printing capability, but in the integrated expertise to bridge this gap reliably.

Thermal distortion, residual stress, and inherent layer-based surface roughness are inherent challenges in metal additive processes like SLM and EBM. These factors frequently result in deviations exceeding ±0.1 mm and surface finishes unsuitable for critical sealing or bearing surfaces without significant post-processing. Service providers must therefore integrate advanced metrology and precision subtractive capabilities as core competencies, not afterthoughts. This requires a deep understanding of how additive builds interact with traditional CNC machining, heat treatment, and finishing techniques to achieve final specifications consistently. Failure to address these nuances transforms the promise of additive manufacturing into a source of production bottlenecks and quality failures.

Wuxi Lead Precision Machinery operates at this critical intersection. Our extensive experience manufacturing precision components for the Beijing Winter Olympics timing mechanisms and certified aerospace hydraulic systems for military platforms provides unequivocal proof of our capability. These applications demand tolerances tighter than ±0.025 mm and surface finishes below Ra 0.8 µm – specifications where compromise is impossible. We apply this same rigor to support 3D printing service providers, offering precision CNC milling, turning, grinding, and specialized finishing services specifically engineered to refine additively manufactured metal parts to exacting standards. Our facility integrates multi-sensor CMMs and on-machine probing to validate and correct for build-induced variations, ensuring every component meets the most demanding requirements.

The transformation from printed part to precision-engineered component is quantifiable. Consider the typical improvements achievable through integrated post-processing:

| Specification | Typical As-Built 3D Print | Lead Precision Finished Part |

|---|---|---|

| Dimensional Accuracy | ±0.10 mm to ±0.25 mm | ±0.01 mm to ±0.025 mm |

| Surface Roughness (Ra) | 12.5 µm to 25.0 µm | 0.4 µm to 1.6 µm |

| Feature Repeatability | Variable (Build Dependent) | < ±0.005 mm (CpK > 1.67) |

| Critical Feature Finish | Often Requires Hand Work | Machined to Print |

For 3D printing service providers targeting Tier 1 aerospace, medical device, or high-end industrial clients, partnering with a precision machining specialist like Lead Precision is not optional – it is fundamental to delivering on the additive promise. Our proven track record in mission-critical applications provides the assurance that your printed components will consistently meet the uncompromising standards required for real-world deployment, transforming additive potential into reliable, high-value production. Precision is the deliverable; everything else is process.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions tailored for high-performance industries, including aerospace, medical, energy, and precision instrumentation. Our technical capabilities are built around state-of-the-art 5-axis CNC machining centers, enabling the production of complex, high-precision components with superior surface finishes and dimensional accuracy. These multi-axis systems allow simultaneous movement across five planes, providing unparalleled flexibility in machining intricate geometries that are often unattainable with conventional 3-axis equipment. This capability is especially critical for 3D printing service providers seeking post-processing solutions for metal additive components, where precision finishing, feature accuracy, and interface alignment are essential.

Our 5-axis machining platforms are integrated with high-speed spindles, advanced tool management systems, and real-time monitoring software to ensure consistent part quality and reduced cycle times. We specialize in a wide range of engineering-grade metals, including titanium alloys (Ti-6Al-4V), Inconel 718 and 625, stainless steels (316L, 17-4 PH), aluminum alloys (7075, 6061), and tool steels. This material versatility, combined with our machining expertise, allows us to support hybrid manufacturing workflows—where additive fabrication is complemented by subtractive precision—to meet the exacting standards of end-use applications.

Quality assurance is embedded throughout our manufacturing process. Every component undergoes rigorous inspection using a Zeiss DuraMax and蔡司 CONTURA G2 Coordinate Measuring Machine (CMM), ensuring full compliance with geometric dimensioning and tolerancing (GD&T) requirements. Our metrology lab is temperature-controlled and certified to ISO 17025 standards, providing traceable measurement results accepted across global supply chains. In addition to CMM inspection, we employ surface roughness testers, hardness testers, and optical comparators to verify material and dimensional integrity.

The table below outlines our standard machining tolerances, which are routinely achieved and documented for customer review. These specifications reflect our ability to meet or exceed industry benchmarks for precision manufacturing.

| Feature | Standard Tolerance | Tight Tolerance Capability | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.01 mm | ±0.005 mm | Up to 500 mm length |

| Hole Diameter | +0.015 / -0.005 mm | +0.008 / -0.002 mm | Reamed or honed |

| Positional Tolerance | ±0.015 mm | ±0.008 mm | Per GD&T |

| Surface Roughness (Ra) | 1.6 μm | 0.4 μm | Machined finish |

| Angular Tolerance | ±0.05° | ±0.02° | 5-axis interpolated |

| Flatness | 0.01 mm per 100 mm | 0.005 mm per 100 mm | Verified via CMM |

Our technical team works closely with 3D printing service providers to bridge the gap between additive innovation and precision engineering. By combining our 5-axis CNC capabilities with comprehensive quality control, we ensure that every component meets functional, regulatory, and performance requirements. Wuxi Lead Precision Machinery is committed to delivering technically advanced, fully traceable, and repeatable manufacturing solutions for the most demanding applications in modern industry.

Material & Finish Options

Material Selection for High-Performance Metal Additive Manufacturing

Selecting the optimal material is foundational for successful metal additive manufacturing (AM) projects, directly impacting part performance, post-processing requirements, and final application viability. As a service provider, understanding the nuanced behavior of key alloys within powder bed fusion processes (SLM, EBM) is critical for advising clients and ensuring build success. Aluminum, steel, and titanium dominate demanding applications but present distinct challenges and opportunities during printing and finishing.

Aluminum alloys, particularly AlSi10Mg and Al6061, offer an exceptional strength-to-weight ratio and thermal conductivity, making them ideal for aerospace brackets, heat exchangers, and lightweight automotive components. However, aluminum’s high thermal conductivity and reflectivity demand precise laser parameter tuning to avoid issues like balling or poor layer adhesion. Post-build, Al6061 responds exceptionally well to anodizing, significantly enhancing surface hardness, corrosion resistance, and enabling color coding – a key value-add service for clients requiring durable, aesthetic finishes. Ensure parts are designed with adequate wall thickness to manage thermal stresses inherent in aluminum AM.

Stainless steels, especially 316L and 17-4 PH, are workhorses for AM due to their excellent corrosion resistance, high strength, and relative printability. 316L excels in marine and chemical environments, while 17-4 PH achieves high strength through precipitation hardening post-print. Steel generally requires less thermal management complexity than aluminum during printing but necessitates careful support structure design to mitigate distortion. Anodizing is not applicable to steel; alternative finishes like electropolishing, passivation, or specialized coatings are required for corrosion resistance and surface refinement. Service providers must strictly control build atmospheres to prevent oxidation, especially with higher-carbon variants.

Titanium alloys, primarily Ti6Al4V (Grade 5), deliver unparalleled strength-to-weight ratios, biocompatibility, and extreme corrosion resistance, dominating aerospace and medical implant production. Titanium’s reactivity mandates ultra-high-purity inert gas environments (Argon) during printing to prevent embrittlement from oxygen/nitrogen pickup. Its low thermal conductivity requires meticulous thermal management strategies to avoid residual stress and cracking. While titanium naturally forms a protective oxide layer, anodizing is primarily used for medical applications to enhance bioactivity or for color identification, not significant wear improvement. Post-processing often involves stress relief and potentially hot isostatic pressing (HIP) for critical components.

The interplay between material selection and achievable finish, particularly anodizing, is crucial. Anodizing is highly effective only on specific aluminum alloys (6061, 7075) and titanium; it is unsuitable for steel. Service providers must verify material compatibility before quoting anodizing services. Below are key comparative properties relevant to AM processing and performance:

| Material | Common AM Alloys | Density (g/cm³) | Typical UTS (MPa) | Key AM Challenge | Anodizing Suitable |

|---|---|---|---|---|---|

| Aluminum | AlSi10Mg, Al6061 | 2.68-2.70 | 300-450 | Thermal management, Reflectivity | Yes (Al6061/7075) |

| Steel | 316L, 17-4 PH | 7.8-7.9 | 550-1300 | Distortion control | No |

| Titanium | Ti6Al4V (Gr5) | 4.43 | 900-1100 | Atmosphere purity, Cracking | Yes (for color/bio) |

Precise material selection, grounded in the realities of the AM process and final application requirements, separates competent service providers from true industry leaders. Understanding these material dynamics allows you to proactively guide clients, optimize build parameters, and deliver parts meeting the highest standards of performance and finish. Wuxi Lead Precision Machinery leverages extensive AM and finishing expertise to support your most demanding metal printing projects.

Manufacturing Process & QC

The production process at Wuxi Lead Precision Machinery is engineered for precision, repeatability, and zero-defect outcomes—critical benchmarks for high-end 3D printing service providers seeking reliable custom metal manufacturing partners. Our workflow is structured into three rigorously controlled phases: Design, Prototyping, and Mass Production. Each phase integrates advanced metrology, material science, and process validation to ensure seamless scalability from concept to volume output.

Design begins with a collaborative engineering review, where our team evaluates geometry, material selection, thermal behavior, and print orientation to optimize for both additive build efficiency and downstream performance. Finite element analysis (FEA) and build simulation software are employed to anticipate residual stress, distortion, and support requirements. This phase ensures manufacturability while maintaining compliance with industry-specific standards such as AS9100 for aerospace or ISO 13485 for medical applications. Design for Additive Manufacturing (DfAM) principles are central, enabling topology optimization and lightweighting without compromising structural integrity.

Prototyping follows with the production of initial builds using the same equipment, parameters, and certified materials designated for mass production. This ensures accurate representation of final part characteristics. Each prototype undergoes full dimensional inspection via coordinate measuring machines (CMM) and 3D scanning, alongside non-destructive testing (NDT) such as computed tomography (CT) scanning to detect internal porosity or lack-of-fusion defects. Mechanical testing, including tensile, fatigue, and hardness evaluation, verifies material performance. Any deviations trigger a root cause analysis and process refinement before progression.

Mass Production is executed under a fully documented Quality Management System compliant with ISO 9001. Each build is monitored in real time using in-situ sensors and layer-wise imaging to detect anomalies during printing. Post-processing—including stress relief, heat treatment, support removal, surface finishing, and optional CNC machining—is performed in-house with tight control over tolerances and surface quality. Every batch is traceable to raw material lot, machine ID, operator, and process parameters. Final inspection includes first-article inspection (FAI) reports and statistical process control (SPC) data to confirm consistency.

Throughout the entire process, our zero-defect philosophy is enforced through preventive controls, continuous monitoring, and closed-loop corrective actions. We specialize in complex, high-value metal components using materials such as Inconel 718, Ti-6Al-4V, AlSi10Mg, and 17-4 PH stainless steel, supporting applications in aerospace, medical, and high-performance industrial sectors.

| Parameter | Specification |

|---|---|

| Build Volume (Max) | 250 x 250 x 325 mm |

| Layer Thickness | 20 – 60 µm |

| Positional Accuracy | ±0.05 mm |

| Surface Roughness (As-Built) | Ra 10 – 15 µm |

| Post-Processing Options | Stress Relieving, Hot Isostatic Pressing (HIP), CNC Machining, Polishing, Coating |

| Supported Materials | Ti-6Al-4V, Inconel 718, AlSi10Mg, 316L, 17-4 PH, Maraging Steel |

| Quality Standards | ISO 9001, AS9100, ISO 13485, NADCAP (pending) |

This integrated approach ensures that 3D printing service providers receive not only precision-manufactured metal parts but also full process transparency, scalability, and compliance—cornerstones of a trusted manufacturing partnership.

Why Choose Wuxi Lead Precision

Elevate Your Metal Additive Capabilities Through Strategic Partnership

For 3D printing service providers operating at the high-end manufacturing tier, the transition from printed prototype to certified, mission-critical metal component demands an exceptional post-processing partner. Wuxi Lead Precision Machinery provides the specialized engineering rigor and precision machining expertise essential to transform your additive output into fully functional, industry-compliant parts. We understand that your reputation hinges on delivering parts meeting exacting aerospace, medical, or energy sector specifications – tolerances you cannot compromise. Our dedicated partnership model bridges the critical gap between metal AM printing and final part qualification, ensuring your service offering consistently exceeds client expectations for quality, repeatability, and technical documentation.

Lead Precision operates as your seamless extension, equipped with the advanced multi-axis CNC milling, precision grinding, and metrology infrastructure required for complex AM geometries. Our engineers collaborate directly with your technical team from the quoting stage, providing manufacturability feedback specific to post-processing challenges inherent in metal AM builds. This proactive engagement prevents costly redesigns and accelerates time-to-shipment. We hold stringent ISO 9001:2015 and AS9100D certifications, maintaining controlled environments and traceable processes demanded by regulated industries. Our facility features dedicated cleanrooms for sensitive medical components and employs non-destructive testing protocols to validate internal integrity post-machining.

The technical demands of finishing intricate lattice structures, thin walls, and internal channels produced via metal AM require capabilities beyond standard machine shops. Our specialized tooling strategies and adaptive machining techniques ensure minimal part distortion while achieving the required surface finishes and dimensional accuracy. The table below outlines our core precision post-processing capabilities relevant to demanding AM applications.

| Specification Category | Capability Range | Relevance to Metal AM Post-Processing |

|---|---|---|

| Dimensional Tolerance | ±0.005 mm (±0.0002″) | Critical for mating surfaces and assemblies in aerospace components |

| Surface Finish (Ra) | As low as 0.4 μm (16 μin) | Meets stringent requirements for fluid dynamics and biocompatibility |

| Maximum Part Size | Ø 600 mm x 1000 mm | Accommodates large-scale industrial AM builds |

| Material Expertise | Titanium (Ti6Al4V), Inconel 718/625, Stainless Steels (17-4PH, 316L), Aluminum Alloys | Full compatibility with prevalent AM metal powders |

| Secondary Processes | Precision Grinding, Micro-Milling, CMM Inspection, Stress Relieving | Ensures geometric accuracy and material stability post-build |

Partnering with Lead Precision mitigates your operational risk and significantly expands the scope of projects you can confidently bid on. We provide comprehensive first-article inspection reports (FAIR), material certifications, and process validation data required for client audits. Our 24-hour engineering response time ensures rapid resolution of technical queries during production runs. This level of integrated support allows you to focus on your core AM printing strengths while guaranteeing clients receive fully finished, certified components on schedule.

Advance your service portfolio beyond basic printing. Contact our technical sales team at [email protected] to discuss your specific metal AM post-processing challenges. Request our detailed technical dossier outlining process capabilities, quality control workflows, and industry-specific case studies. Let Lead Precision become your trusted precision manufacturing partner, transforming additive potential into certified reality.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.